Freeze-drying protective agent for protease K as well as preparation method and application of freeze-drying protective agent

A lyophilized protective agent and protease technology, applied in biochemical equipment and methods, lyophilized transportation, peptide/protein components, etc., can solve the problem that high-end reagent manufacturers cannot meet the requirements of high-end reagent manufacturers, and it is difficult to achieve dry powder specific activity and proteinase K solid content. Low problems, to achieve the effect of white appearance, strong crystal feeling, and low solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The embodiment of the present invention provides a proteinase K lyoprotectant and a preparation method thereof.

[0057] (1) Raw material components

[0058]

[0059]

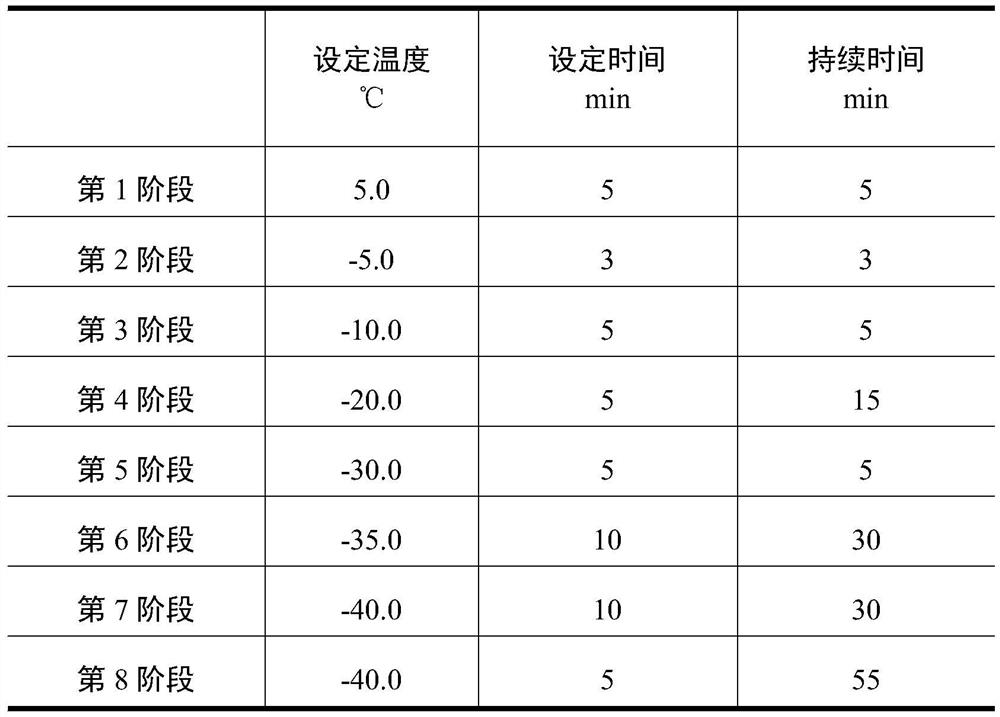

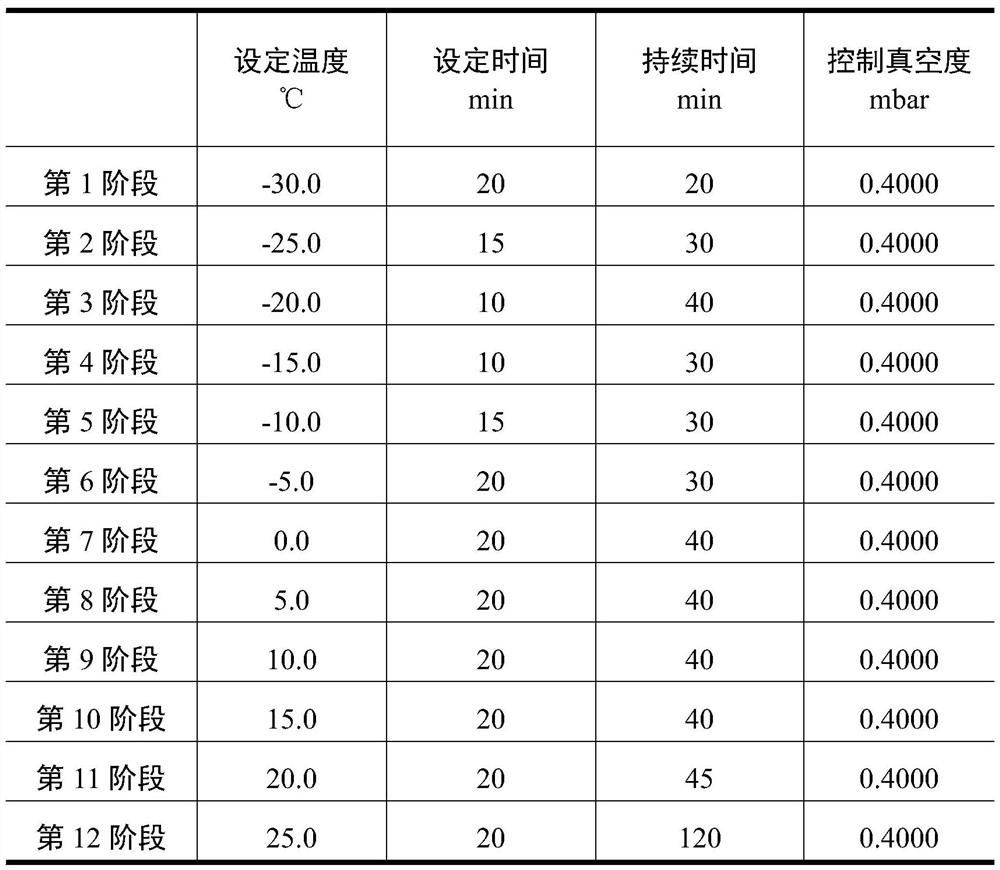

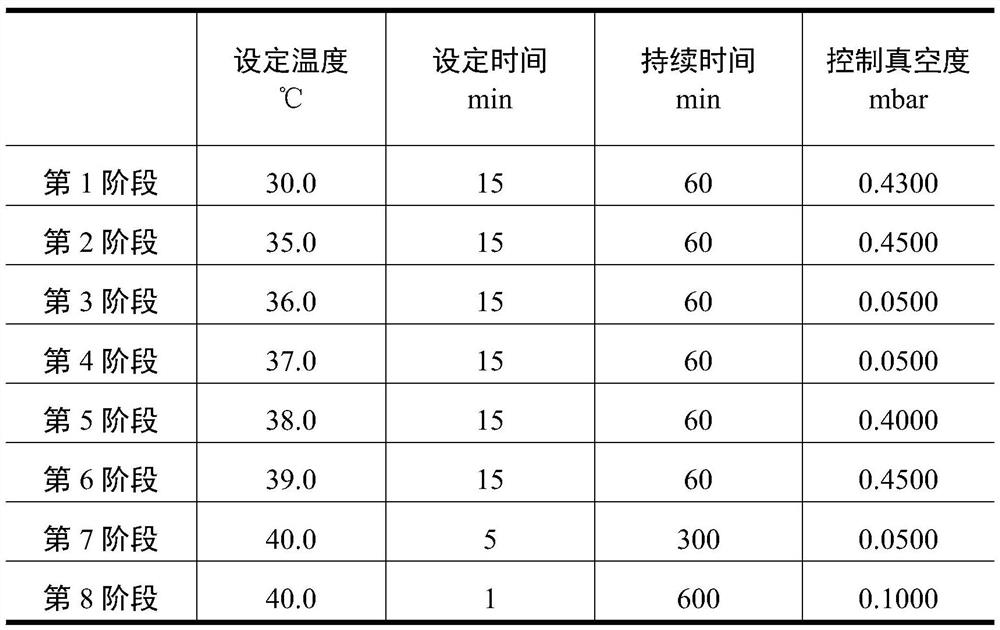

[0060] (2) Preparation method

[0061] S1. Weigh sucrose, trehalose, mannitol, sorbitol, Tween-80 and tert-butanol respectively according to the proportion, dissolve them in 4L of ultrapure water, and then sterilize at 115°C for 20 minutes to obtain solution A;

[0062] S2. Weigh β-alanine, PVP, human serum albumin (HSA), dextrin and dextran respectively according to the ratio, dissolve them in 2.5L of ultrapure water, and then filter them with a filter membrane with a pore size of 0.22um. Obtain solution B;

[0063] S3. Mix solution A and solution B, set the volume to 8.5 L, stir evenly, and obtain;

[0064] Wherein: step S1 and step S2 can be exchanged order or carried out simultaneously.

Embodiment 2

