Washing composite enzyme containing fungus alpha-amylase and preparation method of washing composite enzyme

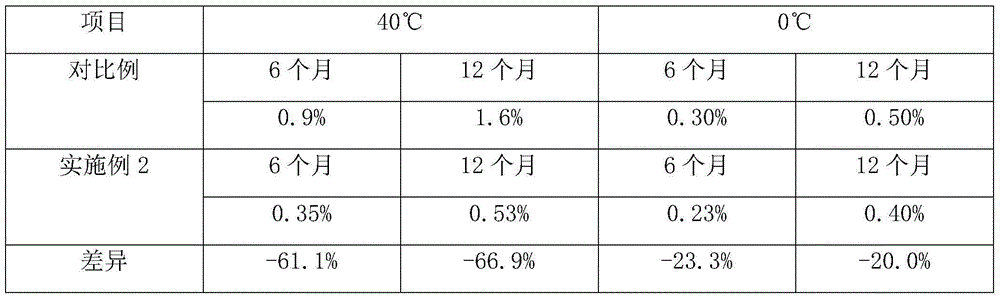

A technology of amylase and compound enzyme, applied in the field of washing compound enzyme, can solve the problems of poor storage stability, single function, single type of washing enzyme, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1 raw material preparation

[0056] 1. Preparation of fungal α-amylase:

[0057] The preparation method of the fungal alpha-amylase comprises the following steps:

[0058] (1) Activation of bacteria

[0059] Inoculate the well-preserved slant strain of Trichoderma reesei CCTCC NO:M 2013602 on the slant medium, culture at 30°C for 40 hours to activate the strain, and activate it 3 times;

[0060] (2) Expanded cultivation of liquid seeds

[0061] ①First-level seed culture: wash the spores of the slanted bacteria after activation in step (1) with sterile water, insert them into a 500-ml shaker flask, fill the liquid seed medium with 100 ml, and culture on a shaker at 30°C and 100rpm for 40 hours;

[0062] ②Cultivation of secondary seeds: Inoculate 10% of the primary seeds into 500 ml secondary seed shake flasks, and the cultivation conditions are the same as those of the primary seeds;

[0063] ③Third-level seed cultivation: insert the second-level seeds int...

Embodiment 2

[0081] A washing complex enzyme containing fungal α-amylase, prepared from the raw materials of the following weight components:

[0082] 50 parts of sawdust, 30 parts of fungal α-amylase, 25 parts of alkaline protease, 25 parts of alkaline lipase, 20 parts of plant extract, 6 parts of alkaline cellulase, 5 parts of nonionic surfactant, 4 parts of activator part, 2 parts of protective agent, 0.4 part of antioxidant;

[0083] The sawdust, fungal α-amylase, and plant extract are all prepared in Example 1;

[0084] The mass components of the nonionic surfactant are: 35 parts of alkyl polyglycosides (APG), 25 parts of alkyl glucamides (AGA), 10 parts of N-dodecyl ethylenediamine triacetate (ED3A) , isomerized alcohol ether carboxylate AEC-110710 parts, lauramide ether carboxylate (LAEC) 7 parts, Pingpingjia c-1251 parts, JFC 1 part;

[0085] The activator is formed by uniformly mixing inorganic salts with the following mass components: 20 parts of sodium sulfate, 12 parts of cal...

Embodiment 3

[0090] A washing complex enzyme containing fungal α-amylase, prepared from the raw materials of the following weight components:

[0091] 45 parts of sawdust, 25 parts of fungal alpha-amylase, 20 parts of alkaline protease, 20 parts of alkaline lipase, 15 parts of plant extract, 3 parts of alkaline cellulase, 2 parts of nonionic surfactant, 2 parts of activator 1 part, 1 part of protective agent, 0.3 part of antioxidant;

[0092] The sawdust, fungal α-amylase, and plant extract are all prepared in Example 1;

[0093] The mass components of the nonionic surfactant are: 30 parts of alkyl polyglycosides (APG), 20 parts of alkyl glucamides (AGA), 8 parts of N-dodecyl ethylenediamine triacetate (ED3A) , isomerized alcohol ether carboxylate AEC-11078 parts, lauramide ether carboxylate (LAEC) 5 parts;

[0094] The activator is formed by uniformly mixing inorganic salts with the following mass components: 15 parts of sodium sulfate, 10 parts of calcium chloride, 5 parts of zinc chlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com