Punching mould for inner cambered-surface towing hook mounting hole of closed bumper

A bumper and mounting hole technology, which is applied in the field of punching dies for processing the mounting holes of the inner arc surface of the closed bumper, can solve the problems of difficult removal, inner arc surface and side wall folds, high production costs, etc., and achieve improvement The effect of product production efficiency, product quality improvement and production cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

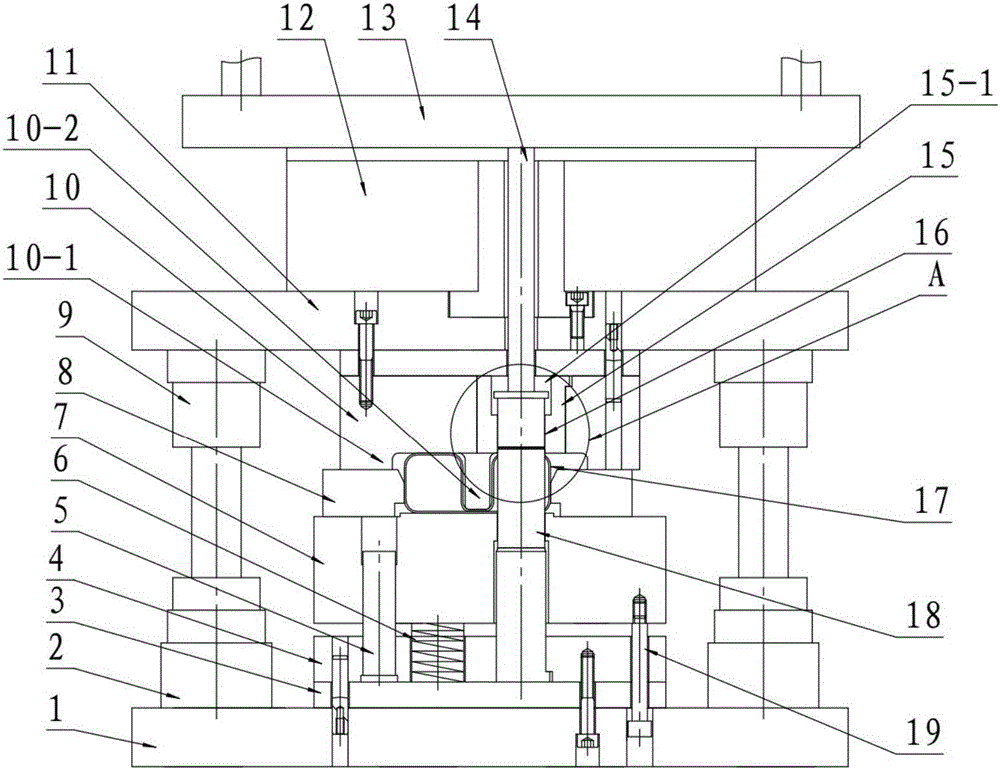

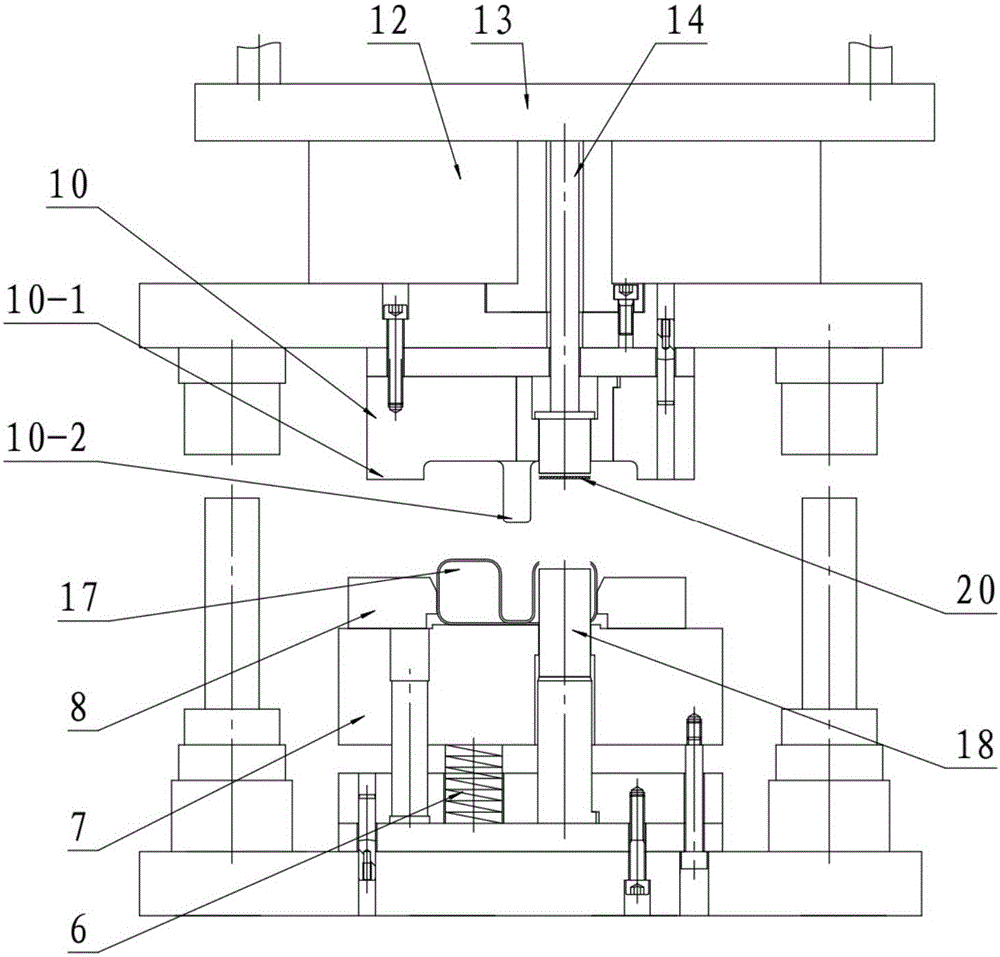

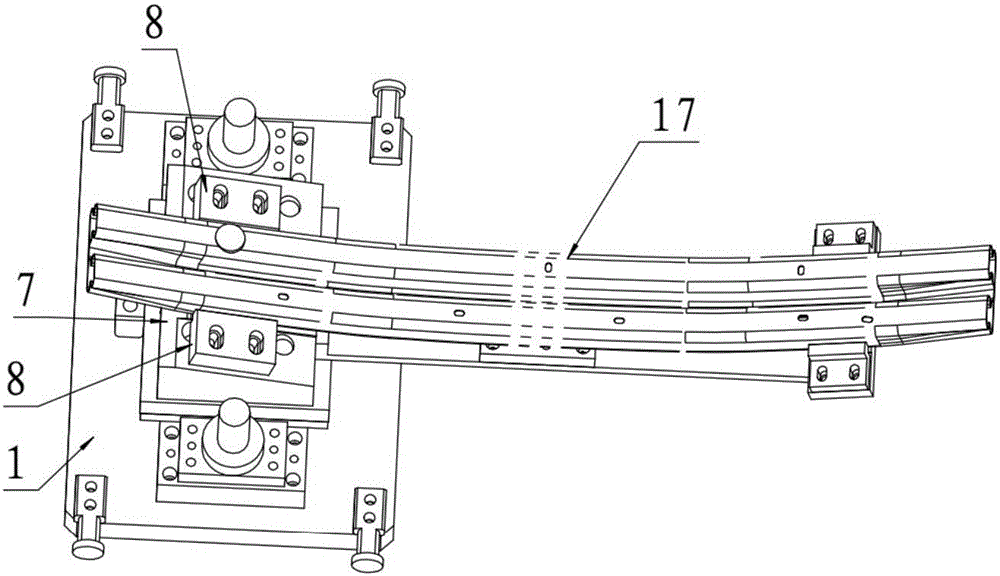

[0022] see figure 1 , figure 2 , the present invention comprises upper formwork 11, lower formwork 1, die 15 and punch 18, upper formwork is connected punch slide block 12, and upper formwork moves up and down with the motion of punch slide block, finishes punching and hits waste operation. Guide posts 2 are arranged symmetrically on the lower formwork, and guide sleeves 9 are provided at the positions corresponding to the upper formwork and each guide post. The convex mold and the concave mold of the mold adopt an inverted structure, that is, the concave mold is on the top and the convex mold is on the bottom. The upper template is fixedly connected with the die fixing plate 10, and the die is fixedly connected with the die fixing plate. The lower template 1 is fixedly connected with the punch backing plate 3, the punch backing plate is fixedly connected with the punch fixing plate 4, and the punch fixing plate is fixedly connected with the punch 18. The lower template i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com