Patents

Literature

45results about How to "Smooth tunneling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

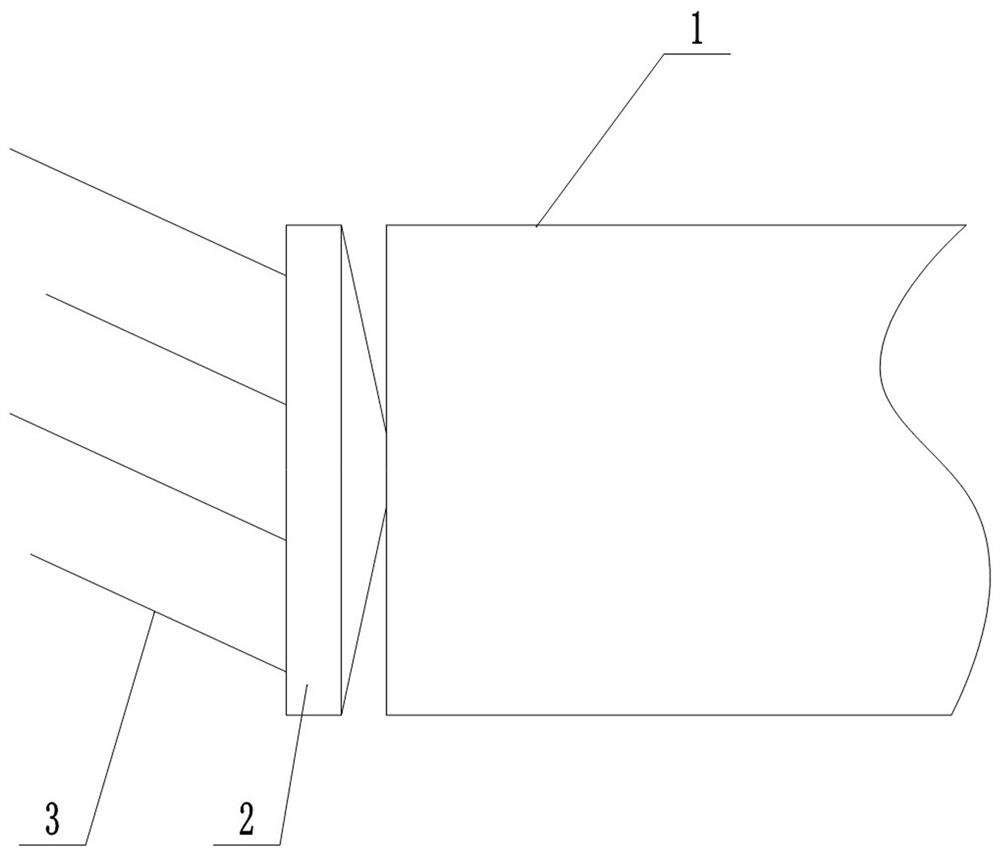

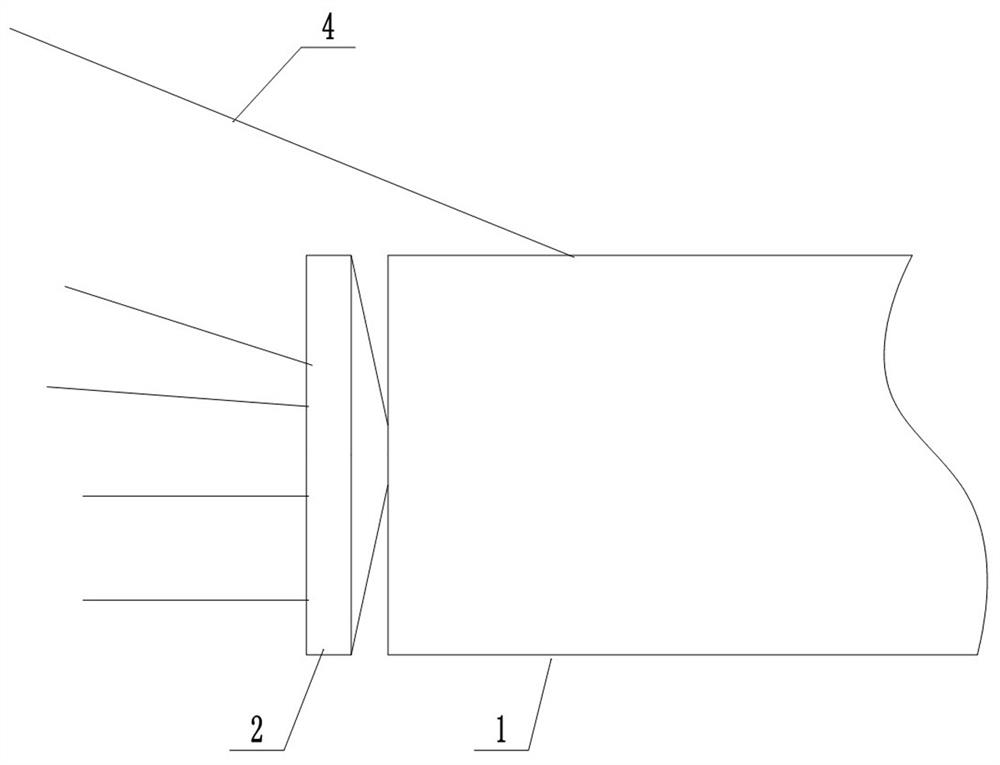

Large-diameter slurry shield comprehensive tunneling method for strong permeable soil and rock composite stratum

