Method and system for separating biomass from activated sludge and application

A technology for activated sludge and biomass, which is applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., and can solve the problems of difficulty in balancing alkali-heat conditions, reduction of total nitrogen in filtrate, and numerous equipment. Achieve the effect of effectively killing harmful microorganisms, reducing alkaline concentration and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

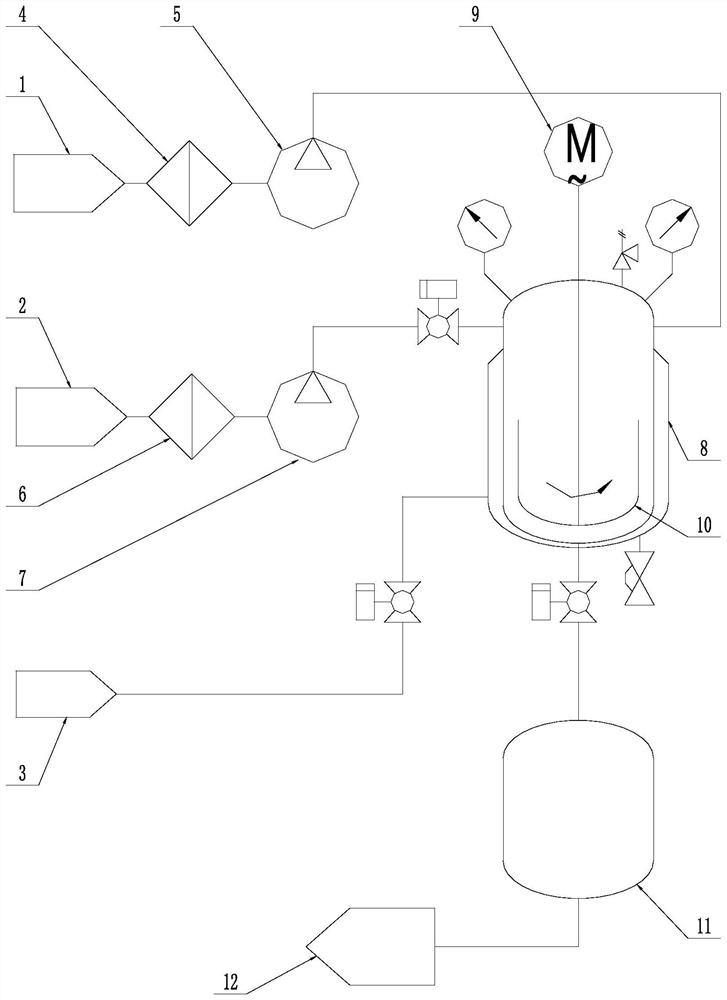

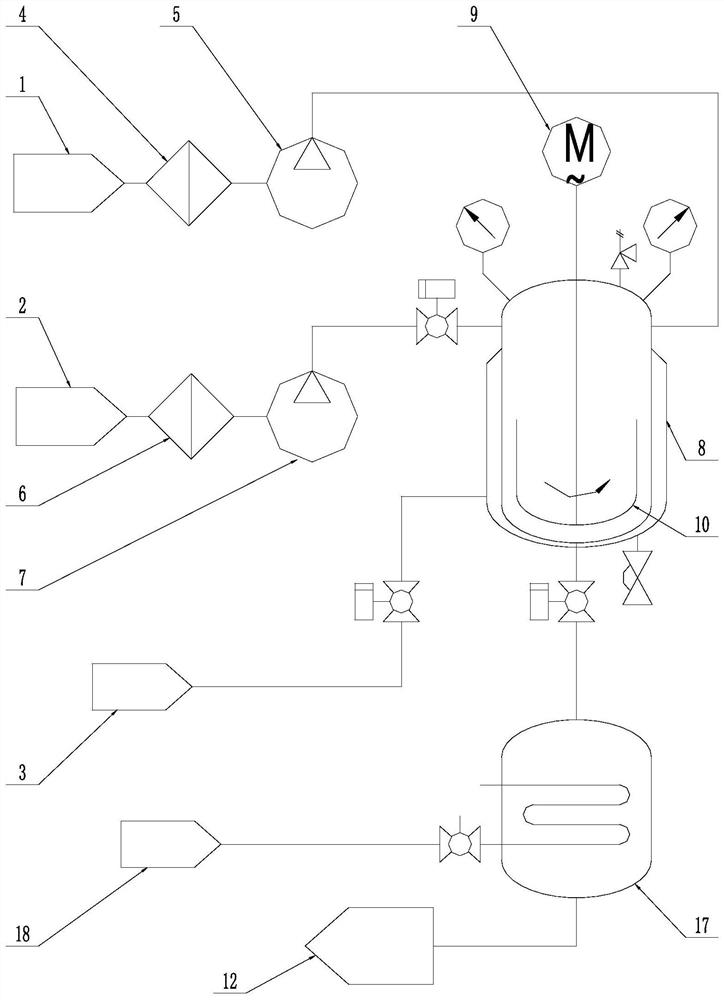

Embodiment 1

[0069] After the slaked lime thick slurry is filtered through the filter screen, it is pumped into the reaction kettle with a thick slurry pump, and then the slaked lime thick slurry is stirred by a vertical anchor or anchor paddle agitator; after the sludge to be treated is filtered through the filter screen, Use a screw pump to pump into the reaction kettle, and continue to use a vertical anchor or anchor paddle stirrer to stir the mixture to make the stirring more uniform; wherein, the Ca content in the mixture is 3.5% by mass percentage in terms of CaO, and the reaction is heated before Reactor for 90 minutes, so that after the material inside the reactor reaches 140°C, react for 240 minutes. After the reaction is completed, the high-temperature sludge after the reaction is discharged into the rapid-cooling heat exchanger for rapid cooling treatment, and the activated sludge mixture after the high-temperature reaction is cooled to 90°C within 100 seconds for storage and slo...

Embodiment 2

