Patents

Literature

30results about How to "Improve flow plasticity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

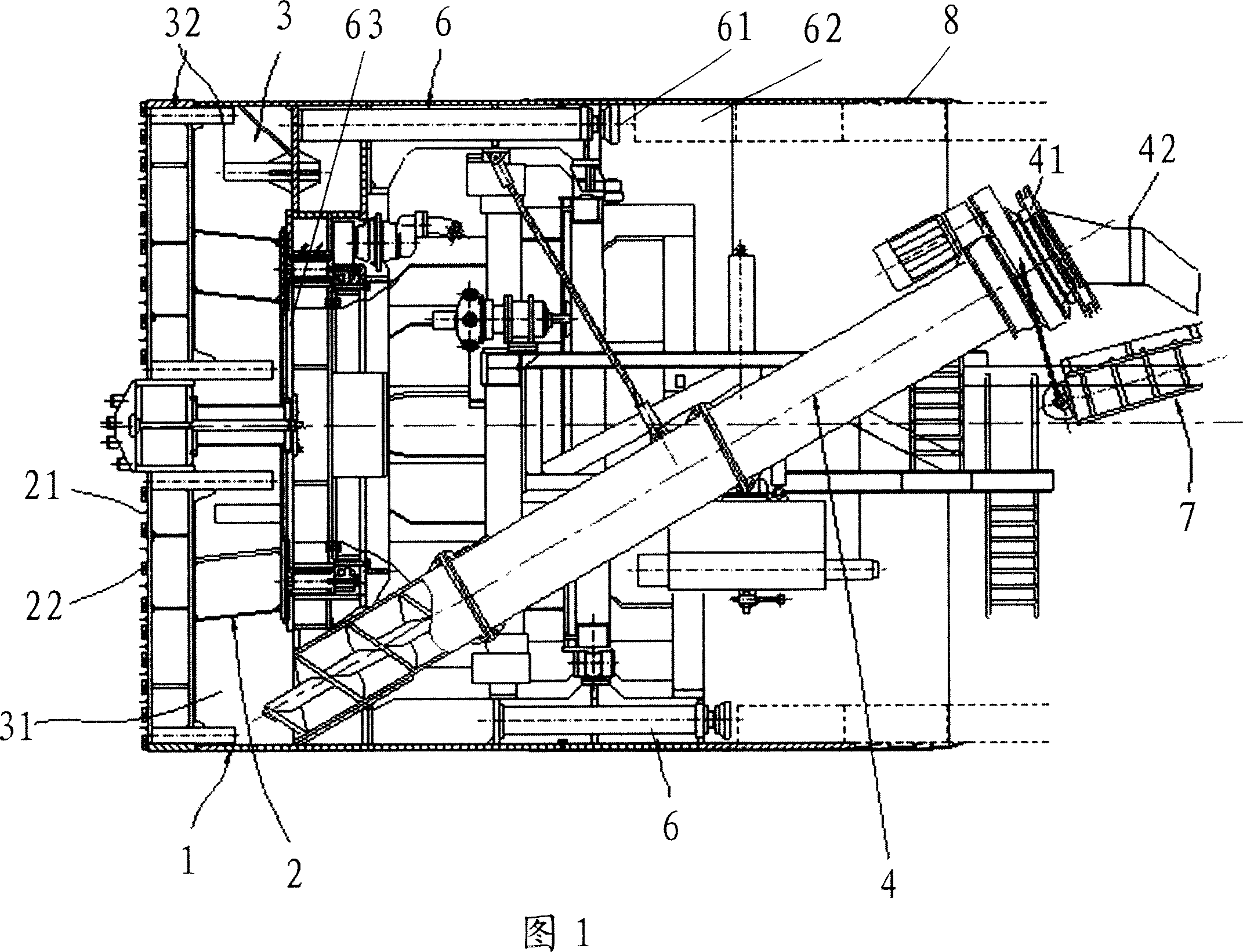

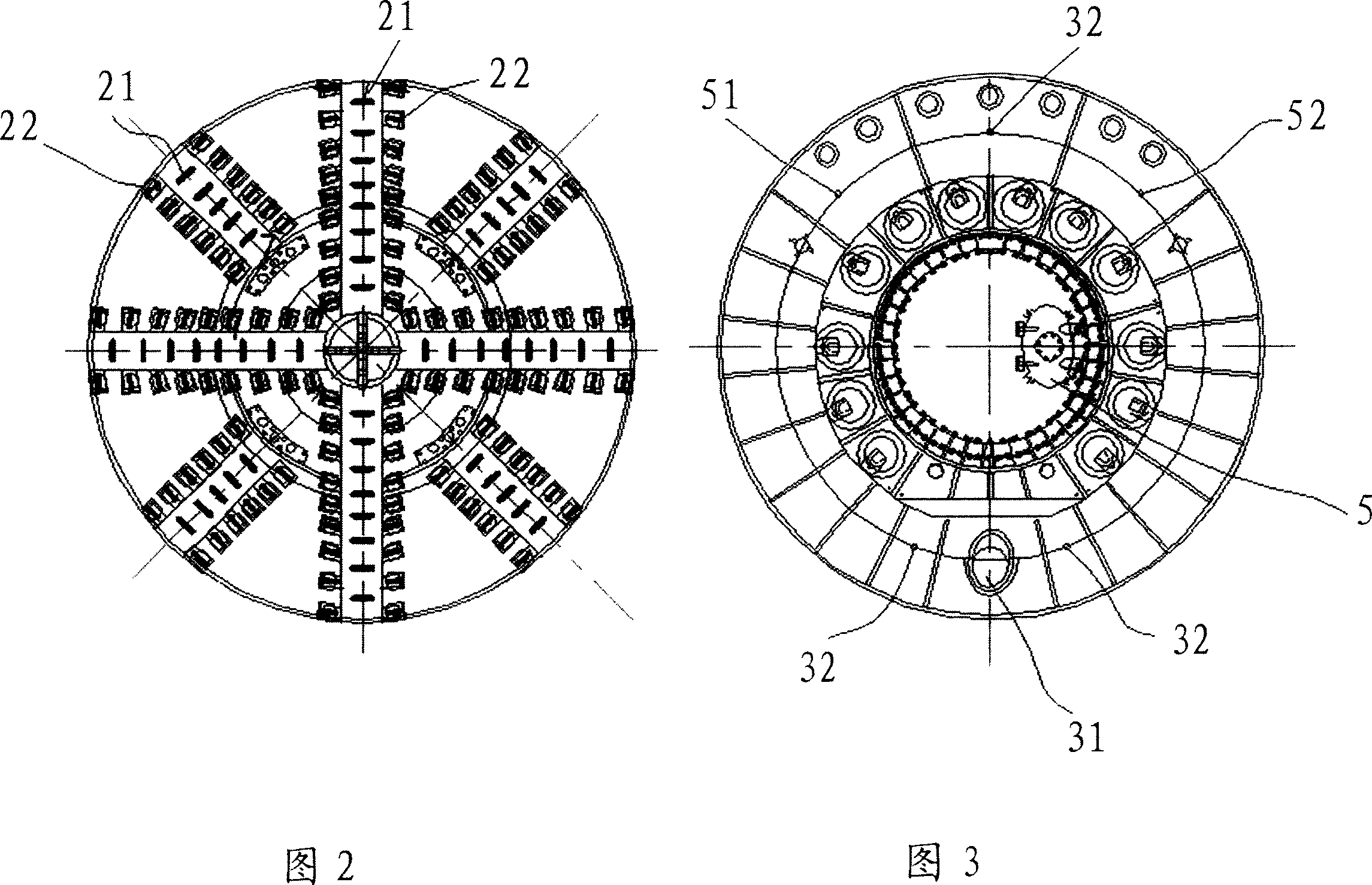

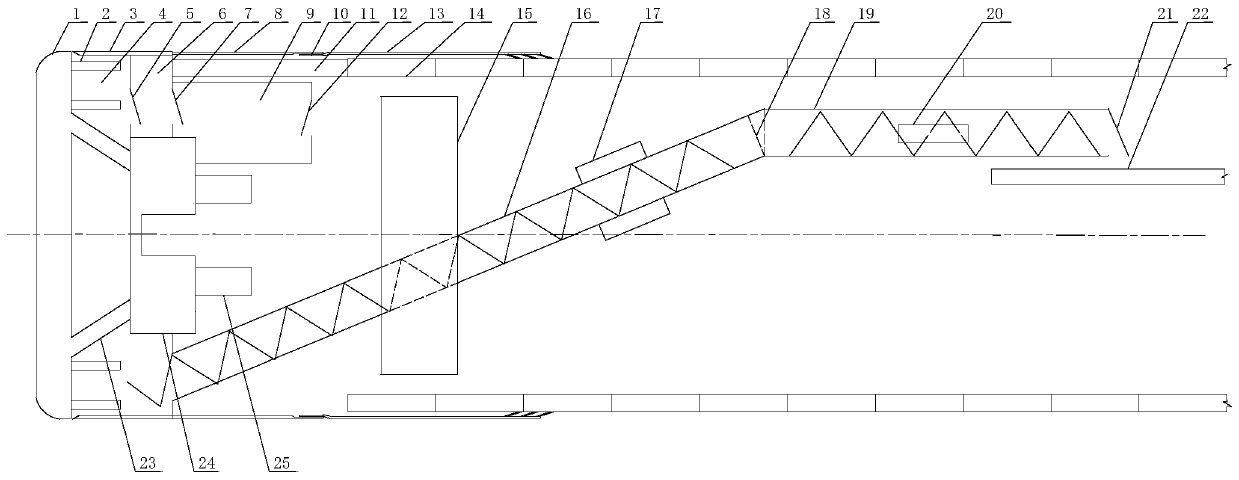

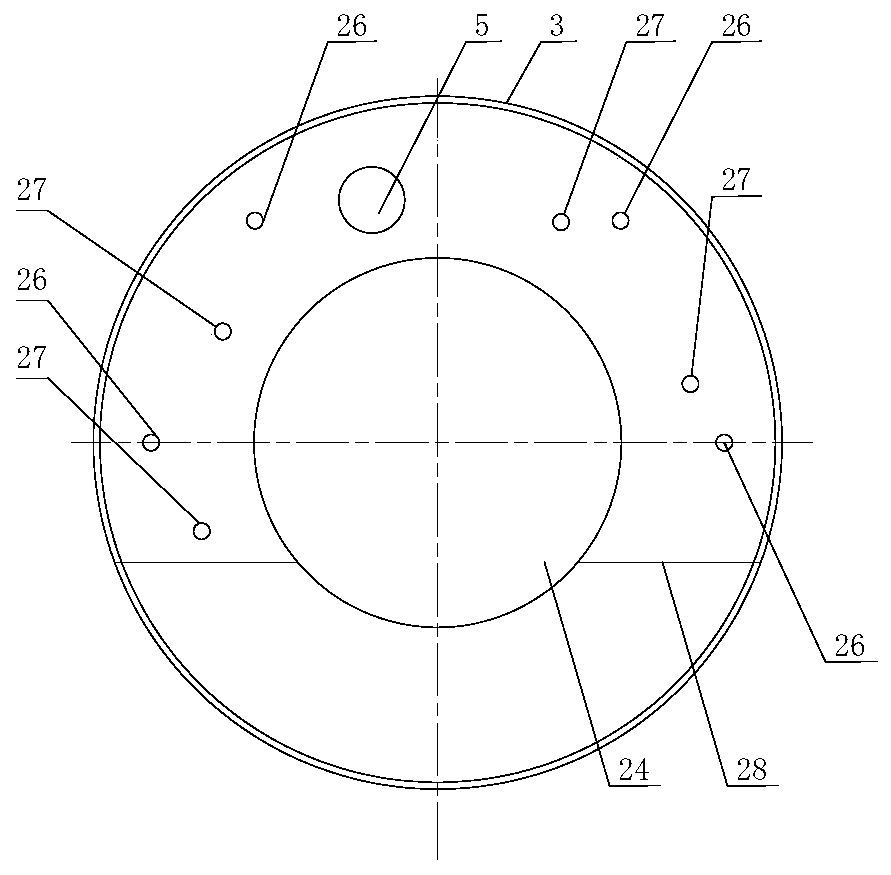

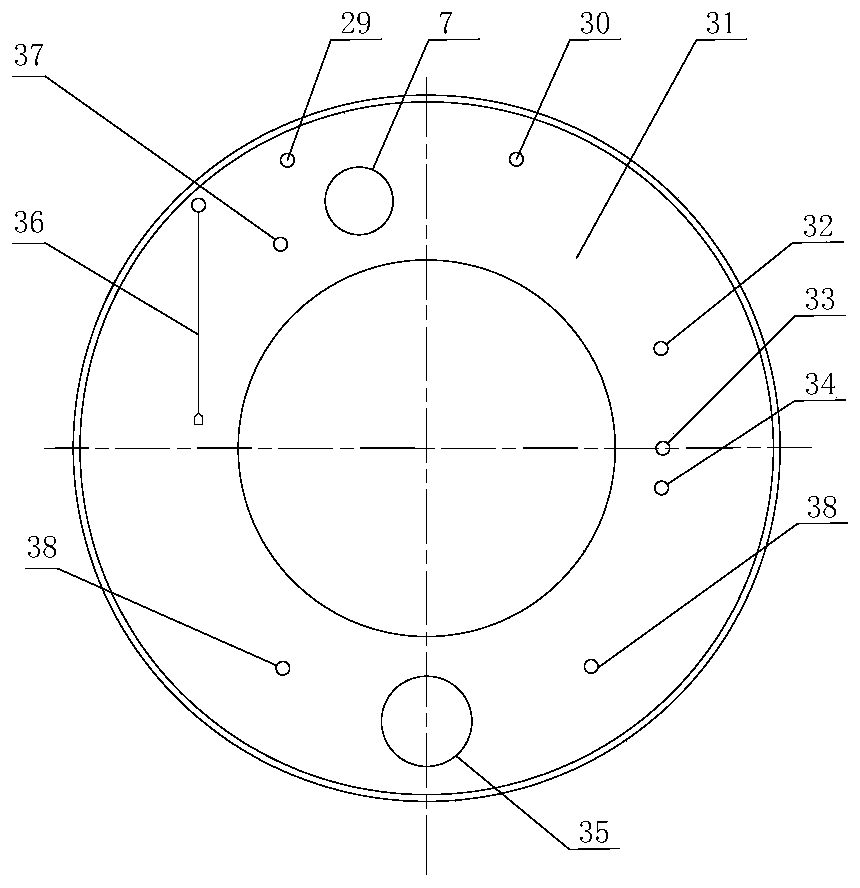

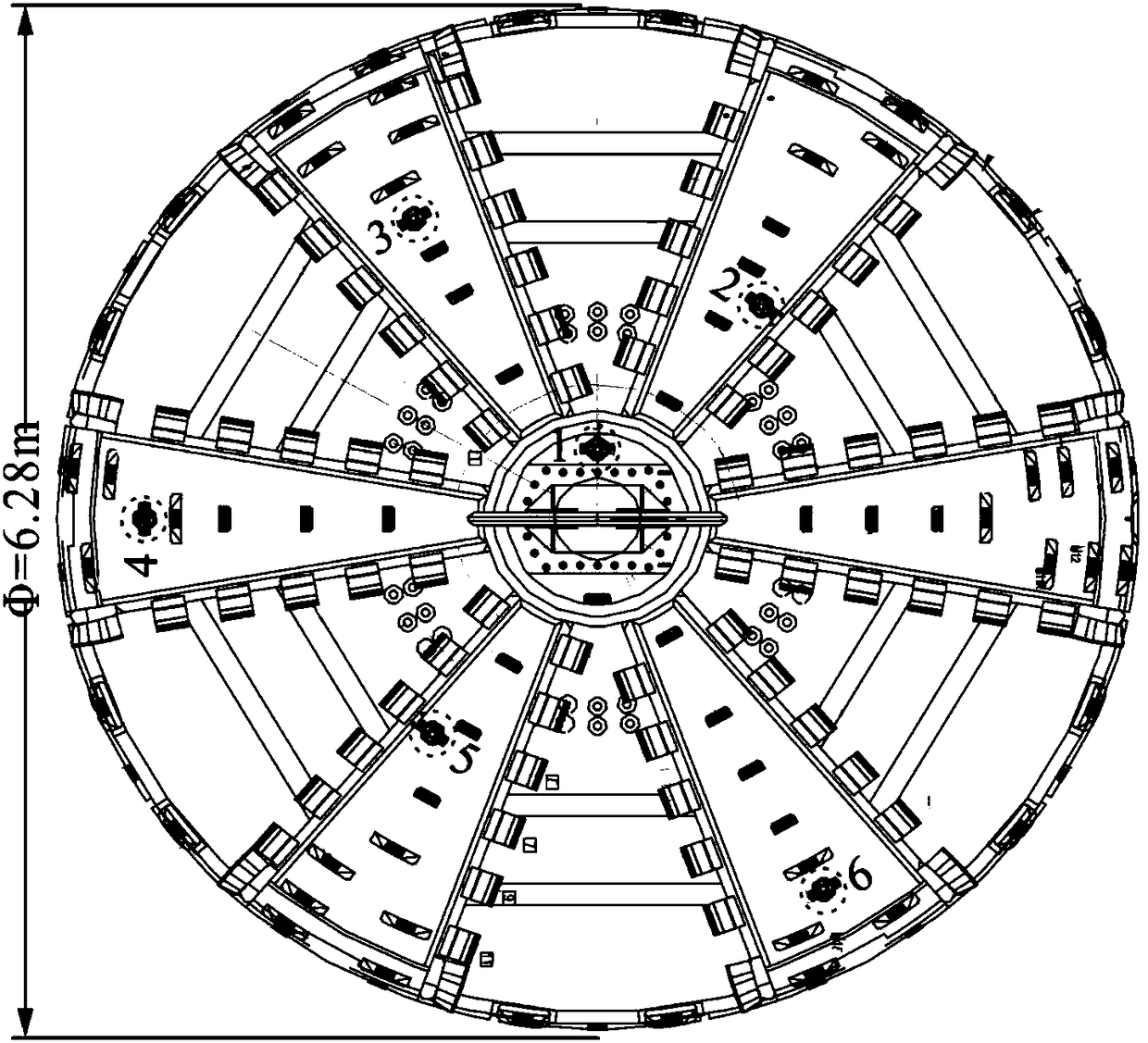

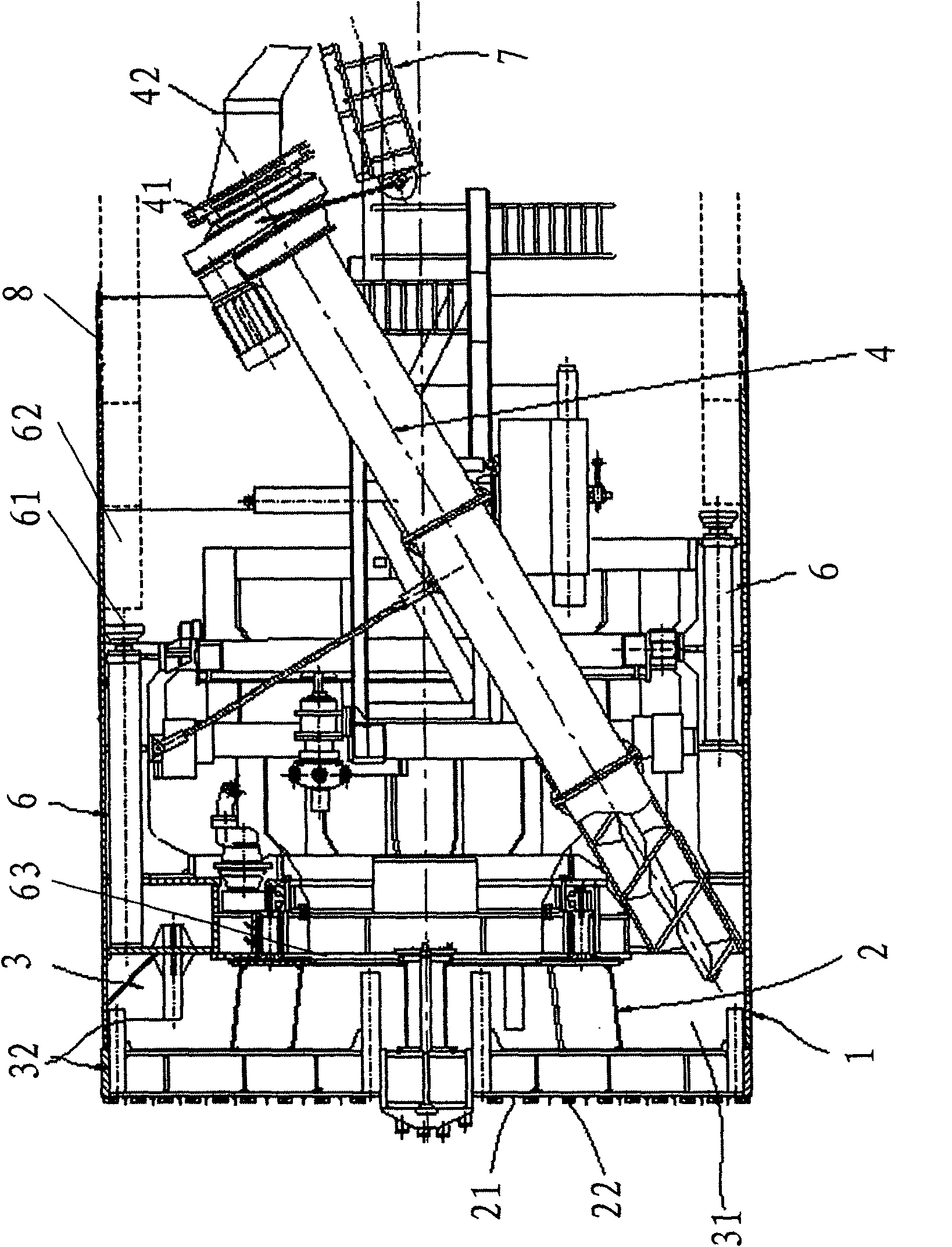

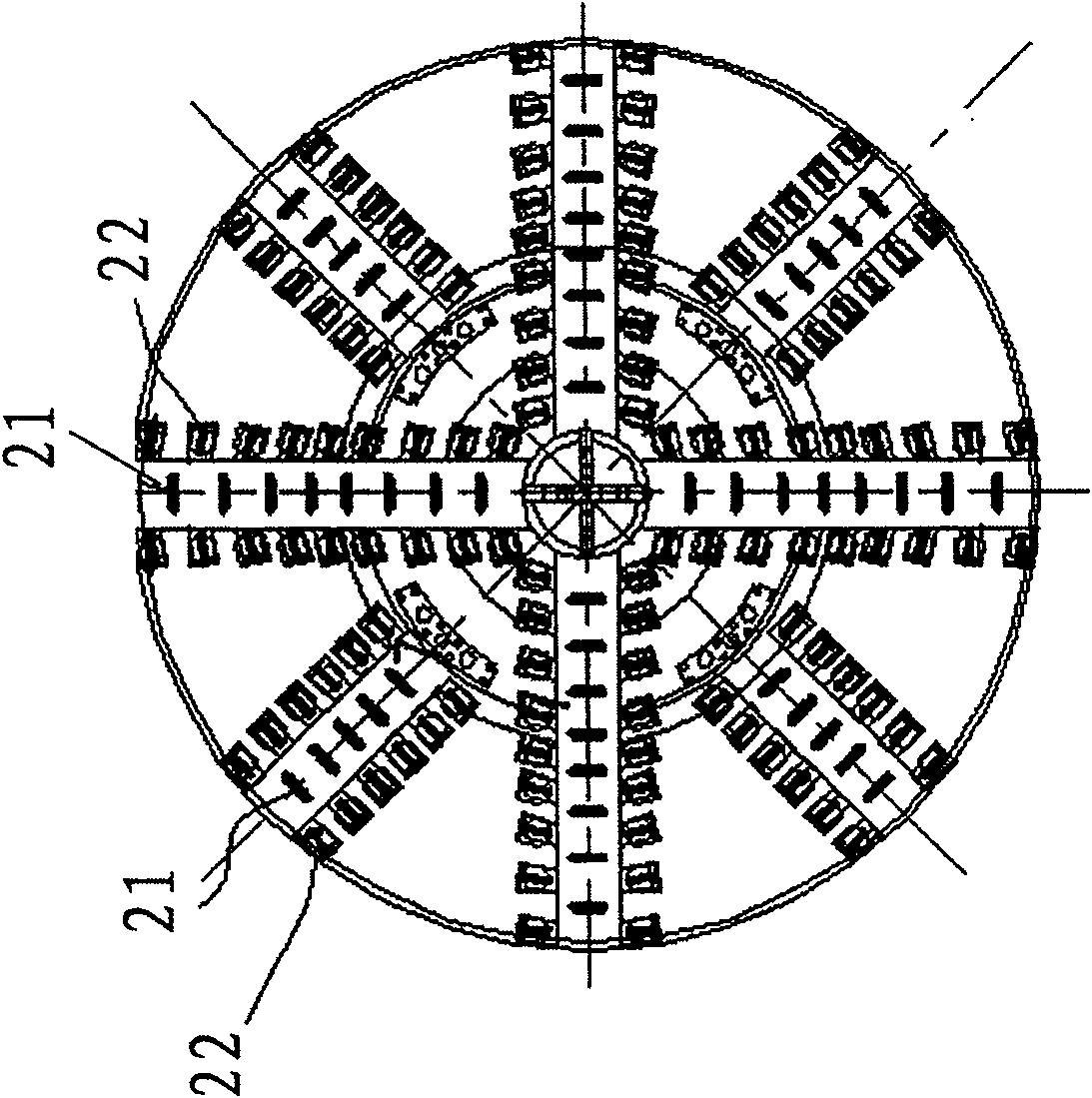

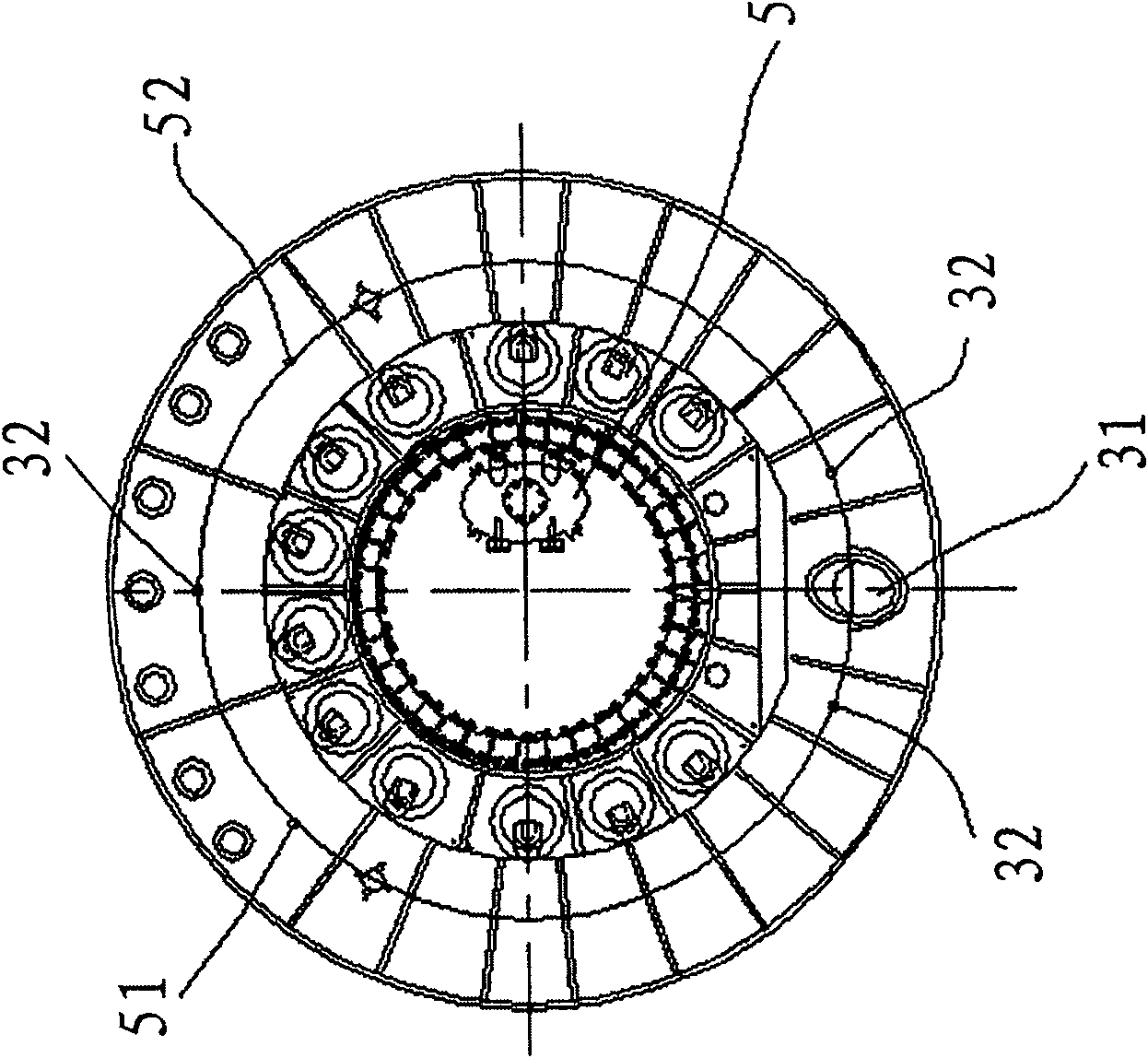

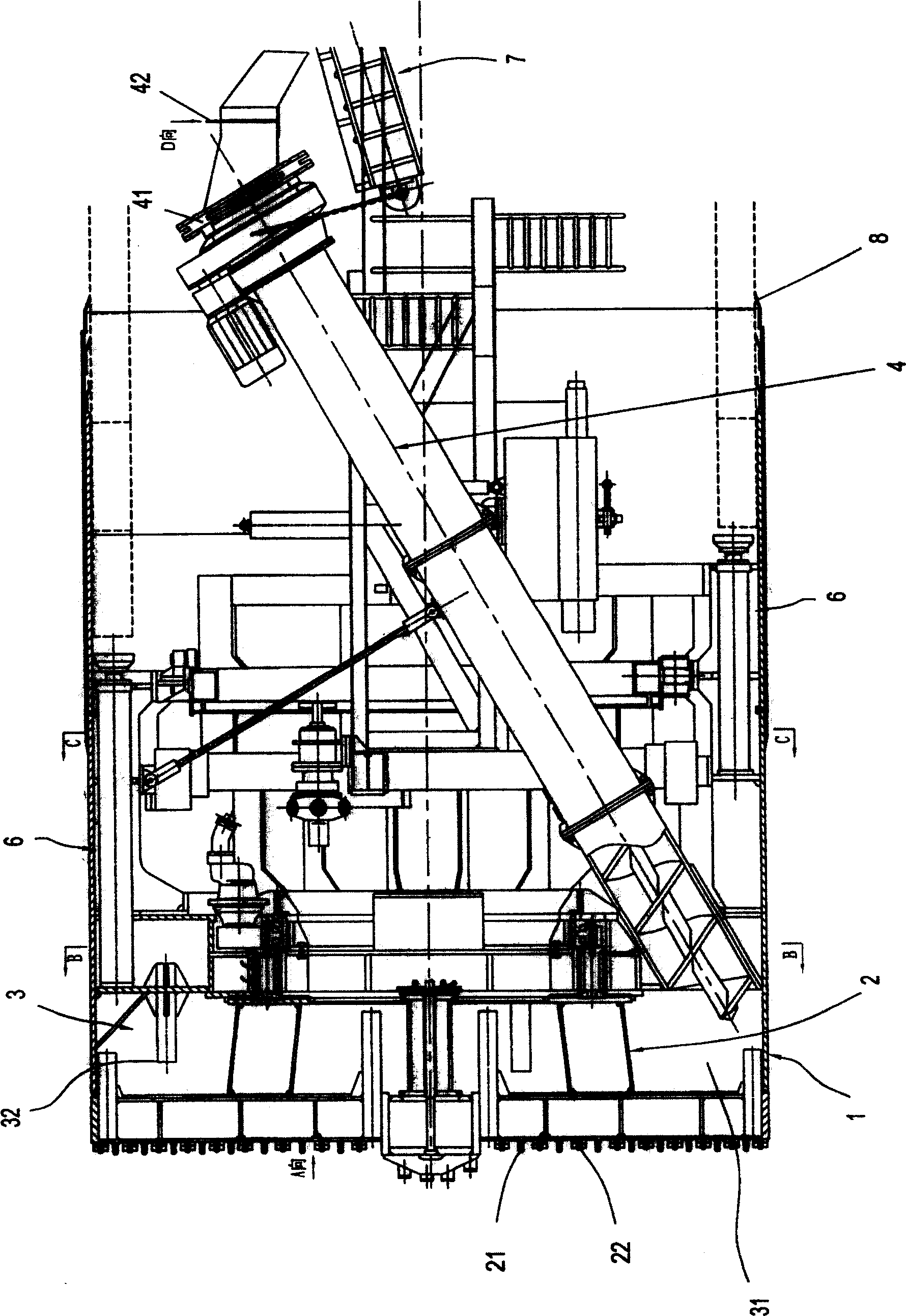

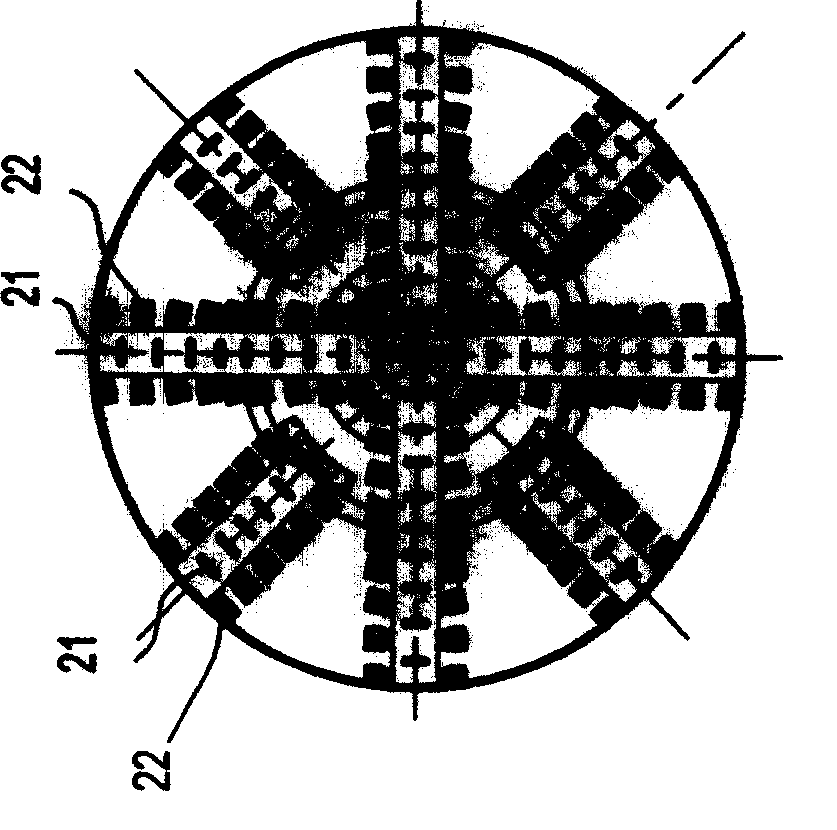

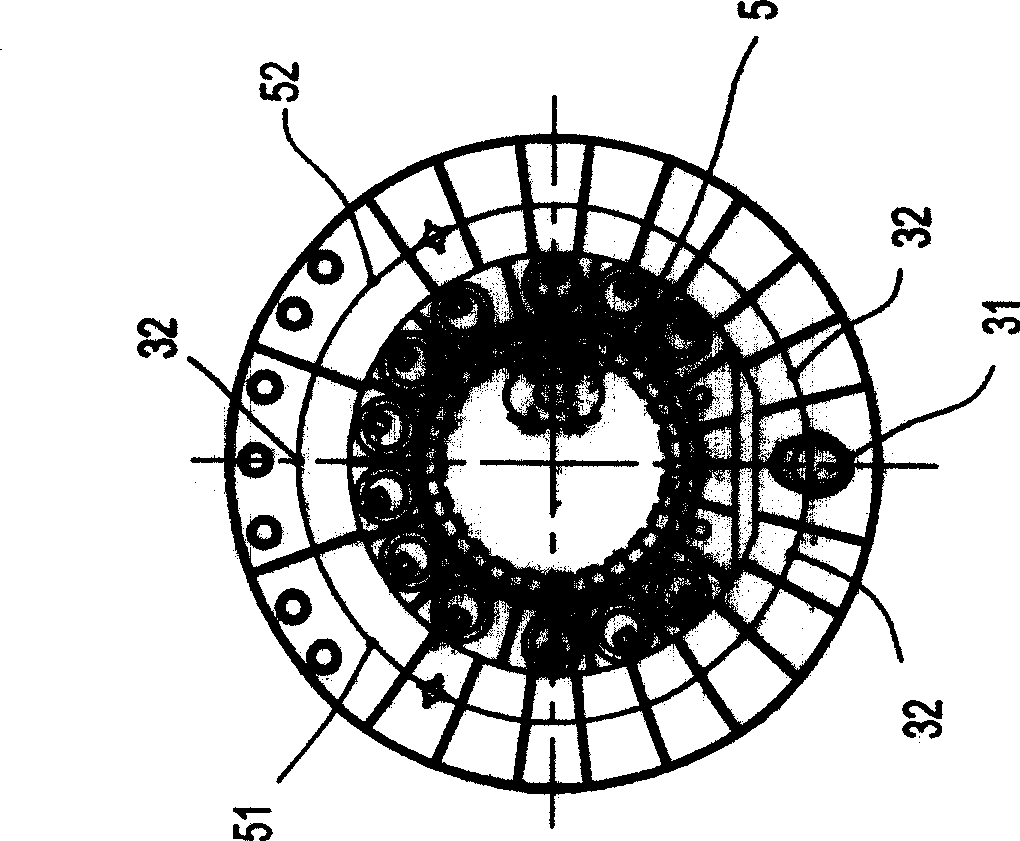

Composite balancing earth-pressure shielding machine

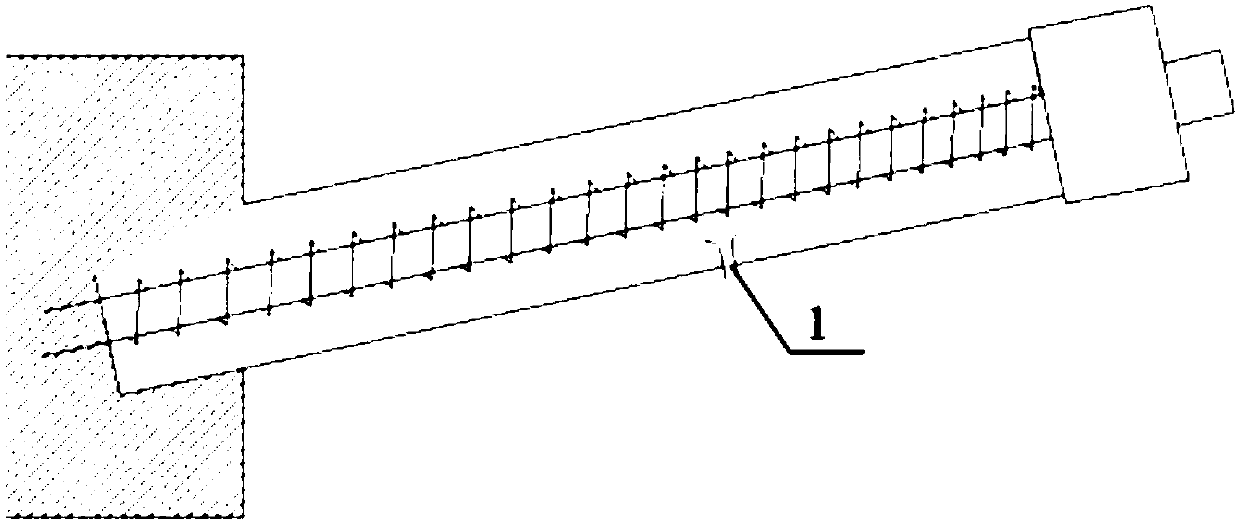

A composite soil pressure balance shield machine, comprising : shell (1), cutter head (2), soil storer (3), spiral conveyer (4) and impelling oil cylinder (6),it is characterized in that the said cutter head is set front of the shell, equipped with tearing knife (21) and the cutting knife (22), and the cutter point of the said cutting knife is a little back of the tearing knife; the soil storer is located rear the cutter head, and its wall surface is installed with injecting holes (32), the rear end is installed with pressure balancing equipment (5), and a soil outlet (31)is set under the soil storer; the inlet under the spiral conveyer connects the soil outlet of the container; the said impelling oil cylinder are uniformly installed along the shell inner wall. The shield machine solves the normal tunneling problem on sand or gravel eggs (gravel) layer of high water permeability, or the normal tunneling problem when it need to pass through more than 30 centimeters large stones and other obstructions.