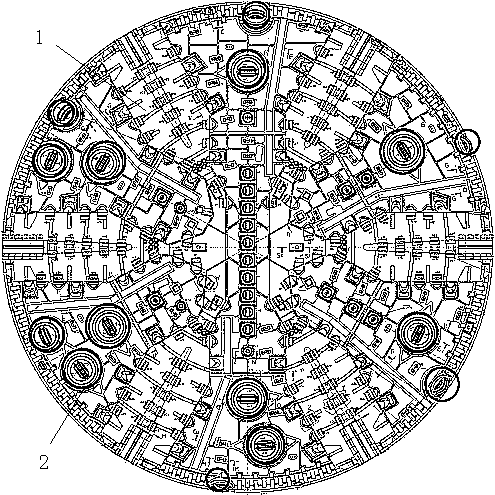

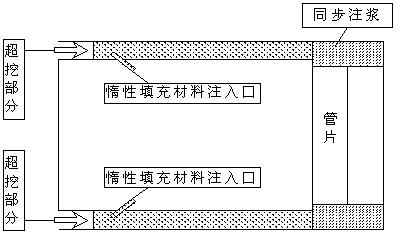

The invention provides a large-diameter slurry shield comprehensive tunneling method for a strong permeable soil and rock composite stratum, and relates to the field of shield construction. Accordingto the method, a combined type atmospheric pressure cutterhead is adopted, cutter locations are arranged on the cutterhead, and tools which can be changed at the atmospheric pressure are installed onthe cutter locations; the cutter locations include a Class I cutter location fixed in the form of the tool and a Class II cutter location which can realize hobbing interchange at the atmospheric pressure; fixed tools are installed on the Class I cutter location, interchangeable tools are installed on the Class II cutter location, and cutting trajectories of the interchangeable tools covers the cutterhead; tunneling process control includes control over the cutterhead rotating speed, control over the cutterhead thrust and torque, control over the cutting opening pressure, control over attitude,and control over synchronous grouting construction parameters; and rigid single-fluid slurry with water dispersion resistance is adopted during synchronous grouting construction. By adopting the combined type atmospheric pressure cutterhead, the two types of tools are sepatrately mounted on the cutterhead, the two types of cutter locations cover the cutting trajectory of the entire cutterhead, the fixed tools are used for cutting soil mass, the interchangeable tools are used for cutting rock mass, and therefore smooth tunneling of composite geology is ensured.