[0071] After the slaked lime thick slurry is filtered through the filter screen, it is pumped into the reaction kettle with a thick slurry pump, and then the slaked lime thick slurry is stirred by a vertical anchor or anchor paddle agitator; after the sludge to be treated is filtered through the filter screen, Use a screw pump to pump into the reaction kettle, and continue to use a vertical anchor or anchor paddle stirrer to stir the mixture to make the stirring more uniform; wherein, the Ca content in the mixture is 3.5% by mass percentage in terms of CaO, and the reaction is heated before Reactor for 90 minutes, so that after the material inside the reactor reaches 140°C, react for 240 minutes. After the reaction is completed, discharge the reacted high-temperature sludge into the quench heat exchanger for quenching treatment, and cool the activated sludge mixture after the high-temperature reaction to 85°C for storage and slow cooling within 110 seconds. The cooled mixture ...

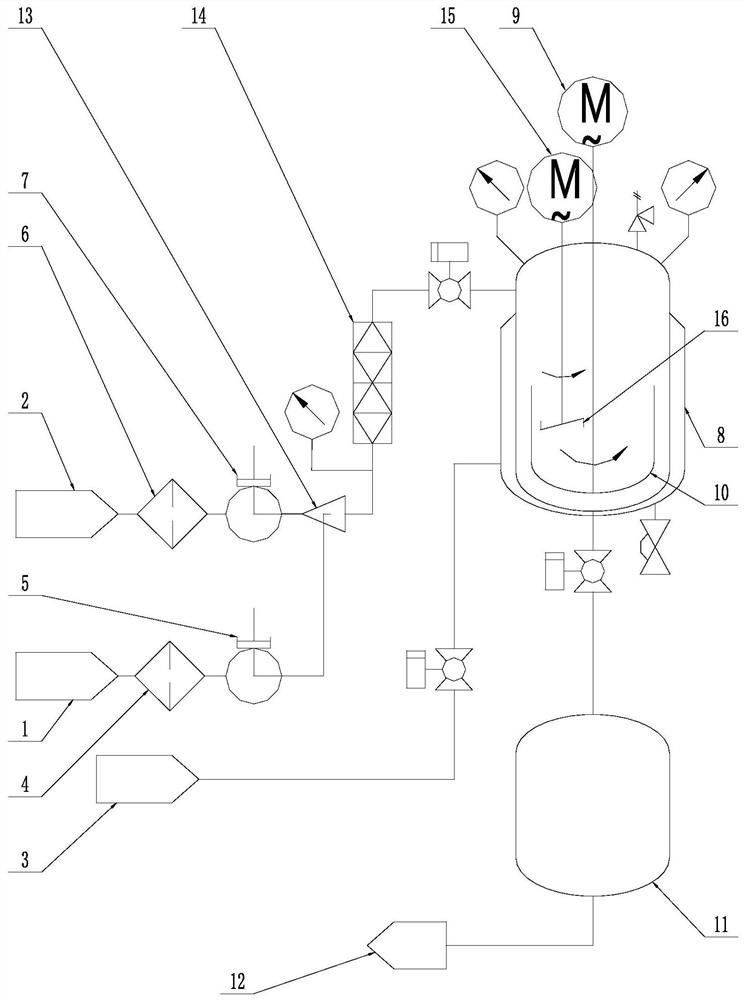

Embodiment 13

[0079]The slaked lime thick slurry is filtered through the filter screen and the activated sludge to be treated is filtered through the filter screen, and then pumped to the mixing port by the thick slurry pump and the screw pump at the same time, and then sent to the static mixer, and the static mixed material enters the The reaction kettle is heated by steam in the jacket of the reaction kettle, wherein the Ca content in the mixture is 2.5% in terms of CaO mass percentage, and the reaction kettle is heated for 90 minutes before the reaction, so that after the internal materials of the reaction kettle reach 140 ° C, the vortex Stir continuously and react for 150min with the linear velocity of the pan stirrer at 0m / s. After the reaction is completed, the high-temperature sludge after the reaction is discharged into the quenching heat exchanger and cooled to 70°C for storage and slow cooling. Finally, the cooled activated sludge is separated from solid and liquid by plate and fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com