Owner:CHINA SHENHUA ENERGY CO LTD

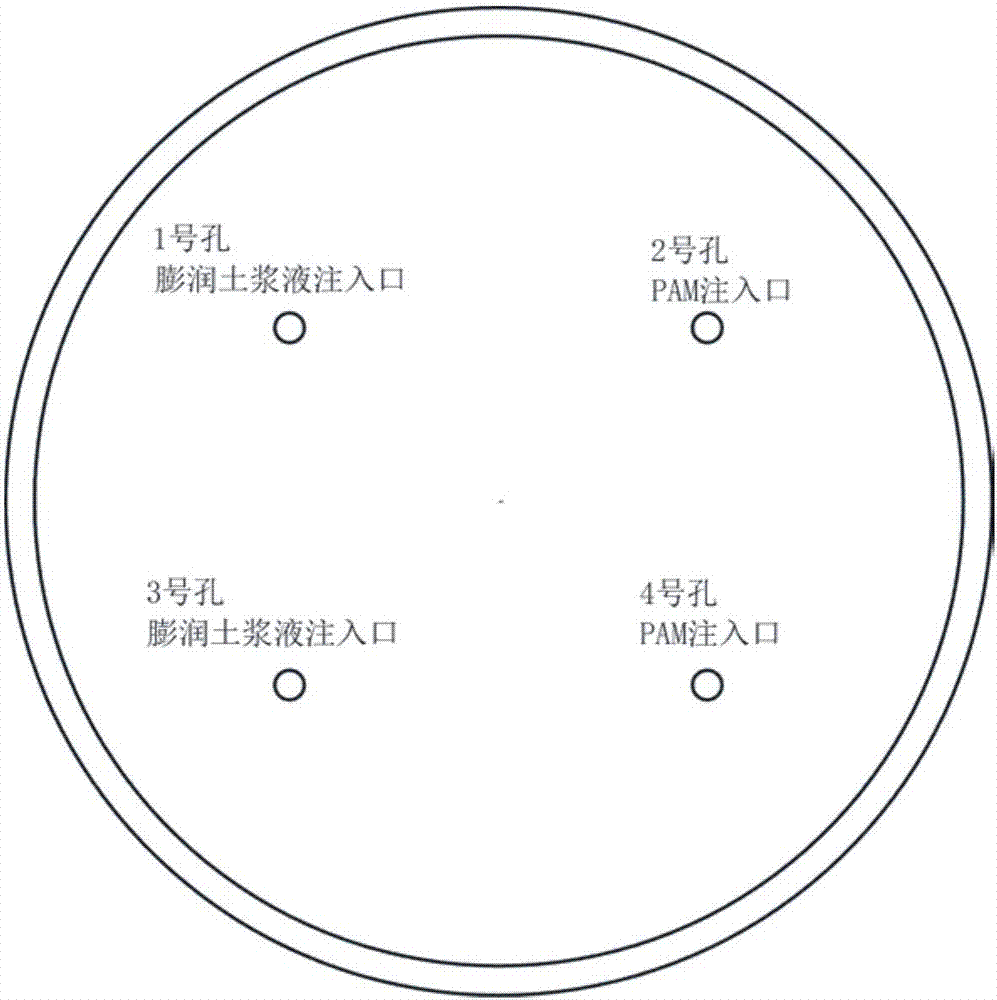

Muck improver for shield construction of water-rich sand layer and construction method of muck improver

InactiveCN107987839AShield construction is convenientImprove flow plasticityBuilding constructionsOrganic fertilisersSoil sciencePolyacrylamide

The invention discloses a muck improver for shield construction of a water-rich sand layer. The muck improver for the shield construction of the water-rich sand layer is prepared from a sodium bentonite solution and a polyacrylamide solution, wherein the sodium bentonite solution accounts for 3.5%-4% of total mass of muck, and the polyacrylamide solution accounts for 3.5%-4% of the total mass of the muck.

Owner:北京城建中南土木工程集团有限公司 +1

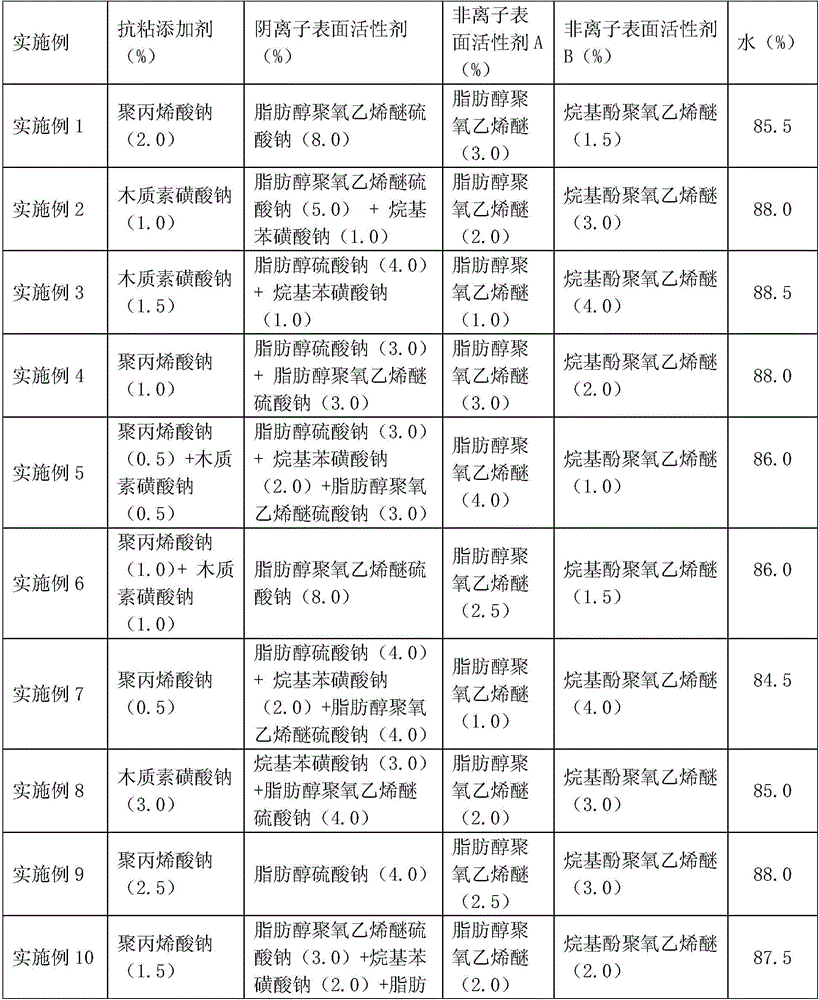

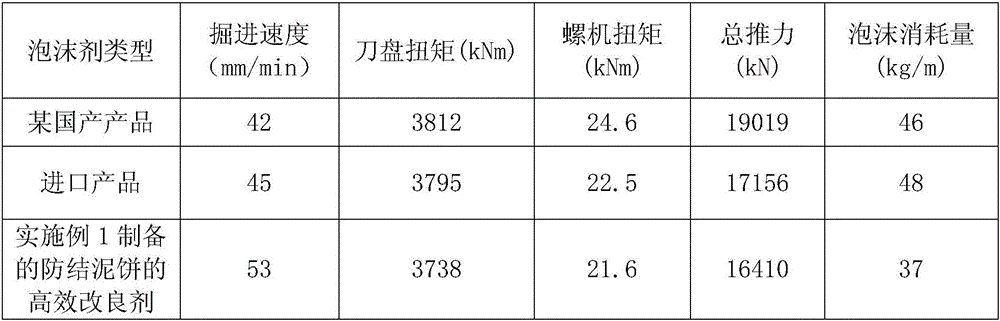

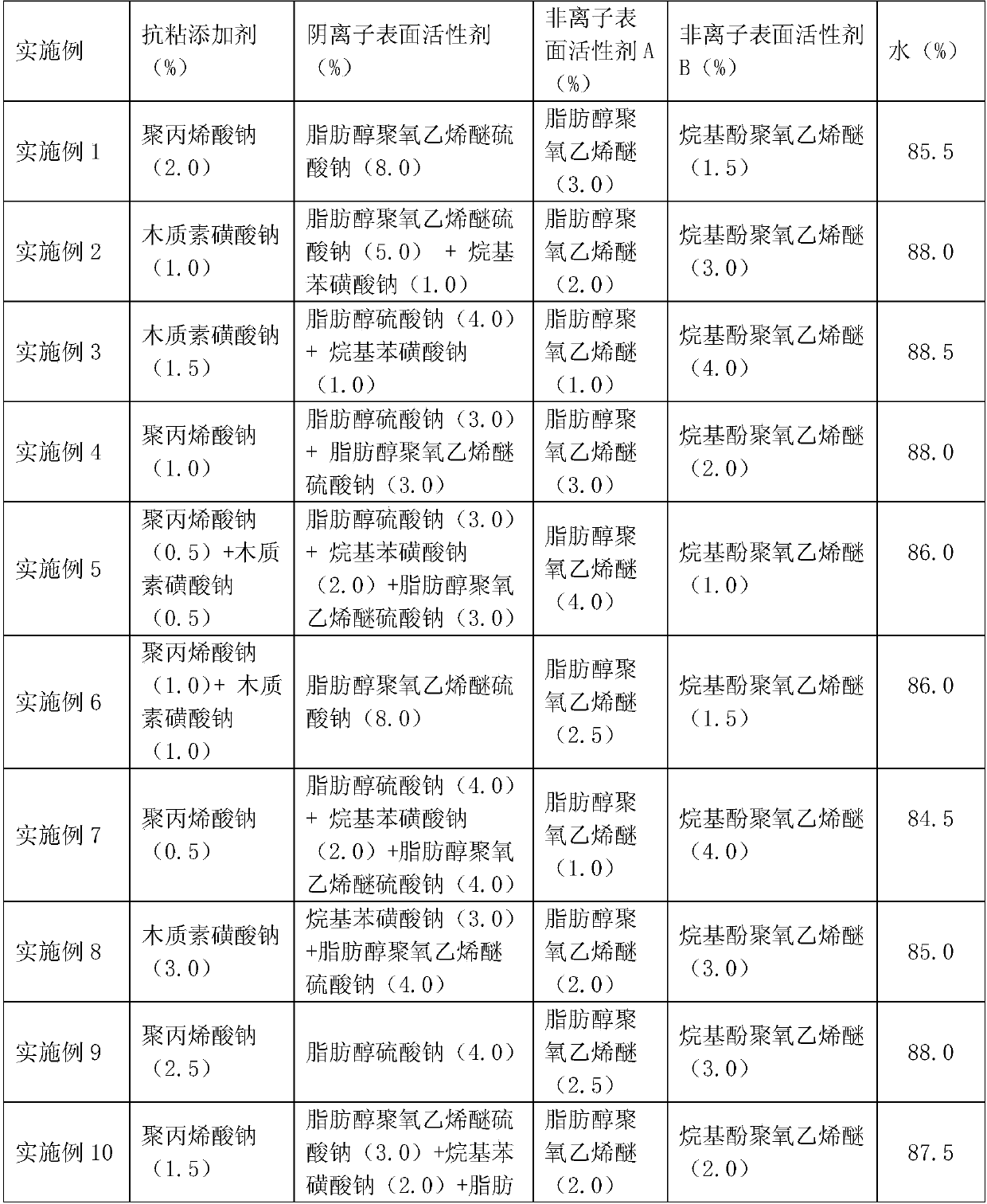

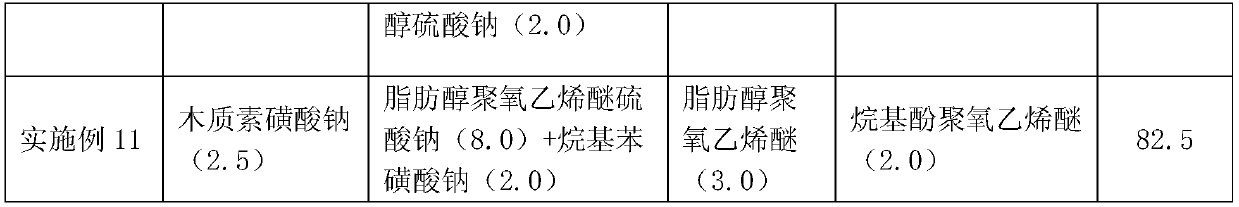

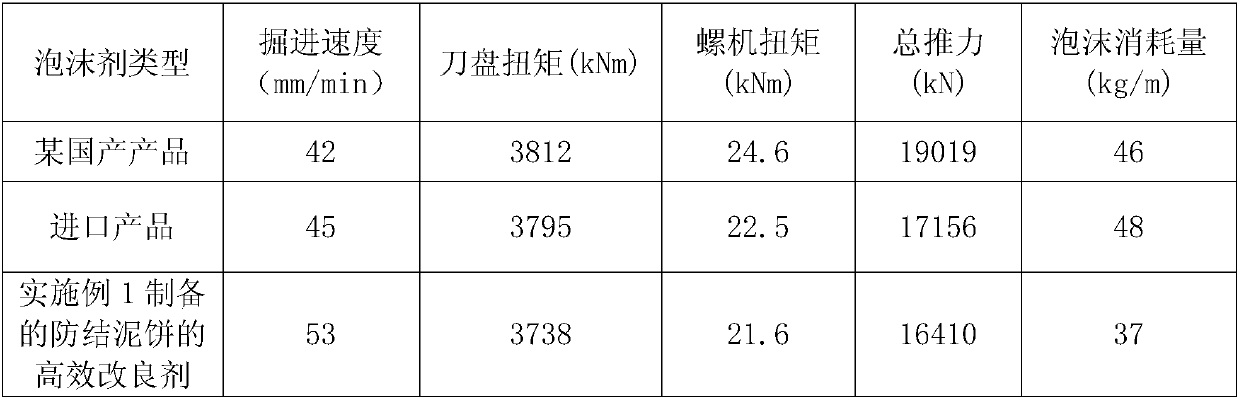

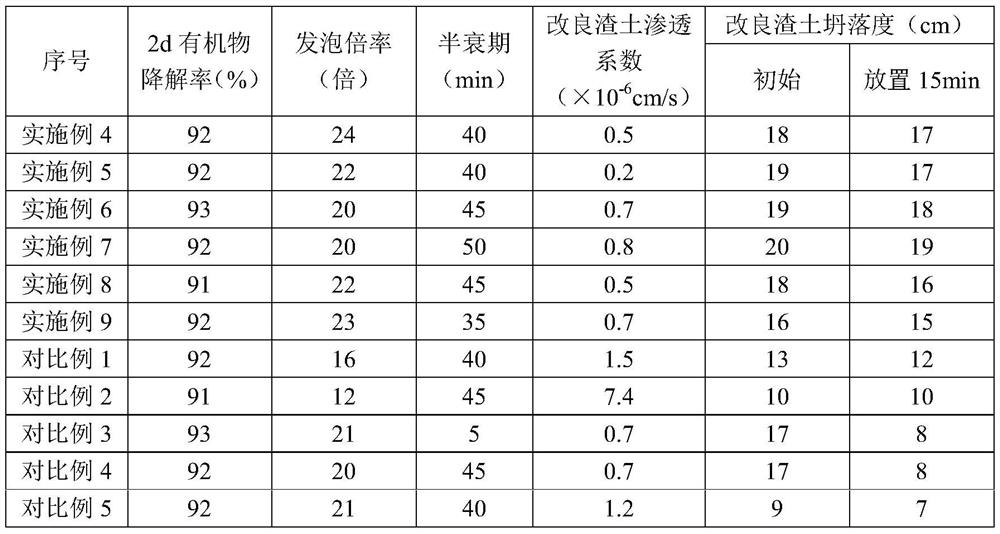

Efficient improver for preventing mud cake

ActiveCN106554780AReduce adhesionImprove flow plasticityBuilding constructionsOrganic fertilisersSodium lignosulfonateBalance water

The invention discloses an efficient improver for preventing mud cake. The efficient improver is prepared from 0.5 to 3.0% by mass of an anti-sticking additive, 4.0 to 10.0% by mass of an anionic surfactant, 1.0 to 4.0% by mass of a nonionic surfactant A, 1.0 to 4.0% by mass of a nonionic surfactant B and the balance water. The anti-sticking additive comprises one or two of sodium polyacrylate and sodium lignosulphonate. The efficient improver significantly reduces the adhesion of the dregs, reduces the adhesion of dregs to a cutter plate and blocking of the cutter plate, improves dreg plasticity and reduces energy consumption.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

New earth pressure balance shield machine and working method thereof

PendingCN110500108AImprove flow plasticityReasonable combinationUnderground chambersTunnel liningSlagAgricultural engineering

The invention discloses a new earth pressure balance shield machine and a working method thereof. The shield machine comprises a cutter head, a front shield, a middle shield, a miter gate, a tail shield, an assembling machine, a main drive and a screw conveyor. A front shield partition board is arranged between the front shield and the middle shield, front shield space is divided into two parts byinstalling a middle partition board in the front shield, the front is a mud chamber, and the rear is an air cushion chamber; the lower part of the middle partition board is not closed; the cutter head is connected with a big gear ring of the main drive by a support arm; a first gate, an air inlet and an overflow port are arranged on the front shield diaphragm board, and a second gate is arrangedon the miter gate; a passage gate and a passive mixing rod are arranged on the middle partition board; an active mixing rod is installed behind the cutter head; the first gate is arranged on the upperpart of the front shield partition board, and the lower part of the front shield partition board is provided with a slag conveying port. The new earth pressure balance shield machine is provided withthe mud chamber and the air cushion chamber, and a mud water balance shield play to the advantage. The shield machine further provides mixing rods, residual soil entering the mud chamber of the shield machine is stirred through the mixing rods, and flow plasticity of the residual soil is further increased.