Owner:CHINA RAILWAY SHISIJU GROUP CORP

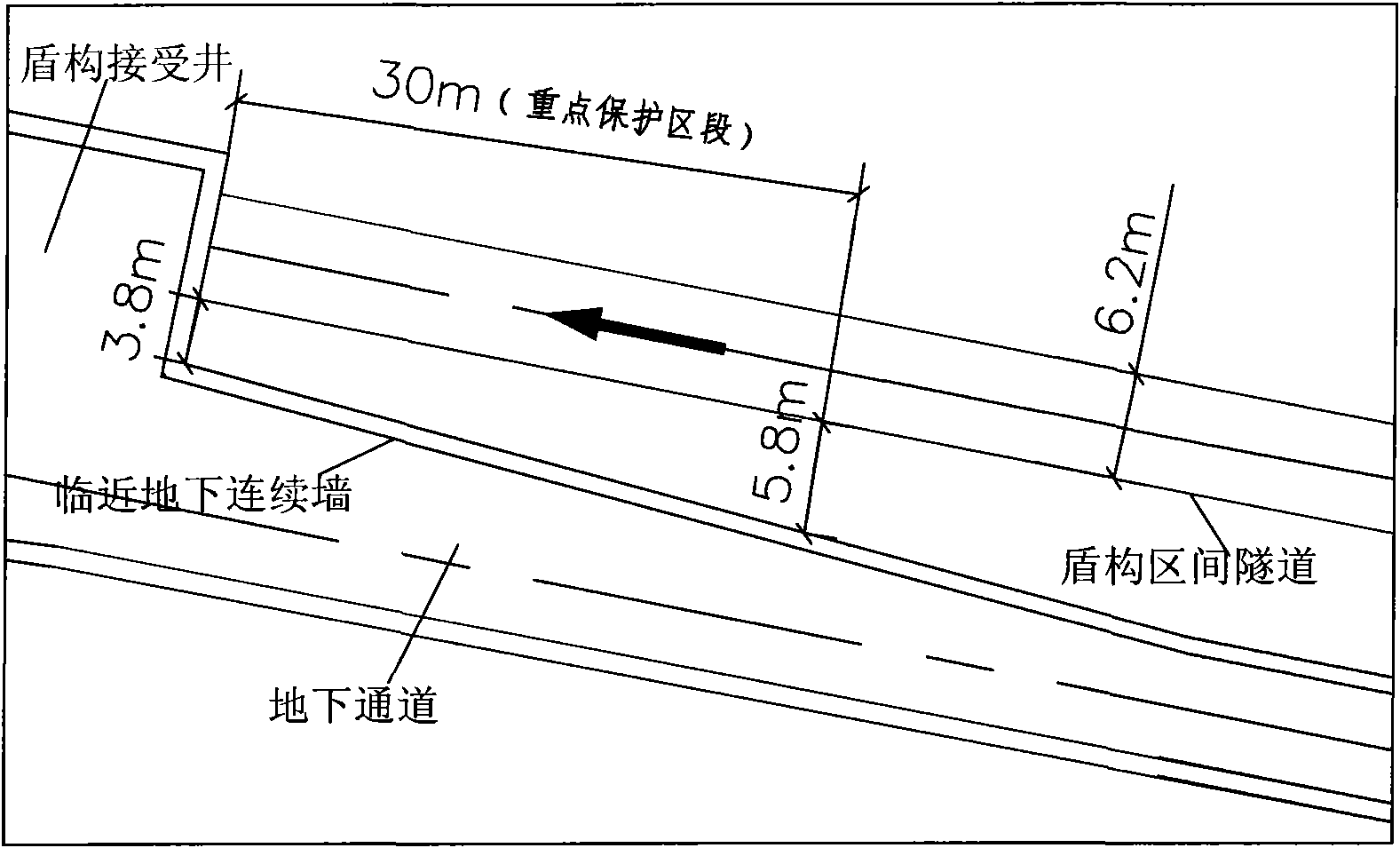

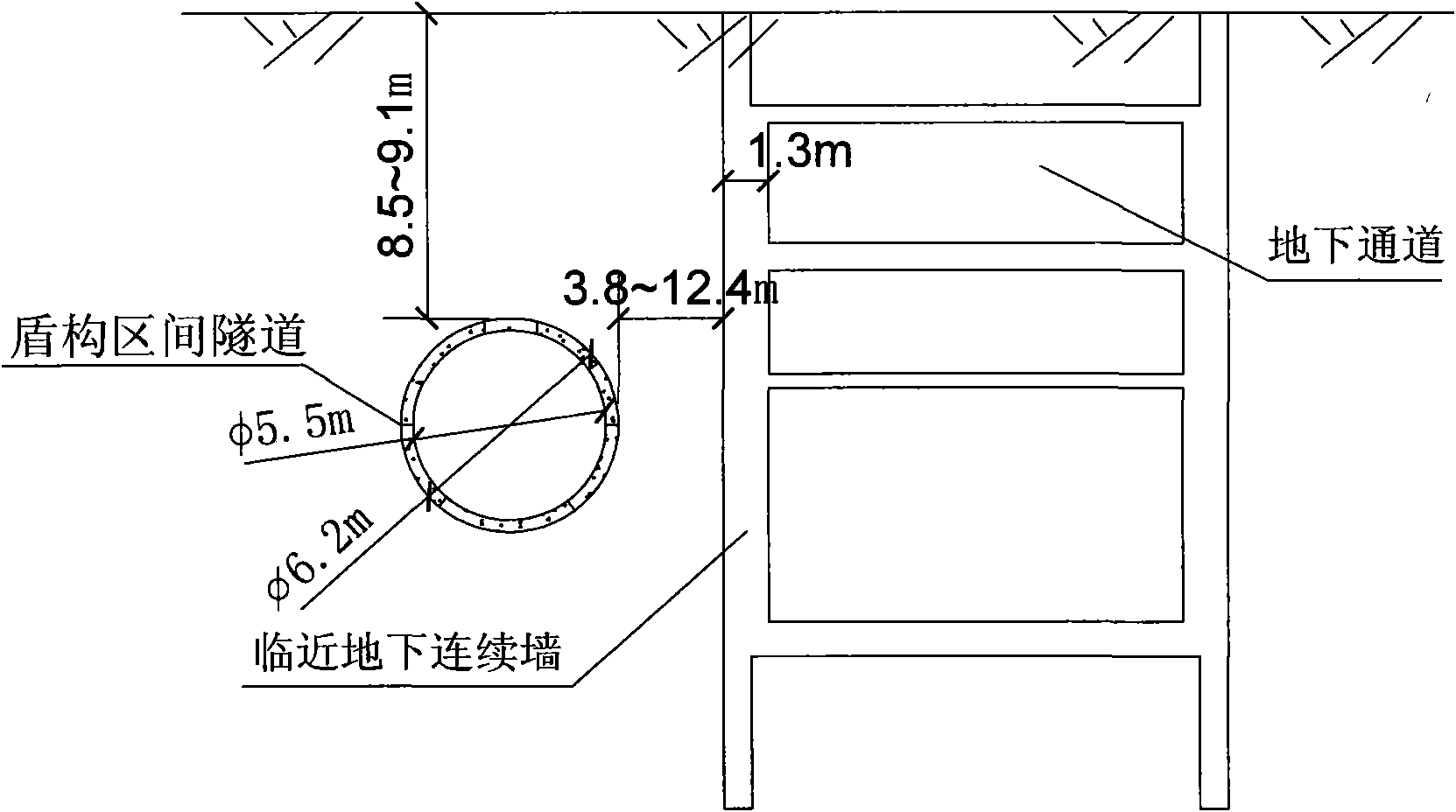

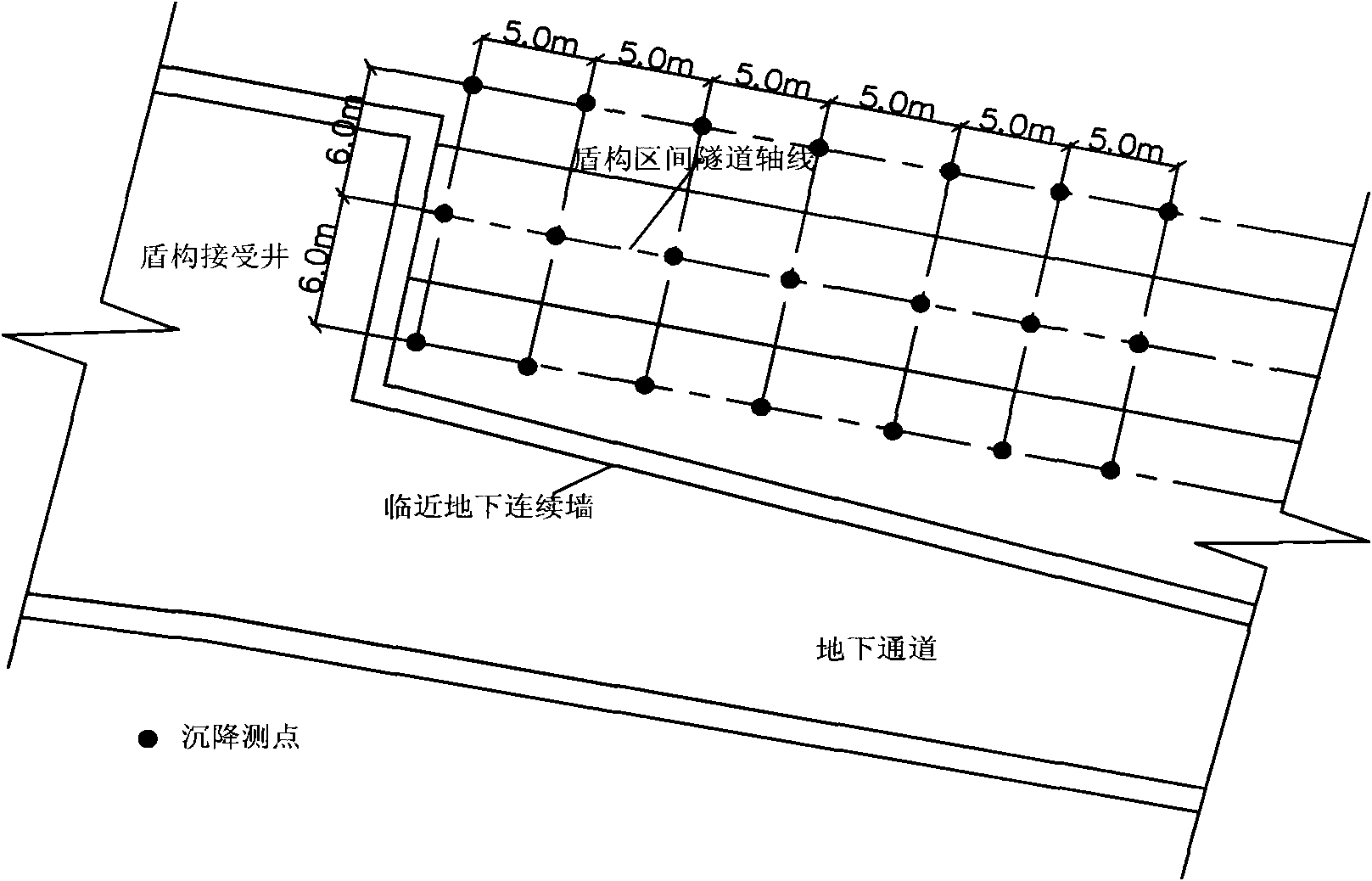

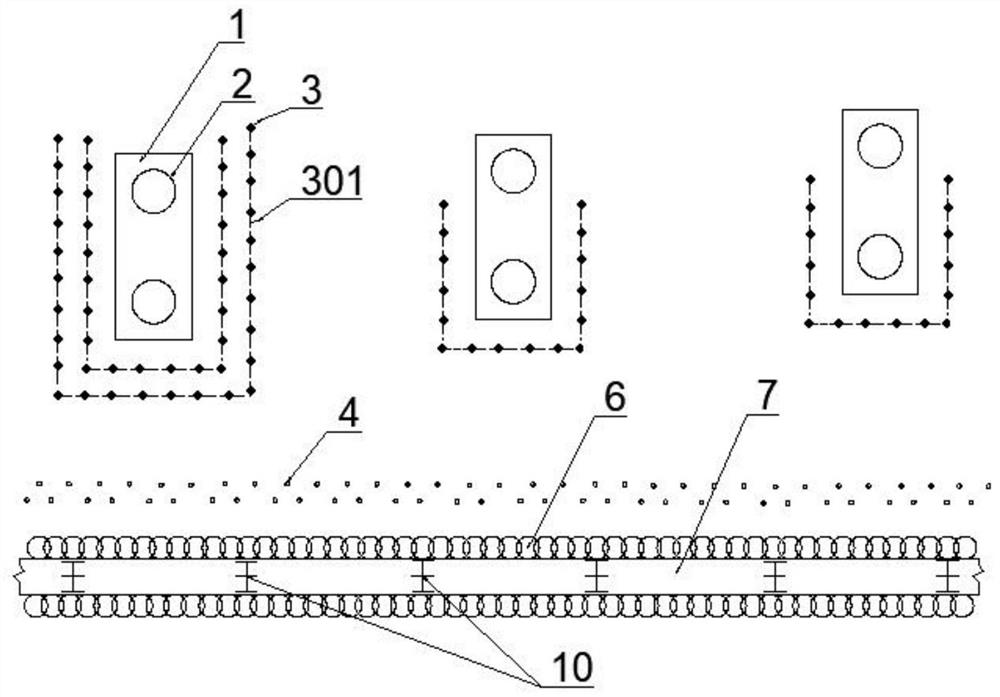

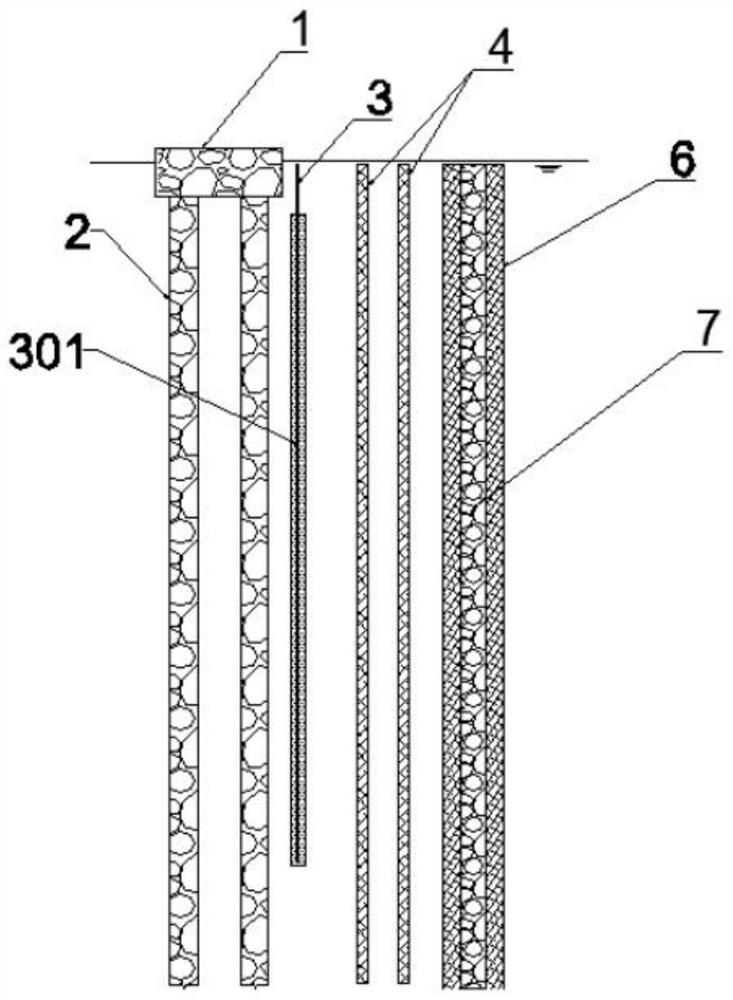

Method for protecting underground structure of single round shield side face construction in close distance

InactiveCN101608548AGuaranteed normal useSmooth tunnelingUnderground chambersTunnel liningMonitoring programMonitoring data

The invention relates to a method for protecting an underground structure of single round shield side face construction in close distance, belonging to the technical field of constructional engineering. The method comprises the following steps: using a Robertson method; determining the parameters of a shield traversing underground structure through the design drawings of the underground structure and tunnels; using three-dimensional finite element model to perform numerical simulation; establishing monitoring programs, carrying out measuring points layout and monitoring in site before traversing construction; detecting the work efficiency of trial push and selecting construction parameters; carrying out construction through monitoring feedback analysis in real time; and tracking and monitoring the set monitoring points until all monitoring data are stabilized within the range of the optimized safety construction parameters of step (6). The invention ensures the normal use and the smooth tunneling of the underground structure, the adopted technical measures is applicable to the requirements of single round shield side face in close distance on passing through various underground structures, thus an important technical assurance is provided.

