Clamper for cleaning and degumming silicon chip

A silicon wafer cleaning and degumming technology, applied in sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve the problems of easy slipping of silicon wafers, high cost, low yield of silicon wafers, etc. Easy to operate, save labor, reduce cost input, and improve the effect of yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

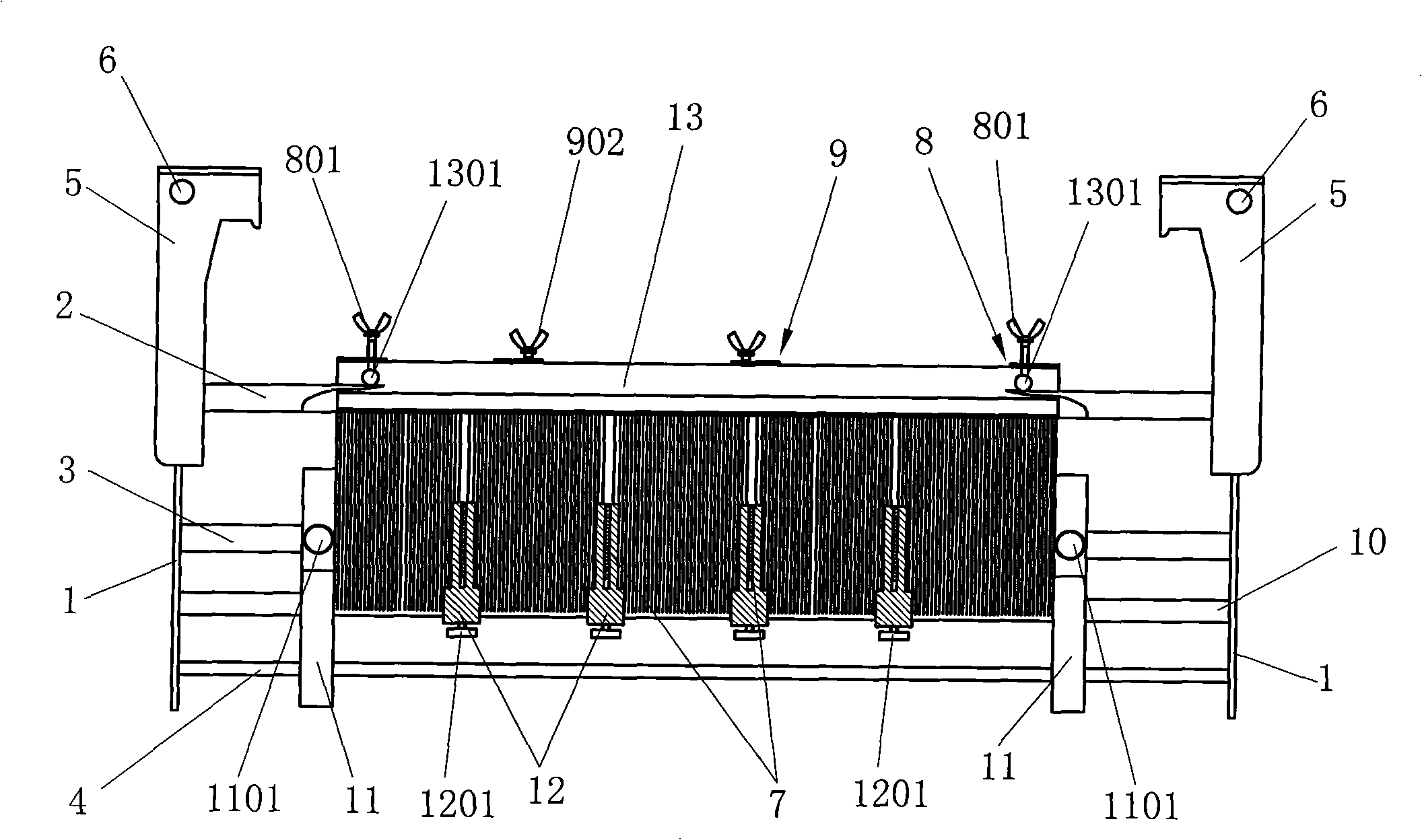

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