[0066] The embodiment of the present invention provides a proteinase K lyoprotectant and a preparation method thereof.

[0067] (1) Raw material components

[0068]

[0069] (2) Preparation method

[0070] S1. Weigh sucrose, trehalose, mannitol, sorbitol, Tween-80 and tert-butanol respectively according to the proportion, dissolve them in 4L of ultrapure water, and then sterilize at 115°C for 20 minutes to obtain solution A;

[0071] S2. Weigh β-alanine, PVP, bovine serum albumin (BSA) and dextrin respectively according to the proportion, dissolve them in 2.5L of ultrapure water, and then filter with a filter membrane with a pore size of 0.22um to obtain solution B;

[0072] S3. Mix solution A and solution B, set the volume to 8.5 L, stir evenly, and obtain;

[0073] Wherein: step S1 and step S2 can be exchanged order or carried out simultaneously.

Embodiment 3

[0075] The embodiment of the present invention provides a proteinase K lyoprotectant and a preparation method thereof.

[0076] (1) Raw material components

[0077]

[0078] (2) Preparation method

[0079] S1. Weigh sucrose, trehalose, mannitol, sorbitol, Tween-80 and tert-butanol respectively according to the proportion, dissolve them in 4L of ultrapure water, and then sterilize at 115°C for 20 minutes to obtain solution A;

[0080] S2, weigh β-alanine, PVP, chicken ovalbumin (OVA) and chitosan respectively by proportioning, dissolve in the ultrapure water of 2.5L, filter with the filter membrane of aperture 0.22um then, obtain solution B;

[0081] S3. Mix solution A and solution B, set the volume to 8.5 L, stir evenly, and obtain;

[0082] Wherein: step S1 and step S2 can be exchanged order or carried out simultaneously.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com