Electrochemical treatment method for arsenic-containing anode mud

A treatment method and anode slime technology, which are applied in the field of pollutant treatment, can solve the problems of unsuitable treatment of toxic solid waste, narrow scope of application, and no public treatment of arsenic-containing anode slime, etc., so as to promote oxidation efficiency, improve recovery rate, and facilitate the The effect of subsequent separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

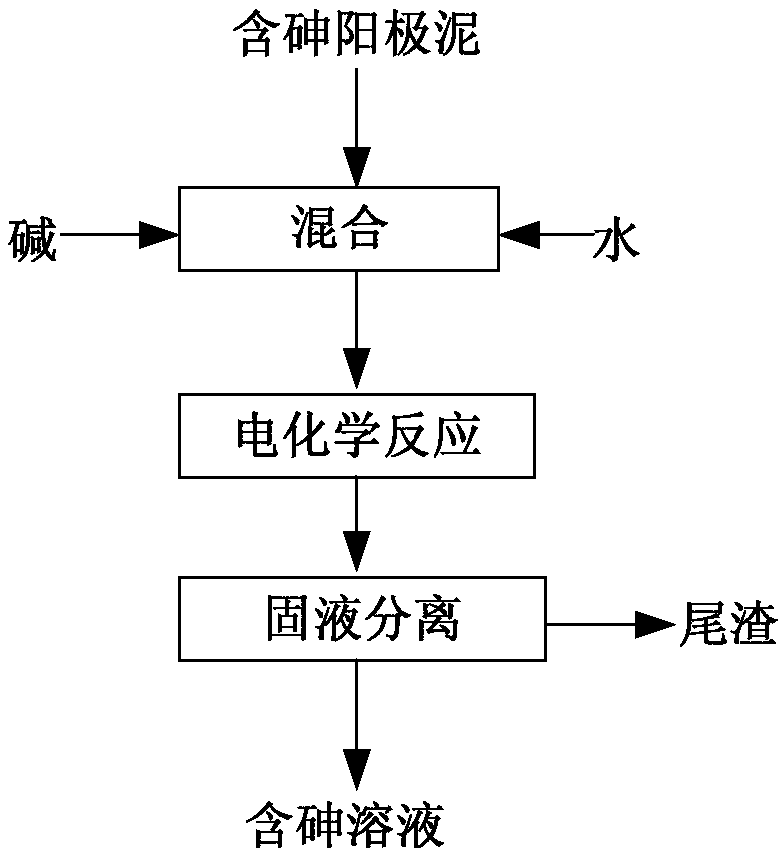

[0062] An electrochemical treatment method for arsenic-containing anode slime, wherein the arsenic-containing anode slime is arsenic-containing anode slime produced in an electrolysis section of a copper smelting process, comprising the following steps:

[0063] (1) Ingredients: Mix arsenic-containing anode slime sieved into 80 meshes with potassium hydroxide aqueous solution to prepare an electrolyte and preheat to 60°C. The potassium hydroxide content in the potassium hydroxide solution is 1M, and the arsenic-containing anode The liquid-solid ratio of mud and potassium hydroxide solution is 1g / L;

[0064] (2) Electrochemical reaction: Add the raw material electrolyte obtained in step (1) into the atmospheric pressure electrolyzer, pass oxygen into the electrolyte, the oxygen flow rate is 400mL / min, the mechanical stirring rate is 800rpm, and the carbon felt electrode is used as the working electrode , with a carbon rod as the counter electrode, a mercury / mercury oxide electr...

Embodiment 2

[0067] An electrochemical treatment method for arsenic-containing anode slime, wherein the arsenic-containing anode slime is arsenic-containing anode slime produced in an electrolysis section of a copper smelting process, comprising the following steps:

[0068] (1) Mix arsenic-containing anode slime with a sodium hydroxide solution having a concentration of 0.01M, and the solid-to-liquid ratio of the arsenic-containing anode slime to the sodium hydroxide solution is 0.1g / L to obtain a mixture;

