Thermal conductive polyurethane synthetic leather production method

A production method and technology of synthetic leather, applied in the direction of textiles and papermaking, can solve the problems affecting the range of use of polyurethane synthetic leather, poor thermal conductivity, etc., and achieve good heat transfer and thermal conductivity, good wear resistance, and good drape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (a) Select viscose-cotton blended plain weave as the base fabric;

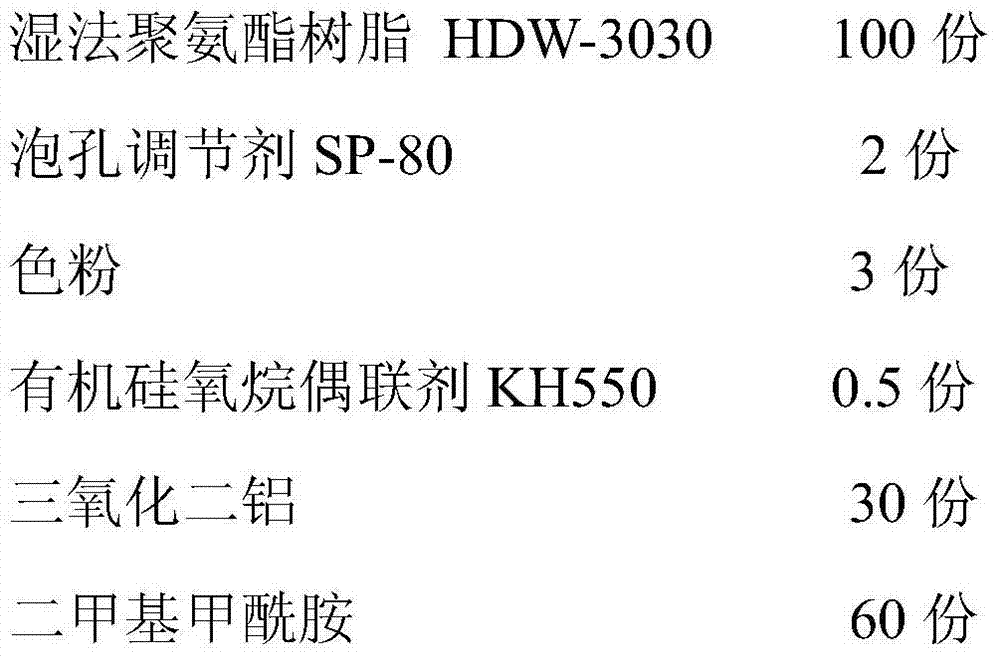

[0043] (b) coating wet-process polyurethane slurry on the base cloth, the coating slurry is prepared according to the following mass ratio:

[0044]

[0045] Put the material into the stirring tank, stir with a high-speed disperser for 30 minutes, centrifuge and defoam for 3 minutes, and then scrape 0.8mm;

[0046] (c) Solidification: DMF concentration 20%, temperature 25°C, time 3min;

[0047] (d) Water washing: temperature 60°C, pressure 2kg, time 10min;

[0048](e) Expansion drying: the width is 138cm~145cm, the temperature is 80~130℃, and the time is 3min;

[0049] (f) Dry veneer: The polyurethane surface layer is prepared according to the following mass ratio:

[0050]

[0051] Put the material into the stirring tank, stir with a high-speed disperser for 30 minutes, centrifuge and defoam for 3 minutes, and then scrape 0.2mm;

[0052] (g) Surface finishing: roller coating of water-based po...

Embodiment 2

[0054] (a) Choose nylon plain weave as the base fabric;

[0055] (b) coating wet-process polyurethane slurry on the base cloth, the coating slurry is prepared according to the following mass ratio:

[0056]

[0057] Put the material into the stirring tank, stir with a high-speed disperser for 30 minutes, centrifuge and defoam for 3 minutes, and then scrape 0.8mm;

[0058] (c) Solidification: DMF concentration 20%, temperature 25°C, time 3min;

[0059] (d) Water washing: temperature 60°C, pressure 2kg, time 10min;

[0060] (e) Expansion drying: the width is 138cm~145cm, the temperature is 80~130℃, and the time is 3min;

