Film pasting device

A film applicator and film lamination technology, applied in packaging and other directions, can solve the problems of air bubbles, improper film, sticking impurities, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

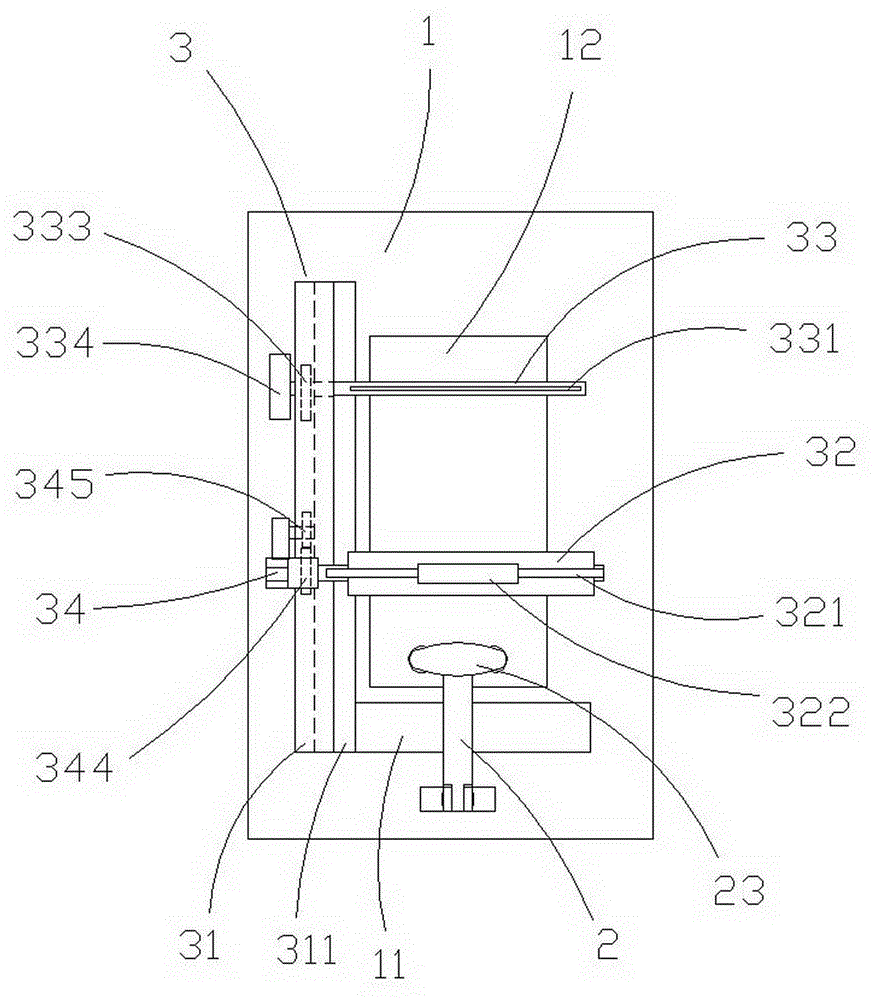

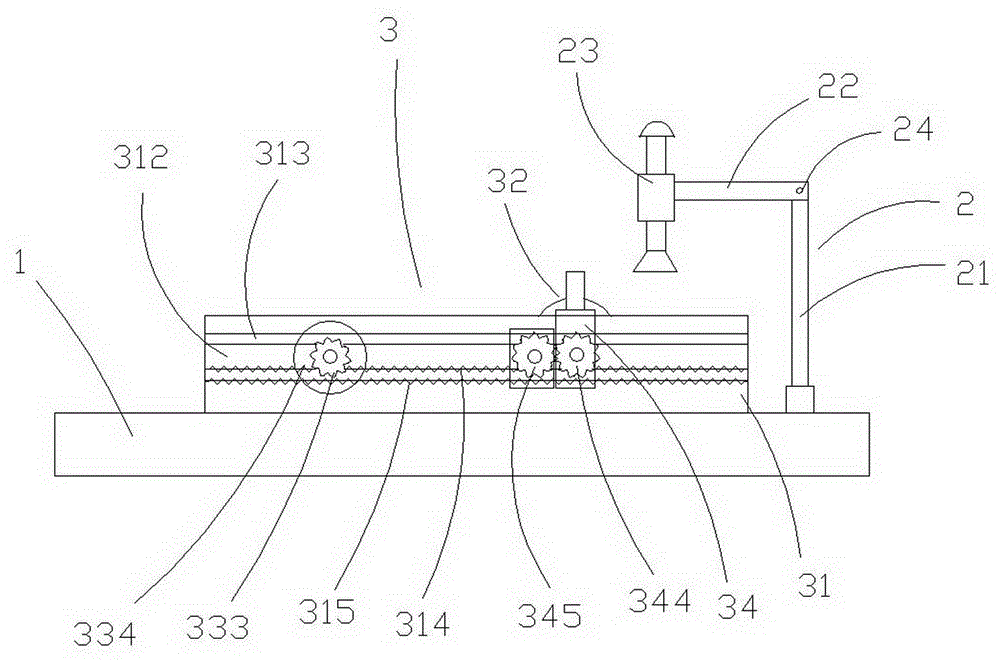

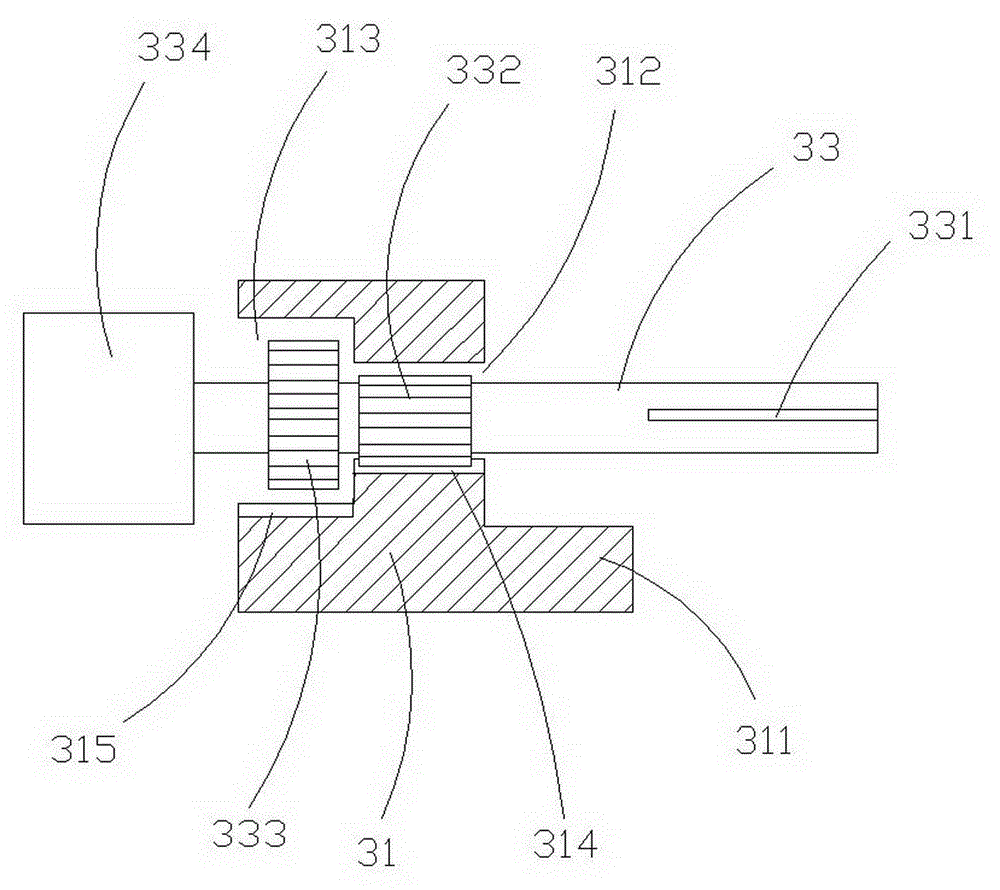

[0022] Such as figure 1 , 2 ,, and 3, a film applicator includes a base 1, a film suction positioning frame 2, and a film pressing device 3. On the panel of the base 1, there is a non-slip cushion 12 for placing a mobile phone. The side is provided with baffle plate 11, and the upright strut 21 of suction film positioning frame 2 is fixed on the outside of baffle plate 11, and upright strut 21 is connected with transverse strut 22 through shaft pin 24 rotation, and the top of transverse strut 22 is provided with two A film suction device 23, the film suction device is suspended above the non-slip cushion 12, that is, above the lower end of the mobile phone. The side of the baffle 11 is provided with a lamination device 3, the base 31 of the lamination device is at right angles to the baffle 11, and the adjacent two sides of the mobile phone are attached to the baffle 311 and the baffle on the base 31 of the lamination device. 11, the height of the baffle and the baffle plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com