A special dreg improvement agent for shield tunneling in sand and pebble strata

A technology of muck soil improvement and sand and pebbles, which is applied in application, building structure, soil conditioning materials, etc., can solve the problems of poor plastic flow of sand and pebbles, difficulty in establishing soil pressure, and abnormal excavation parameters, so as to improve flow plasticity and prevent Gushing, lubricious and cohesive for fast and full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

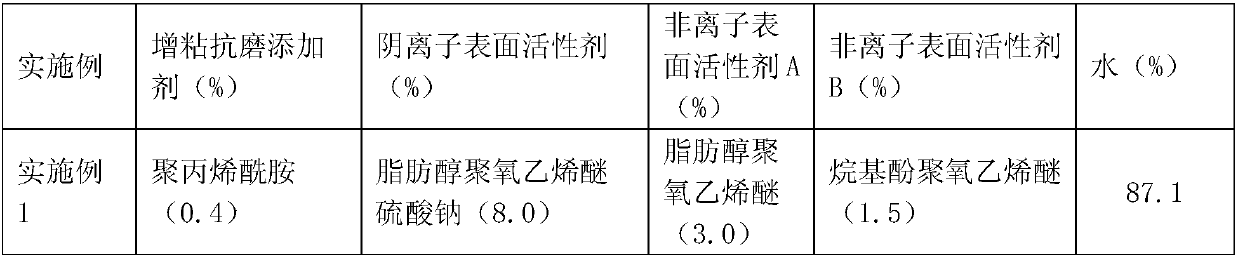

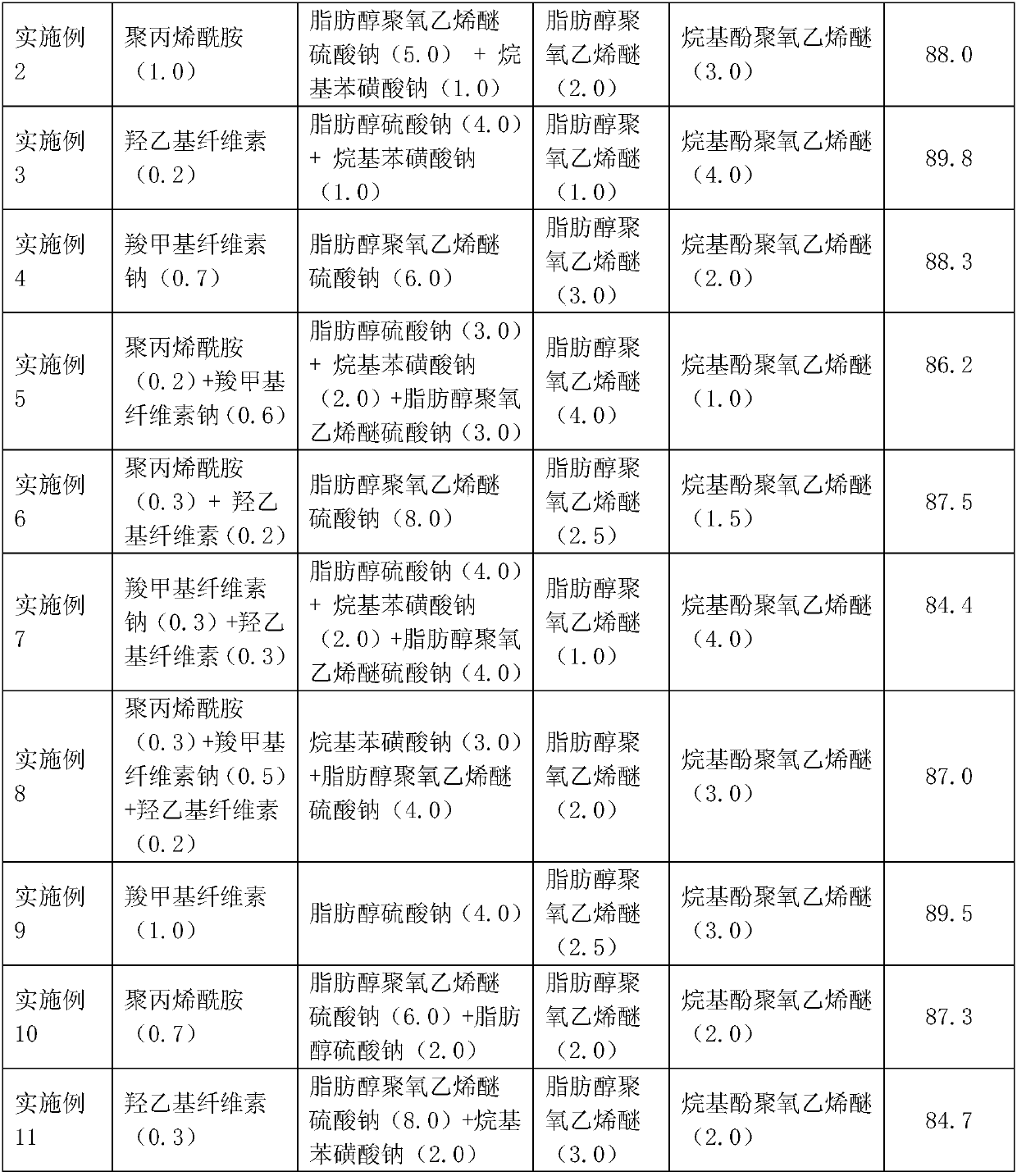

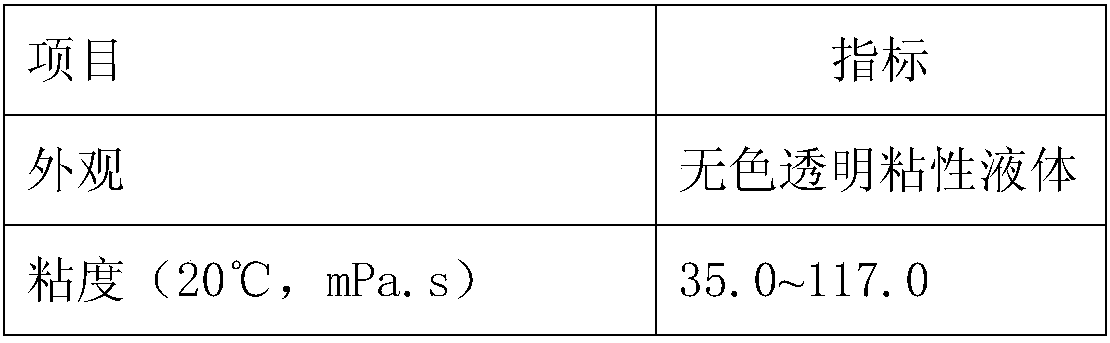

[0011] The present invention is a special slag modifier for shield tunneling in sand and pebble strata, which is made of the following raw materials in mass content: 0.2-1.0% of viscosity-increasing and anti-wear additive, 4.0-10.0% of anionic surfactant, and 1.0% of non-ionic surfactant A ~4.0% and nonionic surfactant B 1.0~4.0%, the balance is water, and the total mass is 100%; the viscosity-increasing and anti-wear additives are anionic polyacrylamide, sodium carboxymethylcellulose, hydroxyethyl cellulose A mixture of one or more ingredients. Preferably, the viscosity-increasing and anti-wear additive is 0.5-0.7%, the anionic surfactant is 6.0-8.0%, the non-ionic surfactant A is 2.0-3.0% and the non-ionic surfactant B is 1.5-3.0%. Wherein, the anionic surfactant is a mixture of fatty alcohol polyoxyethylene ether sodium sulfate and fatty alcohol sodium sulfate or one or both of them; or one or both of fatty alcohol polyoxyethylene ether sodium sulfate and fatty alcohol sodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com