Aluminium packaging can and production method

A production method and technology for packaging cans, applied in the field of aluminum packaging cans and production, can solve the problems of high storage cost, inconvenient printing, low added value, etc., and achieve the effect of improving product grade, highlighting corporate brand, and large economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] A further detailed description will be made below in conjunction with the accompanying drawings and embodiments of the present invention:

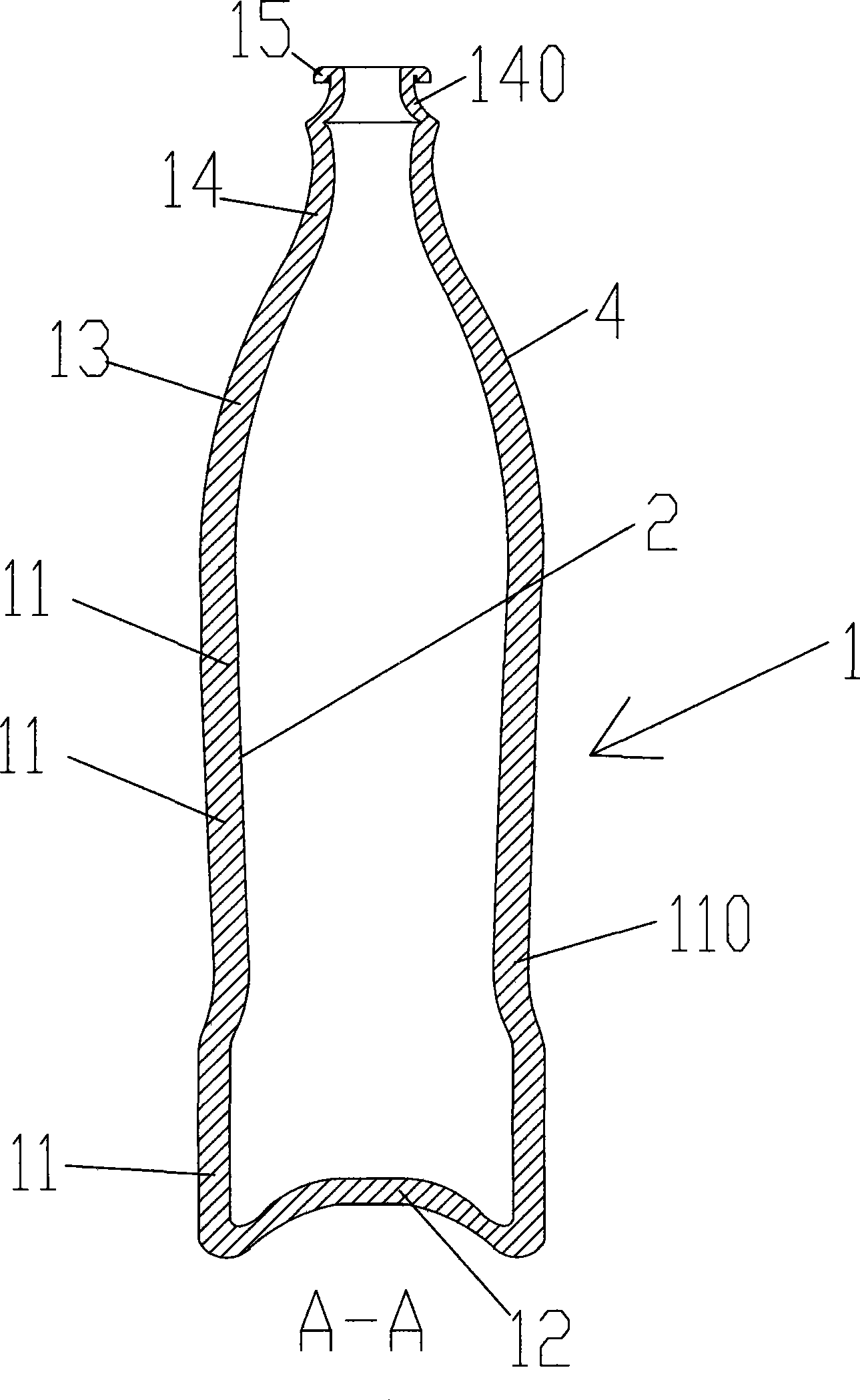

[0031] Such as Figure 1~2 As shown, the aluminum packaging can related to the present invention includes a can barrel 11, a can bottom 12, a can shoulder 13, a can neck 14 and a can mouth 15, and an inner part that is convenient for holding is contracted in the middle of the can barrel 11. The concave arc-shaped inner recess 110, the tank 11 at the lower part of the inner recess 110 is cylindrical, and the longitudinal section of the tank 11 at the upper part is a convex arc. Due to the existence of the inner concave part 110, it is very convenient and comfortable for people to hold it, and the friction force is increased, so that the aluminum packaging can is not easy to slip from the hand. The upper part of the tank neck 14 has a constricted part 140 that is thicker at the bottom and thinner at the top. The longitudinal section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com