Preparation method of self-colored bamboo fiber filter tip

A bamboo fiber and filter technology is applied in the field of preparation of natural bamboo fiber filters, which can solve the problems that have not been obtained and have not been effectively and reasonably comprehensively utilized, and achieve the effects of soft texture, significant social and economic benefits, and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

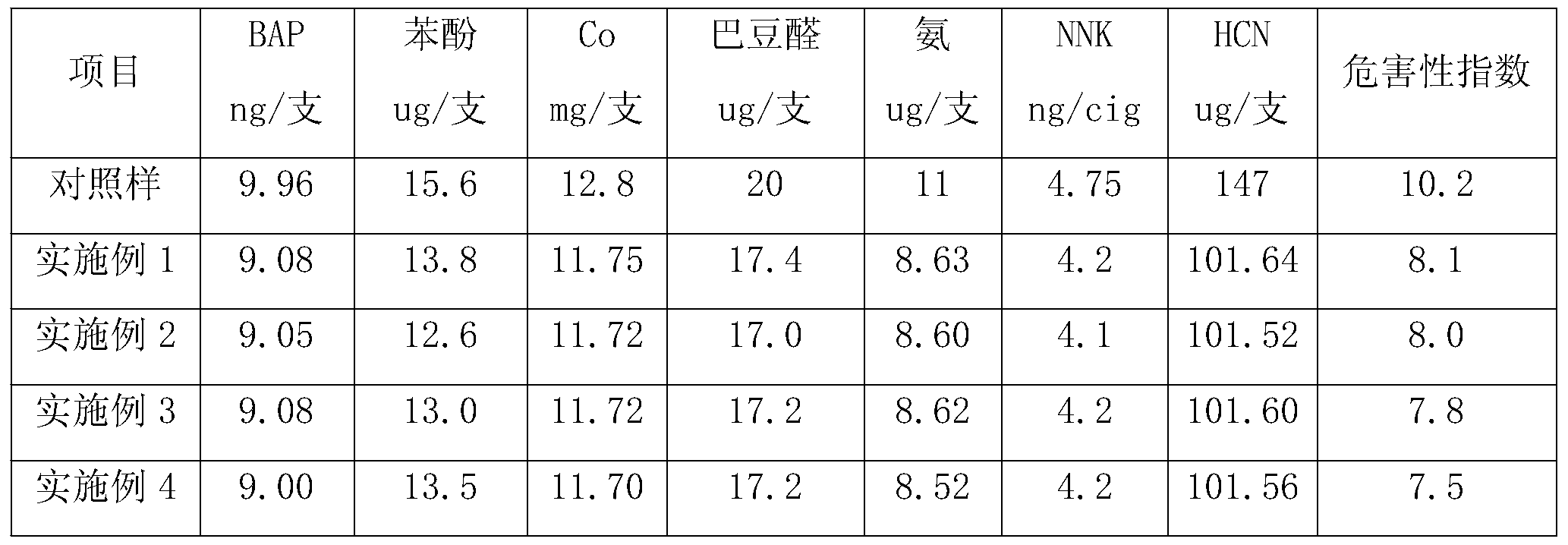

Examples

Embodiment 1

[0021] Embodiment 1: a kind of preparation method of natural color bamboo fiber filter, it may further comprise the steps:

[0022] S1. Raw material disintegration: choose moso bamboo fiber as raw material, and dry the raw material into pieces with a length of 2cm

[0023] S2. Cooking: mix the tablet and cooking liquid according to the material-liquid ratio of 1g:2.5ml, then add it to the cooking pot, heat it up to 135°C for the first time, keep it warm for 110 minutes, and then perform a small deflation for 15 minutes, the second heating condition To heat up to 160°C within 70 minutes, keep warm for 60 minutes, and finally perform a large outgassing to obtain high-hardness bamboo pulp with a potassium permanganate value of 26; wherein, the cooking liquid is 10% KOH;

[0024] S3. Washing: the high-hardness bamboo pulp is washed and screened through a pressure sieve and a vacuum pulp washer to obtain clean bamboo pulp with a concentration of 3%;

[0025] S4. Paper making: copy...

Embodiment 2

[0028] Embodiment 2: a kind of preparation method of natural color bamboo fiber filter, it may further comprise the steps:

[0029] S1. Raw material disintegration: select yellow bamboo, Cizhu and water bamboo fibers as raw materials, and dry the raw materials into flakes with a length of 4 cm;

[0030] S2. Cooking: mix the tablet and the cooking liquid evenly according to the ratio of 1g:4ml of material to liquid, then add it into the cooking pot, heat it up to 150°C for the first time, keep it warm for 140min, and then perform a small deflation for 25min, the second heating condition is Heating up to 175° C. within 90 minutes, keeping the temperature for 80 minutes, and finally degassing to obtain a high-hardness bamboo pulp with a potassium permanganate value of 38; wherein, the cooking liquid is 17% KOH;

[0031] S3. Washing: the high-hardness bamboo pulp is washed and screened through a pressure sieve and a vacuum pulp washer to obtain clean bamboo pulp with a concentrati...

Embodiment 3

[0035] Embodiment 3: a kind of preparation method of natural color bamboo fiber filter, it may further comprise the steps:

[0036] S1. Raw material disintegration: choose white bamboo and westerly bamboo fiber as raw materials, and dry the raw materials into flakes with a length of 3 cm;

[0037] S2. Cooking: mix the tablet and the cooking liquid evenly according to the material-liquid ratio of 1g:3ml, then add it to the cooking pot, heat it up to 140°C for the first time, keep it warm for 125 minutes, and then perform a small deflation for 18 minutes, and the second heating condition is: Heating up to 165° C. within 78 minutes, keeping the temperature for 68 minutes, and finally degassing to obtain high-hardness bamboo pulp with a potassium permanganate value of 30; wherein, the cooking liquid is 12% KOH;

[0038] S3. Washing: the high-hardness bamboo pulp is washed and screened through a pressure sieve and a vacuum pulp washer to obtain clean bamboo pulp with a concentratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com