Preparation method of high-stability carboxymethyl hydroxyethyl cellulose

A carboxymethyl hydroxyethyl, high-stability technology, applied in the field of cellulose production, can solve problems such as poor high-temperature stability, and achieve the effect of improving stability and storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] Concrete, the preparation method of high stability carboxymethyl hydroxyethyl cellulose comprises the following steps:

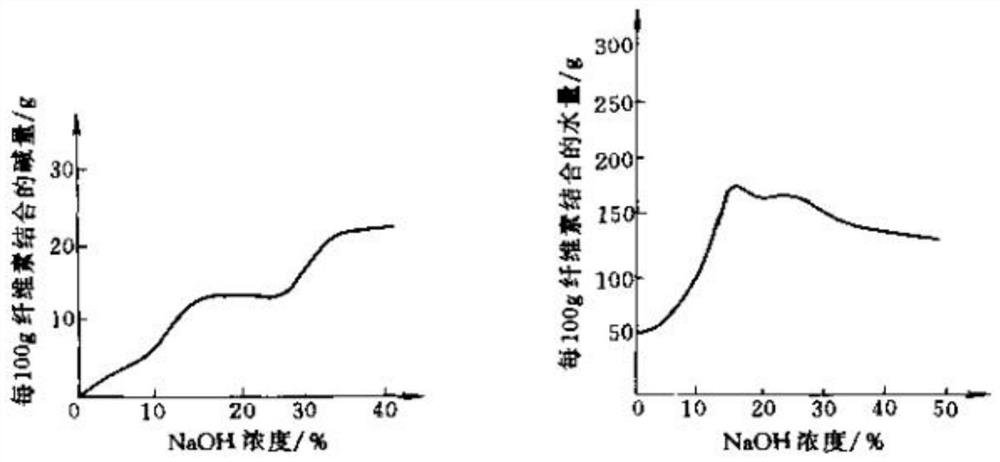

[0042] A, sodium hydroxide and the mixed solvent of organic solvent-water are mixed, carry out alkali;

[0043]B. After alkalization, cool down, add refined cotton, and alkalization;

[0044] C, after alkalization finishes, add etherifying agent chloroacetic acid, heat up and carry out the etherification reaction of the first stage;

[0045] D, after the first stage etherification reaction finishes, cool, add acid to adjust the alkali concentration of the system to 10~20wt%;

[0046] E, then add etherification agent oxirane, heat up and carry out the second stage etherification reaction;

[0047] F. After the second-stage etherification reaction, cool down, add acid to neutralize the system until the pH of the system is 6.0-7.0, and then separate, wash, cross-link and dry to obtain high-stability carboxymethyl hydroxyethyl cellulose.

[0048] In st...

Embodiment 1

[0059] A. Add 3.0kg of caustic soda and 20kg of mixed solvent (3.0kg of water and 17.0kg of pure isopropanol) to a 50L reactor, stir and heat up to 55°C, and keep warm for 1.5h;

[0060] B. Cool down to 10-25°C, add 2.0kg of cotton powder, evacuate and replace 5 times, fill with nitrogen 0.15MPa, and alkalize at 20°C for 1.5h;

[0061] C. Add 2.0kg of chloroacetic acid solution (dissolve 1.2kg of chloroacetic acid in 0.8kg of isopropanol), raise the temperature for 30min to 65°C, keep the temperature for 1h, and carry out the first stage etherification reaction;

[0062] D. After the first stage etherification reaction is finished, cool down to 35° C., add 2.18 kg of glacial acetic acid for neutralization, and adjust the alkali concentration of the system to 12.03 wt %;

[0063] E. Then add 2.1kg etherification agent ethylene oxide, fill with nitrogen gas 0.20MPa, heat up for 35min to 80°C, keep warm for 3.0h, and carry out the second stage etherification reaction;

[0064] F...

Embodiment 2

[0066] A, add caustic soda 2.85kg, 18kg mixed solvent (3.6kg water and 14.4kg pure isopropanol) in the 50L reactor, stir and heat up to 70 ℃, heat preservation alkali 1h;

[0067] B. Cool down to 10-25°C, add 2.0kg of cotton powder, vacuumize and replace 4 times, fill with nitrogen gas 0.20MPa, and alkalize at 25°C for 2.5h;

[0068] C. Add 2.9kg of chloroacetic acid solution (dissolve 1.6kg of chloroacetic acid in 1.3kg of isopropanol), heat up for 35min to 60°C, keep warm for 2h, and carry out the first stage etherification reaction;

[0069] D. After the etherification reaction in the first stage is finished, cool down to 35° C., add 0.9 kg of glacial acetic acid for neutralization, and adjust the alkali concentration of the system to 17.67 wt %;

[0070] E. Then add 1.8kg etherification agent ethylene oxide, fill with nitrogen gas 0.30MPa, raise the temperature for 40min to 92°C, keep the temperature for 1.5h, and carry out the second stage etherification reaction;

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com