Owner:SHANGHAI JIAO TONG UNIV

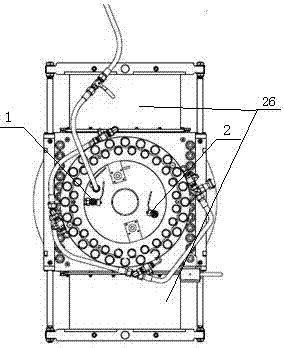

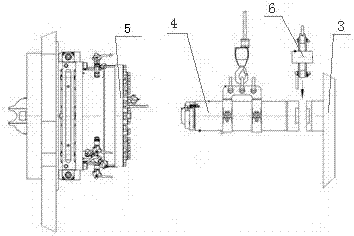

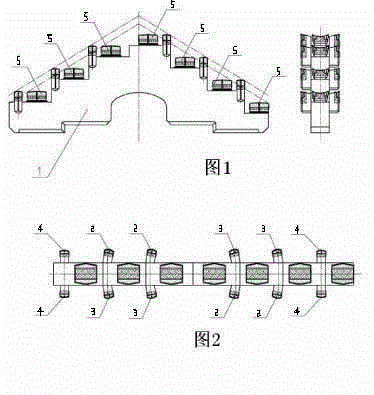

Normal pressure hobbing cutter and teeth cutter exchange technological method for compound stratum shield

The invention provides the technical scheme of a normal pressure hobbing cutter and teeth cutter exchange technological method for compound stratum shield. The technological method comprises the following operation steps of cutter drum washing, oil cylinder fixing, cutter drum bolt loosening, oil cylinder retraction, cutter drum hoisting, gate washing, gate closing, balancing of the pressure difference between the interior and the exterior of a gate, oil cylinder thorough retraction, oil cylinder dismounting and temporary storage, cutter drum complete drawing-out, replacement of a tool on a cutter drum and cutter drum mounting. By adoption of the technological method, a normal pressure hobbing cutter replacement technology and a normal pressure hobbing cutter and teeth cutter exchange technology are successfully achieved for the first time, the cutter replacement time is greatly shortened, cost is reduced, and smooth excavation of a shield tunneling machine is ensured.

Owner:CHINA RAILWAY SHISIJU GROUP CORP

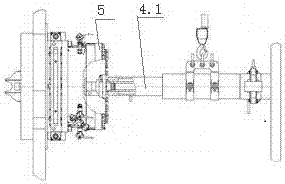

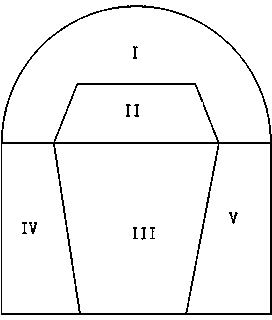

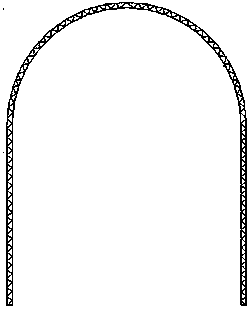

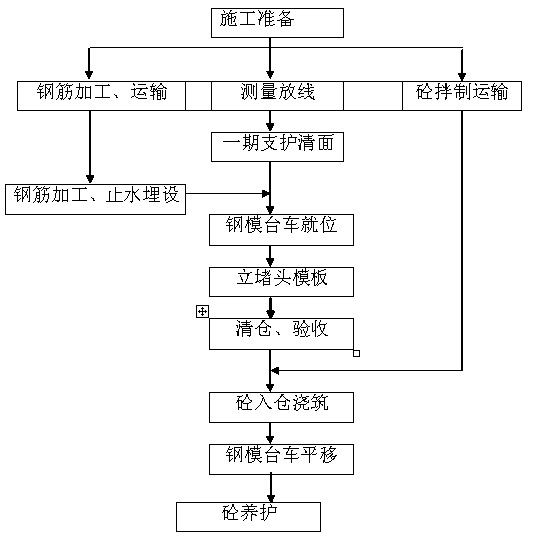

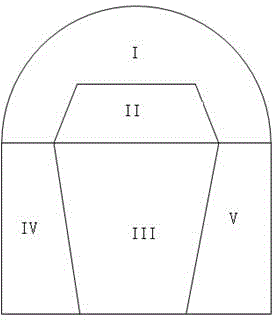

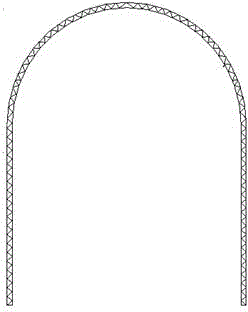

Soft rock tunnel construction method

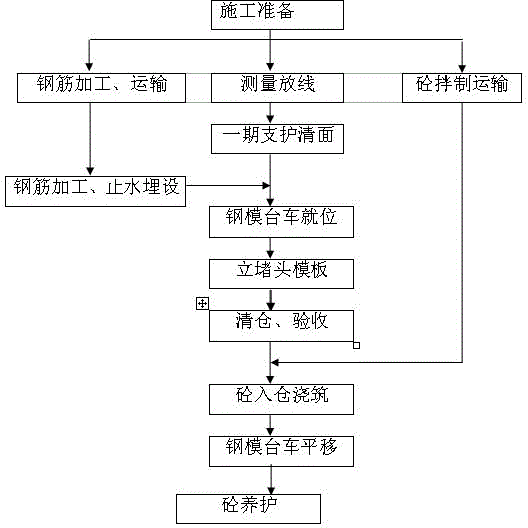

ActiveCN103410524AHigh measurement accuracyReduce investmentUnderground chambersTunnel liningRock tunnelEngineering

The invention provides a soft rock tunnel construction method. The soft rock tunnel construction method comprises the following steps of: densely arranging grid arch frames in a tunnel, mounting and fixing the grid arch frames, hanging nets, mounting steel arch frames and net sheets, and then checking and accepting the steel arch frames and the net sheets; then, coating top arches and side walls, operating a steel mould trolley and pouring concrete into the side walls; pouring the concrete into top arches; and maintaining. By adopting the soft rock tunnel construction method, the construction efficiency of the soft rock tunnel is improved, the construction safety is ensured and the construction cost is lowered.