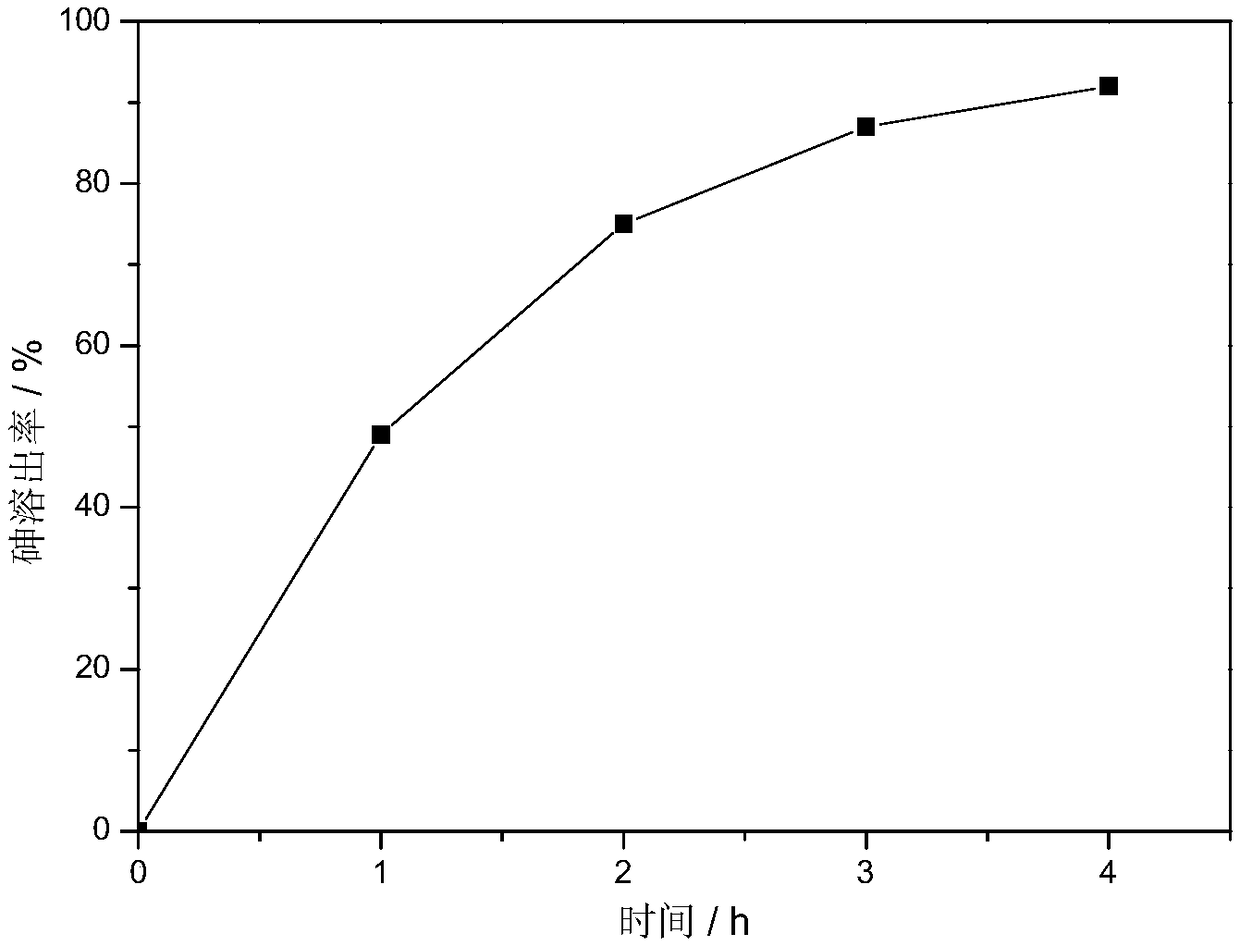

[0069] (2) The mixture is placed in an electrolytic cell as an electrolyte, and an electrochemical catalytic oxidation reaction is carried out at 20° C. and a stirring speed of 2100 rpm. During the electrochemical catalytic oxidation process, oxygen-enriched air is introduced into the mixture; Wherein, the time of the electrochemical catalytic oxidation reaction is 2h, the voltage of the electrolytic cell is -0.4V, and the flow rate of the oxygen-enriched air is 100mL / min; the electrol...

Embodiment 3

[0072] An electrochemical treatment method for arsenic-containing anode slime, wherein the arsenic-containing anode slime is arsenic-containing anode slime produced in an electrolysis section of a copper smelting process, comprising the following steps:

[0073] (1) mixing the arsenic-containing anode slime with an alkali solution having a concentration of 10M, the solid-to-liquid ratio of the arsenic-containing anode slime and the alkali solution being 100g / L to obtain a mixture;

[0074] (2) The mixture is placed in an electrolytic cell as an electrolyte, and an electrochemical catalytic oxidation reaction is performed at 140° C. and a stirring speed of 800 rpm, and air is introduced into the mixture during the electrochemical catalytic oxidation process; wherein, The time of the electrochemical catalytic oxidation reaction is 1h, the voltage of the electrolytic cell is-5.0V, and the flow rate of feeding air is 500mL / min; the graphite plate is used as the working electrode in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com