Owner:POWERCHINA RAILWAY CONSTR +2

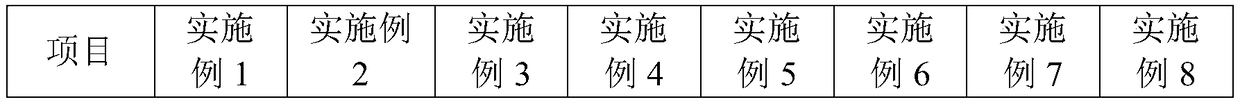

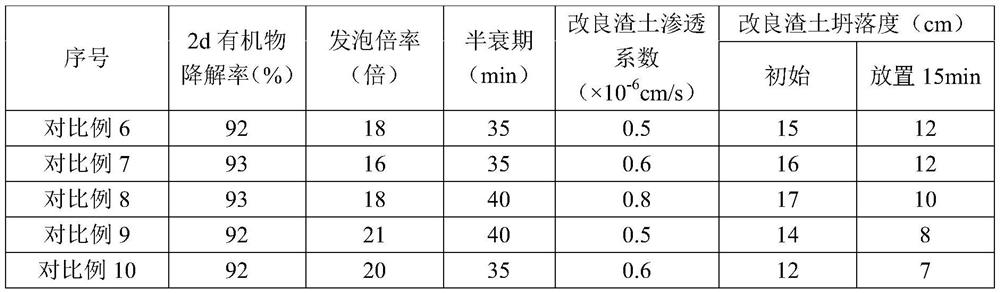

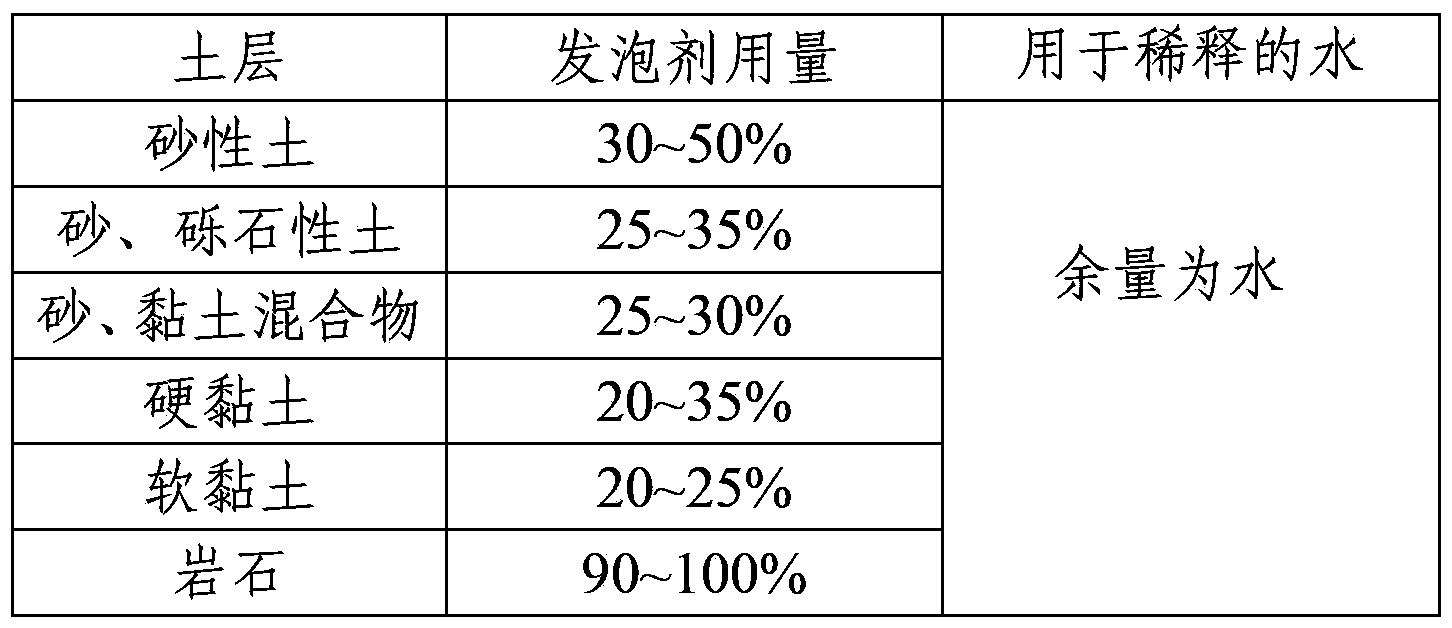

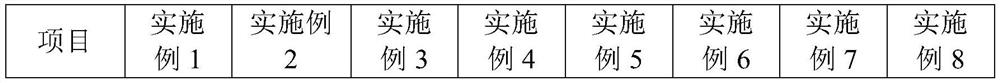

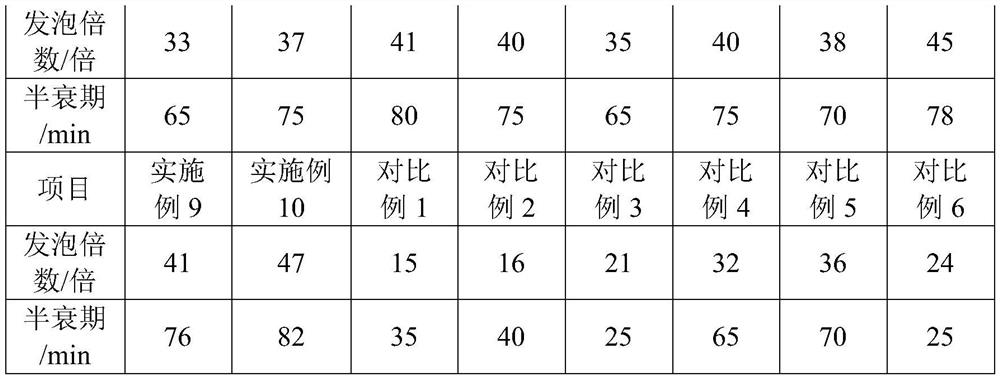

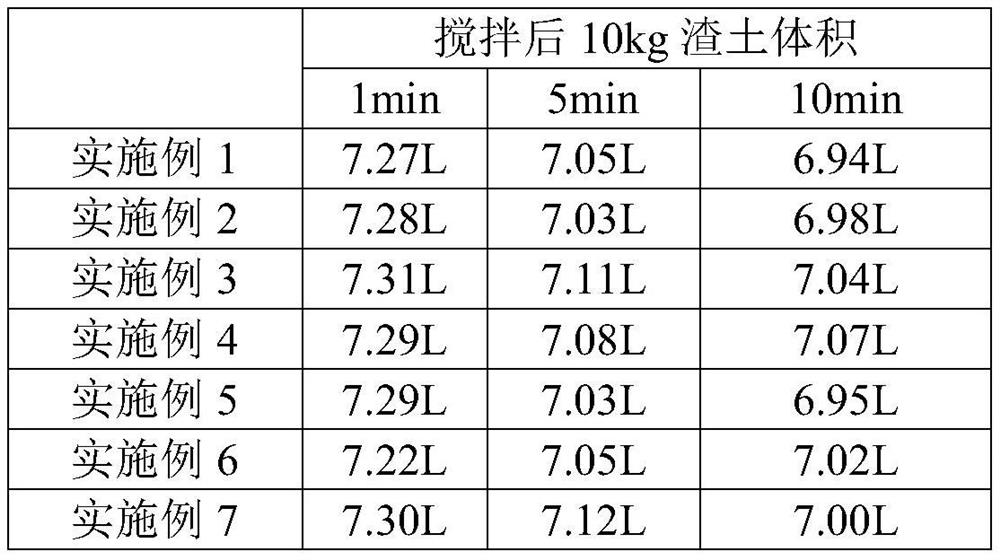

Foaming agent for improvement of slag oil of soil pressure balance shield and preparation method thereof

ActiveCN109054842AGood foaming effectEnhanced surface forceBuilding constructionsOrganic fertilisersPolyethylene oxideSlag

The invention provides a foaming agent for improvement of slag oil of a soil pressure balance shield and a preparation method thereof. The foaming agent for the improvement of the slag oil of the soilpressure balance shield is prepared from the following components in percentage by weight: 4% to 8% of alpha-alkenyl sodium sulfonate, 8% to 12% of lauryl sodium sulfate, 3% to 5% of alkylphenol polyoxyethylene, 0.05% to 0.2% of xanthan gum, 1% to 4% of coconut oil fatty acid diethanolamide, 1% to 3% of sodium gluconate, 0.5% to 2% of polyethylene oxide, 1% to 2% of polyaspartic acid, and the balance of water. The foaming agent has the advantages that by adopting the alpha-alkenyl sodium sulfonate, the lauryl sodium sulfate and the alkylphenol polyoxyethylene to prepare the foaming agent, thefoaming ability is enhanced under the compounding and cooperation function of the alpha-alkenyl sodium sulfonate, the lauryl sodium sulfate and the alkylphenol polyoxyethylene; the foaming time is greater than 30 times; by adopting the coconut oil fatty acid diethanolamide to enhance the surface action force of the air foam through cooperation, the stability of the foam under the high-speed shearing function of a knife disc is improved; the pressure fluctuation of a soil bin is reduced; the stability of the excavated surface of the shield is improved.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

Water-rich diabase and slate irregular mutual invasion rock shield residue soil improving method

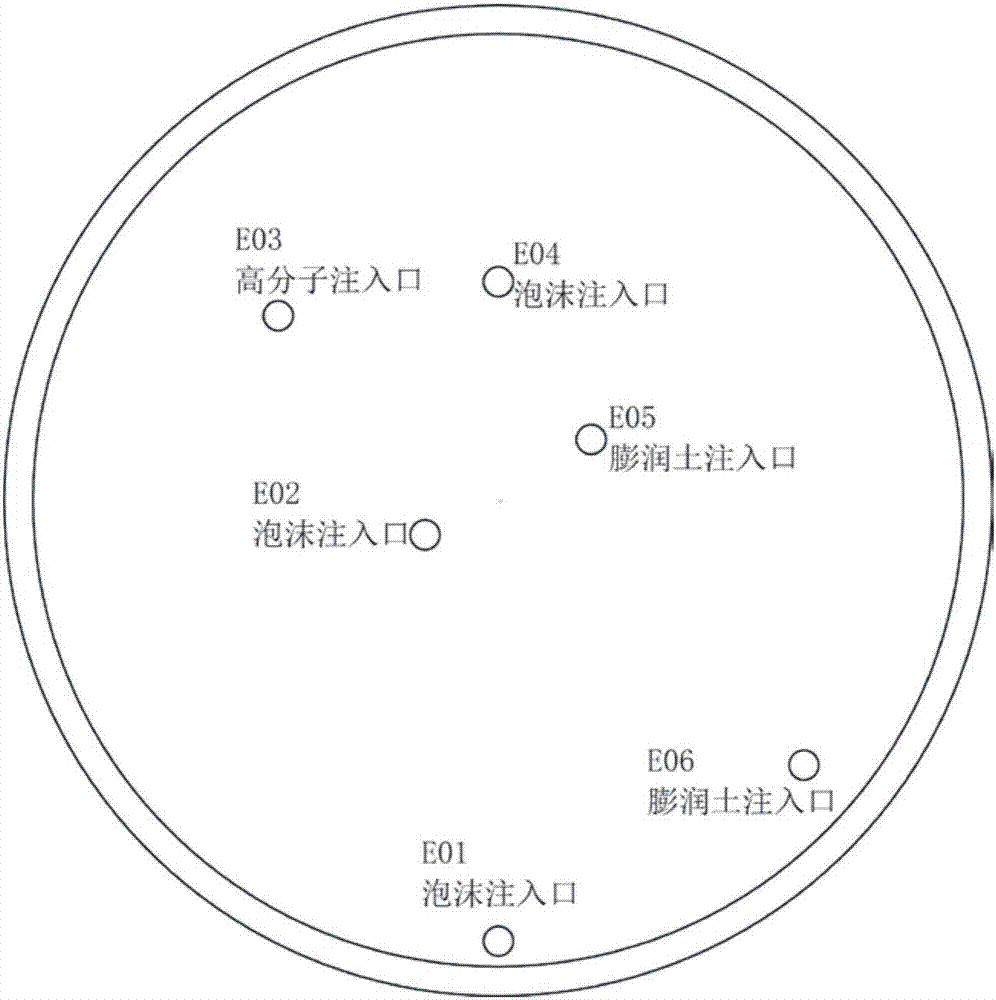

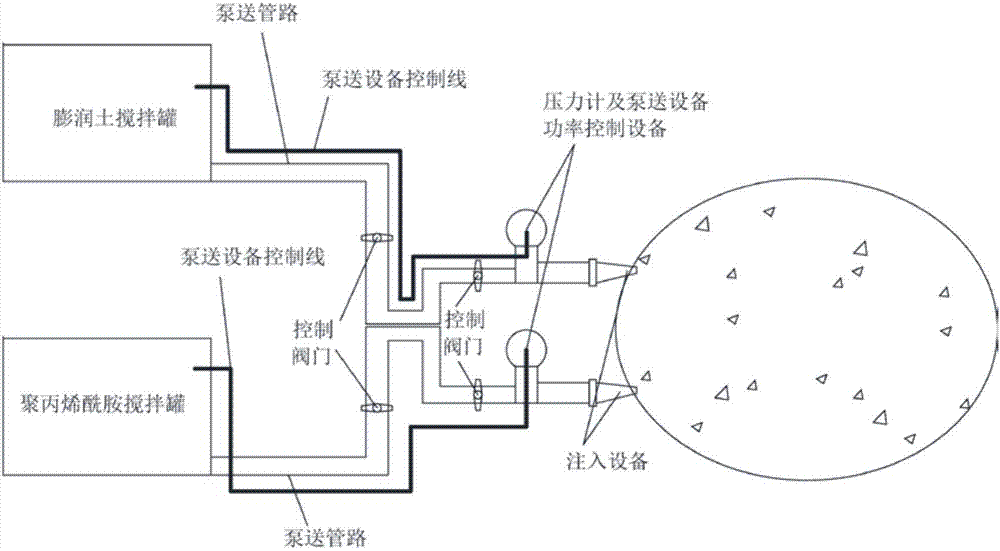

The invention discloses a water-rich diabase and slate irregular mutual invasion rock shield residue soil improving method. According to the method, through an injection passage of a cutter head panel and hole positions on each spider arranged in front of a shield cutter head, a polymer injection system is used for injecting high-volume high-molecular polymers into residue soil; meanwhile, through an injection passage and hole positions in a soil cabin, a foam mixing generating system is used for injecting medium-concentration foam into the residue soil for composite injection.

Owner:BEIJING URBAN CONSTR DESIGN & DEV GRP CO +1

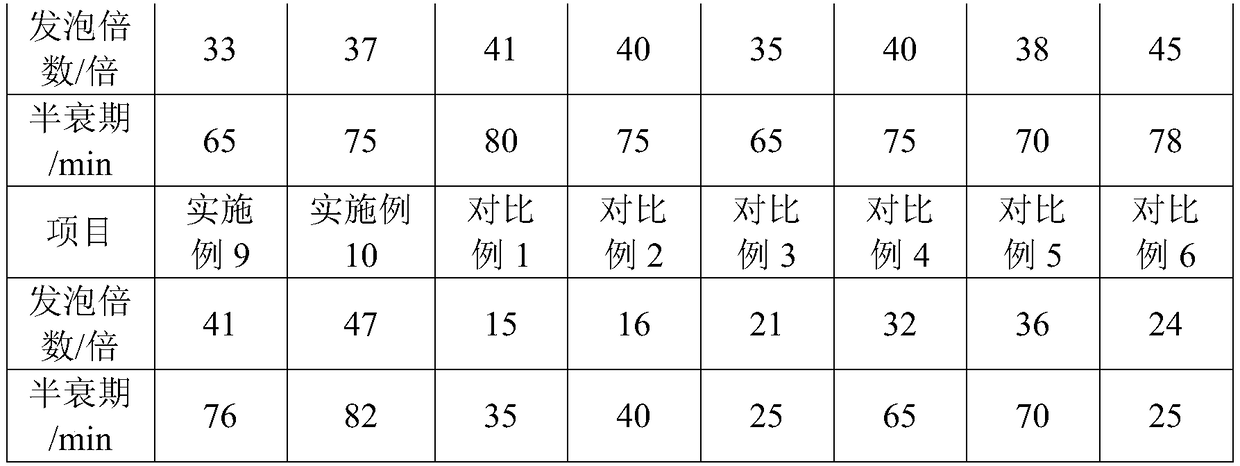

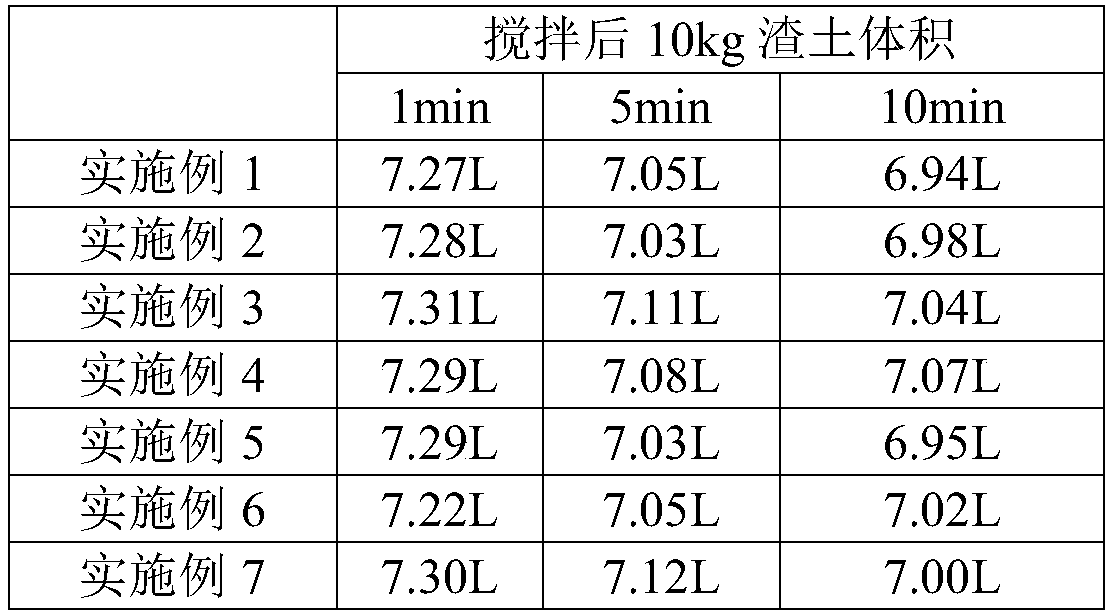

Dispersant for improving clay and preparation method thereof

InactiveCN110157446AReduce viscosityImprove flow plasticityBuilding constructionsOrganic fertilisersShield tunnelingViscosity

The embodiment of that present application relates to the technical field of underground engineering construction material, in particular to a dispersant for improving clay and a preparation method thereof. The dispersant is composed of organic dispersant, inorganic dispersant, dispersing assistant, surfactant and water, in which, by weight percent, wherein the weight percent content of the organic dispersant is 1 to 3 percent, the weight percent content of the inorganic dispersant is 4 to 10 percent, the weight percent content of the dispersion assistant is 2 to 6 percent, the weight percentcontent of the surfactant is 1 to 5 percent, and the weight percent content of the water is 76 to 92 percent. The dispersant can reduce the viscosity of clay, improve the flow plasticity and dispersion of clay, thus ensuring the shield tunneling in clay ground to avoid mud cake phenomenon, which is conducive to ensure the smooth progress of shield tunneling.

