Dispersant for improving clay and preparation method thereof

A technology of dispersant and dispersant aid, which is applied in the field of improved clay dispersant and its preparation, which can solve the problems of shield machine damage, tool wear, and tool head torque drop, etc., to improve flow plasticity and dispersibility, and reduce viscosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

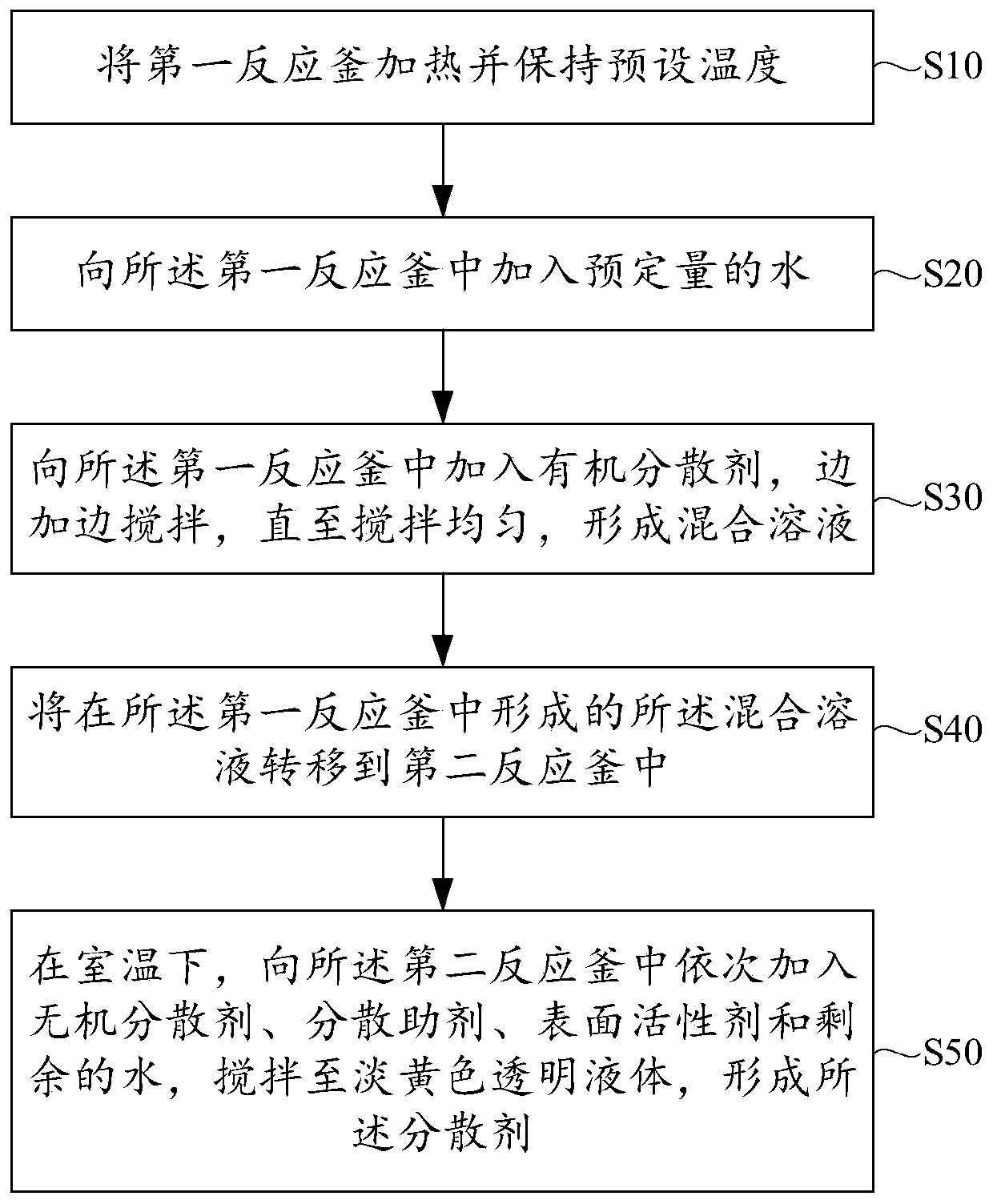

Method used

Image

Examples

Embodiment 1

[0029] The embodiment of the present application provides a dispersant for improving clay, the dispersant is composed of organic dispersant, inorganic dispersant, dispersion aid, surfactant and water, wherein, in weight percentage, the organic dispersant The weight percentage content is 1% to 3%, the weight percentage content of the inorganic dispersant is 4% to 10%, the weight percentage content of the dispersing aid is 2% to 6%, and the weight percentage content of the surfactant is 1% to 5%. %, the weight percentage content of water is 76%~92%.

[0030] Among the above dispersants, the organic dispersant can be at least one of polyacrylamide, hydroxypropyl cellulose, carboxymethyl cellulose and triethylhexyl phosphoric acid, such as: the organic dispersant can be polyacrylamide, hydroxypropyl cellulose Any one of propyl cellulose, carboxymethyl cellulose and triethylhexyl phosphate, organic dispersant can also use polyacrylamide, hydroxypropyl cellulose, carboxymethyl cellu...

Embodiment 2

[0046] The embodiment of the present application provides a dispersant for improving clay, the dispersant includes organic dispersant, inorganic dispersant, dispersion aid, surfactant and water, wherein, in weight percentage, the weight of organic dispersant The percentage content is 2%, the weight percentage content of the inorganic dispersant is 7%, the weight percentage content of the dispersing aid is 4%, the weight percentage content of the surfactant is 3%, and the weight percentage content of the water is 84%.

[0047] Among the above-mentioned dispersants, the organic dispersant can use any combination of polyacrylamide, hydroxypropyl cellulose, carboxymethyl cellulose and triethylhexyl phosphoric acid; the inorganic dispersant can use sodium hexametaphosphate, water glass, coke Any combination of sodium phosphate and sodium tripolyphosphate; any combination of polyethylene glycol, propylene glycol, glycerin and HPMA can be used as a dispersing aid; the surfactant can b...

Embodiment 3

[0052] The embodiment of the present application provides a dispersant for improving clay, the dispersant includes organic dispersant, inorganic dispersant, dispersion aid, surfactant and water, wherein, in weight percentage, the weight of organic dispersant The percentage content is 1%, the weight percentage content of the inorganic dispersant is 8%, the weight percentage content of the dispersing aid is 3%, the weight percentage content of the surfactant is 2%, and the weight percentage content of the water is 86%.

[0053] Among the above-mentioned dispersants, the organic dispersant can use any combination of polyacrylamide, hydroxypropyl cellulose, carboxymethyl cellulose and triethylhexyl phosphoric acid; the inorganic dispersant can use sodium hexametaphosphate, water glass, coke Any combination of sodium phosphate and sodium tripolyphosphate; any combination of polyethylene glycol, propylene glycol, glycerin and HPMA can be used as a dispersing aid; the surfactant can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com