Manufacture of planar display appearance surface pare down apparatus of glass substrates for planar display

A flat-panel display and glass substrate technology, used in semiconductor/solid-state device manufacturing, identification devices, manufacturing tools, etc., can solve problems such as bending and breakage, achieve high process productivity, high flatness, and promote replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, the best mode for carrying out the invention of the present application (hereinafter referred to as embodiment) will be described.

[0043] In the following description, a liquid crystal display (hereinafter referred to as LCD) is used as an example of the FPD.

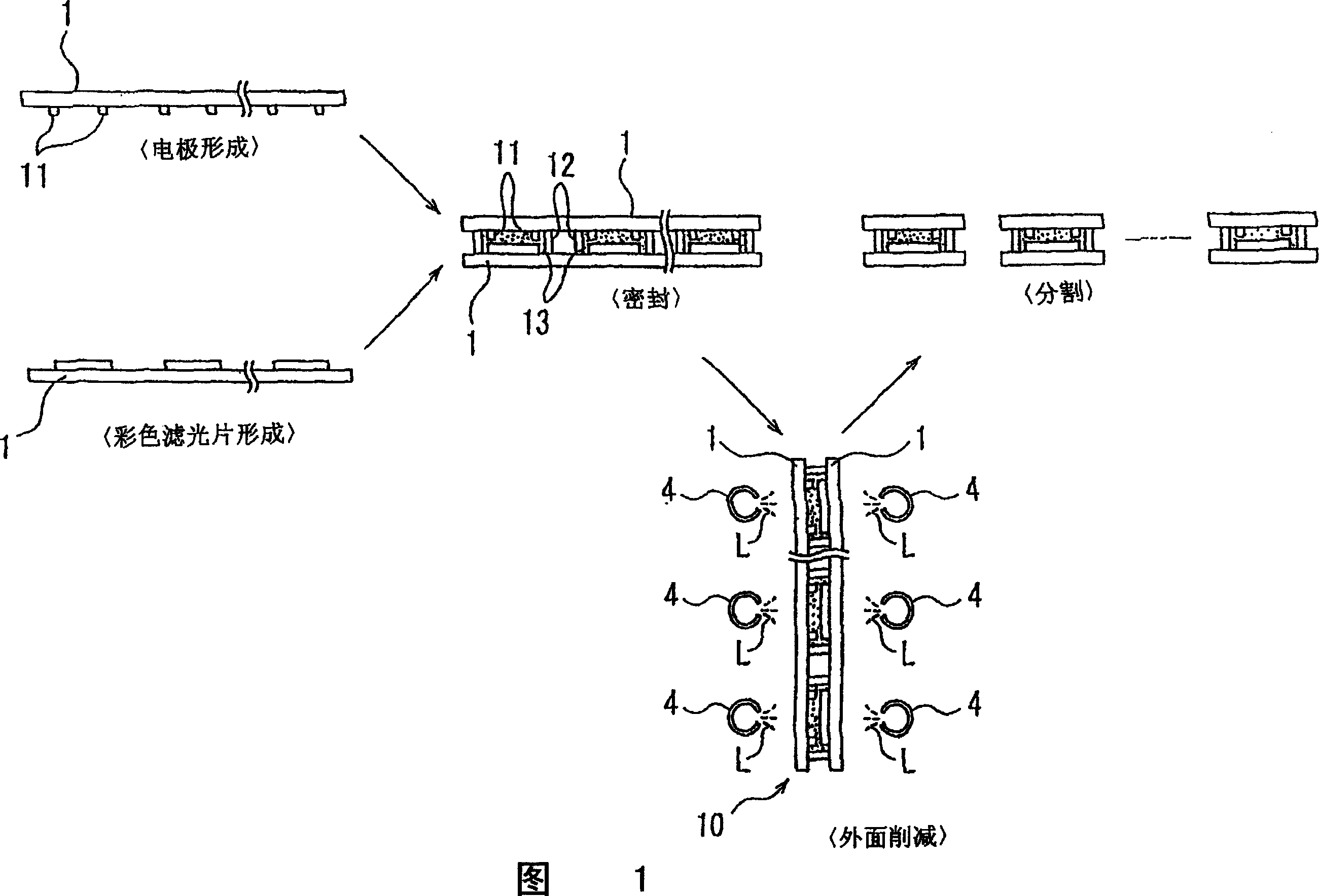

[0044] FIG. 1 is a schematic diagram showing a method of manufacturing an FPD in the embodiment. The method shown in FIG. 1 is, for example, a method of manufacturing LCDs for mobile phones. The method shown in FIG. 1 includes: an electrode forming process of forming an electrode 11 on one of a pair of substrates 1, both of which are glass substrates; after the electrode forming process, the pair of substrates 1 are bonded via a sealing material 12, and liquid crystal is injected inside. 13 a sealing step of subsequent sealing; and a thinning step of reducing the thickness of the outer surfaces of both glass substrates 1 after the sealing step.

[0045] In the manufacturing method shown in FIG. 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com