Owner:CHINA RAILWAY FIFTH SURVEY & DESIGN INST GRP

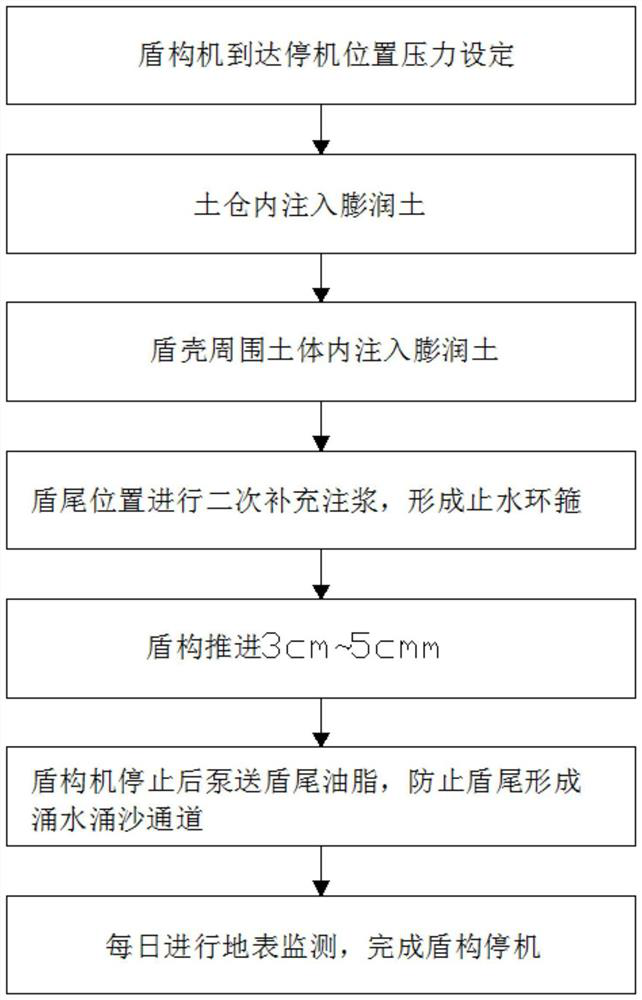

Long-time shutdown construction method for water-rich sand layer shield

InactiveCN112523763AImprove stabilityImprove flow plasticityUnderground chambersTunnel liningOil and greaseStructural engineering

The invention relates to the technical field of shield construction, in particular to a long-time shutdown construction method for a water-rich sand layer shield. The method comprises the following steps that S1, the pressure of a shield tunneling machine reaching a stop position is set; S2, bentonite is injected into the soil bin; S3, bentonite is injected into a soil body around the shield shell; S4, secondary supplementary grouting is conducted on the shield tail position, and a water stop hoop is formed; S5, the shield is pushed by 3 cm to 5 cm; S6, after the shield machine stops, pumpingshield tail grease; and S7, earth surface monitoring is conducted every day, and shield shutdown is completed. By means of the method, the influence of soft geology on long-time shutdown of the shieldis avoided, it is guaranteed that shield construction meets the design requirement, and construction recovery of the shield tunneling machine is facilitated. The method is mainly applied to the aspect of long-time shutdown of the water-rich sand layer shield.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

Muck improvement material for earth pressure balance jacking pipe in anhydrous sand layer

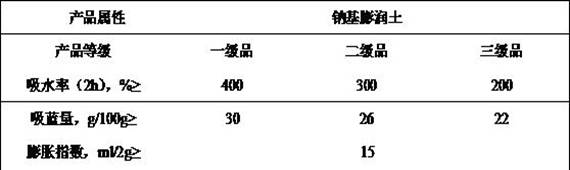

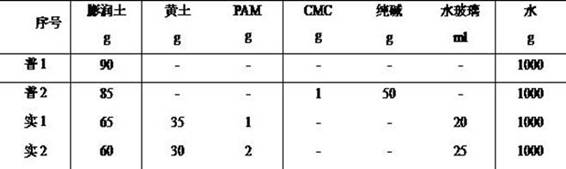

ActiveCN112552929AEasy to reinforceReduce settlement displacementBuilding constructionsOrganic fertilisersSoil scienceSodium Bentonite

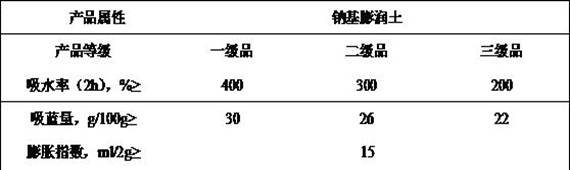

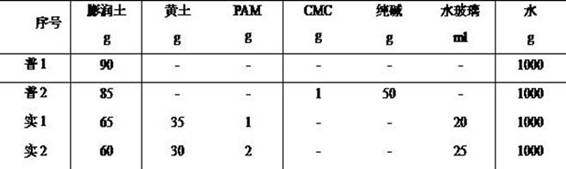

The invention relates to a muck improvement material for an earth pressure balance jacking pipe in an anhydrous sand layer, the muck improvement material is composed of an improver and a filler, the improver is formed by uniformly mixing and stirring bentonite, loess, an admixture and water, the bentonite is sodium bentonite, the loess is Q3 loess, the admixture is polyacrylamide (PAM) and water glass, the mass ratio of the sodium bentonite to the Q3 loess to the polyacrylamide (PAM) to the water glass to the water is 50-70: 30-40: 1-2: 20-30: 1000; the filler is formed by uniformly mixing andstirring loess and water, the loess is Q3 loess, and the mass ratio of the Q3 loess to the water in the filler is 1: 0.8-1. By applying the method, the improvement effect of muck cut off from the tunnel face in the soil cabin during jacking construction of the jacking pipe in the anhydrous sand layer can be effectively improved, the settlement displacement of the soil body in front of the tunnelface is effectively reduced, and the method has positive significance in jacking pipe engineering construction.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

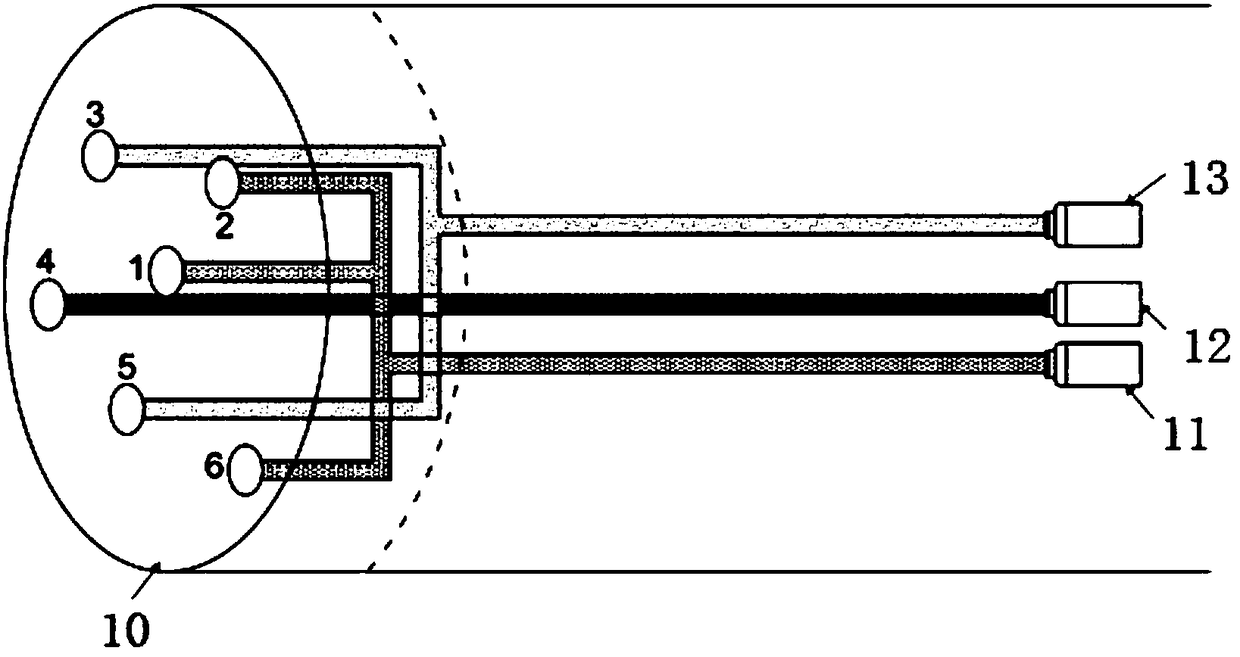

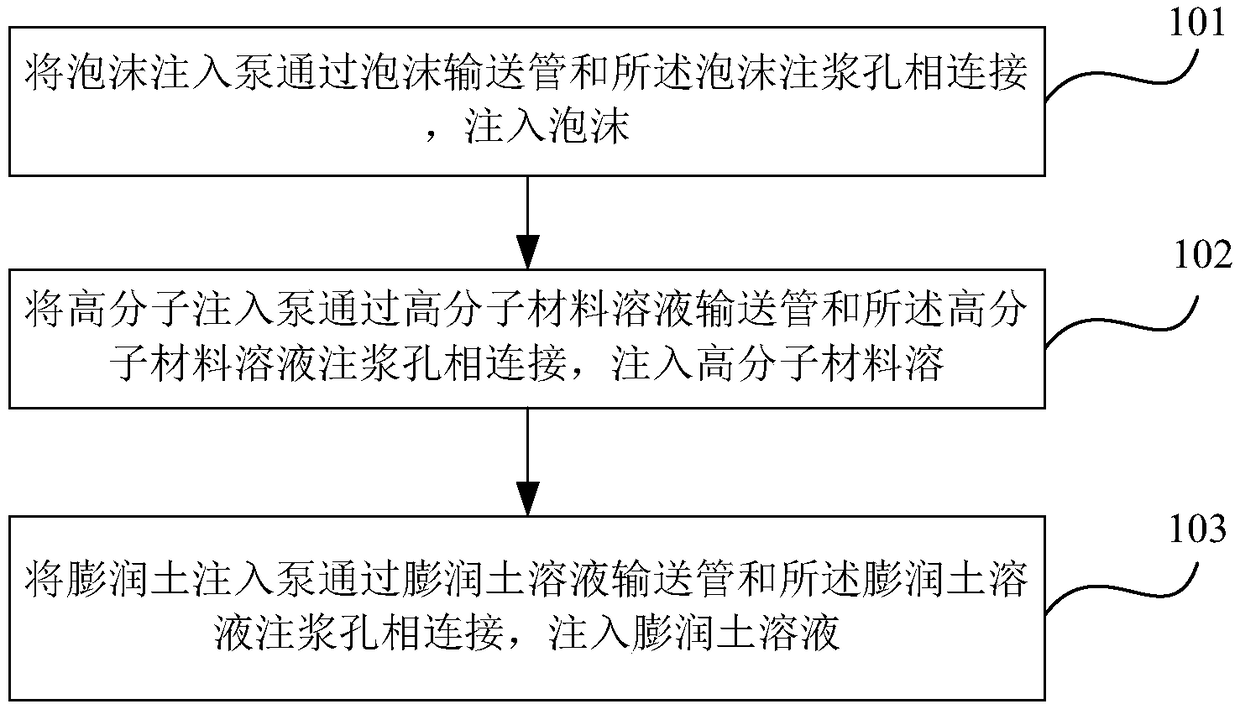

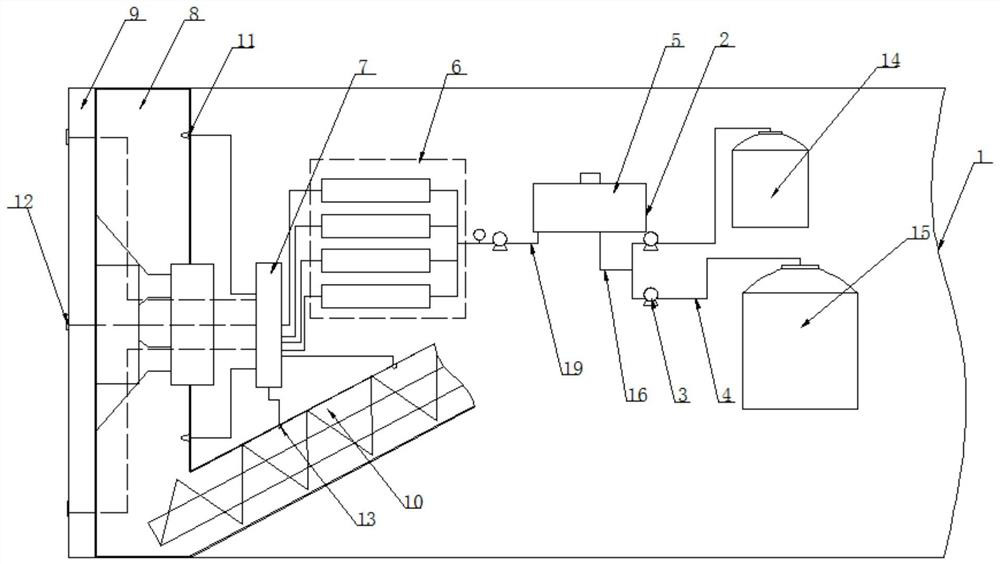

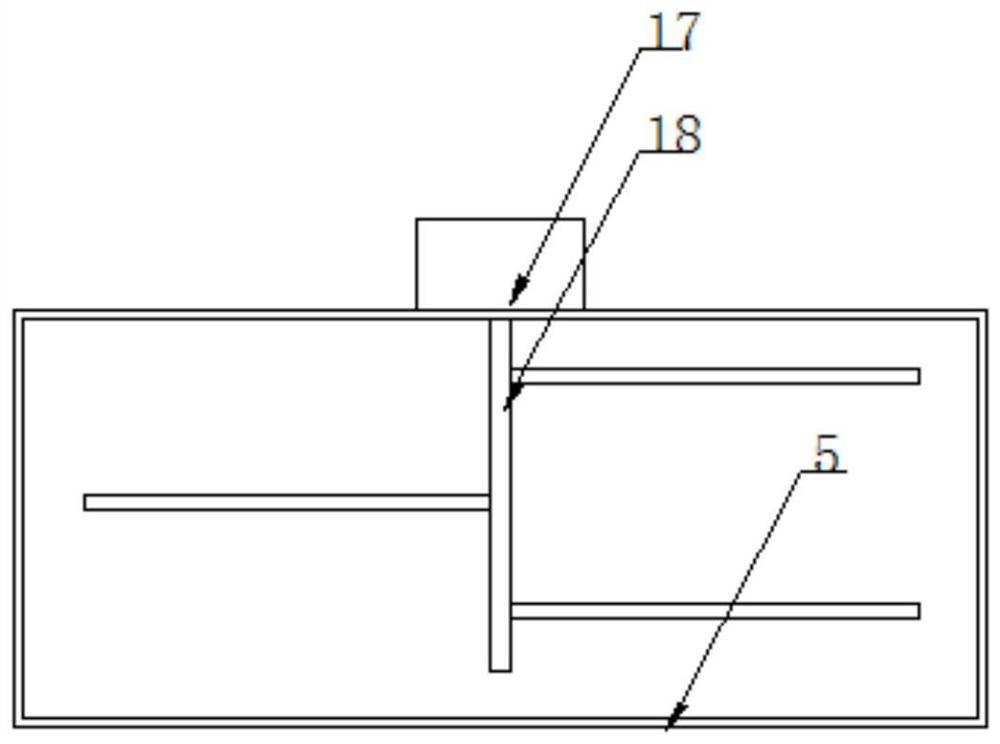

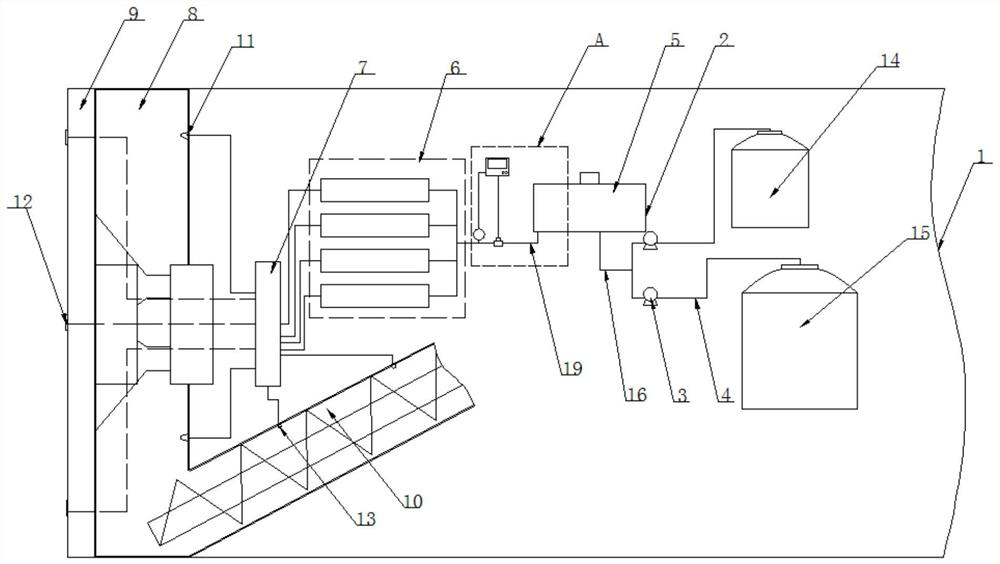

Slag soil improvement construction device and method for shield construction

The embodiment of the invention provides a slag soil improvement construction device and method for shield construction. The device comprises a shield cutter head, a foam injection pump, a polymer injection pump and a bentonite injection pump; at least three grouting holes are formed in the shield cutter head from the center position to the outside, and the three grouting holes include a foam grouting hole, a bentonite solution grouting hole and a polymer material solution grouting hole; the foam injection pump is connected with the foam grouting hole through a foam conveying pipe; the polymerinjection pump is connected with the polymer material solution grouting hole through a polymer material solution conveying pipe; the bentonite injection pump is connected with the bentonite solutiongrouting hole through a bentonite solution conveying pipe. The device ensures the smooth tunneling of a shield, the foam injection hole ensures that the foam plays a role in reducing the resistance tothe cutter head, and the bentonite solution grouting hole and the polymer material solution grouting hole achieve the purpose of improving the flow plasticity and permeability of slag soil during theconstruction of a coarse sand layer zone in the rich water.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

