Alkaline activity inhibition material based on active sandstone aggregate and preparation method thereof

A technology of alkali activity and sandstone, which is applied in the field of concrete engineering, can solve the problems of untested long-term effect, poor adaptability, research on alkali activity inhibitory materials has not been reported, etc., to achieve secondary utilization of waste into treasure and reduce accumulation Land occupation and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A preparation method of an alkali activity inhibiting material based on active sandstone aggregate, comprising the following steps:

[0048] (1) The sandstone aggregate with potentially harmful alkali activity is ground through an RM2200 vertical mill, and the feed rate of the mill is controlled to 22t / h, the speed of the separator is 40Hz, the pressure of the grinding roller is 6.7MPaMPa, the temperature of the inlet mill is 190℃, and the outlet temperature is 190℃. The grinding temperature is 71°C, and the sandstone fine powder with a sieve residue of 45 μm and 5.5% is obtained.

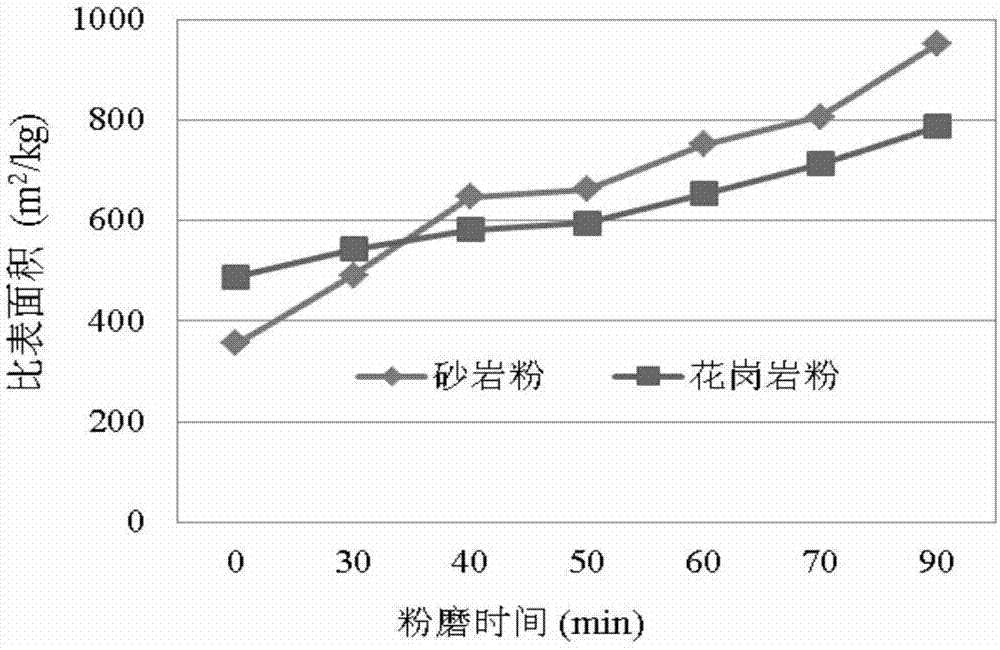

[0049] (2) The sandstone fine powder obtained by step (1) is continuously put into the SMQ conical ball mill for secondary grinding, the mass ratio of the ball to material is controlled at 5:1, the ball milling speed is 300r / min, and the grinding time is 90min. The specific surface area is 950m 2 / kg sandstone powder.

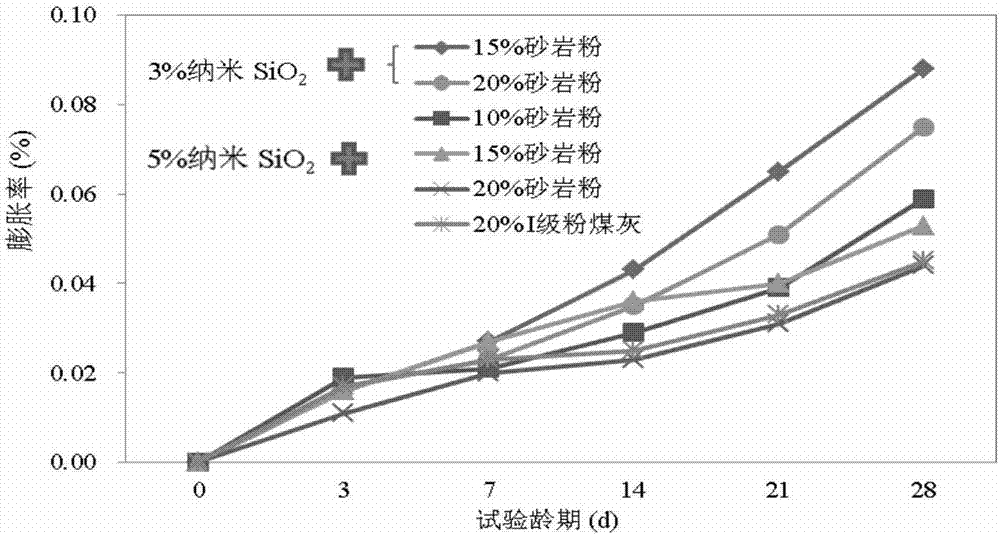

[0050] (3) Take 87% medium heat cement, 10% sandstone powder and 3% na...

Embodiment 2

[0052] A preparation method of an alkali activity inhibiting material based on active sandstone aggregate, comprising the following steps:

[0053] (1) The sandstone aggregate with potentially harmful alkali activity is ground through an RM2200 vertical mill, and the feed rate of the mill is controlled to 22t / h, the speed of the separator is 40Hz, the pressure of the grinding roller is 6.7MPaMPa, the temperature of the inlet mill is 190℃, and the outlet temperature is 190℃. The grinding temperature is 71°C, and the sandstone fine powder with a sieve residue of 45 μm and 5.5% is obtained.

[0054] (2) The sandstone fine powder obtained by step (1) is continuously put into the SMQ conical ball mill for secondary grinding, the mass ratio of the ball to material is controlled at 5:1, the ball milling speed is 200r / min, and the grinding time is 50min. The specific surface area is 645m 2 / kg sandstone powder.

[0055] (3) Take by weight 82% medium heat cement, 15% sandstone powder...

Embodiment 3

[0057] A preparation method of an alkali activity inhibiting material based on active sandstone aggregate, comprising the following steps:

[0058] (1) The sandstone aggregate with potentially harmful alkali activity is ground through an RM2200 vertical mill, and the feed rate of the mill is controlled to 16t / h, the separator speed is 40Hz, the pressure of the grinding roller is 7.0MPa, the temperature of the inlet mill is 154°C, and the outlet temperature is 154°C. The grinding temperature is 70°C, and the sandstone fine powder with a sieve residue of 45 μm and 3.0% is obtained.

[0059] (2) The fine sandstone powder obtained in step (1) is put into the SMQ conical ball mill for secondary grinding, the mass ratio of the ball to material is controlled at 5:1, the ball milling speed is 200r / min, and the grinding time is 50min. The specific surface area is 662m 2 / kg sandstone powder.

[0060] (3) Take 77% medium heat cement, 20% sandstone powder and 3% nanometer SiO by mass r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com