Owner:GEZHOUBA XINJIANG ENG +1

Muck modifier guaranteeing smooth tunneling of shield tunneling machine

InactiveCN103102886ASmooth tunnelingEasy to excavateBuilding constructionsOrganic fertilisersSlurryShield tunneling

The invention discloses a muck modifier guaranteeing smooth tunneling of a shield tunneling machine. The muck modifier consists of sodium bentonite slurry, foam solution and shield slurrying agent, wherein the amount of the sodium bentonite slurry is 0-60 parts by mass, the amount of the foam solution is 50-70 parts by mass, the amount of high-molecular polymer is 0.5-1 part by mass, and the amount of the shield slurrying agent is 3-5 parts by mass. The muck modifier disclosed by the invention not only can ensure smooth tunneling of a shield tunneling machine, but also can reduce the abrasion of cutter and tool as well as the replacement of tool so as to lower the cost, shorten the construction period and guarantee safe operation of an engineering.

Owner:BEIJING URBAN CONSTR DESIGN & DEV GRP CO

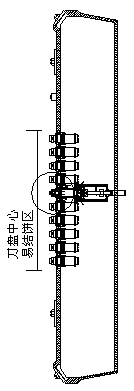

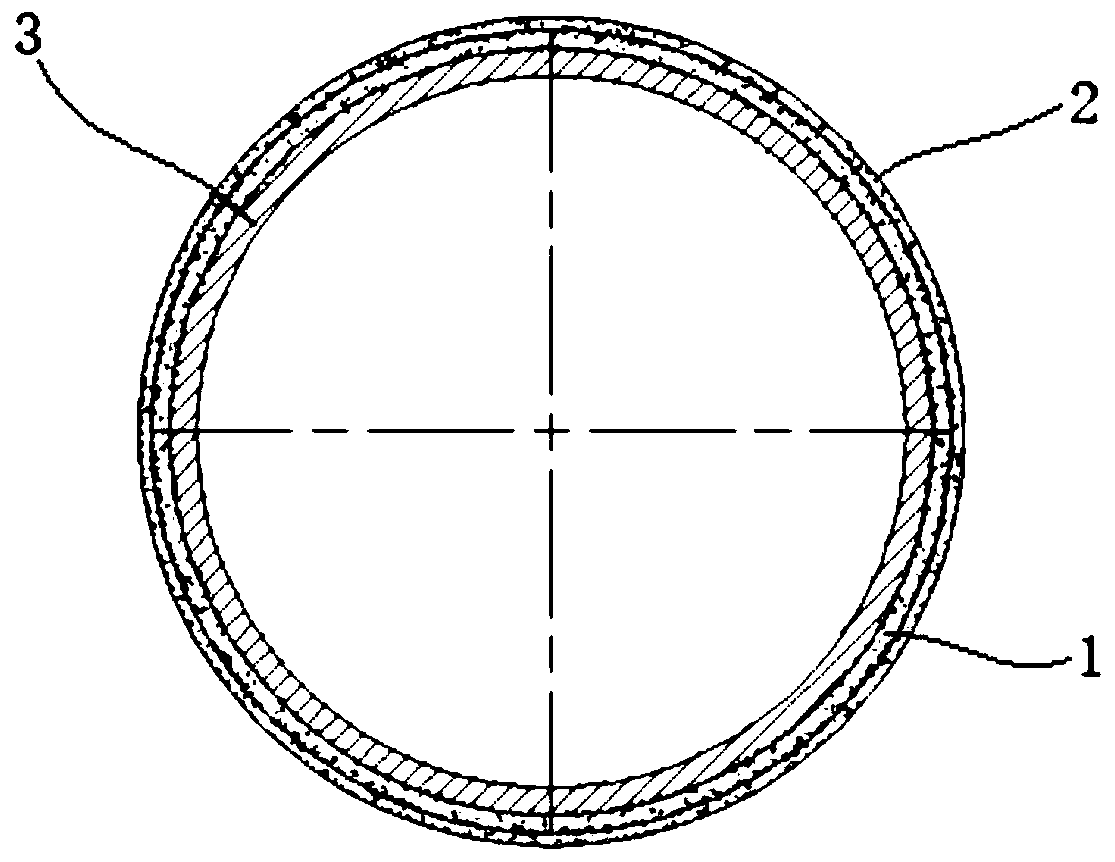

Fishtail center cutter for shield machine

InactiveCN103061775ASolve the problem that the cutter cannot be arrangedEasy to cutTunnelsShield machineTunnel construction

The invention discloses a fishtail center cutter for a shield machine and belongs to the field of the shield machine of tunnel construction. The center cutter is characterized in that a cutter (2), a cutter (3), a cutter (4) and a cutter (5) are welded to a cutter body (1), the cutter (2), the cutter (3) and the cutter (4) are located on two sides of the cutter body, the cutter (5) is distributed on the upper portion of the cutter body (1), the cutter (2), the cutter (3) and the cutter (4) are reinforcing advanced cutters and the cutter (5) is a reinforcing cutting knife. When the shield machine runs in the soft land layer, the cutting knife cannot be arranged at the central position of a knife disk, the cutters are used for improving the chipping and stirring effect of the soil of the central position of the excavated surface, the problem that the cutter knife cannot be arranged at the central position of the knife disk of the soft land layer is solved, the chipping problem of the central position soil can be solved, the fluidity of chipped soil can be improved, and the whole tunneling effect of the shield machine can be improved greatly. The center cutter can save the construction cost, save the construction time and improve the construction efficiency and can be widely used in the shield machine industry.