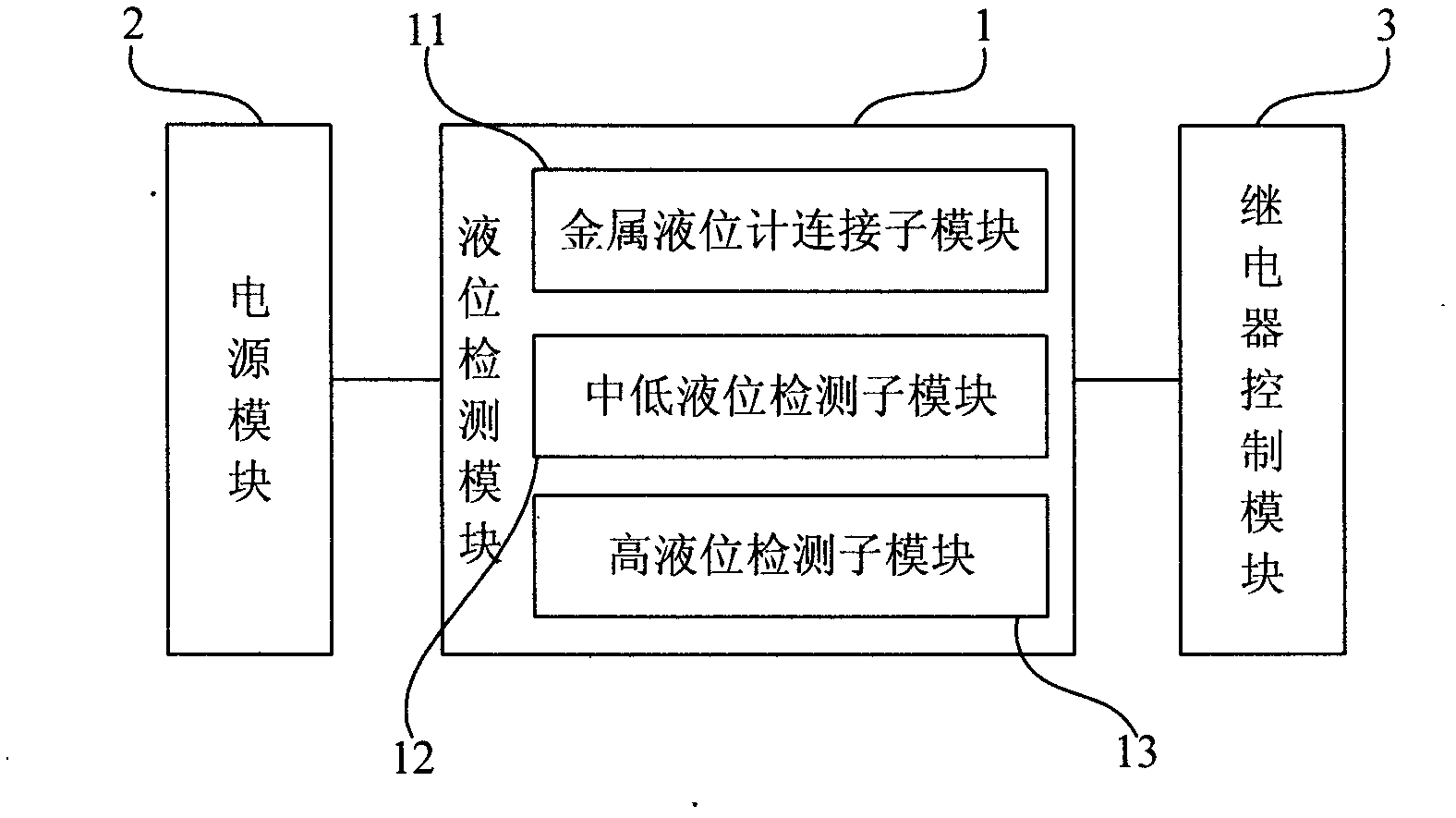

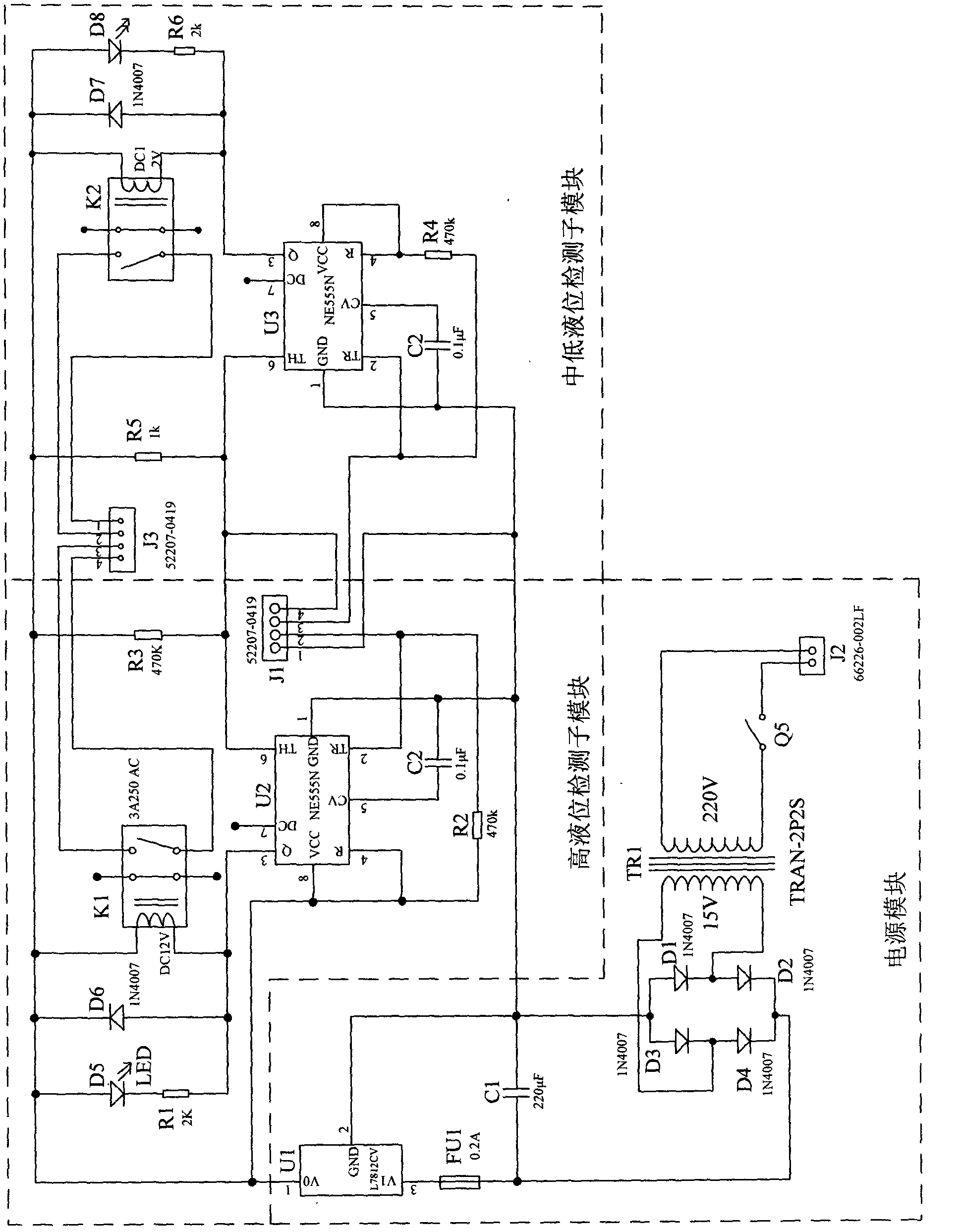

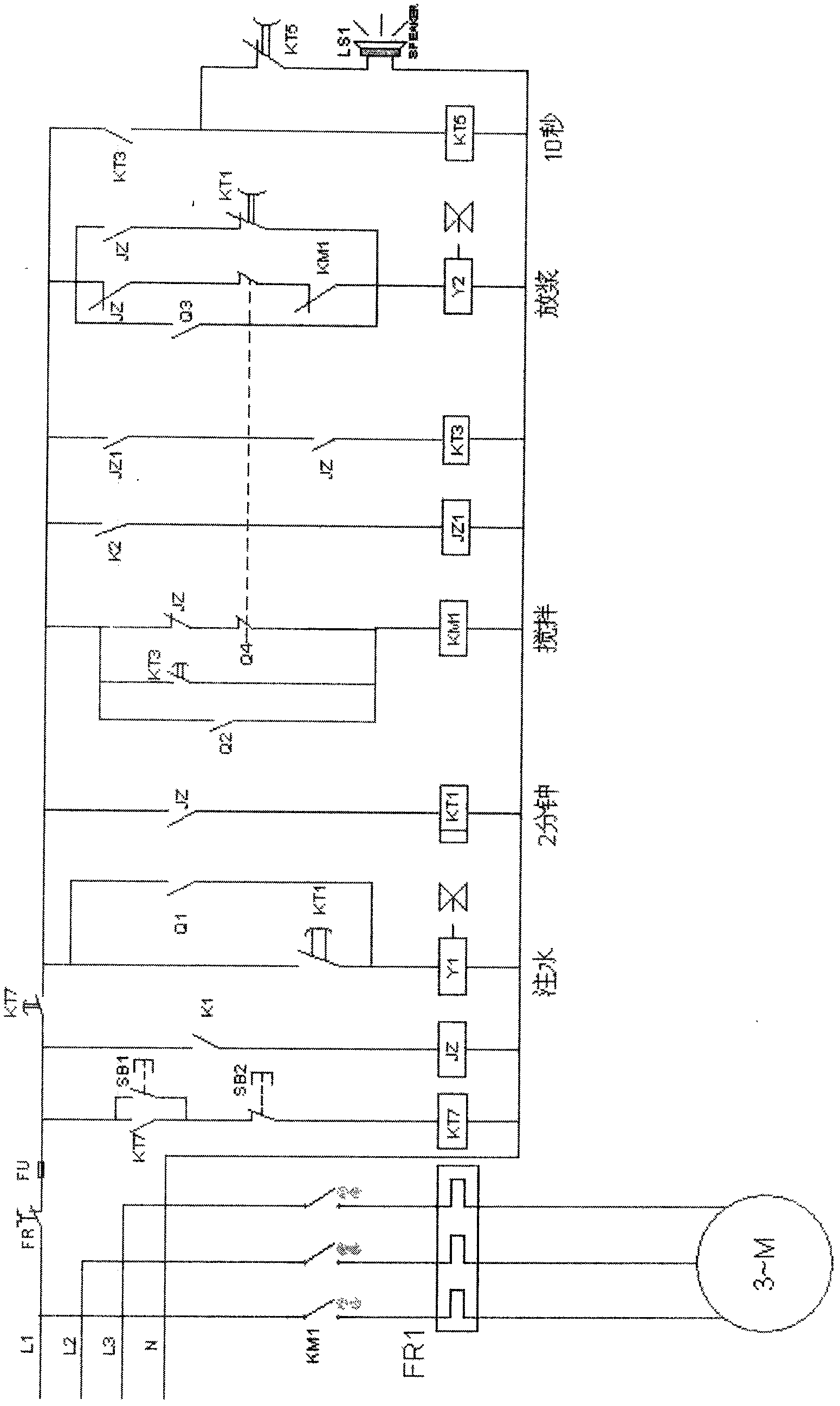

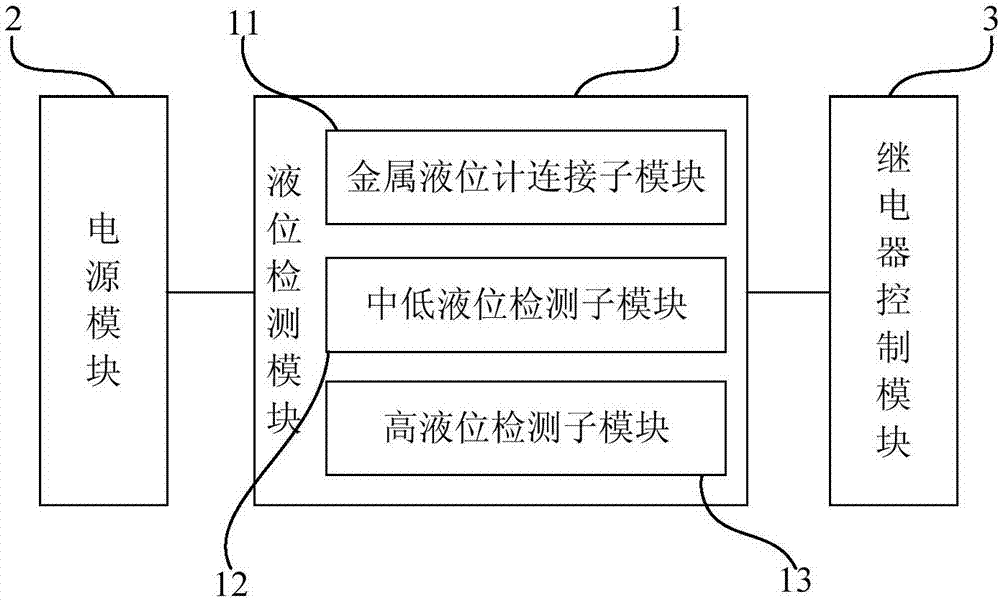

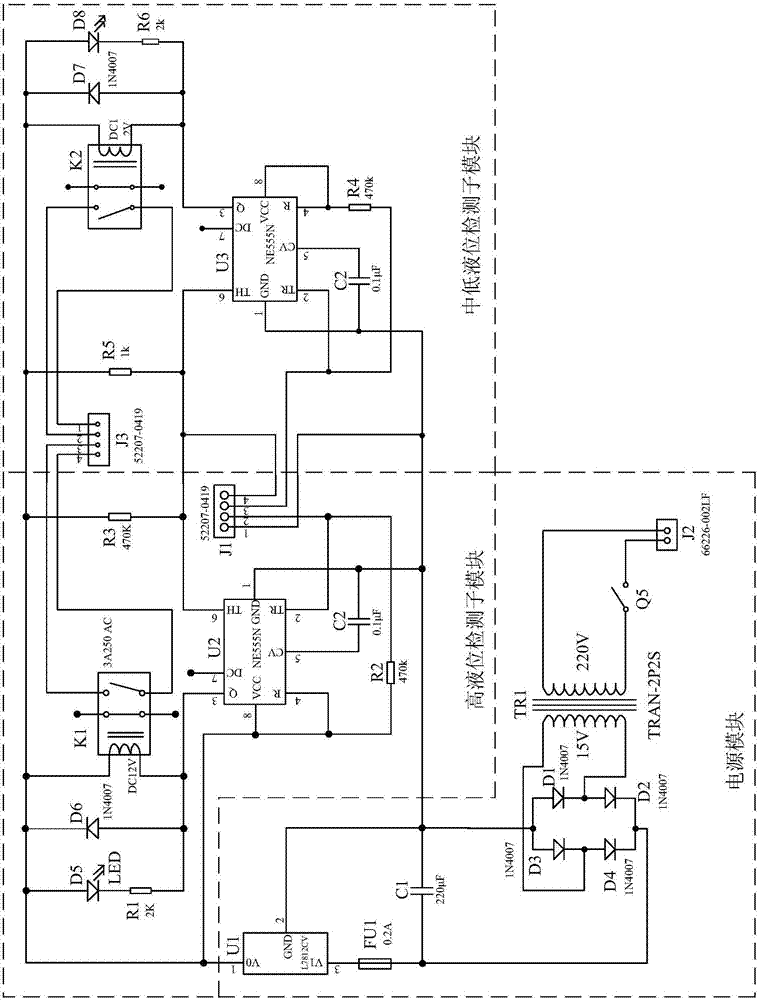

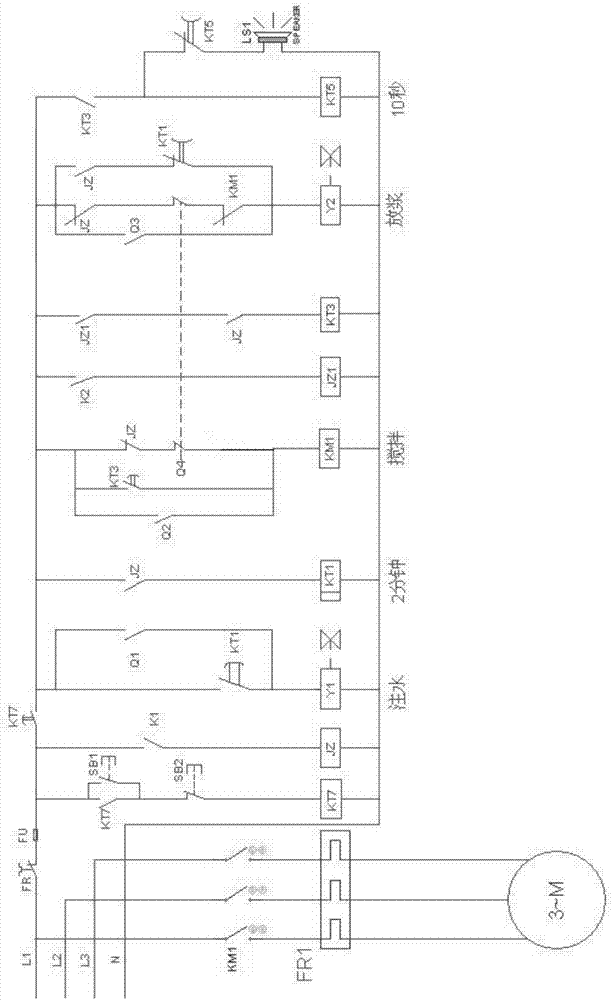

Bentonite slurrying control system for shield construction and method

The invention discloses a bentonite slurrying control system for shield construction. The bentonite slurrying control system for the shield construction comprises a liquid level detection module, a power source module, and a relay control module, wherein the liquid level detection module is used for detecting a liquid level of a stirring tank and outputting different signals according to a low liquid level of the stirring tank, a middle liquid level of the stirring tank, and a high liquid level of the stirring tank, the power source module supplies power to the liquid level detection module, and the relay control module is used for controlling working conditions of the stirring tank according to the different signals output by the liquid level detection module. The liquid level detection module is connected with the relay control module. The liquid level detection module comprises a metal liquid level meter connection sub-module, a high liquid level detection sub-module, and a middle and low liquid level detection sub-module. The invention further discloses a control method. Due to the fact that the bentonite slurrying control system for the shield construction and the control method are adopted, control to proportion and output of bentonite slurry in the full section non-water sand bed shield construction can be achieved, at the same time, soil flow ductility of shield muck can be improved, and abrasion degree of a shield cutter-disc is decreased.

Owner:THE 3RD ENG CO LTD OF CHINA RAILWAY 18TH BUREAU GRP +1

Composite balancing earth-pressure shielding machine

A composite earth pressure balance shield machine, comprising: a casing (1), a cutter head (2), a soil bin (3), a screw conveyor (4) and a propelling oil cylinder (6), characterized in that: the The cutter head is located at the front of the casing, and the cutter head is provided with a tearing knife (21) and a cutting knife (22) at the same time, and the blade of the cutting knife is slightly behind the tearing knife; the soil bin is located at the rear of the cutter head , and the back wall of the soil bin is provided with a grouting hole (32), an air pressure balance device (5) is installed at the rear of the soil bin, and an excavation port (31) is provided at the bottom of the soil bin; the lower entrance of the screw conveyor is connected to the soil bin. The excavation openings of the casings are connected; the propelling oil cylinders are evenly arranged along the inner wall of the casing. The shield machine can solve the normal excavation problem in the highly permeable gravel-sand soil layer or the egg (gravel) stone soil layer, or the normal excavation problem when it needs to pass through obstacles such as large stones over 30 cm.

Owner:CHINA SHENHUA ENERGY CO LTD

Foaming agent for improving shield muck in cohesive soil layer and preparation method and use method of foaming agent

PendingCN114015448AStable expansion ratioLow priceBuilding constructionsOrganic fertilisersSucroseSoil science

The invention discloses a foaming agent for improving shield muck in a cohesive soil layer. The foaming agent comprises a foaming agent base solution, powder abelmoschus manihot gum as an additive and water; the volume part ratio of the foaming agent base solution to the water is (3-15): 100, and the mass part ratio of the additive to the water is (0.025-0.1): 100; the foaming agent base solution comprises a solid material alkyl sucrose glycoside serving as a main foaming agent and a liquid material fatty alcohol-polyoxyethylene ether sodium sulfate serving as an auxiliary foaming agent, and the volume fraction ratio of the alkyl sucrose glycoside to the fatty alcohol-polyoxyethylene ether sodium sulfate is 2: 1. Meanwhile, the invention further discloses a preparation method of the foaming agent for improving the shield muck in the cohesive soil layer and a use method of the foaming agent for improving the shield muck in the cohesive soil layer. The foaming agent is suitable for earth pressure balance shield muck improvement construction of the cohesive soil layer, the foaming ratio of the foaming agent is higher than 20 times, the half-life period is longer than 1200 s, the half-life period is almost zero within 5 min, generated foam is high in stability, high in gas-liquid level strength and high in foam density, and the foaming agent can enter soil gaps easily to improve the flow plasticity of the soil.

