Electrochemical treatment method for arsenic-containing soot

A treatment method and electrochemical technology, applied in the field of pollutant treatment, can solve the problems of undisclosed treatment of arsenic-containing soot, the increase of harmful components of As in the charge, and the reduction of the processing capacity of the flash furnace, so as to achieve the promotion of oxidation efficiency, reduction of alkali concentration, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

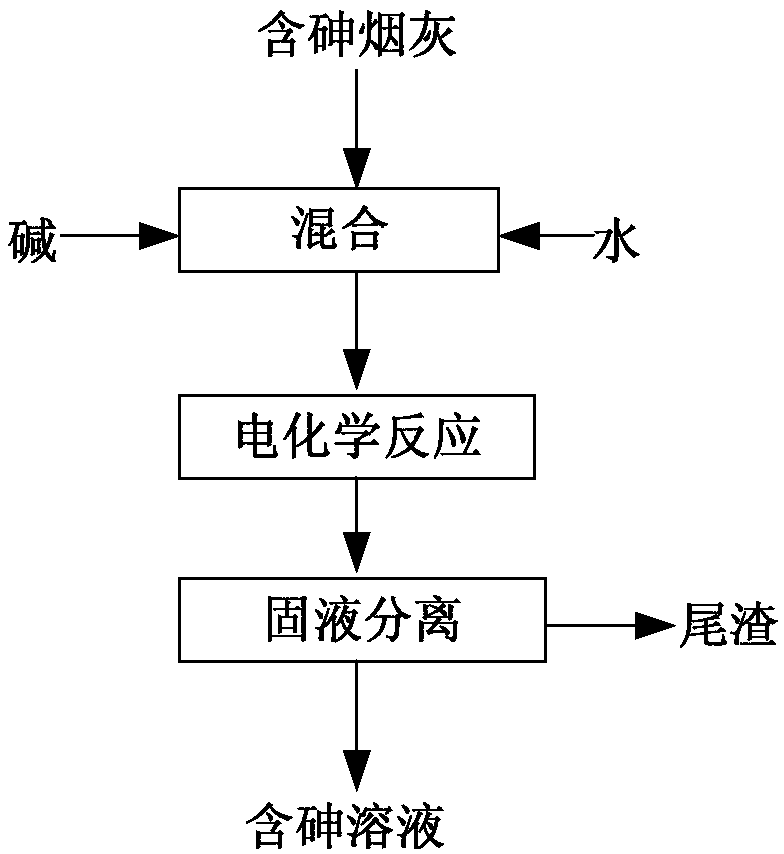

Method used

Image

Examples

Embodiment 1

[0063] An electrochemical treatment method for arsenic-containing soot, wherein the arsenic-containing soot is copper converter white soot, comprising the steps of:

[0064] (1) Ingredients: Mix arsenic-containing soot sieved to 80 mesh with potassium hydroxide aqueous solution to prepare an electrolyte, and preheat to 60°C, wherein the content of potassium hydroxide in the potassium hydroxide solution is 1M, arsenic-containing soot and The liquid-solid ratio of potassium hydroxide solution is 1g / L;

