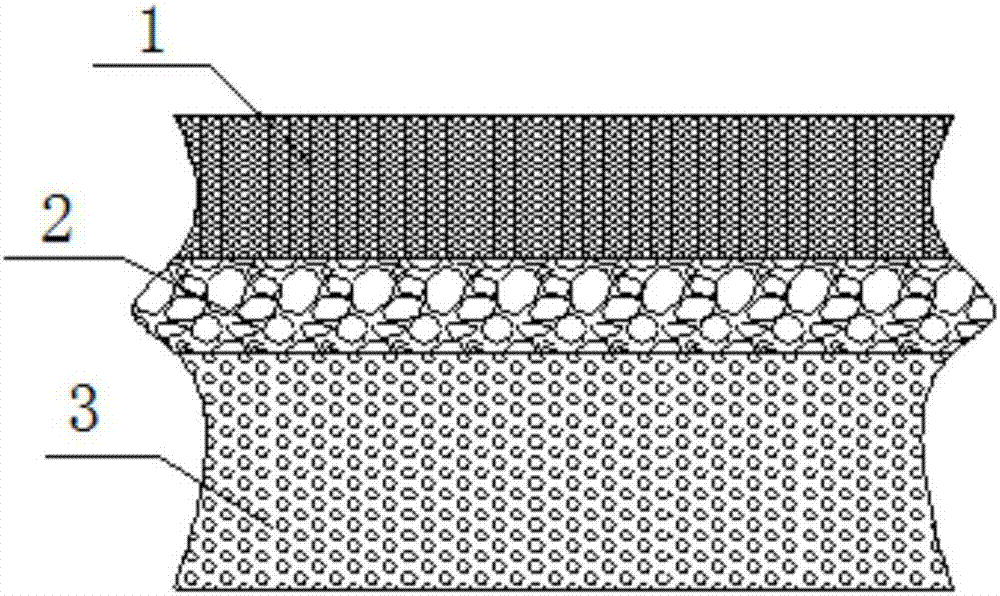

Lean asphalt macadam transition layer mixed material and semi-rigid base asphalt pavement

A technology of asphalt crushed stone and transition layer, which is applied to the coagulation pavement, roads, roads and other directions of on-site paving, can solve the problems of poor construction performance and loose surface of binder-free granules, etc. Reflective cracks and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

