Andalusite fiber size and preparation method thereof

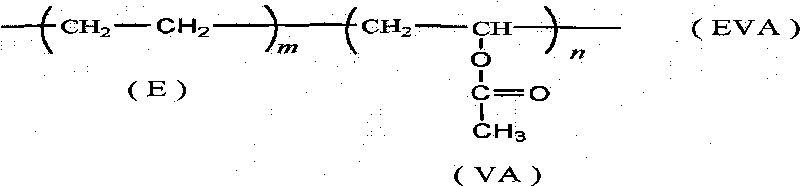

A technology of sizing agent and andalusite, which is used in the field of andalusite fiber sizing agent and its preparation, can solve the problems of no strong chemical bond, poor film-forming property, and increased friction coefficient between fibers and machinery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

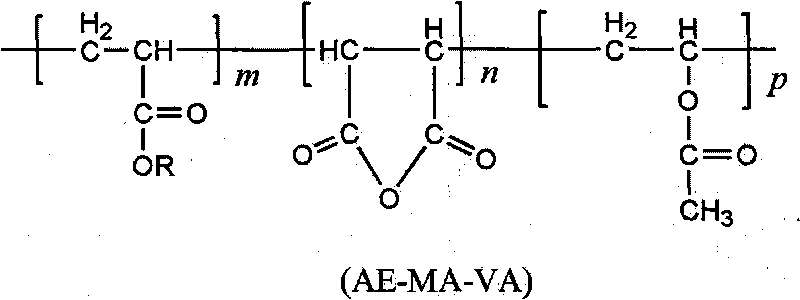

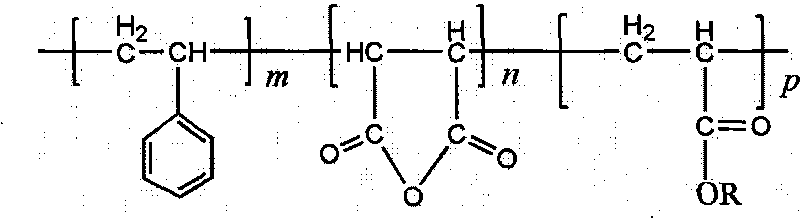

[0086] The preparation of film-forming agent: the preparation method of film-forming agent styrene-maleic anhydride-octadecyl acrylate copolymer (St-MA-OA), its step is:

[0087] In the reaction flask equipped with thermometer, stirrer and reflux condenser, add 20.8g of styrene, 19.6g of maleic anhydride, 97.2g of octadecyl acrylate, 0.3g of initiator benzoyl peroxide (BPO) and 250mL toluene, blow nitrogen to remove the oxygen in the reaction flask, stir and heat up to 110-120°C, react for 6-8h, after the reaction is terminated, purify the copolymer with ethanol, and dry it in vacuum at 70°C for 8 hours.

[0088] 1. Add 315.0g of stearic acid, 75.0g of triethanolamine, and 3.0g of p-toluenesulfonic acid into a general-purpose reaction kettle equipped with mechanical stirring and temperature control devices, and react for 1 hour at a temperature of 80-150°C to obtain The product is ready for use.

[0089] 2. Add 110.0g EVA and 220.0g St-MA-OA to the antistatic agent synthesize...

Embodiment 2

[0096] 1. Add 325.0g of stearic acid, 75.0g of triethanolamine, and 3.0g of p-toluenesulfonic acid into a general-purpose reaction kettle equipped with a mechanical stirring and temperature control device, and react for 1 hour at a temperature of 80-150°C to obtain The product is ready for use.

[0097] 2. Add 320.0 g of St-MA-OA to the antistatic agent synthesized above, react at 100-140° C. for 1.5 h, and the resulting mixture is ready for use.

[0098] 3. Add 20.0g of silane coupling agent KH-550, 28.0g of ethylene bisstearic acid amide, and 400.0g of softener-b to the mixture synthesized above, react at 100-150°C for 1 hour, cool and discharge , the resulting product is the wetting agent. The pH of the final product is controlled at 6-7.

[0099] B. On-site preparation of infiltration agent;

[0100] 4. Accurately weigh the infiltration agent, and add the material according to the mass / volume ratio, that is, 1.0kg infiltration agent / 40 liters of water.

[0101] 5. The ...

Embodiment 3

[0104] 1. Add 315.0g of stearic acid, 95.0g of triethanolamine, and 3.5g of p-toluenesulfonic acid into a general-purpose reaction kettle with a mechanical stirring and temperature control device, and react at a temperature of 90-150°C for 1 hour to obtain The product is ready for use.

[0105] 2. Add 54.0g EVA and 266.0g St-MA-OA to the antistatic agent synthesized above, react at 100-140°C for 1.5h, and the resulting mixture is ready for use.

[0106] 3. Add 20.0g of KH-550, 18.0g of ethylene bisstearic acid amide and 400.0g of softener-a / softener-c mixture to the mixture synthesized above. This softener-c mixture contains 15% triethanolamine stearate monoester, 45% triethanolamine stearate diester and 40% triethanolamine stearate triester, reacts at 130°C for 1h, cools, and discharges the obtained The product is a wetting agent. The pH of the final product is controlled at 6-7.

[0107] B. On-site preparation of infiltration agent;

[0108] 4. Accurately weigh the infil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com