A kind of preparation method of electrolyte and the zinc-nickel battery of its application

An electrolyte and conductive solution technology, which is applied in the direction of nickel storage battery, composite electrolyte, alkaline storage battery, etc., can solve the problems of electrolyte performance degradation, incomplete dissolution, and increased difficulty in the dissolution process, so as to suppress negative electrode dendrites and save energy. The effect of stabilizing dissolution time and dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

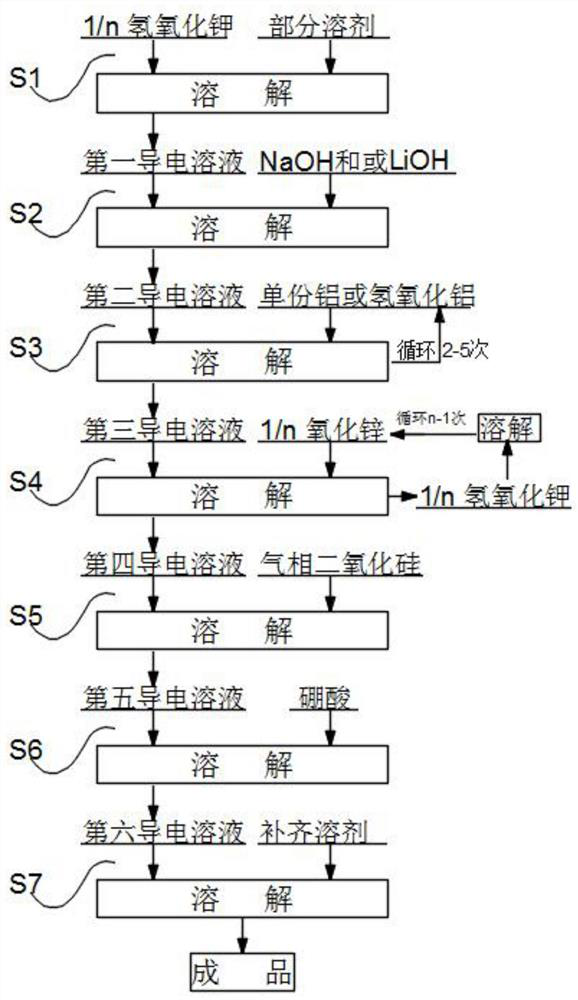

Image

Examples

Embodiment 1

[0048] The composition of electrolytic solution in the present embodiment is as follows: choosing potassium hydroxide is the potassium hydroxide of 400g, the lithium hydroxide of 25g, the aluminum hydroxide of 2g, the zinc oxide of 82g, the fumed silica of 0.17g, the boric acid of 13.6, 866g of pure water.

[0049] S1, take by weighing the pure water that consumption is 600g in reaction container, add the potassium hydroxide of 50g to pure water, stir and heat, after potassium hydroxide dissolves completely, obtain the first conductive solution;

[0050] S2, add 25g of lithium hydroxide to the first conductive solution, keep stirring and heating, until the lithium hydroxide is completely dissolved to obtain the second conductive solution;

[0051] S3. Add aluminum hydroxide to the second conductive solution twice, add 1g of aluminum hydroxide each time, after the aluminum hydroxide added last time is completely dissolved, then proceed to the next step of dissolving operation u...

Embodiment 2

[0060] The composition of the electrolyte in this embodiment is as follows: the electrolyte potassium hydroxide is 536g of potassium hydroxide, 45g of a mixed solution of sodium hydroxide and lithium hydroxide, and the ratio of sodium hydroxide and lithium hydroxide is 2:1 by weight , that is, sodium hydroxide is 30g, lithium hydroxide is 15g, aluminum of 0.8g, zinc oxide of 122g, fumed silica of 0.3, boric acid of 21.4g, pure water of 782g.

[0061] S1. Take by weighing 650g of pure water in the reaction vessel, add 134g of potassium hydroxide to the pure water, stir and heat, and obtain the first conductive solution after the potassium hydroxide is completely dissolved;

[0062] S2. Add 45g of sodium hydroxide and lithium hydroxide mixed solution to the first conductive solution, keep stirring and heating until the sodium hydroxide and lithium hydroxide mixed solution is completely dissolved to obtain the second conductive solution;

[0063] S3. Add aluminum to the second co...

Embodiment 3

[0071] The composition of electrolyte in the present embodiment is as follows: 400g of potassium hydroxide, 25g of lithium hydroxide, 2g of aluminum hydroxide, 82g of zinc oxide, 0.17g of fumed silica, 13.6 of boric acid, and 866g of pure water.

[0072] A kind of preparation method of electrolytic solution, the preparation steps of this electrolytic solution are as follows:

[0073] S1. Take by weighing 600g of pure water in the reaction vessel, add 40g of potassium hydroxide at the same time, stir and heat, mix and dissolve to form the first conductive solution;

[0074] S2. Mixing and dissolving lithium hydroxide in an amount of 25g and the first conductive solution to form a second conductive solution, keeping stirring and heating;

[0075] S3, dissolving 2g of alumina in the second conductive solution five times, keeping stirring and heating, and finally preparing the third conductive solution;

[0076] S4. Mix and dissolve 8.2g of zinc oxide in the third conductive solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com