Owner:SHANDONG TECHGONG GEOTECHN ENG EQUIP CO LTD +1

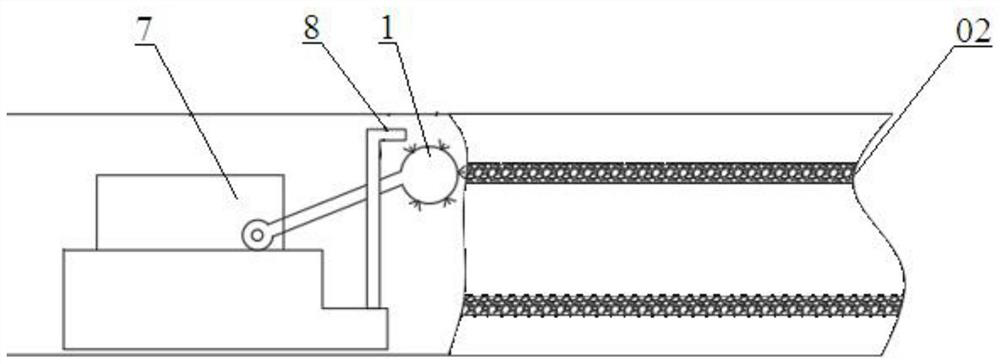

Full face tunnel boring machine tunneling extrusion deformation machine jamming disaster safety control method

ActiveCN110656951AIncrease investmentHigh input costUnderground chambersTunnel liningTunnel boring machineWall rock

The invention relates to a full face tunnel boring machine tunneling extrusion deformation machine jamming disaster safety control method. The method includes the steps of evaluating the surrounding rock extrusion deformation levels of a full face tunnel boring machine in the tunneling process; and determining different-combination tunneling and step-by-step joint surrounding rock support strategies according to the different extrusion deformation levels. By means of the method, reasonable calculation of the surrounding rock extrusion deformation levels can be achieved, and construction site operation and calculation are facilitated; reasonable tunneling parameter adjustment and step-by-step joint surrounding rock support control are carried out according to the surrounding rock extrusiondeformation degrees, machine jamming is avoided under the surrounding rock deformation working condition, smooth tunneling is ensured, delay of the construction period due to frequent downtime is avoided, the tunneling efficiency is better improved, material and labor cost increase caused by excessive supporting is avoided, and project construction is more economical and reasonable; and a varietyof support methods are organically combined, the effects of strengthening and supporting surrounding rocks are effectively improved, the restoration and improvement of the stress state of the surrounding rocks are realized, the self-bearing capacity of the surrounding rocks is improved, and the construction safety is greatly improved.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI +2