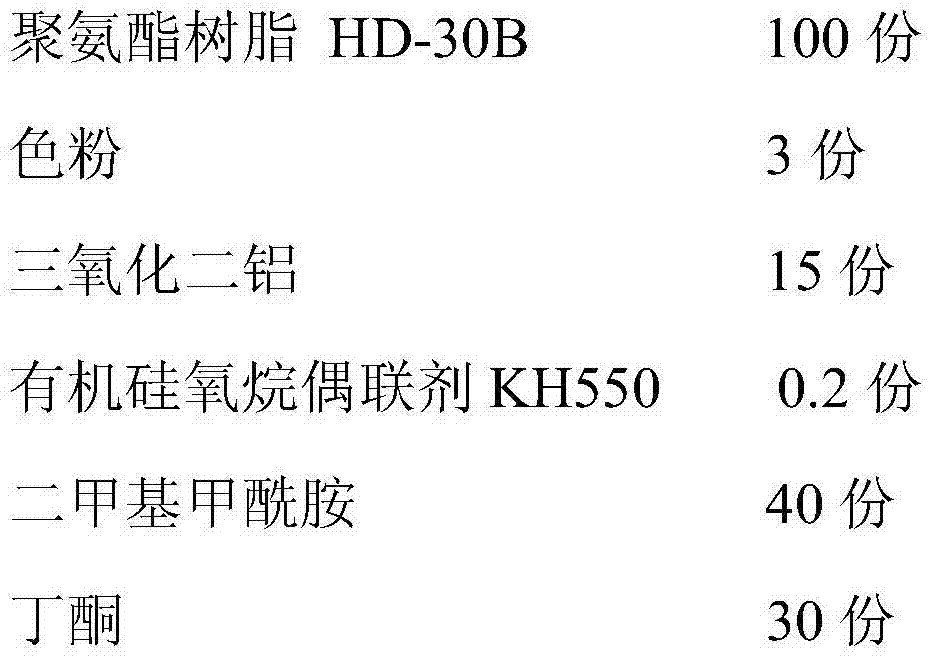

[0061] (f) Dry veneer: The polyurethane surface layer is prepared according to the following mass ratio:

[0062]

[0063] Put the material into the stirring tank, stir with a high-speed disperser for 30 minutes, centrifuge and defoam for 3 minutes, and then scrape 0.2mm;

[0064] (g) Surface finishing: roller coating of water-based polyurethane surfa...

Embodiment 3

[0066] (a) Choose nylon plain weave as the base fabric;

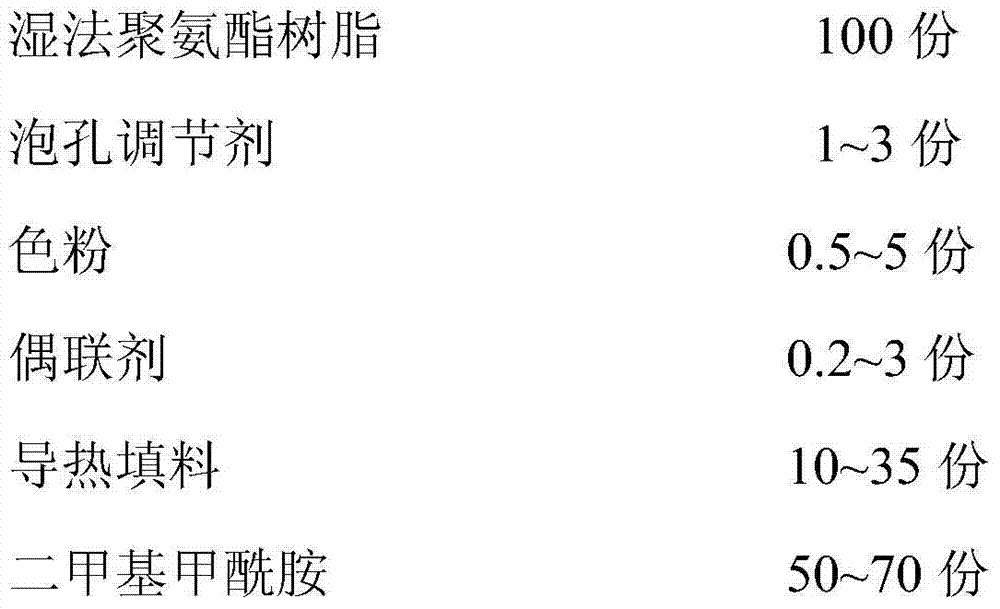

[0067] (b) coating wet-process polyurethane slurry on the base cloth, the coating slurry is prepared according to the following mass ratio:

[0068]

[0069] Put the material into the stirring tank, stir with a high-speed disperser for 30 minutes, centrifuge and defoam for 3 minutes, and then scrape 0.8mm;

[0070] (c) Solidification: DMF concentration 22%, temperature 25°C, time 3min;

[0071] (d) Water washing: temperature 60°C, pressure 2kg, time 10min;

[0072] (e) Expansion drying: the width is 138cm~145cm, the temperature is 80~130℃, and the time is 3min;

[0073] (f) Dry veneer: The polyurethane surface layer is prepared according to the following mass ratio:

[0074]

[0075] Put the material into the stirring tank, stir with a high-speed disperser for 30 minutes, centrifuge and defoam for 3 minutes, and then scrape 0.2mm;

[0076] (g) Surface finishing: roller coating of water-based polyurethane surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com