Owner:FUZHOU UNIV

Water-reducing improver for shield construction of water-rich stratum and construction method thereof

InactiveCN107841310AImprove flow plasticityImprove permeabilityBuilding constructionsOrganic fertilisersSlagPhosphoric acid

The invention discloses a water-reducing improver for shield construction of a water-rich stratum and a construction method thereof. The water-reducing improver is prepared from water glass and concentrated phosphoric acid solution, wherein the water glass and the concentrated phosphoric acid solution react with water in slag soil to generate silica gel and form the water-reducing improver. The construction method of the water-reducing improver comprises the following steps: (1) when the water content and the water pressure of the stratum are large to cause a serious spewing phenomenon in theshield construction, starting an injection pump of water glass solution and concentrated phosphoric acid solution, and stopping operation of a spiral soil remover; (2) opening a grouting hole, firstlyinjecting the concentrated phosphoric acid solution with the concentration of 90%; (3) injecting the concentrated phosphoric acid solution for about 5-10 minutes, and after the concentrated phosphoric acid is fully mixed with the slag soil, stopping grouting and washing a grouting pipe; (4) opening the grouting hole, and injecting the water glass solution; (5) injecting the water glass solution for about 5-10 minutes, and leading the water glass solution and the concentrated phosphoric acid solution to react fully; (6) washing the grouting pipe and restarting the spiral soil remover to removeinternal slag soil.

Owner:北京城建中南土木工程集团有限公司 +1

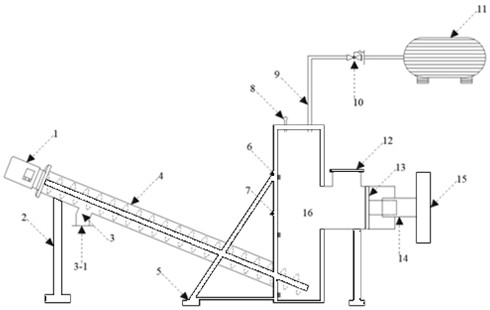

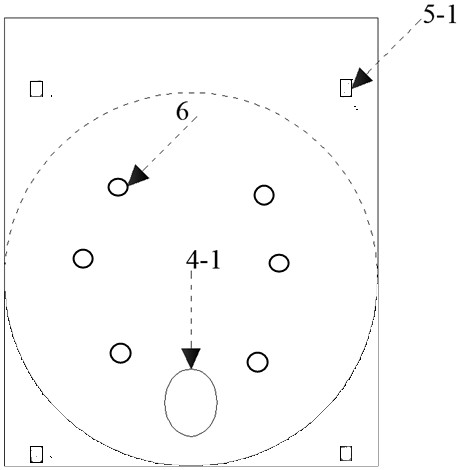

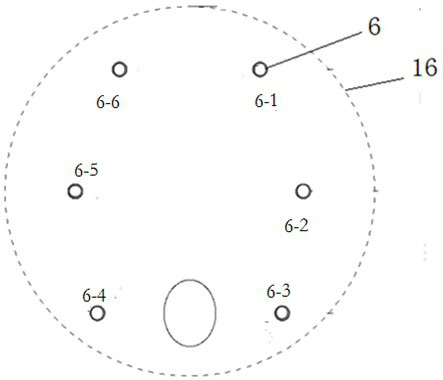

Testing device and testing method for muck improvement effect evaluation

ActiveCN114858657AEnsure safe drivingImprove flow plasticitySolid waste managementFlow propertiesScale modelStructural engineering

The invention belongs to the technical field of muck improvement in shield construction, and provides a test device and a test method for muck improvement effect evaluation, which can simulate the physical and mechanical properties of muck in the actual shield excavation and deslagging process and intuitively evaluate the unobstructed degree of muck discharge. The actual pressure value of a shield soil cabin can be simulated, and whether improved muck is homogeneous and good in flow plasticity or not is evaluated from the new angle of transmission efficiency and apparent density of muck force; the device is reasonable in design and high in operability, a small-scale model test is carried out before actual shield construction, the construction efficiency can be improved, and safe tunneling of a shield is guaranteed.

Owner:GUANGZHOU METRO DESIGN & RES INST

A kind of soil improvement material for earth pressure balance pipe jacking in anhydrous sand layer

ActiveCN112552929BEasy to reinforceReduce settlement displacementBuilding constructionsOrganic fertilisersSodium BentoniteSoil science

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

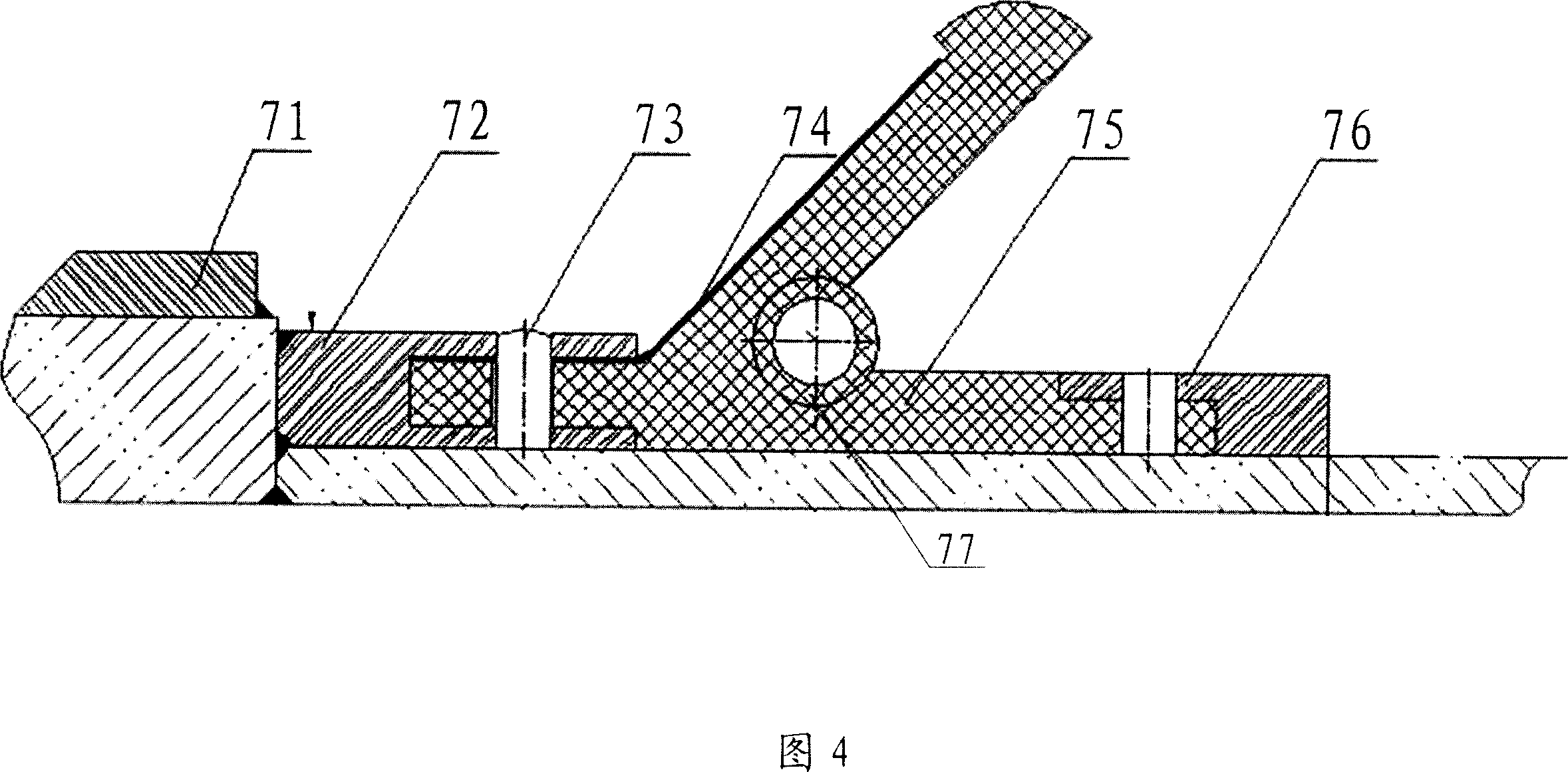

Combined balance shield machine

The composite balanced tunnel shield machine includes machine shell, capstan in the front of the machine shell, earth bin on the back of the capstan, screw conveyer for conveying cut earth and driving oil cylinders distributed homogeneously around the machine shell. It features the capstan with both tearing tools and cutting tools; the earth bin with several slurry injecting holes in the back wall; and pneumatic balancer installed in the back part of the earth bin. The screw conveyer is provided with two gates including the first hydraulic gate and the second manual gate; and 26 driving oil cylinders are distributed homogeneously around the machine shell. There are in the shield machine tail three tail sealing steel wire brushes with tail grease in between and the last brush capable of being replaced. Or, the shield machine tail may be water stopping sealed with polyurethane or other material and the last brush may replaced with type-Y sealing rubber brush for stopping water.

Owner:SHANGHAI FOUND ENG GRP

A special dreg improvement agent for shield tunneling in sand and pebble strata

ActiveCN106566555BIncrease the speed of excavationImprove cohesionOther chemical processesBuilding constructionsOsmotic coefficientSediment

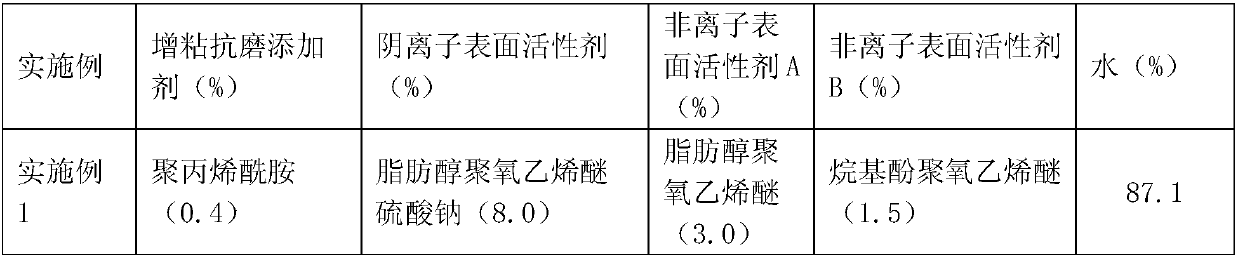

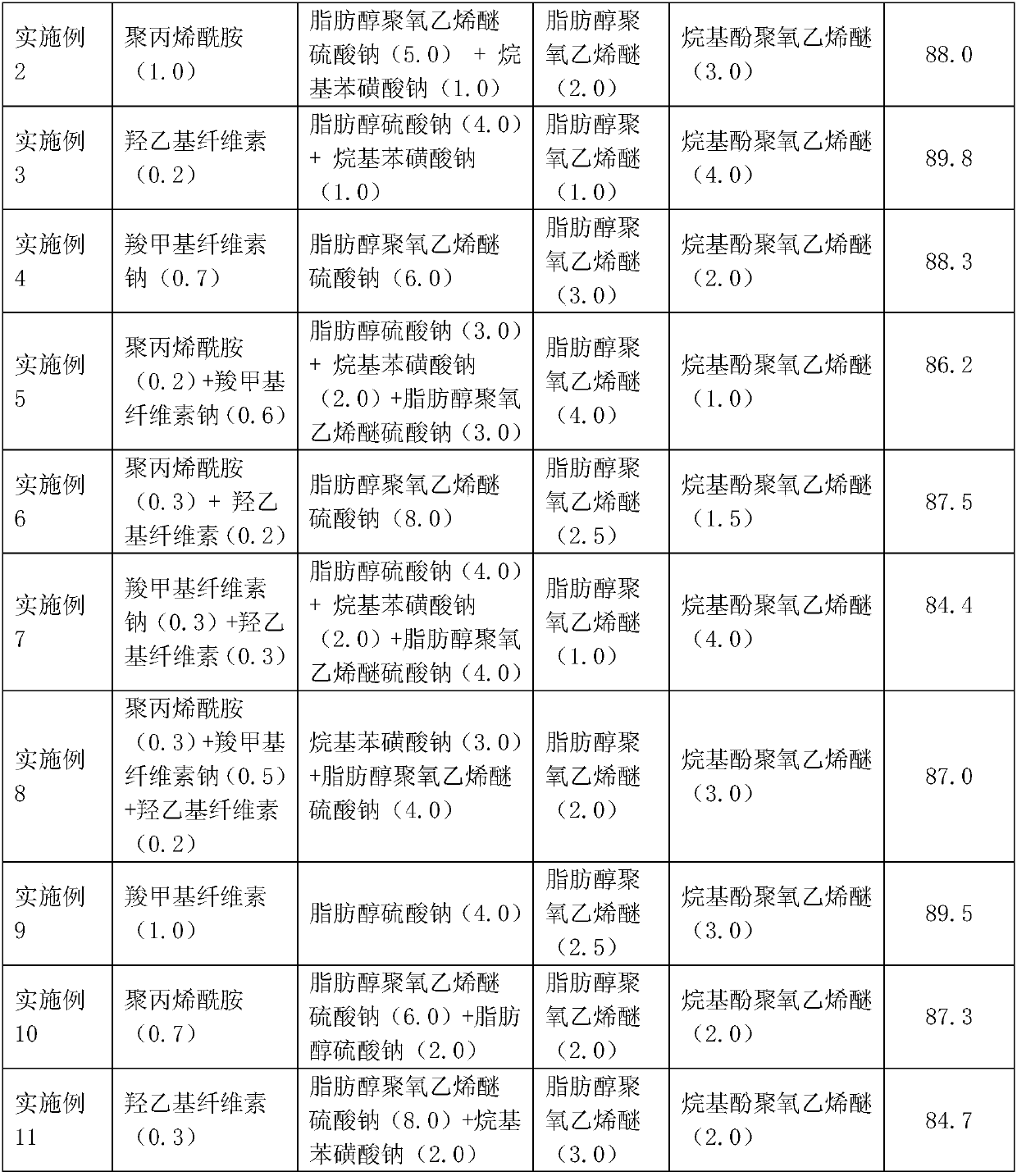

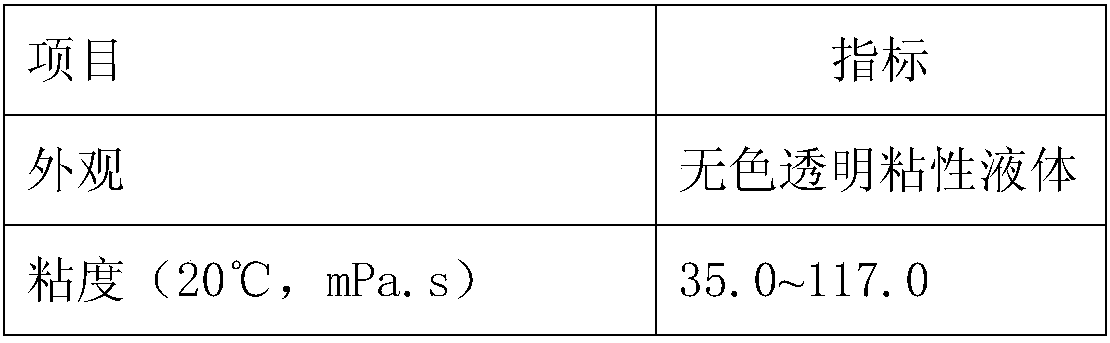

The invention discloses a muck improver special for a sandy gravel stratum shield. The muck improver is prepared from the following raw materials in percent by mass: 0.2-1.0% of a tackifying antiwear additive, 4.0-10.0% of an anionic surfactant, 1.0-4.0% of a nonionic surfactant A, 1.0-4.0% of a nonionic surfactant B and the balance of water with a total mass percent of 100%, wherein the tackifying antiwear additive is one or a mixture of anionic polyacrylamide, sodium carboxymethylcellulose and hydroxyethyl cellulose. The muck improver special for the sandy gravel stratum shield remarkably increases muck cohesive force, decreases osmotic coefficient and internal friction angle of muck, reduces abrasion of muck to equipment, improves flow plasticity of muck and reduces energy consumption.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

A kind of admixture for improving water-rich sand egg formation shield dregs and its preparation method

The present invention provides a water-rich sand egg formation shield dreg improvement admixture and a preparation method thereof. The dreg improvement admixture is a water-rich sand egg formation shield dreg improvement admixture, which comprises or consists of the following mass: Content composition: tackifier A 0.1~1wt%, tackifier B 0.025~1wt%, surfactant 0.025~0.5wt%, pumping agent 1~10wt%, pH regulator 0.01~0.06wt%, mineral 5-15wt% class modifier and water. After the dregs improvement admixture described in the present invention is used to improve the shield muck in the water-rich sand egg formation, it can better avoid and reduce the occurrence of gushing during the construction of the earth pressure balance shield, and ensure the safe and smooth implementation of the construction. And the cut soil is easy to transport.

Owner:SHANDONG UNIV

A high-efficiency improver for anti-sludge cake

ActiveCN106554780BReduce adhesionImprove flow plasticityBuilding constructionsOrganic fertilisersSodium lignosulfonateBalance water

The invention discloses an efficient improver for preventing mud cake. The efficient improver is prepared from 0.5 to 3.0% by mass of an anti-sticking additive, 4.0 to 10.0% by mass of an anionic surfactant, 1.0 to 4.0% by mass of a nonionic surfactant A, 1.0 to 4.0% by mass of a nonionic surfactant B and the balance water. The anti-sticking additive comprises one or two of sodium polyacrylate and sodium lignosulphonate. The efficient improver significantly reduces the adhesion of the dregs, reduces the adhesion of dregs to a cutter plate and blocking of the cutter plate, improves dreg plasticity and reduces energy consumption.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

A kind of easily degradable environment-friendly dispersing foam agent for mudstone geological shield and preparation method

ActiveCN112552922BHigh viscosityEasy to degradeBuilding constructionsOrganic fertilisersCarrageenanEthyl group

The invention relates to an easily degradable environment-friendly dispersing foaming agent for mudstone geological shield and a preparation method. The foaming agent is calculated according to the weight percentage, and is composed of the following raw materials by weight percentage: 5-15% of alkyl ethyl sulfonate , rhamnolipid 2-5%, lactate 1-3%, carrageenan 0.5-1%, citric acid 1-3%, potassium tannin 0.5-2%, chitosan 0.2-0.7%, more The amount is water. The raw materials used in the present invention can be rapidly degraded by microorganisms in the natural environment, and there is no secondary toxic by-products, which highlights the great environmental protection feature. The prepared foaming agent has the advantages of small environmental impact, strong foaming ability, good foam stability, fast mudstone dispersion speed, and excellent slag soil improvement effect. It solves the technical problems such as the traditional foaming agent polluting the soil and water environment and the mudstone dispersion effect is poor, expanding the backfill treatment method of shield slag, and at the same time increasing the efficiency of mudstone geological shield, reducing the cost of shield construction, environmental protection and economy. The benefits are significant.

