A kind of electrochemical treatment method of arsenic-containing anode slime

A treatment method and anode slime technology, applied in the field of pollutant treatment, can solve the problems of undisclosed treatment of arsenic-containing anode slime, narrow scope of application, inapplicability of toxic solid waste, etc., so as to promote oxidation efficiency, improve recovery rate, facilitate The effect of subsequent separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

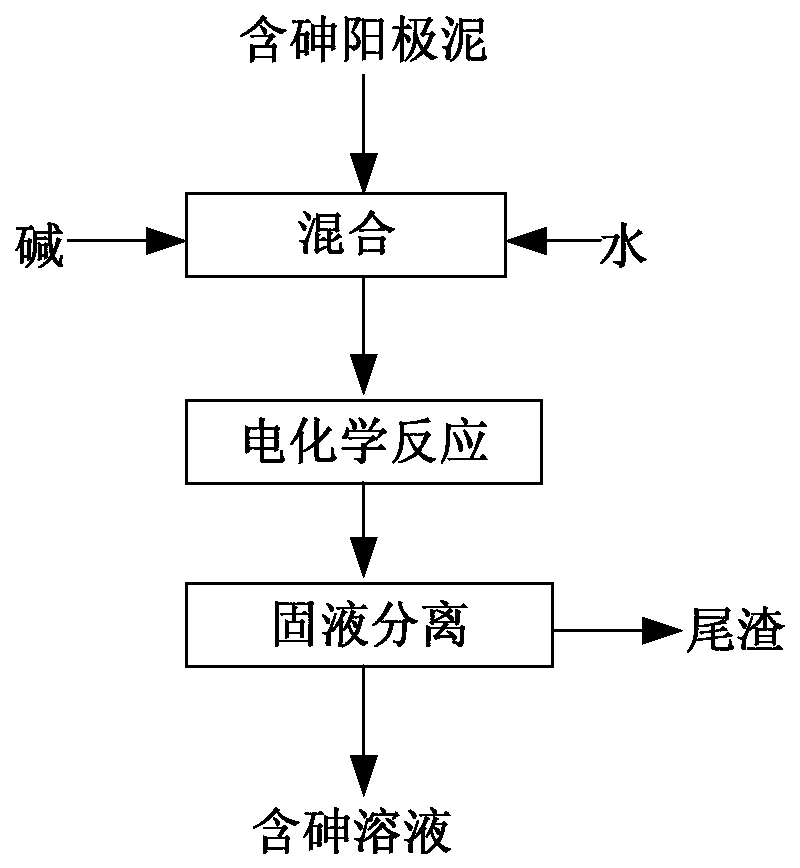

Method used

Image

Examples

Embodiment 1

[0062] An electrochemical treatment method for arsenic-containing anode slime, wherein the arsenic-containing anode slime is arsenic-containing anode slime produced in an electrolysis section of a copper smelting process, comprising the following steps:

[0063] (1) Ingredients: Mix arsenic-containing anode slime sieved into 80 meshes with potassium hydroxide aqueous solution to prepare an electrolyte and preheat to 60°C. The potassium hydroxide content in the potassium hydroxide solution is 1M, and the arsenic-containing anode The liquid-solid ratio of mud and potassium hydroxide solution is 1g / L;