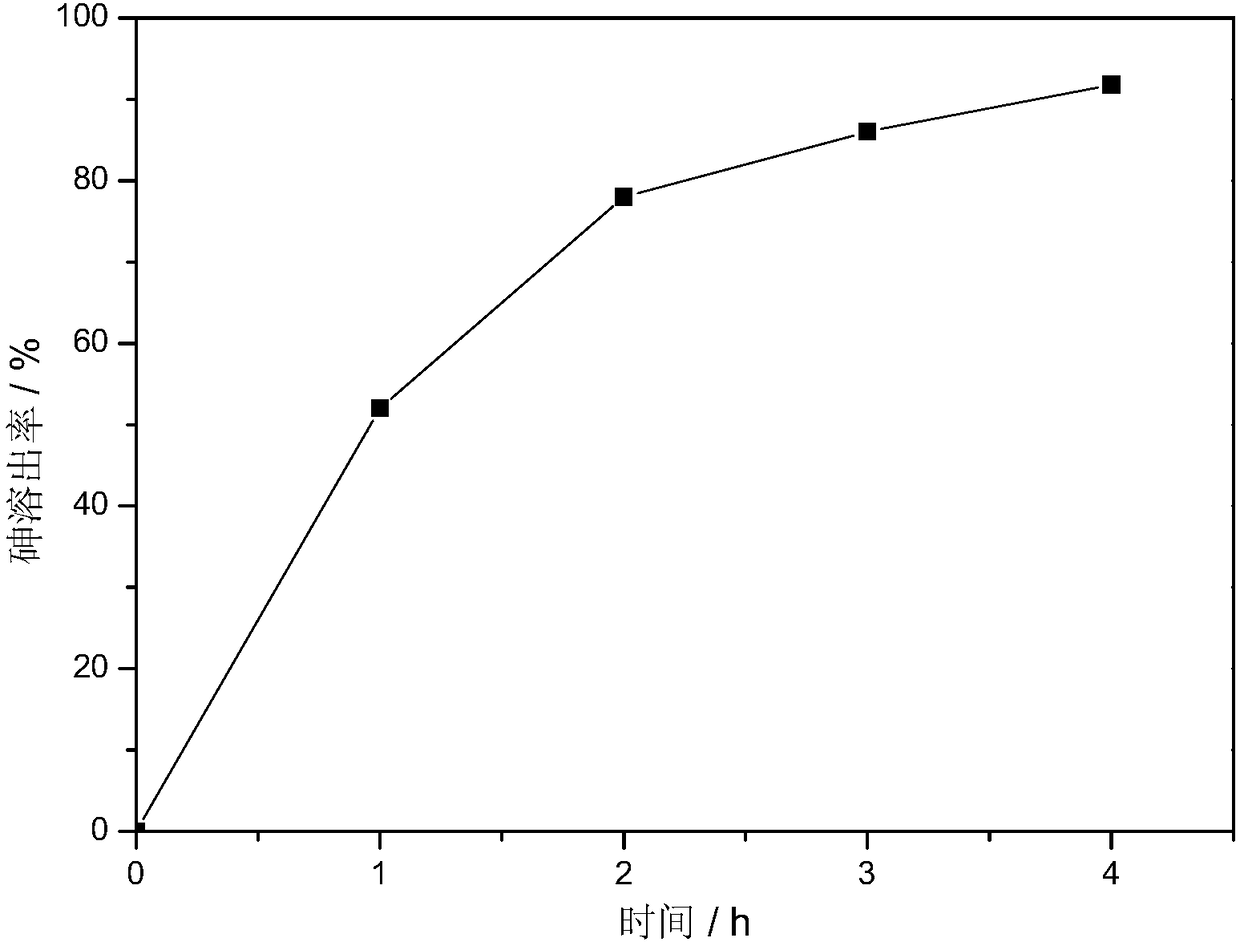

[0065] (2) Electrochemical reaction: Add the raw material electrolyte obtained in step (1) into the atmospheric pressure electrolyzer, pass oxygen into the electrolyte, the oxygen flow rate is 400mL / min, the mechanical stirring rate is 800rpm, and the carbon felt electrode is used as the working electrode , with a carbon rod as the counter electrode, a mercury / mercury oxide electrode as the reference electrode, the control potential is -1V, the electrochemical reaction time is 4h...

Embodiment 2

[0068] An electrochemical treatment method for arsenic-containing soot, wherein the arsenic-containing soot is copper converter white soot, comprising the steps of:

[0069] (1) Mixing the arsenic-containing soot with a sodium hydroxide solution whose concentration is 0.01M, the solid-to-liquid ratio of the arsenic-containing soot and the sodium hydroxide solution is 0.1g / L to obtain a mixture;

[0070] (2) The mixture is placed in an electrolytic cell as an electrolyte, and an electrochemical catalytic oxidation reaction is carried out at 20° C. and a stirring speed of 2100 rpm. During the electrochemical catalytic oxidation process, oxygen-enriched air is introduced into the mixture; Wherein, the time of the electrochemical catalytic oxidation reaction is 2h, the voltage of the electrolytic cell is -0.4V, and the flow rate of the oxygen-enriched air is 100mL / min; the electrolytic cell uses a graphite rod as a working electrode and a platinum electrode as a As the counter ele...

Embodiment 3

[0073] An electrochemical treatment method for arsenic-containing soot, wherein the arsenic-containing soot is copper converter white soot, comprising the steps of:

[0074] (1) mixing the arsenic-containing soot with an alkali solution having a concentration of 10M, the solid-to-liquid ratio of the arsenic-containing soot and the alkali solution being 100g / L to obtain a mixture;

[0075] (2) The mixture is placed in an electrolytic cell as an electrolyte, and an electrochemical catalytic oxidation reaction is performed at 140° C. and a stirring speed of 800 rpm, and air is introduced into the mixture during the electrochemical catalytic oxidation process; wherein, The time of the electrochemical catalytic oxidation reaction is 1h, the voltage of the electrolytic cell is-5.0V, and the flow rate of feeding air is 500mL / min; the graphite plate is used as the working electrode in the electrolytic cell, and the graphite plate is the counter electrode. The mercury / mercury oxide ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com