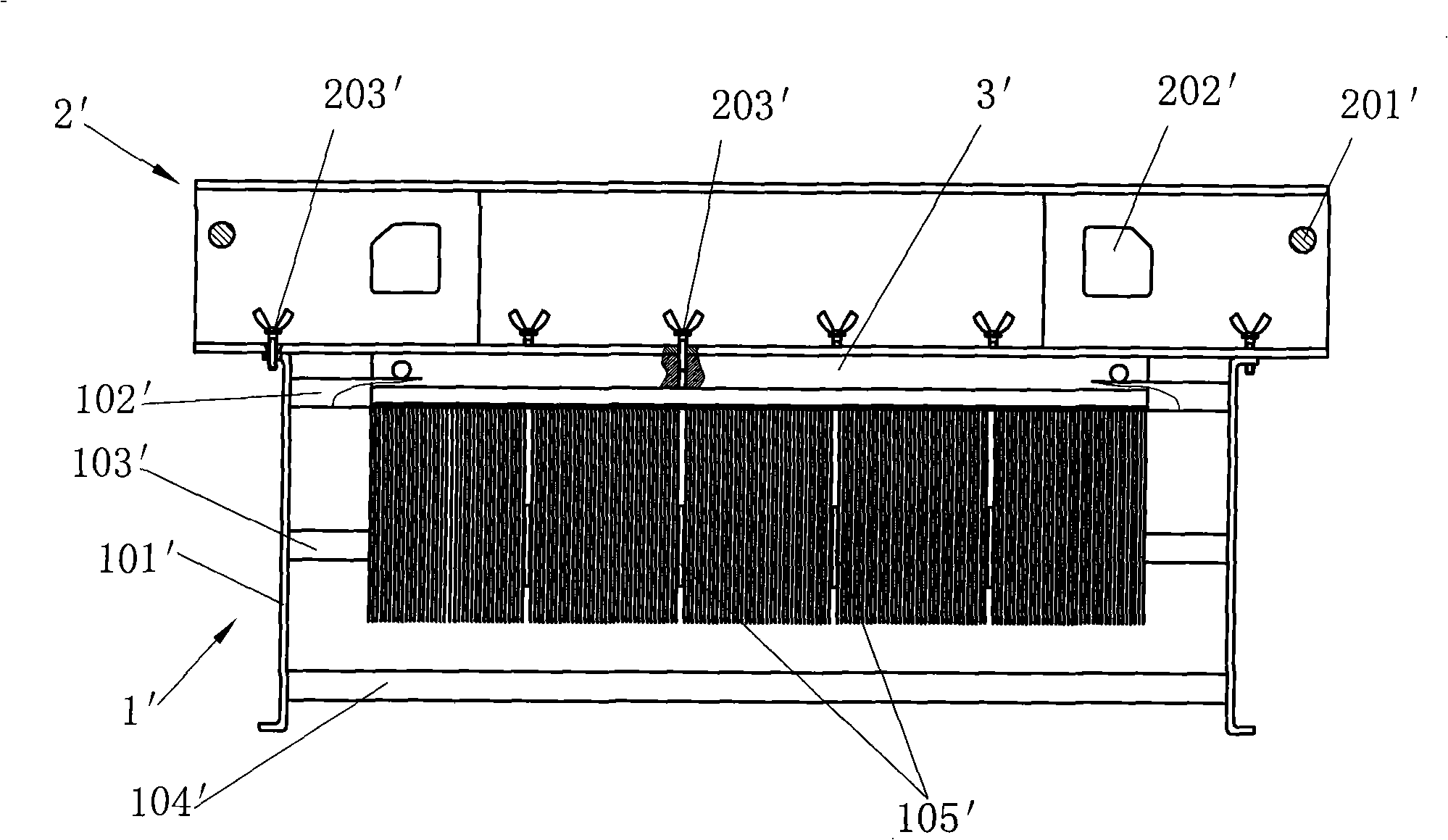

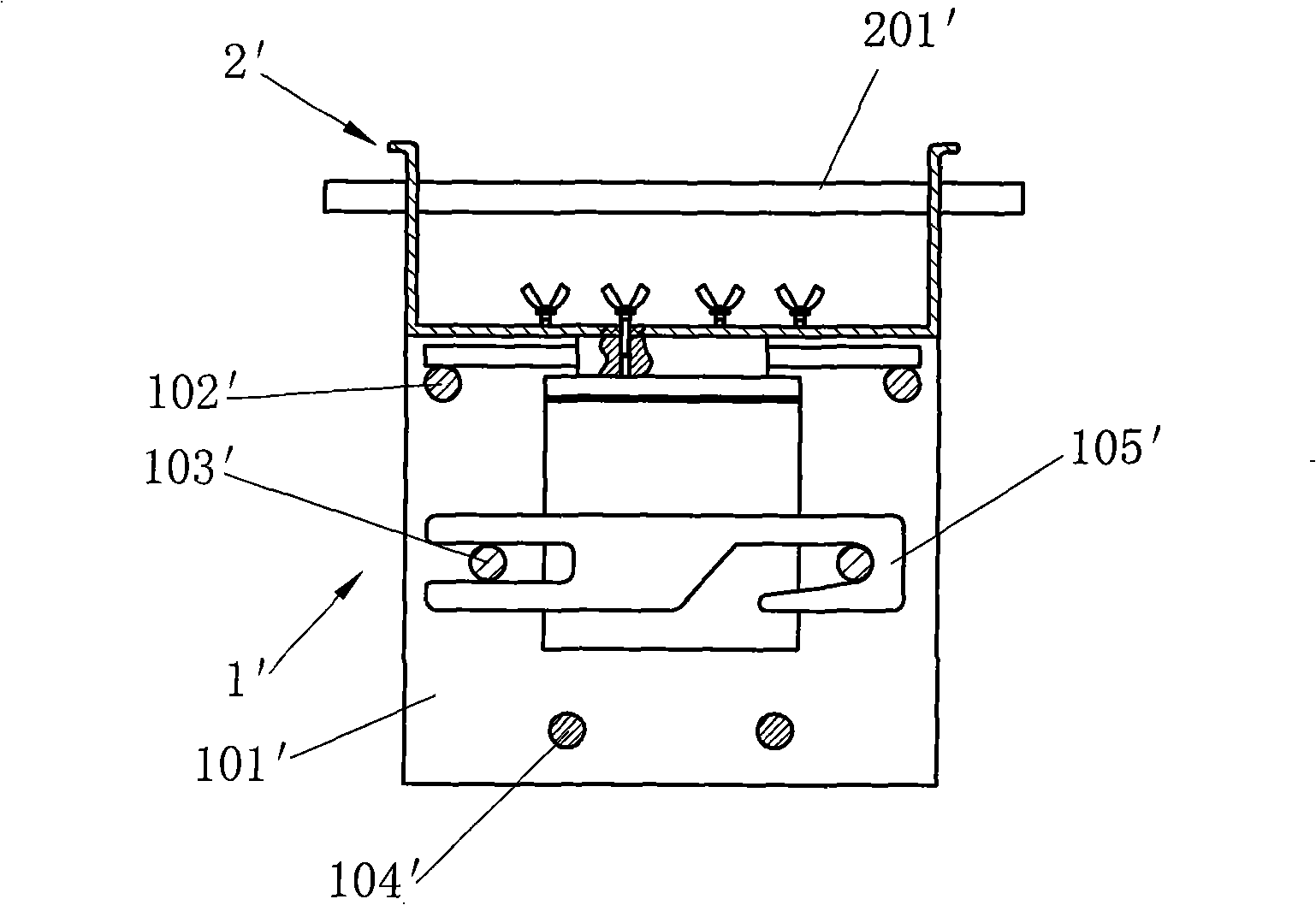

[0025] Such as image 3 , 4 , 5, the present invention comprises two side plates 1 and a pair of upper guide rods 2, partition plate guide rods 3 and lower guide rods 4 installed between the two side plates 1, on the partition plate guide rods 3 There are four partition plates 7 for clamping, and lifting hooks 5 are provided on both sides of the side plate 1, and handles 6 are connected between the lifting hooks 5. The lifting hooks 5 are used to lift the entire fixture in the cleaning and degumming machine, and the handles 6 are used as artificial Handles for carrying. The upper sliding sleeve of the upper guide rod 2 has two pairs of machine board fixing clips 8 and two pairs of machine board limit clips 9, the machine board fixing clips 8 and the machine board limit clips 9 can slide on the upper guide rod 2, The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com