Aluminum packaging can and manufacturing method

A manufacturing method and technology of packaging cans, which are applied in the directions of packaging, transportation and packaging, cans, etc., can solve the problems of poor visual effects, inability to adapt to filling, high storage costs, etc., achieve enhanced visual three-dimensionality, increase production added value, Highlight the effect of corporate brand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A further detailed description will be made below in conjunction with the accompanying drawings and embodiments of the present invention:

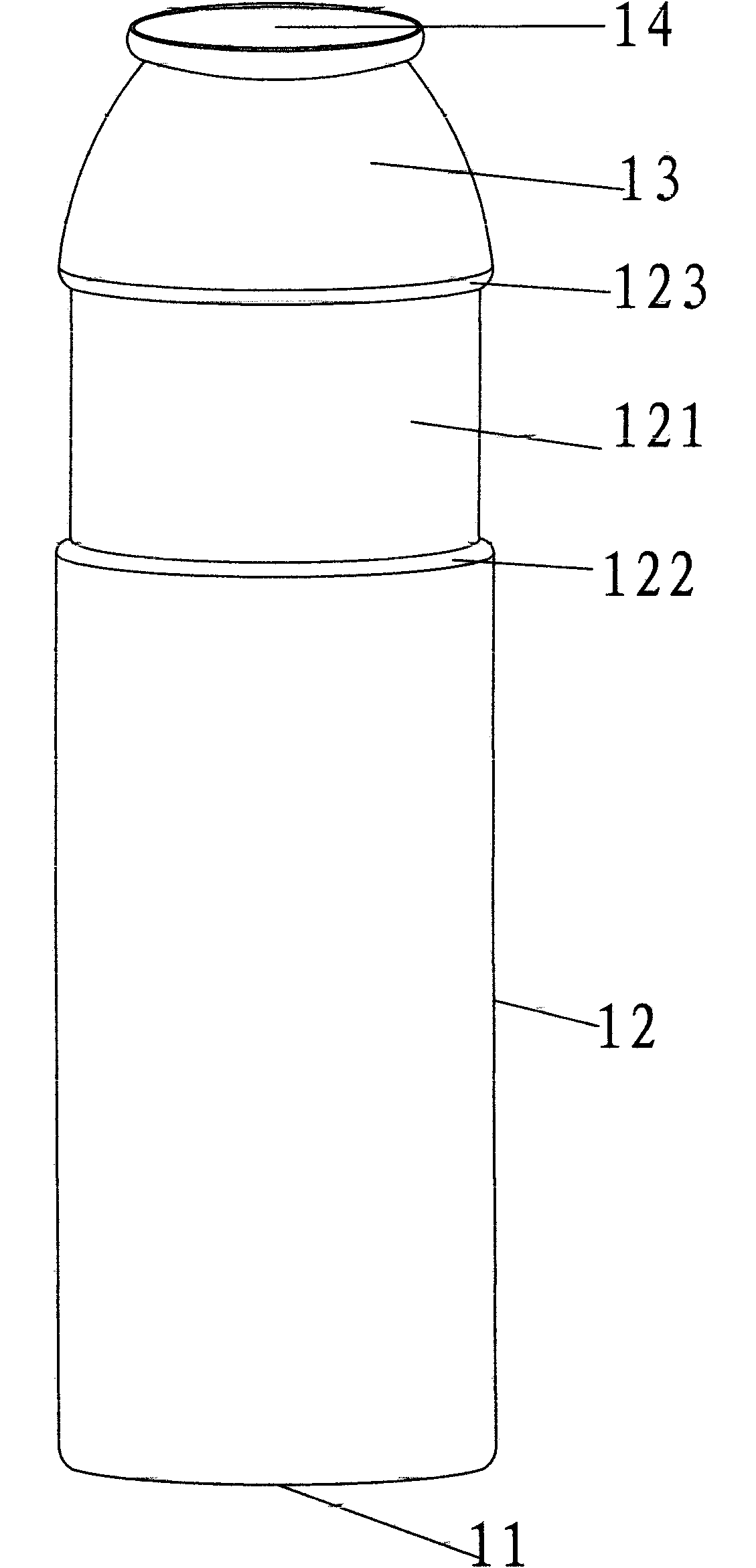

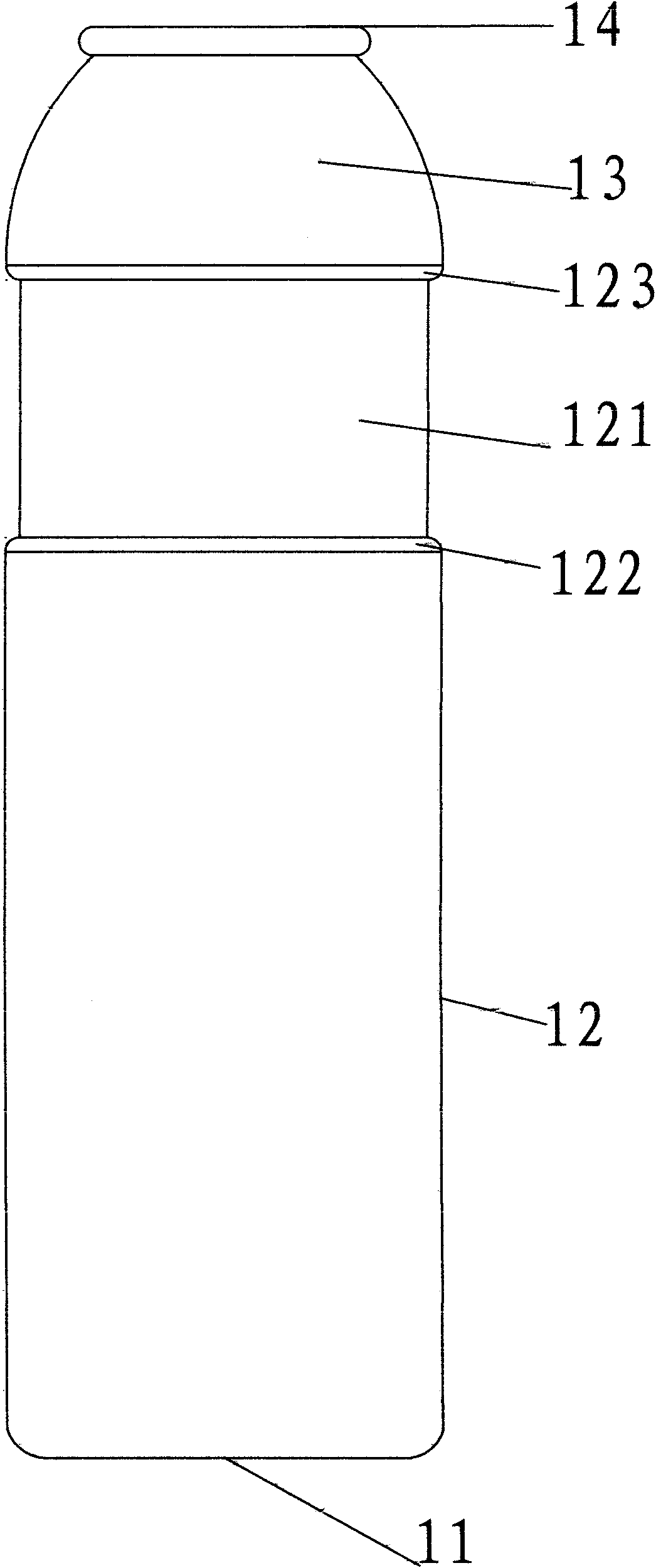

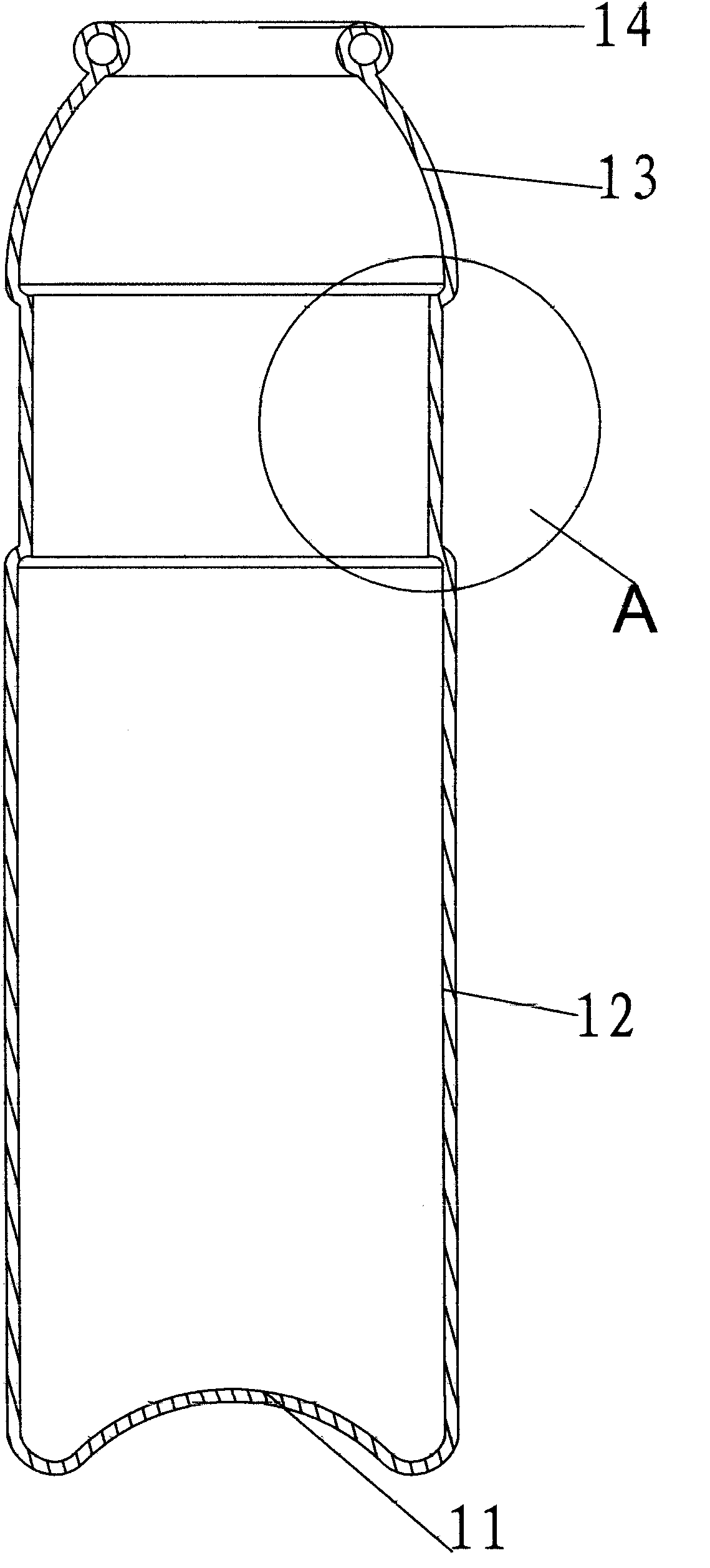

[0027] Such as Figure 1~4 As shown, the product of the present invention is an aluminum packaging can, which includes a can bottom 11, a can body 12, a can shoulder 13, and a can mouth 14. A The annular inner recess 121 is provided with an outwardly protruding lower annular step 122 between the annular inner recess 121 and the tank body 12 below, and an outwardly protruding upper annular step 123 is provided between the annular inner recess 121 and the tank shoulder 13 .

[0028] The edge of the tank bottom 11 extends upwards to form the tank body 12, the tank body 12 shrinks upwards to form an annular inner recess 121, the annular inner recess 121 extends upwards to form the tank shoulder 13, and the upper part of the tank shoulder 13 is flanged to form a lipped tank mouth 14, The tank bottom 11, the tank body 12, the annular inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com