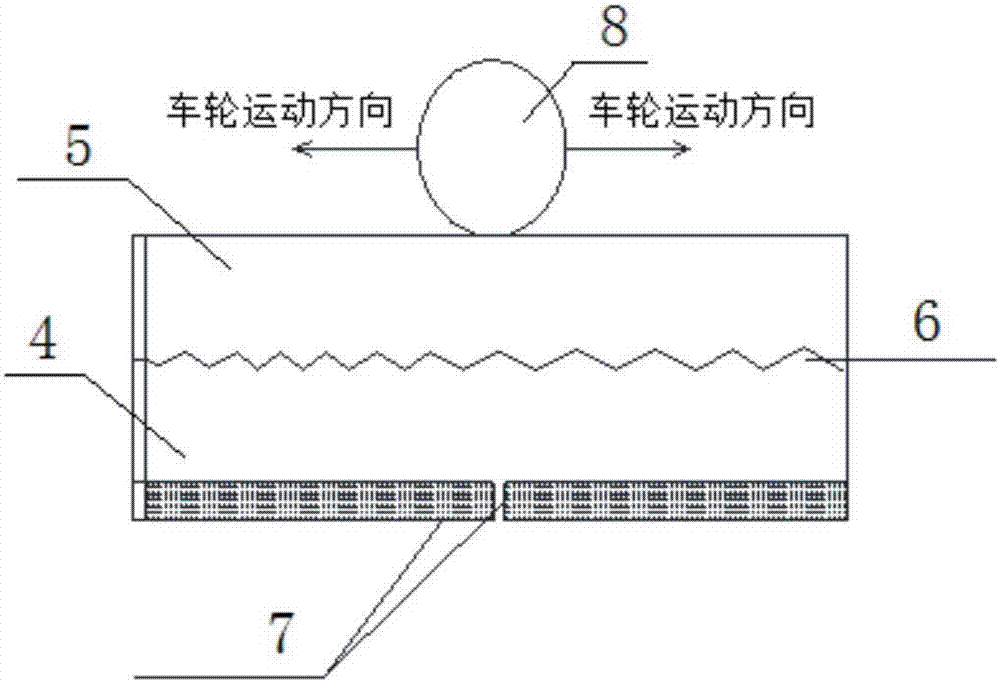

Method used

Image

Examples

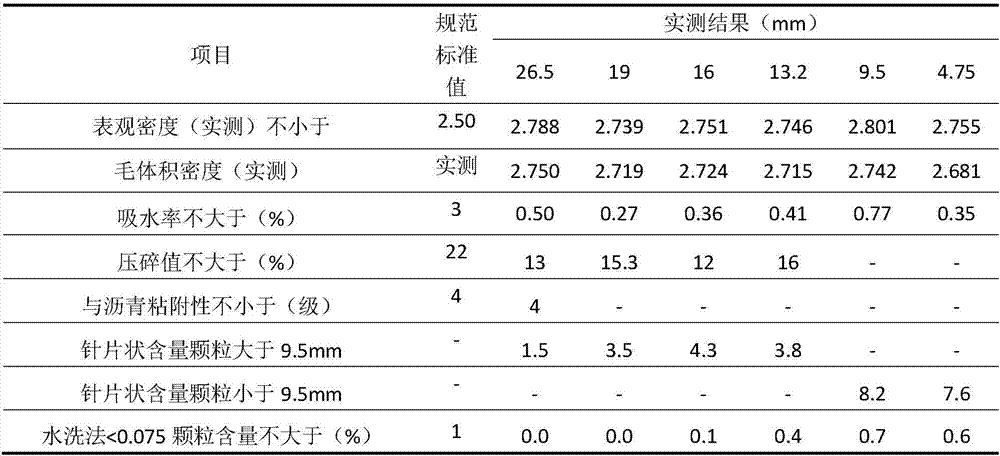

Embodiment 1

[0052] A bridge deck waterproof adhesive layer material, comprising the following components by weight percentage:

[0053] Asphalt: 2.5%, slag powder: 2.5%, the rest is aggregate, and the aggregate grading range is:

[0054] Aggregate with particle size less than 31.5mm accounts for 100% of the total mass of graded aggregate;

[0055] Aggregate with particle size less than 26.3mm accounts for 94.3% of the total mass of graded aggregate;

[0056] Aggregate with particle size less than 19mm accounts for 85.7% of the total mass of graded aggregate;

[0057] Aggregate with particle size less than 16mm accounts for 76.2% of the total mass of graded aggregate;

[0058] Aggregate with particle size less than 13.2mm accounts for 52.4% of the total mass of graded aggregate;

[0059] Aggregate with particle size less than 9.5mm accounts for 32.0% of the total mass of graded aggregate;

[0060] Aggregate with particle size less than 4.75mm accounts for 15.0% of the total mass of gra...

Embodiment 2

[0068] A bridge deck waterproof adhesive layer material, comprising the following components by weight percentage:

[0069] Asphalt: 2.55%, slag powder: 2.55%, the rest is aggregate, and the aggregate grading range is:

[0070] Aggregate with particle size less than 31.5mm accounts for 100% of the total mass of graded aggregate;

[0071] Aggregate with particle size less than 26.3mm accounts for 94.6% of the total mass of graded aggregate;

[0072] Aggregate with particle size less than 19mm accounts for 86.6% of the total mass of graded aggregate;

[0073] Aggregate with particle size less than 16mm accounts for 77.6% of the total mass of graded aggregate;

[0074] Aggregate with particle size less than 13.2mm accounts for 55.2% of the total mass of graded aggregate;

[0075] Aggregate with particle size less than 9.5mm accounts for 36.0% of the total mass of graded aggregate;

[0076] Aggregate with particle size less than 4.75mm accounts for 20.0% of the total mass of g...

Embodiment 3

[0084] A bridge deck waterproof adhesive layer material, comprising the following components by weight percentage:

[0085] Asphalt: 2.75%, slag powder: 2.75%, the rest is aggregate, and the aggregate grading range is:

[0086] Aggregate with particle size less than 31.5mm accounts for 100% of the total mass of graded aggregate;

[0087] Aggregate with particle size less than 26.3mm accounts for 95.0% of the total mass of graded aggregate;

[0088] Aggregate with particle size less than 19mm accounts for 87.4% of the total mass of graded aggregate;

[0089] Aggregate with particle size less than 16mm accounts for 79.0% of the total mass of graded aggregate;

[0090] Aggregate with particle size less than 13.2mm accounts for 58.0% of the total mass of graded aggregate;

[0091] Aggregate with particle size less than 9.5mm accounts for 40.0% of the total mass of graded aggregate;

[0092] Aggregate with particle size less than 4.75mm accounts for 25.0% of the total mass of g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com