Bio-enzyme modified roller compacted concrete road engineering construction technology

A technology for roller compacted concrete and road engineering, which is applied in the direction of roads, roads, and on-site coagulation pavement. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

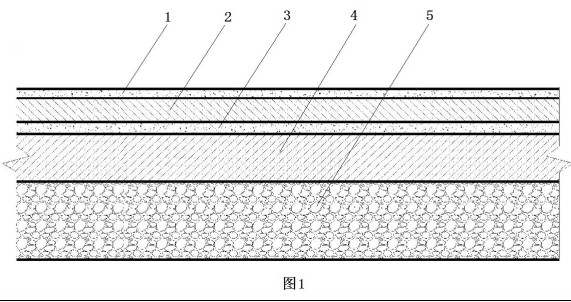

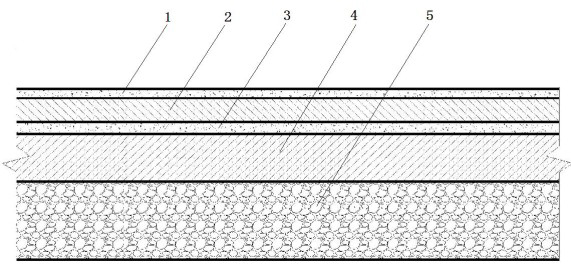

[0020] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0021] In July 2010, the inventor made a bio-enzyme-modified roller compacted concrete road test project construction on his own kiwi fruit park road in Lianghekou Village, Cenxi Township, Xiushan County, Chongqing City, and the construction road surface was 2100m long. The construction steps are as follows:

[0022] First prepare the materials, prepare biological modifiers, flexible fibers, coarse aggregates, sand, cement and biological enzymes, and the mixture ratio is: biological modifiers: flexible fibers: coarse aggregates: sand: cement = 2: 1:1650:495:250. Dry mixing is carried out first, that is, the above-mentioned proportioning materials are forced to mix, and then the biological enzyme is sprayed, that is, the biological enzyme solution is evenly sprayed on the dry-mixed material. The ratio of biological enzyme to the mixed mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com