Construction machinery for long spiral press pouring concrete lock pin combination piles

A technology of construction machinery and concrete, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., to achieve the effect of cost saving, high efficiency and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

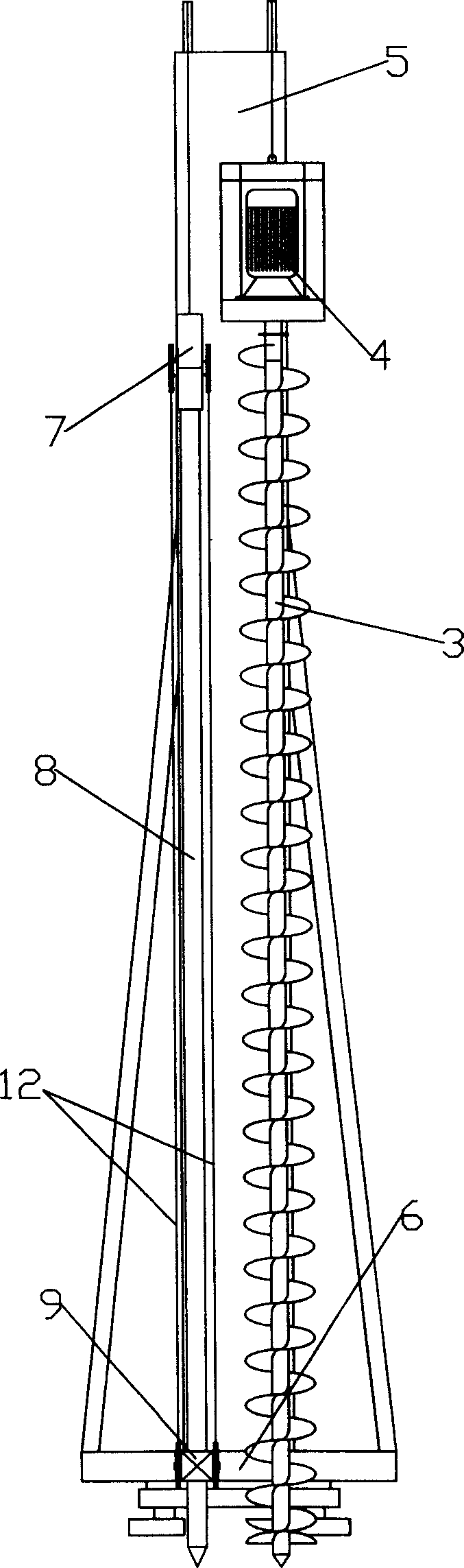

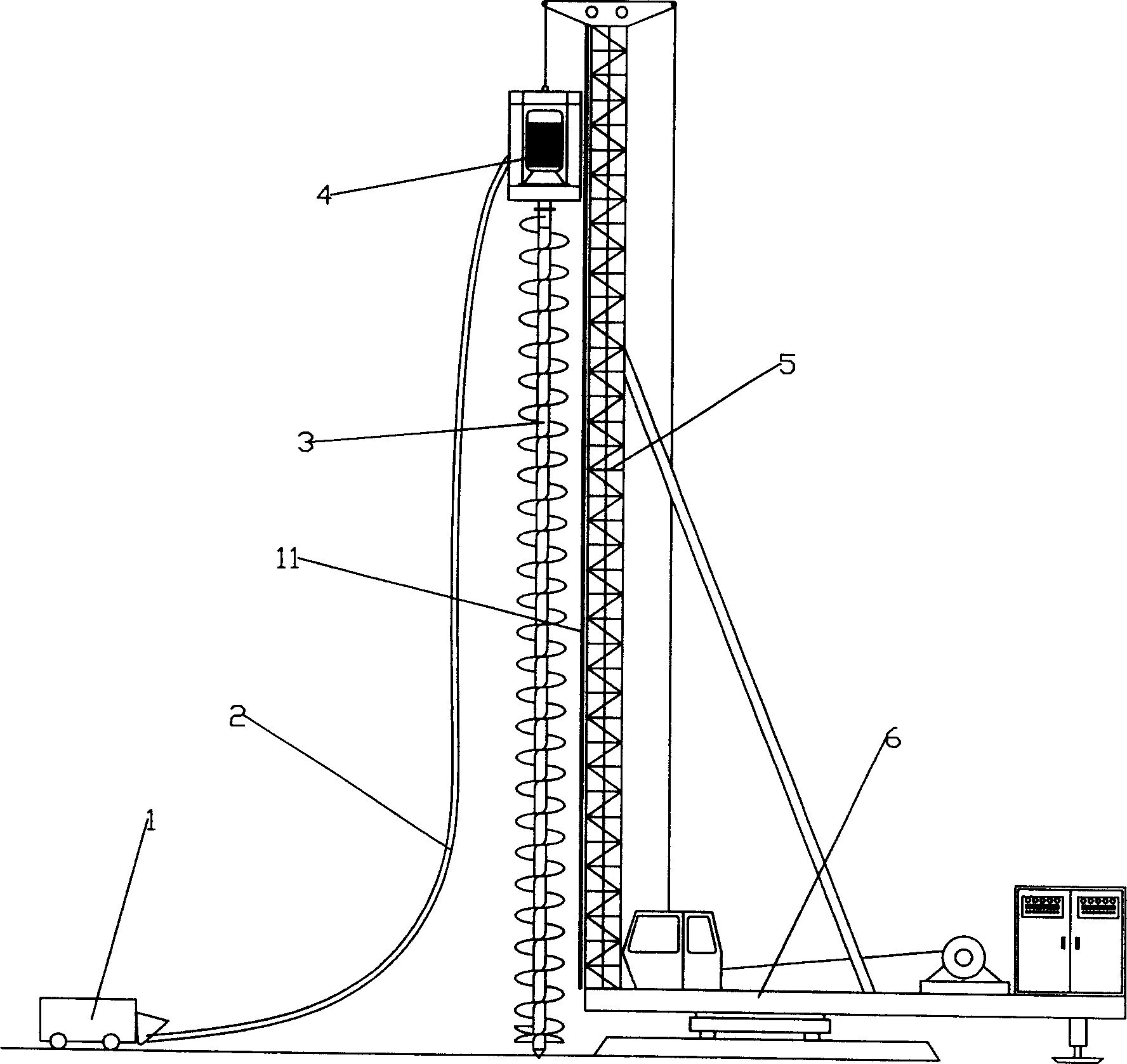

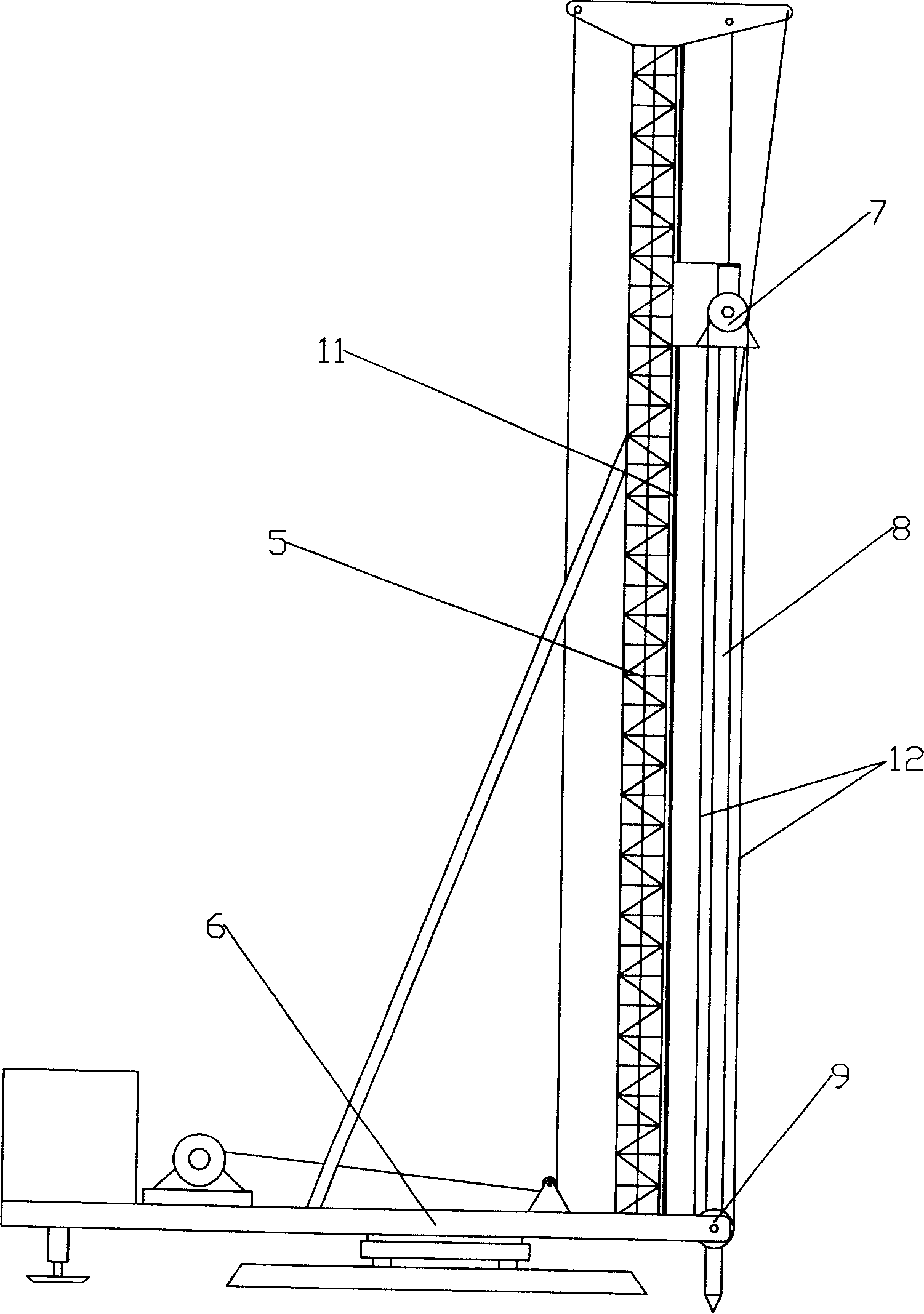

[0027] like figure 1 As shown, a shared pile driver mast 5 is installed on the walking chassis 6 of the walking pile driver. The static pile pressing mechanism that pile core pile presser 7, pile core guider 9, pile presser pressurizing rope 12 form. The long auger drill pipe 3 and the long auger power head 4 are suspended on the mast 5 of the pile driver, and the weight of the three plus the weight of the walking chassis 6 of the pile driver can all be pressed on the prefabricated reinforced concrete plug by the pile presser rope 12. On the core 8, the insert core has enough downward pressure to be pressed into the plain concrete pile body. If the pile pressure is still not enough, the long auger drill pipe can be drilled into the ground to a certain depth to make it a ground anchor to provide additional pressure piles. Reaction force.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com