Owner:RAILWAY NO 10 ENG GRP CO LTD +1

Foaming agent for earth pressure balance shield machine

The invention discloses a foaming agent for an earth pressure balance shield machine. The foaming agent for the earth pressure balance shield machine comprises the following ingredients: by weight, 6-12% of sodium fatty alcohol ether sulfate, 3-6% of fatty acid diethanolamide, 3-6% of lauramidopropylamine oxide, 4-5% of sodium aliphatic alcohol sulfate, 0.2-0.3% of methyl chloride isothiazolinone, 0.1-0.2% of disodium ethylenediamintetraacetate, and the balance deionized water. All the ingredients are evenly mixed into colorless transparent water-solubility solution under ordinary temperature, density of the solution under the temperature of 25 DEG C is 1.05 + / - 0.05 grams per cubic meter, and potential of hydrogen value is 7+-0.5. The foaming agent for the earth pressure balance shield is fine, rich and stable in foam, long in foam half-life period and high in permeability, capable of obviously reducing torque of a tool plate due to excellent lubricating performance of the agent, environment-friendly, and capable of meeting the requirement of improving muck during a digging process of the earth balance shield machine.

Owner:GUANGZHOU CHAIVO ABRASIVES

Residue soil improvement system of shield tunneling machine

The invention discloses a shield tunneling machine muck improvement system, and belongs to the technical field of shield tunneling machine muck improvement, the shield tunneling machine muck improvement system comprises a shield tunneling machine body, the front end of the shield tunneling machine body is provided with a cutterhead, a soil bin and a screw conveyor, the soil bin is located on the rear side of the cutterhead and is communicated with a discharging runner on the cutterhead, and the screw conveyor is fixedly installed at the bottom of the rear side of the soil bin; the shield tunneling machine comprises a shield tunneling machine body, the shield tunneling machine body is internally provided with a soil bin, the soil bin is communicated with the bottom of the soil bin, and the shield tunneling machine body is further internally provided with a foam system used for injecting a foaming agent into muck so as to improve the muck. The additive is mixed with the soil slag through rotary stirring of the cutter head, stirring of the soil bin stirring device or rotary stirring of the spiral conveyor, so that the slag soil cut by a shield has good flow plasticity, appropriate consistency, low water permeability and small frictional resistance, and the ideal working condition of shield tunneling under different geological conditions can be met.

Owner:江苏西尔德建设工程有限公司

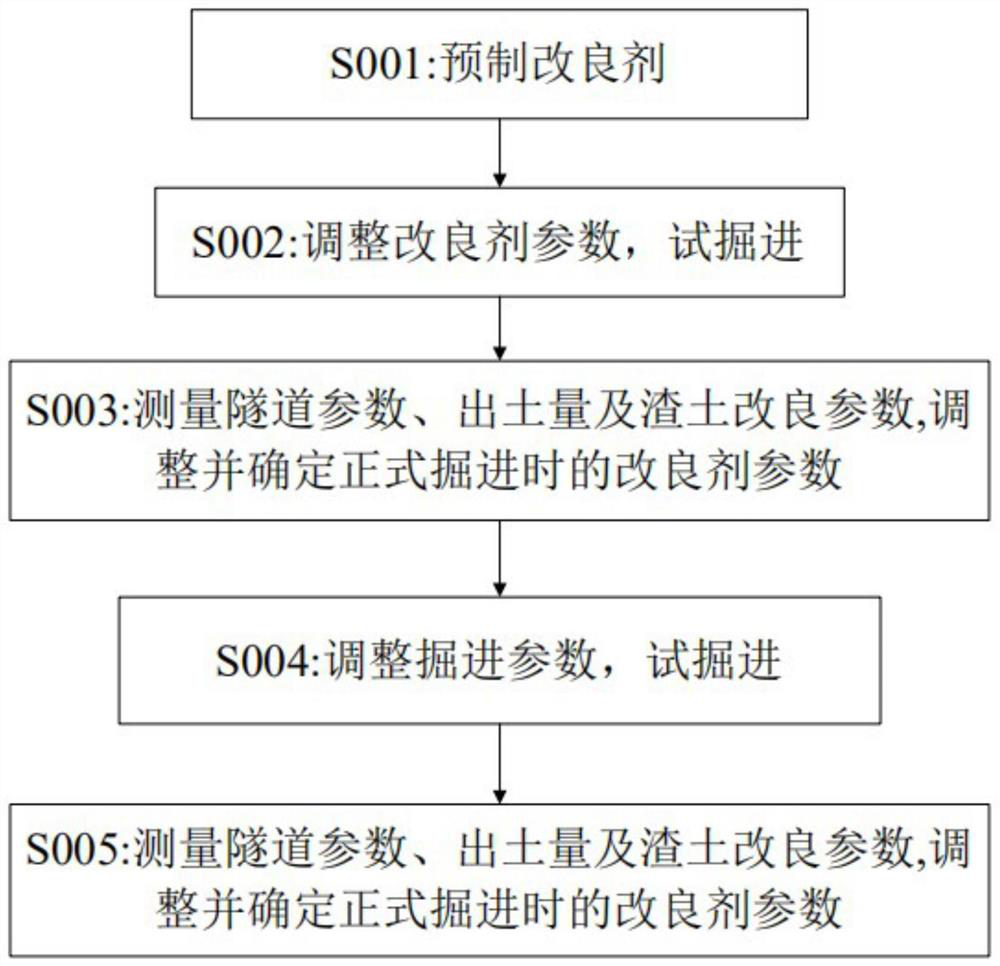

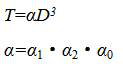

A construction test method for improving the slag soil of shield tunneling with water-rich sand layer

A water-rich sand layer shield tunneling slag improvement construction test method includes the following steps: 1. Adding prefabricated modifiers to the shield machine cutter head, soil bin and screw conveyor respectively. 2. Determine the modifier parameters: Select the first 100m of the shield as the test section, set the same excavation parameters, and set different modifier parameters, and test the excavation in the test section. 3. Measure the parameters of the tunnel, the amount of unearthed soil and the improvement parameters of the slag after the excavation, and adjust the parameters of the modifier to determine the parameters of the modifier during the formal excavation. 4. Determine the excavation parameters: the parameters of the modifier are the same, and the shield machine will try to excavate in the test section under different excavation parameters. 5. Measure the tunnel parameters, excavation volume and slag improvement parameters after excavation and adjust the excavation parameters to determine the formal excavation parameters of the shield machine. The method solves the problem that in the prior art, due to the unreasonable setting of the modifier parameters and the tunneling parameters, the slag soil improvement effect is not good, the tunneling speed is reduced, and the wear of the shield machine is increased.

Owner:CHINA RAILWAY NO 9 GRP NO 7 ENG CO LTD

Bentonite Slurry Control System for Shield Construction

The invention discloses a bentonite pulping control system for shield construction, which includes a liquid level detection module for detecting the liquid level of a stirring tank and outputting different signals according to three liquid levels of the stirring tank, namely, low, medium and high. The power supply module powered by the liquid level detection module and the relay control module used to control the working state of the mixing tank according to the different signals output by the liquid level detection module, the liquid level detection module is connected to the relay control module , the liquid level detection module includes a metal liquid level gauge connection sub-module, a high liquid level detection sub-module and a medium-low liquid level detection sub-module. The invention also discloses a control method. The present invention adopts the above-mentioned bentonite pulping control system for shield tunneling, which can realize the ratio and output control of bentonite slurry in the construction of full-section anhydrous sand layer shield, and can improve the flow plasticity of shield dregs and reduce the amount of shielding. The degree of wear of the cutter head.

Owner:THE 3RD ENG CO LTD OF CHINA RAILWAY 18TH BUREAU GRP +1

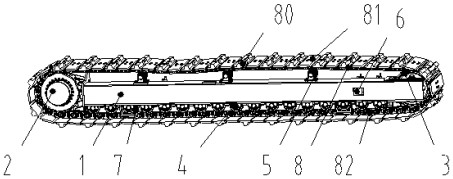

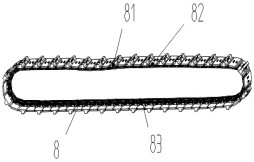

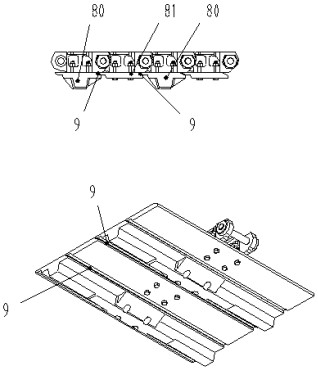

Walking track device for deep sea polymetallic nodule mining area

PendingCN114590087AThere are different ways to prevent subsidenceDifferent ways to increase the driving forceAmphibious vehiclesEndless track vehiclesDrive wheelMining engineering

The invention discloses a deep sea polymetallic nodule mining area walking track device, which comprises a walking frame, and a driving wheel, a guide wheel, a bearing wheel, a drag chain wheel, a tensioning mechanism, a rail guard and a track which are arranged on the walking frame, and is characterized in that the track consists of an annular caterpillar track, and a driving plate and a compaction plate which are arranged on a caterpillar track section in a staggered manner; the driving plate and the compaction plate are provided with sealing surfaces; and sealing surfaces of the driving plates and the compacting plates which are mounted in a staggered manner are overlapped to form sealing. The device has the advantages of subsidence prevention, good driving performance, light weight, seawater corrosion resistance, simplicity in installation and debugging and the like.

Owner:闻志君

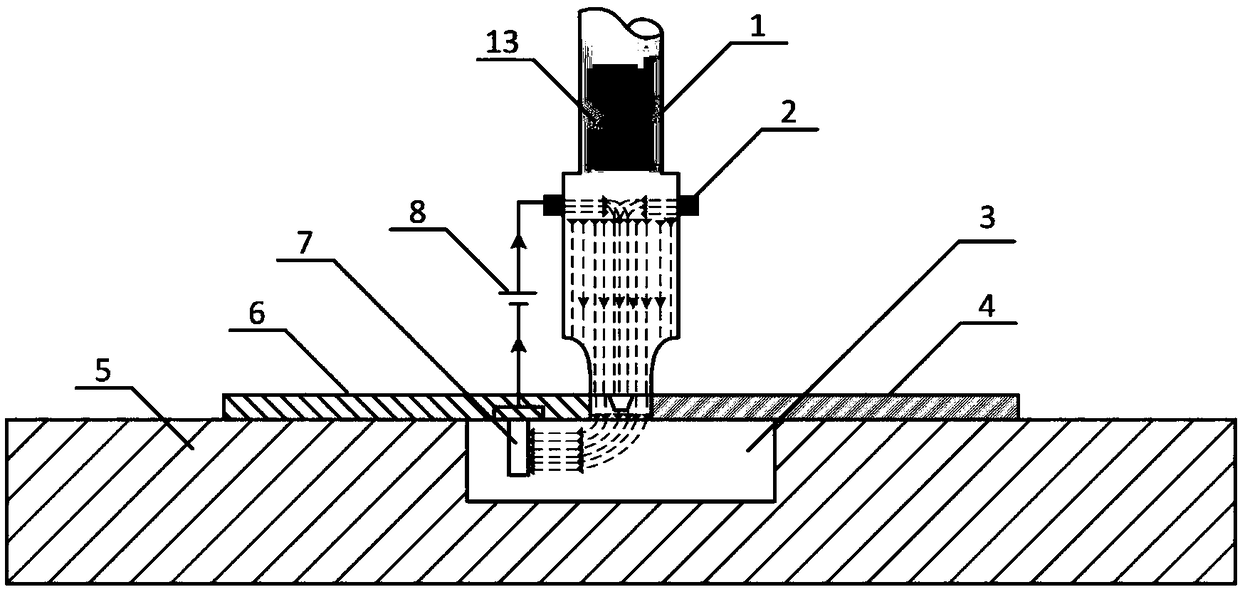

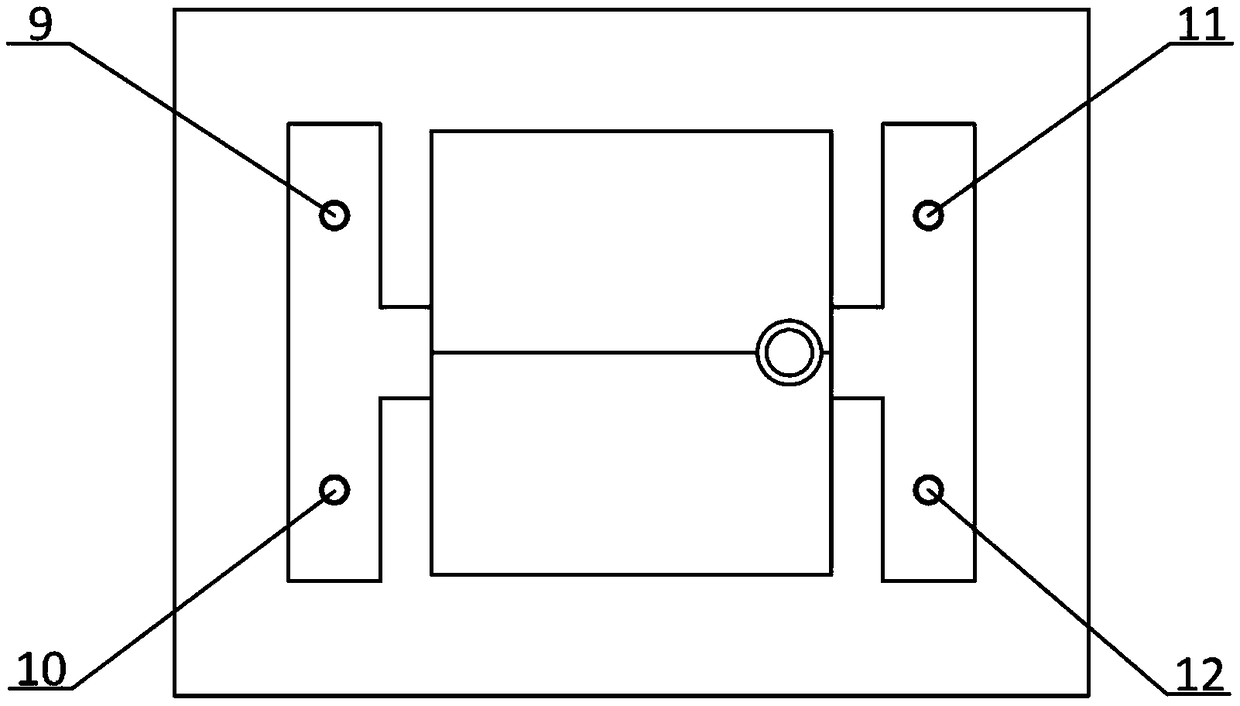

Current-carrying friction stir welding method based on adjustable current distribution

InactiveCN108890119AGrain refinementReduce wearNon-electric welding apparatusEngineeringMechanical property

The invention discloses a current-carrying friction stir welding method based on adjustable current distribution. According to the method, a stir head serves as an electrode of a current auxiliary heat source; under on and off of an external power switch, high-density current flows through a to-be-welded base material through a stir needle, and returns to a power supply unit through a bottom conducting plate, and thus, a hybrid heat-source for friction stir welding is formed by resistance heat and friction stir mechanical heat. During welding, current distribution and flowing direction are adjusted and controlled through the conducting plate according to processing requirements, temperature difference between the advancing side and the retreating side of a weld joint is changed, requirements on weld preheating and post weld heat treatment are met, and mechanical property of the weld joint is improved. Further, plasticity of the material during welding is improved, the temperature fielddistribution of the advancing side and the retreating side of the weld joint during the welding is adjusted, crystal grains are refined, abrasion to the stir needle during the welding is reduced, andweld quality and work efficiency are both improved.

Owner:BEIJING UNIV OF TECH

Foaming agent for improving shield muck in coastal silt soil layer, and preparation and use methods thereof

PendingCN114381274AStable expansion ratioLow priceBuilding constructionsOrganic fertilisersSucroseSoil science

The invention discloses a foaming agent for improving shield muck in a coastal silt soil layer. The foaming agent is prepared from a foaming agent base solution, a Changqing dispersing agent, powder abelmoschus manihot gum, flaxseed gum and water, the volume part ratio of the foaming agent base solution to the water is (4-12): 100, the volume part ratio of the liquid additive to the water is (2-10): 100, the volume part ratio of the powder additive to the water is (0.01-0.12): 100, and the mass part ratio of the powder abelmoschus manihot gum to the flaxseed gum is 1: 1; the foaming agent base solution comprises a liquid material alkyl sucrose glycoside and a solid material fatty alcohol polyoxyethylene ether sodium sulfate, and the volume part ratio is 2.5: 1. The invention also discloses a preparation method and a use method of the composition. The foaming ratio of the foaming agent is higher than 25 times, the half-life period is longer than 1500s, the half-life period within 5min is zero, the foam stability is high, the gas-liquid level strength is high, the foam density is high, the foaming agent can enter soil body gaps to improve the flow plasticity of the soil body, and the adhesion of the sludge cohesive soil is reduced.

Owner:FUZHOU UNIV

Foam agent for earth pressure balance shield dregs improvement and preparation method thereof

ActiveCN109054842BGood foaming effectEnhanced surface forceBuilding constructionsOrganic fertilisersPolyethylene oxideAlkylphenol

The invention provides a foaming agent for improvement of slag oil of a soil pressure balance shield and a preparation method thereof. The foaming agent for the improvement of the slag oil of the soilpressure balance shield is prepared from the following components in percentage by weight: 4% to 8% of alpha-alkenyl sodium sulfonate, 8% to 12% of lauryl sodium sulfate, 3% to 5% of alkylphenol polyoxyethylene, 0.05% to 0.2% of xanthan gum, 1% to 4% of coconut oil fatty acid diethanolamide, 1% to 3% of sodium gluconate, 0.5% to 2% of polyethylene oxide, 1% to 2% of polyaspartic acid, and the balance of water. The foaming agent has the advantages that by adopting the alpha-alkenyl sodium sulfonate, the lauryl sodium sulfate and the alkylphenol polyoxyethylene to prepare the foaming agent, thefoaming ability is enhanced under the compounding and cooperation function of the alpha-alkenyl sodium sulfonate, the lauryl sodium sulfate and the alkylphenol polyoxyethylene; the foaming time is greater than 30 times; by adopting the coconut oil fatty acid diethanolamide to enhance the surface action force of the air foam through cooperation, the stability of the foam under the high-speed shearing function of a knife disc is improved; the pressure fluctuation of a soil bin is reduced; the stability of the excavated surface of the shield is improved.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

Foaming agent for earth pressure balance shield machine

The invention belongs to the field of foaming agent technology, and aims to solve the problem that the foam uniformity, stability, lubricity, permeability and other properties of the current domestic foaming agent cannot fully meet the requirements for foam in shield tunneling construction, and the adaptability has certain limitations. , providing a foaming agent for an earth pressure balance shield machine. It is prepared from sodium lauryl sulfate, sodium fatty alcohol polyoxyethylene ether sulfate, sodium α-olefin sulfonate, modified silicone resin polyether emulsion, and water in a certain proportion. The foaming agent of the present invention has stable performance, good foaming effect, and long foam stabilization time, and can be well used for improving dregs in hard plastic and soft plastic expansive clays, and can improve the flow plasticity and stability of the excavated soil. Water-based, can prevent the compaction and adhesion of the soil, prevent the cutterhead from forming cakes, and rely on the support of air bubbles to maintain the pressure of the soil bin; its raw materials are easy to obtain and low in price, which effectively reduces construction costs; bulk chemical products are used, and the product is pollution-free , without any toxic and side effects on the muck and the surrounding environment.

Owner:CHINA RAILWAY NO 3 GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com