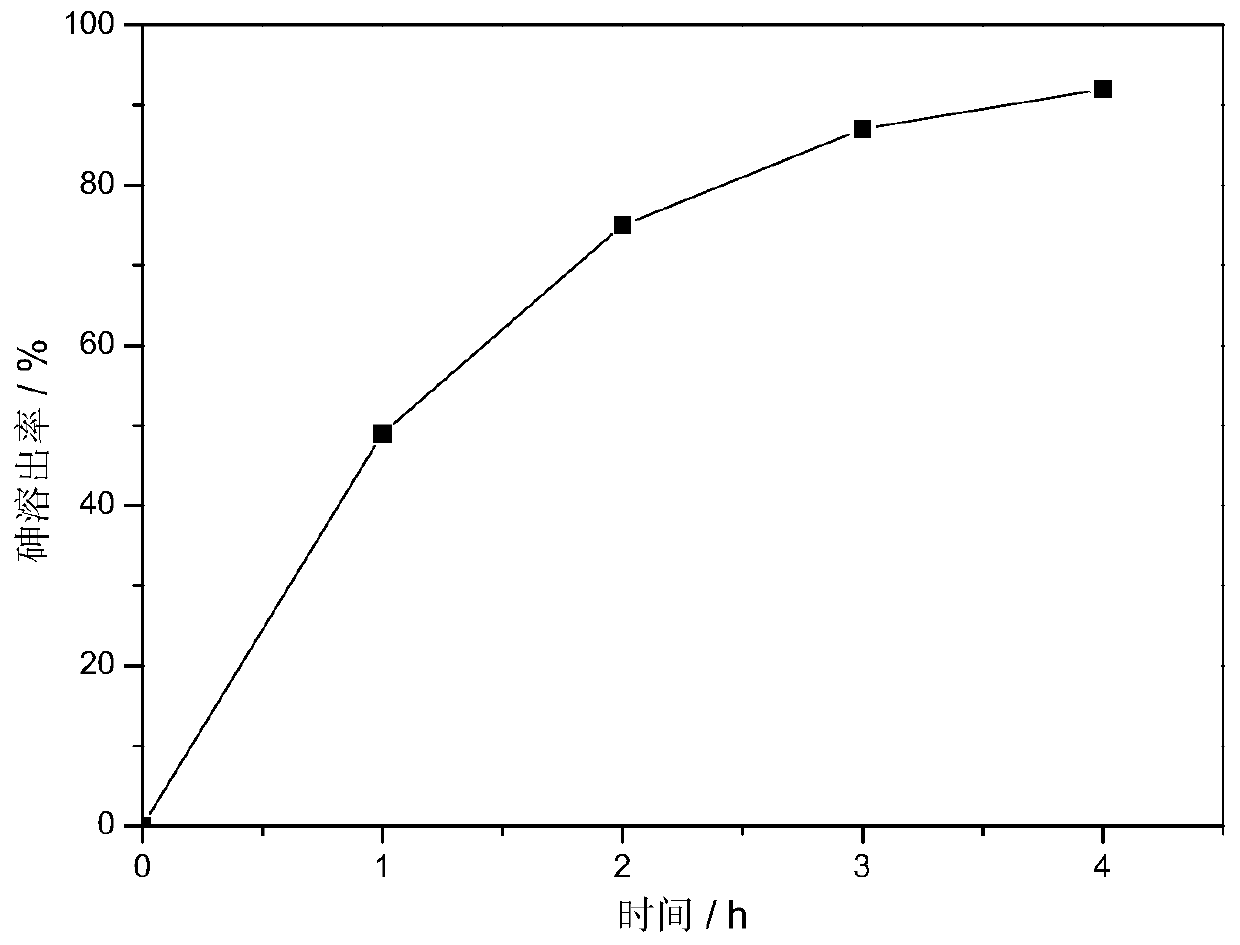

[0064] (2) Electrochemical reaction: Add the raw material electrolyte obtained in step (1) into the atmospheric pressure electrolyzer, pass oxygen into the electrolyte, the oxygen flow rate is 400mL / min, the mechanical stirring rate is 800rpm, and the carbon felt electrode is used as the working electrode , with a carbon rod as the counter electrode, a mercury / mercury oxide electr...

Embodiment 2

[0067] An electrochemical treatment method for arsenic-containing anode slime, wherein the arsenic-containing anode slime is arsenic-containing anode slime produced in an electrolysis section of a copper smelting process, comprising the following steps:

[0068] (1) Mix arsenic-containing anode slime with a sodium hydroxide solution having a concentration of 0.01M, and the solid-to-liquid ratio of the arsenic-containing anode slime to the sodium hydroxide solution is 0.1g / L to obtain a mixture;

[0069] (2) The mixture is placed in an electrolytic cell as an electrolyte, and an electrochemical catalytic oxidation reaction is carried out at 20° C. and a stirring speed of 2100 rpm. During the electrochemical catalytic oxidation process, oxygen-enriched air is introduced into the mixture; Wherein, the time of the electrochemical catalytic oxidation reaction is 2h, the voltage of the electrolytic cell is -0.4V, and the flow rate of the oxygen-enriched air is 100mL / min; the electrol...

Embodiment 3

[0072] An electrochemical treatment method for arsenic-containing anode slime, wherein the arsenic-containing anode slime is arsenic-containing anode slime produced in an electrolysis section of a copper smelting process, comprising the following steps:

[0073] (1) mixing the arsenic-containing anode slime with an alkali solution having a concentration of 10M, the solid-to-liquid ratio of the arsenic-containing anode slime and the alkali solution being 100g / L, to obtain a mixture;

[0074] (2) The mixture is placed in an electrolytic cell as an electrolyte, and an electrochemical catalytic oxidation reaction is performed at 140° C. and a stirring speed of 800 rpm, and air is introduced into the mixture during the electrochemical catalytic oxidation process; wherein, The time of the electrochemical catalytic oxidation reaction is 1h, the voltage of the electrolytic cell is-5.0V, and the flow rate of feeding air is 500mL / min; the graphite plate is used as the working electrode i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com