Method and device for recovering hydrogen on purge gas in synthetic ammonia and gas stored in tank

A technology for storing tank gas and releasing gas, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of increasing equipment investment, low total recovery rate of recovered hydrogen, and reducing utilization value, etc., to ensure normal operation. running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

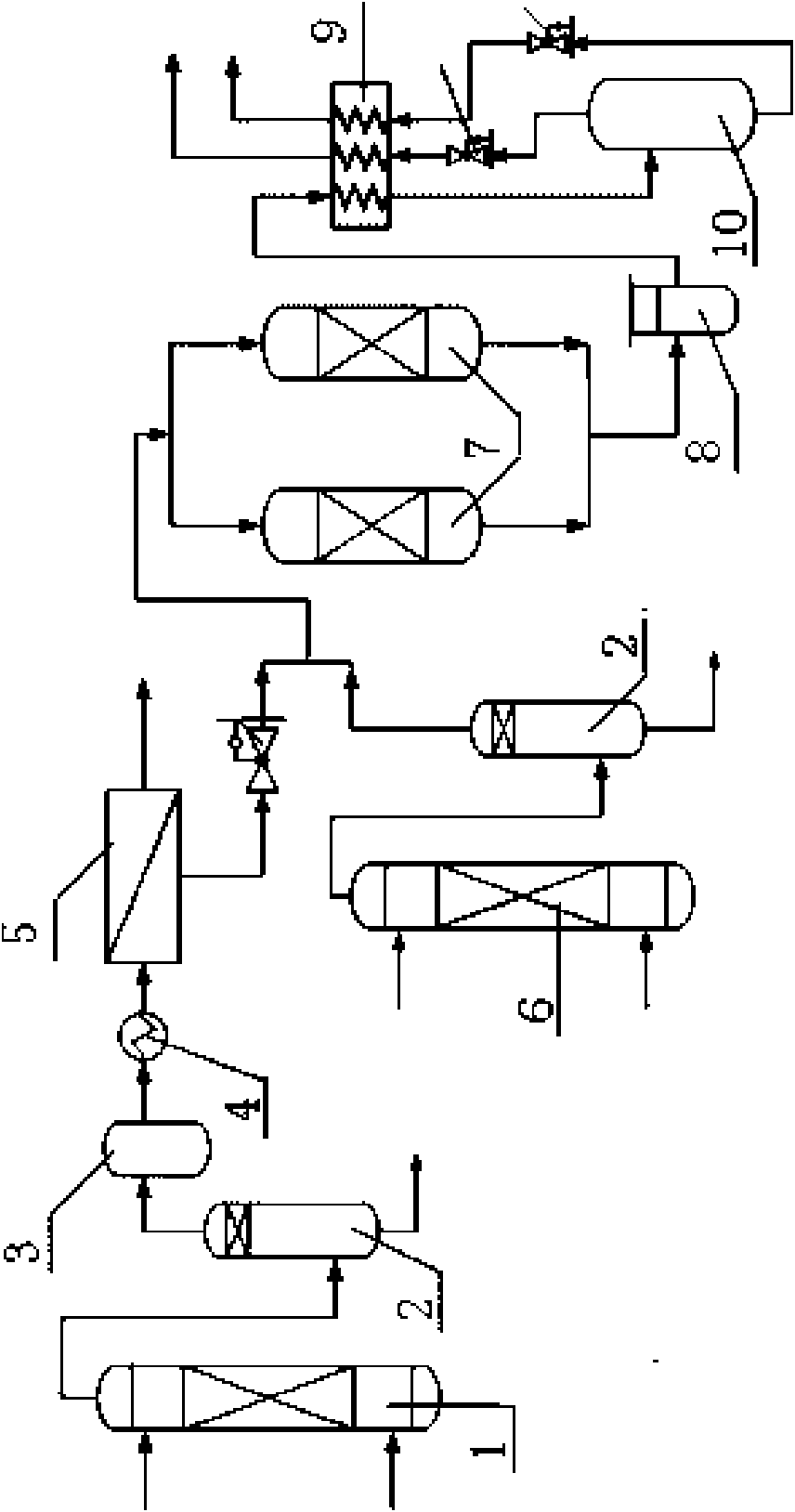

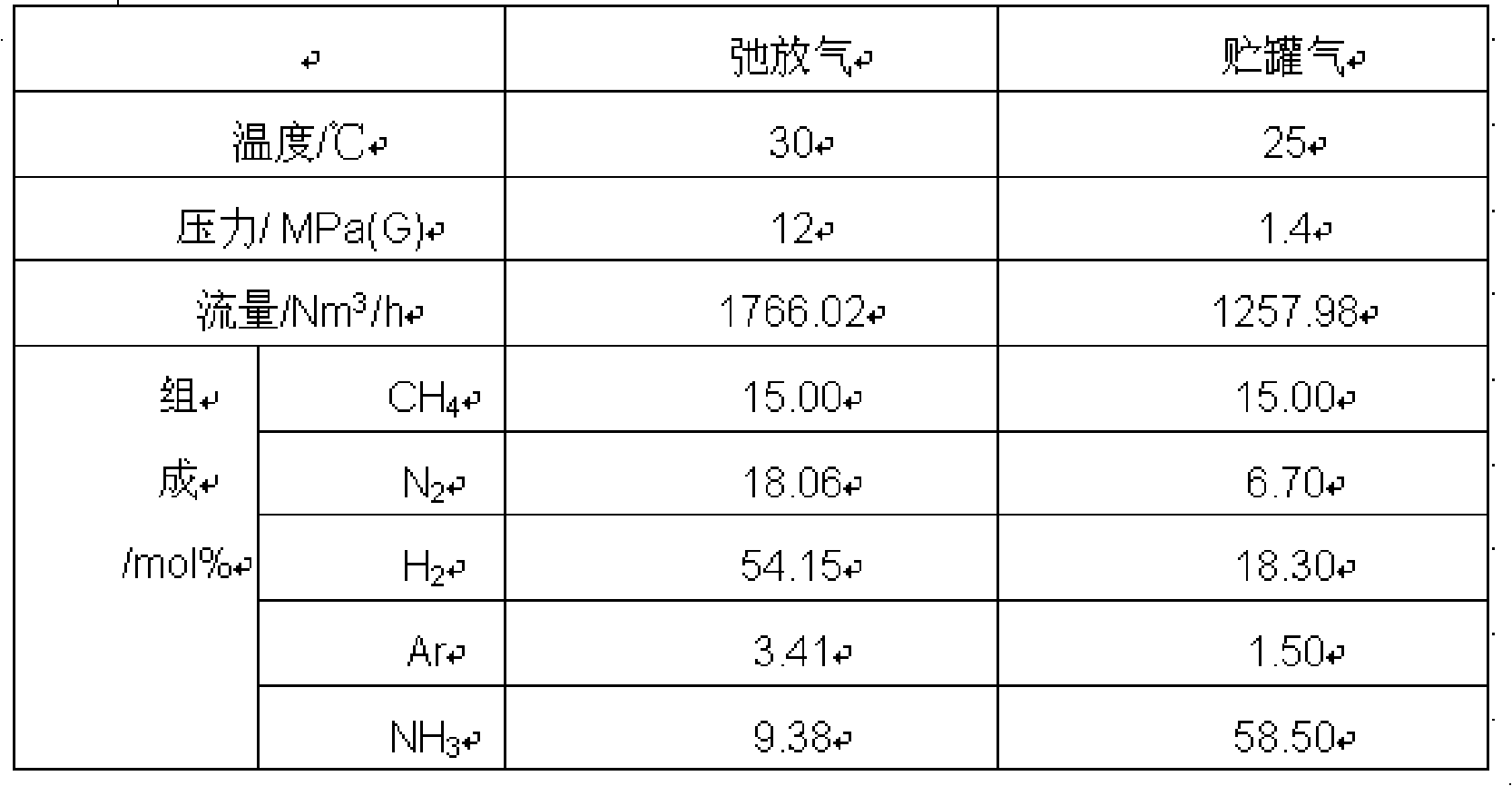

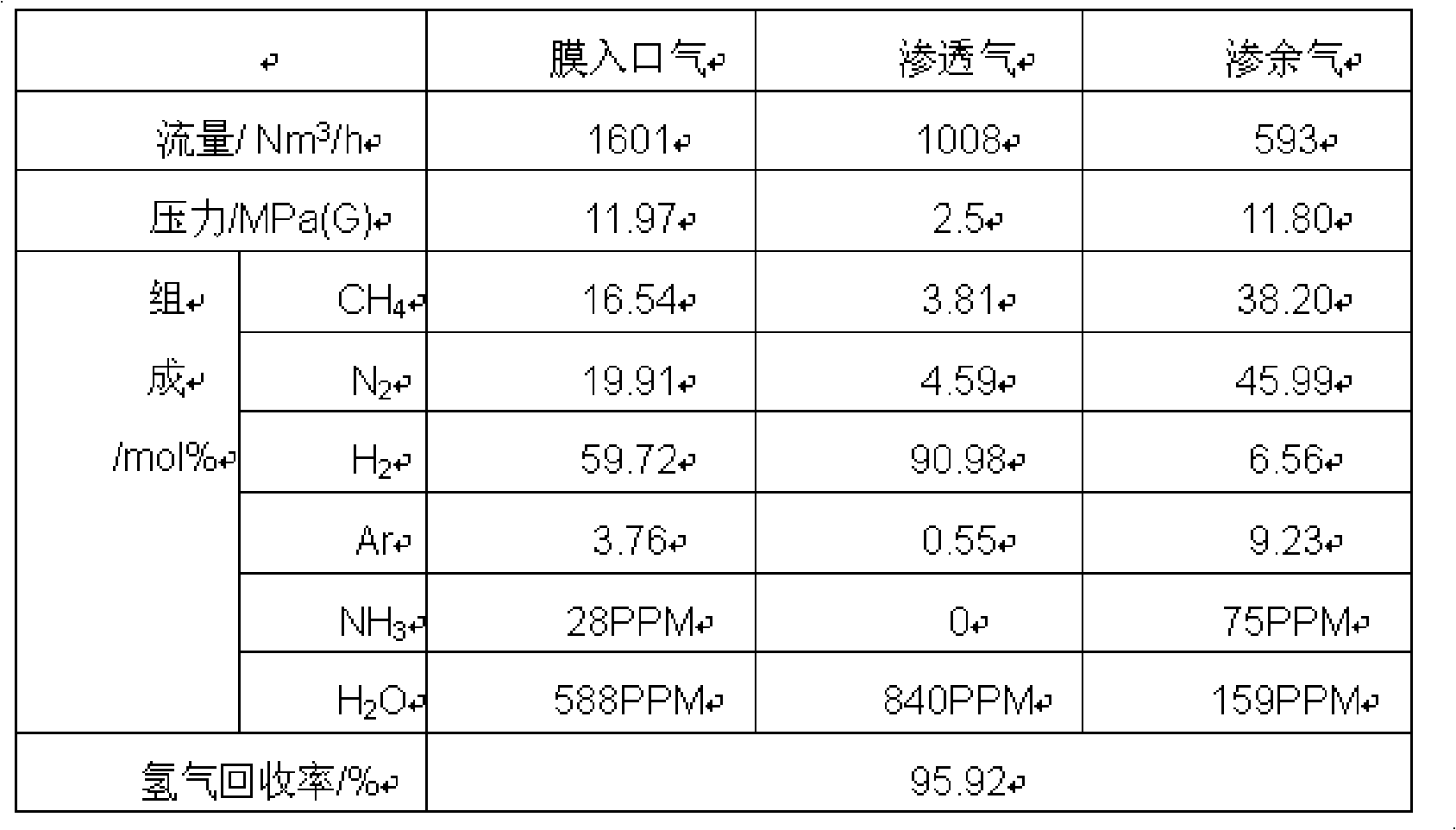

[0036] Embodiment 1: as figure 1 As shown, the relaxation gas washing tower 1 and the storage tank gas washing tower 6 are used to wash the relaxation gas and the storage tank gas respectively to remove ammonia, and the relaxation gas and the storage tank gas are separated from the top of the tower. The sprayed soft water is reversely contacted, and most of the ammonia is washed away by water, and the product at the bottom of the ammonia washing tower is an ammonia solution with a concentration of about 20-30%; Liquid water, ammonia content in the resulting gas <200PPM. The hydrogen content in the release gas after ammonia washing is about 60%; the release gas after ammonia washing passes through the precision filter 3 to remove water mist, and the preheater 4 adjusts the temperature to 40-60°C before entering the hydrogen membrane separator 5. The synthesis pressure of synthetic ammonia is generally about 13-30MPa. If it enters the hydrogen membrane separator 5 to recover hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com