Aluminum variable wall special-shaped packaging tin and manufacturing method thereof

A manufacturing method and technology of packaging cans, applied in packaging, transportation and packaging, rigid containers, etc., can solve the problems of not being able to be thinned at will, not being able to adapt to filling, and inconvenient printing, etc., to achieve a visually beautiful overall appearance and a three-dimensional visual effect The effect of enhancing and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing:

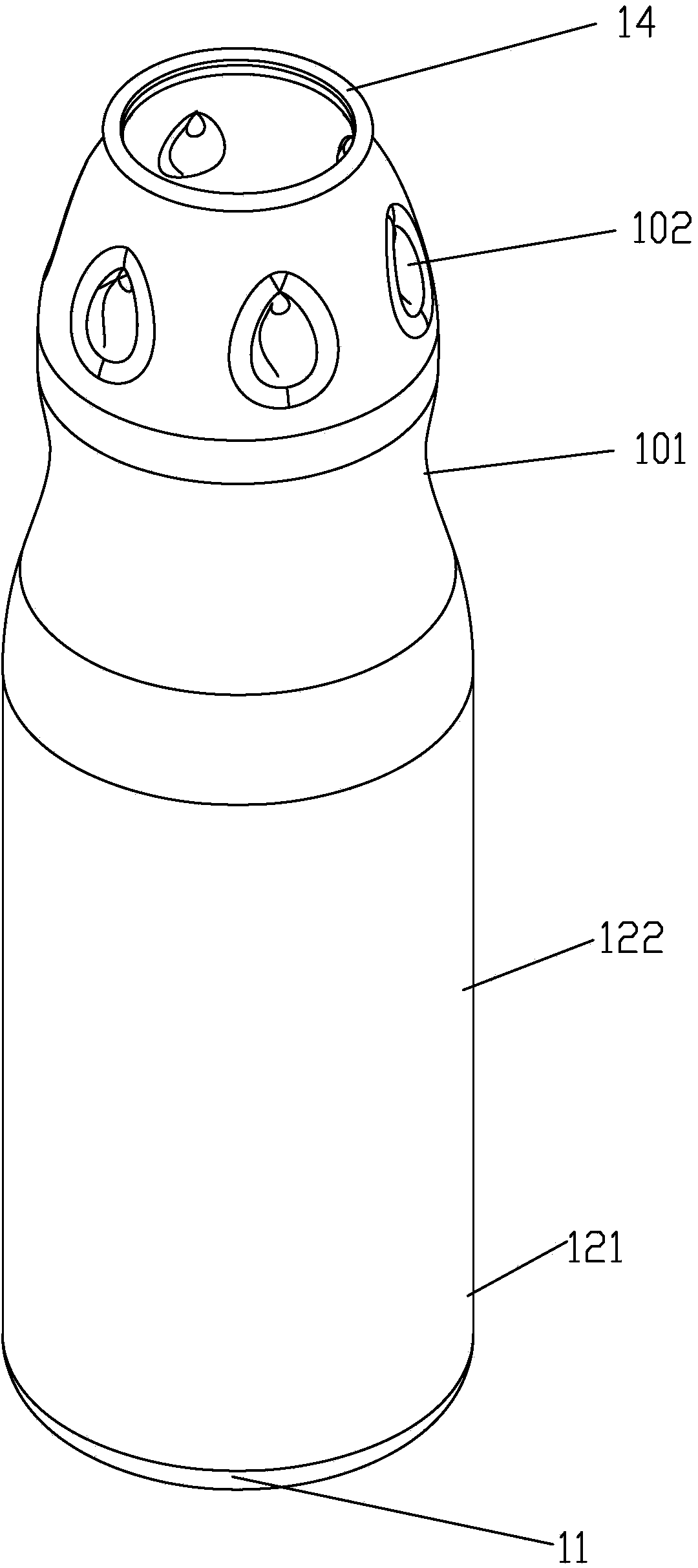

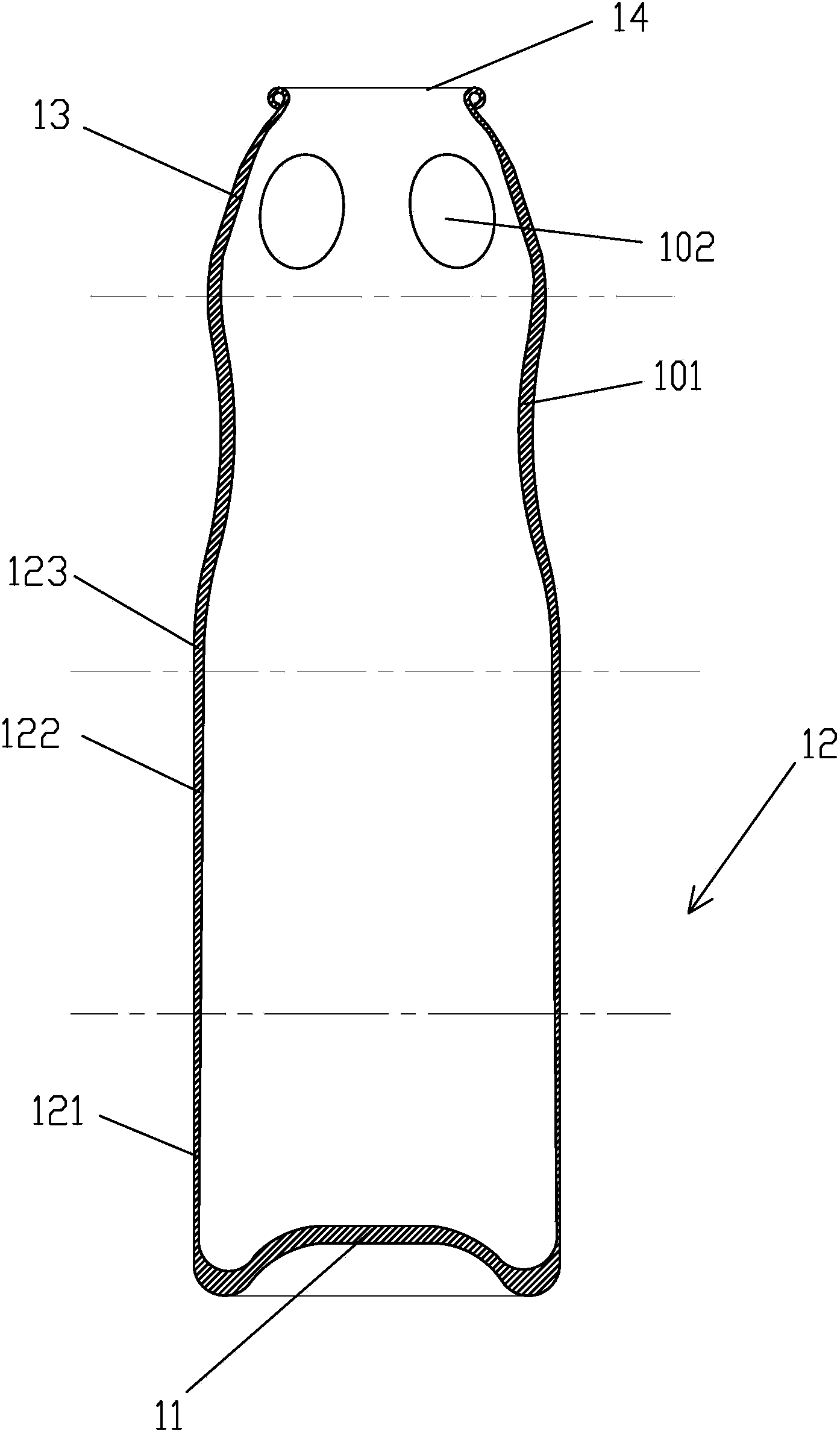

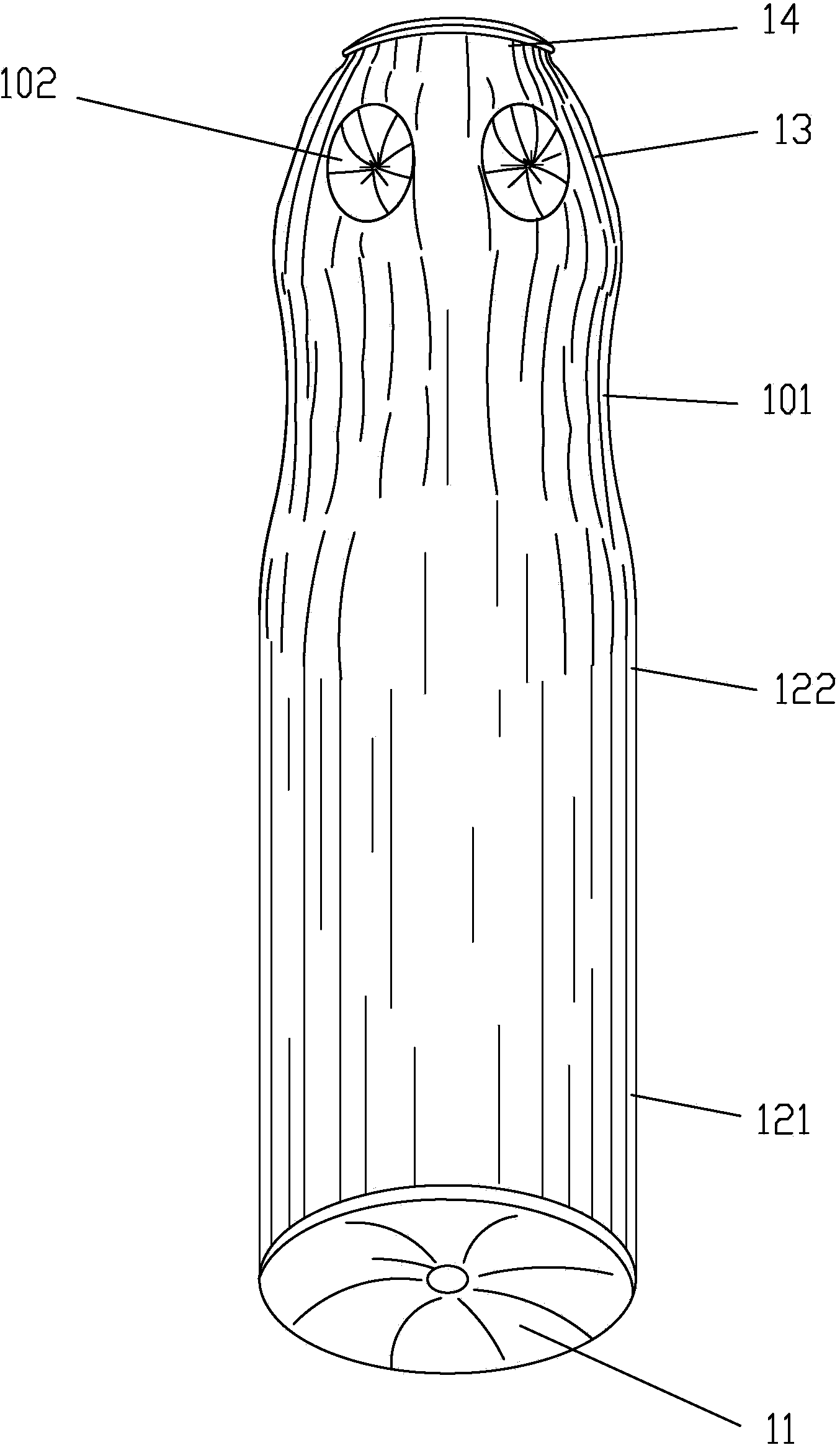

[0035] An aluminum variable-wall special-shaped packaging can, comprising a can bottom 11, a can barrel 12, a can shoulder 13, and a can mouth 14. The can barrel 12 is divided into a lower section 121 of the barrel body whose wall thickness increases sequentially along the direction from the can bottom 11 to the can shoulder 13. The middle section 122 of the barrel and the upper section 123 of the barrel, the lower section 121 of the barrel is a section of equal wall thickness, the middle section of the barrel 202 is a variable wall section whose wall thickness gradually becomes thicker, and the upper section 123 of the barrel is also a section of equal wall thickness. The lower section 121 of the cylinder body is a straight wall section.

[0036] In this aluminum variable-wall special-shaped packaging can, a certain amount of aluminum discs 4 and an appropriate amount of l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com