Three-way ball valve

A three-way ball valve and valve seat technology, used in multi-way valves, valve details, valve devices, etc., can solve the problems of large valve body size, poor medium flow, small flow rate, etc., and achieve large flow channel space and flow. Smooth, volume-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

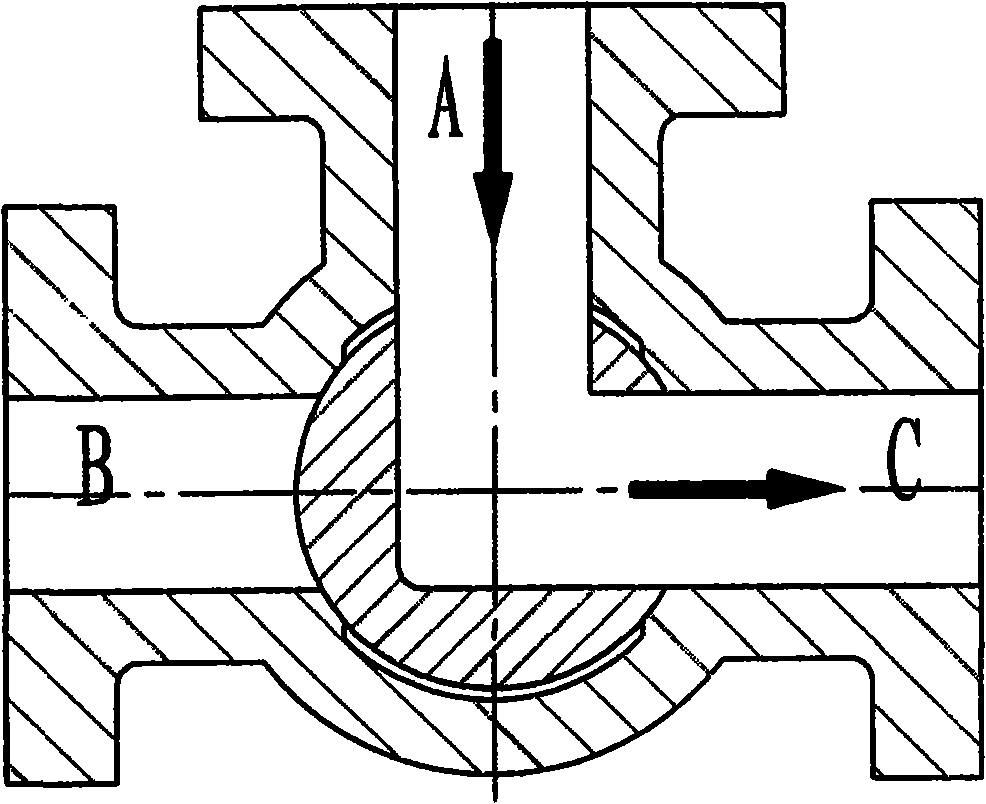

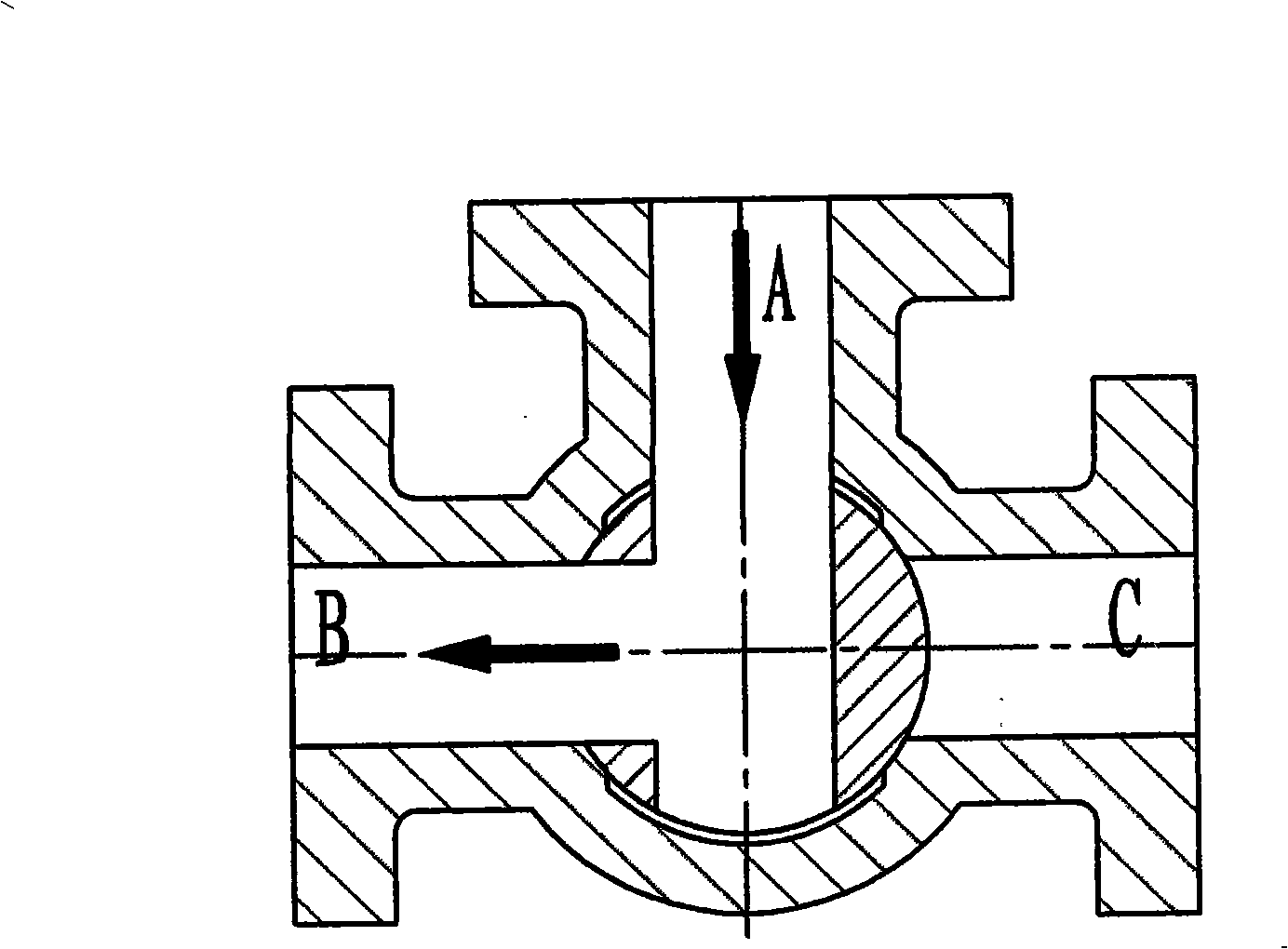

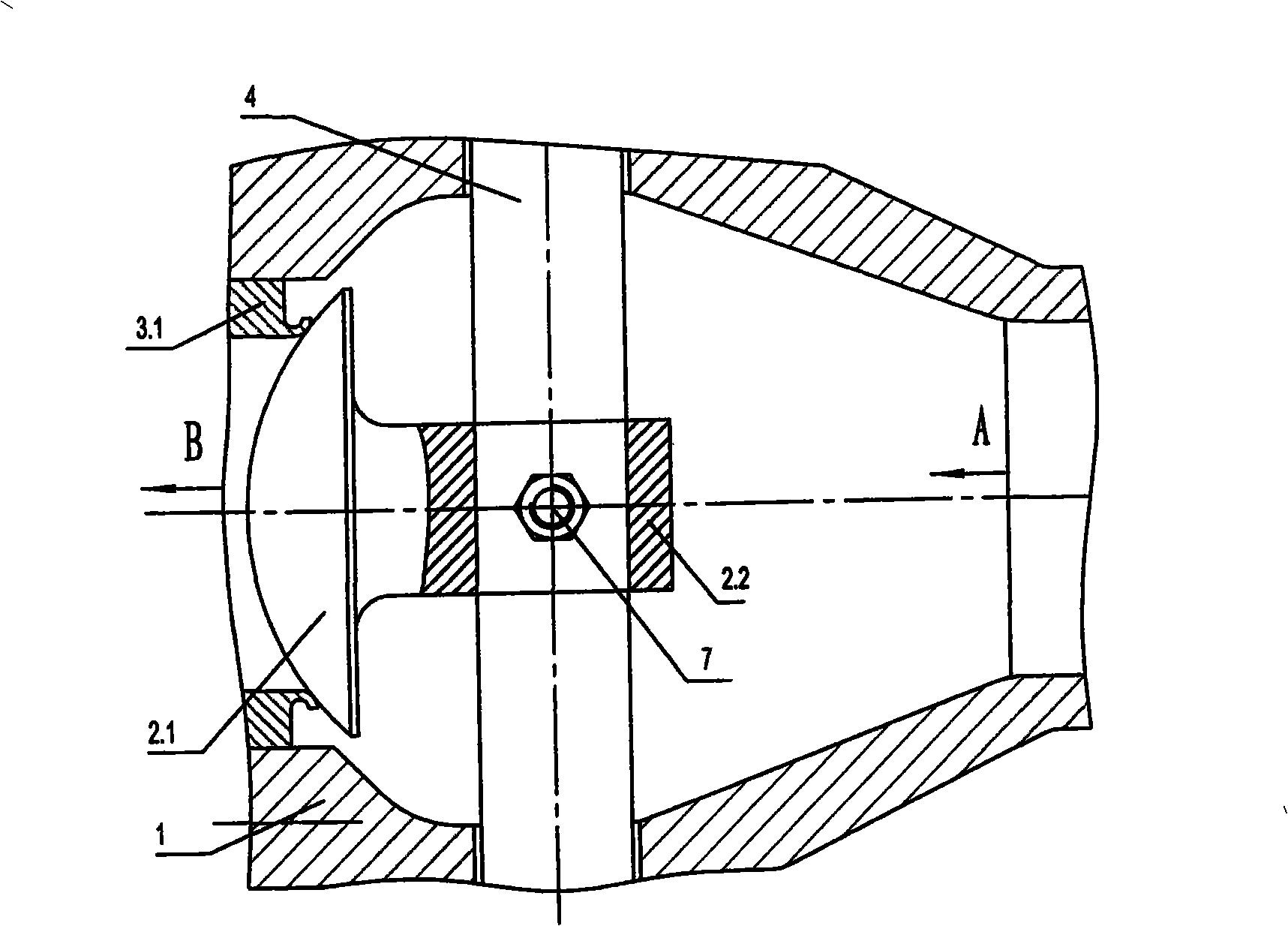

[0026] see image 3 , Figure 4 : The three-way ball valve includes a valve body 1, a valve seat 3, a valve core 2, and a valve stem 4. The valve body 1 has a medium inflow channel A and two medium outflow channels B and C, and the inner channels of the medium outflow channels B and C are The ports are respectively provided with valve seats 3 (3.1, 3.2).

[0027] The characteristic of this three-way ball valve is that the valve core 2 is designed as a special structure, which is composed of two parts, the spherical crown 2.1 and the handle 2.2. The spherical crown 2.1 is hemispherical, with a spherical surface and a flat surface; Valve seat 3; handle 2.2 is located on the plane of spherical crown 2.1, and the overall shape of valve core 2 is "umbrella" shape, such as image 3 shown. There is an assembly hole for connecting the valve stem 4 on the handle 2.2, which is fixedly connected with the valve stem 4 through the connecting piece 7.

[0028] The spherical crown 2.1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com