Self-centering multi-claw chuck device

A claw chuck and self-centering technology, which is applied in the field of self-centering multi-jaw chuck devices, can solve problems such as the inability to guarantee the coaxiality of the inner holes at both ends of special-shaped workpieces, the inability to process special-shaped workpieces, and difficult processing operations. To achieve the effect of ensuring the final machining accuracy, good clamping effect and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

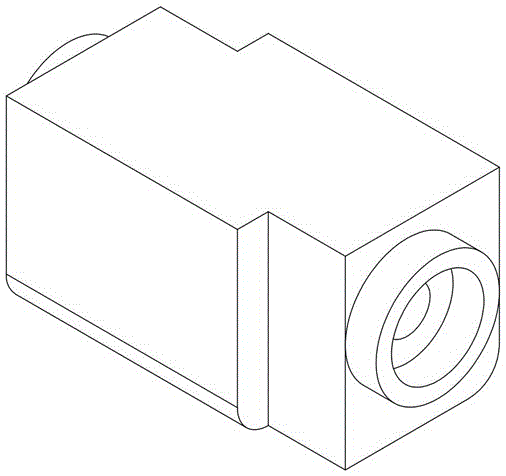

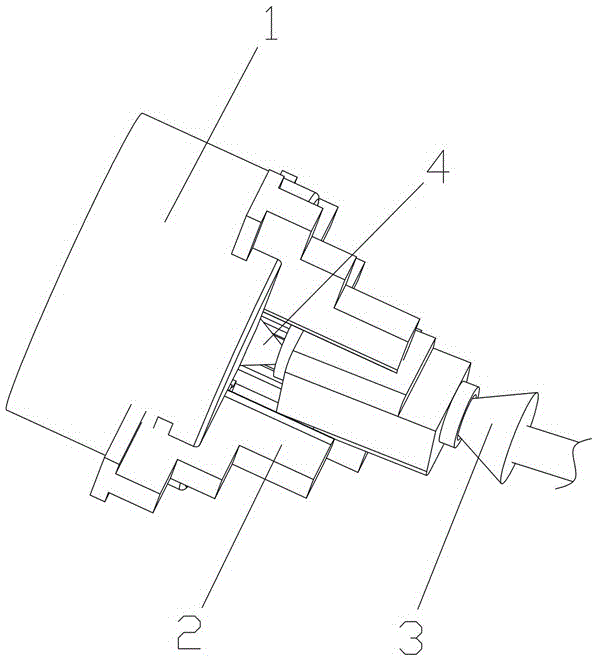

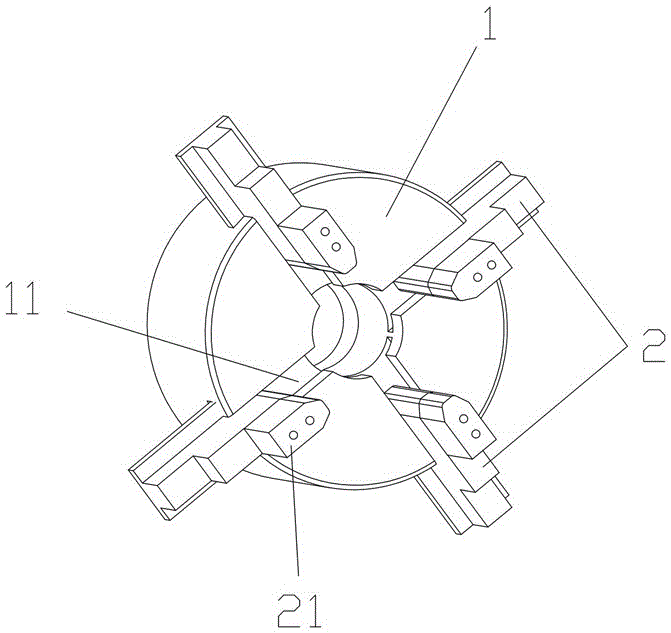

[0029] Such as Figure 1 to Figure 7 As shown, the present invention provides a self-centering multi-jaw chuck device, which is used to cooperate with a processing machine tool after clamping a workpiece so that the processing machine tool can process the clamped workpiece. The self-centering multi-jaw chuck device includes a chuck base 1, on which a plurality of jaws 2 are arranged in a circumferential manner, and a plurality of jaws 2 are enclosed to form a fixed cavity for placing workpieces. The claws 2 can move back and forth independently along the radial direction of the chuck base 1 for clamping the workpiece in the fixed cavity. The centering top assembly 4, the central axis of the centering top assembly 4 coincides with the central axis of the tailstock top 3. During operation, the tailstock top 3 and the centering top assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com