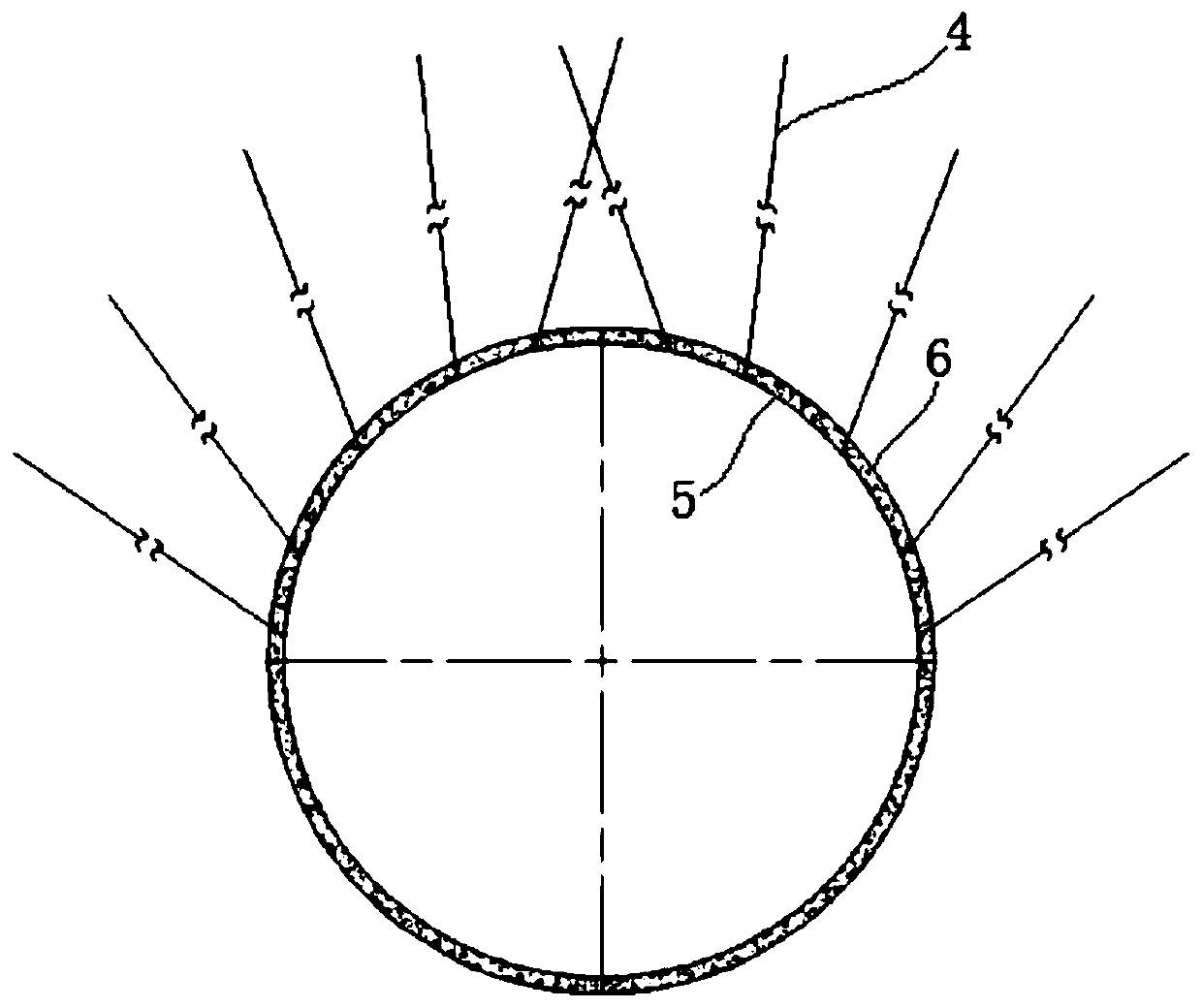

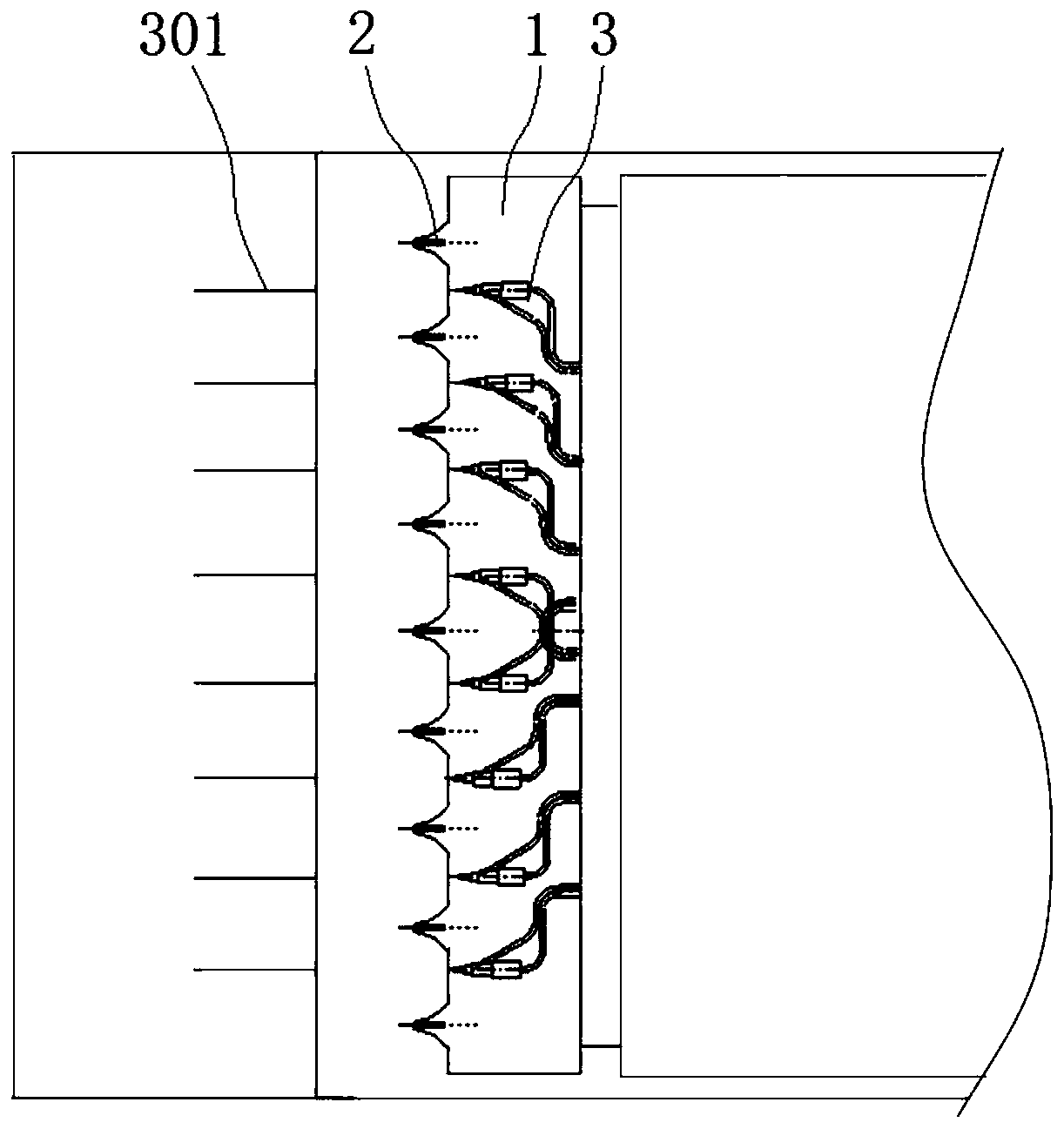

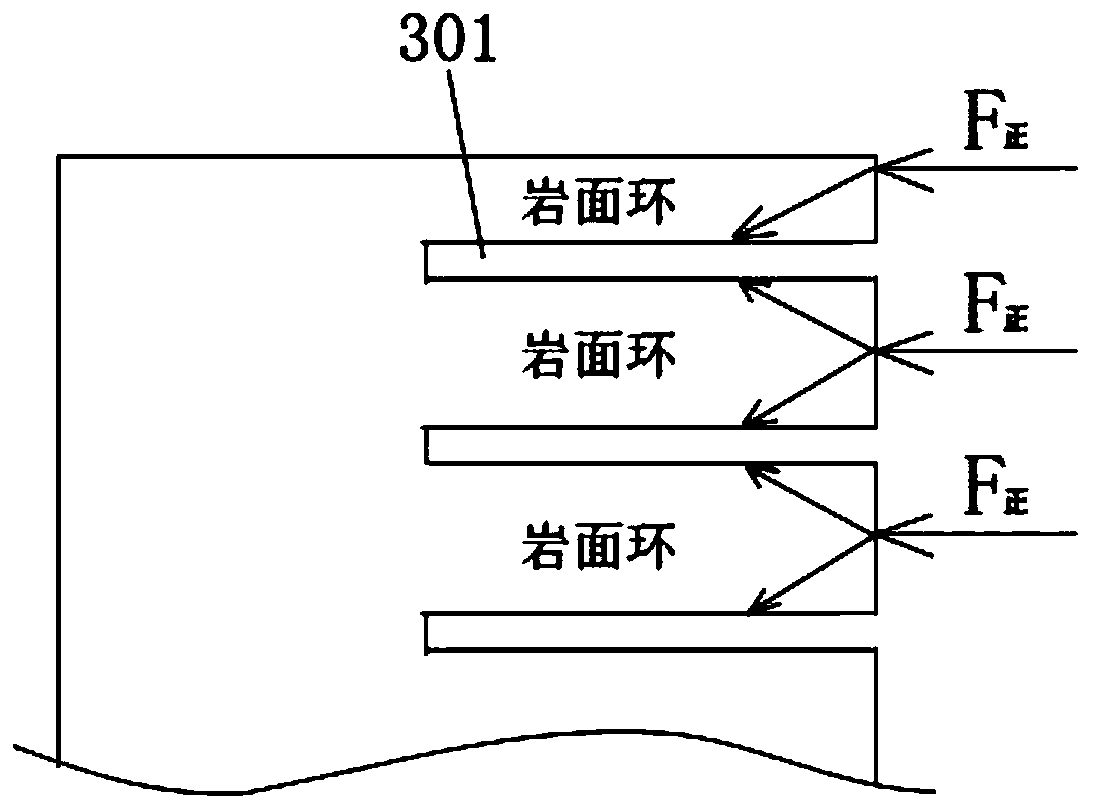

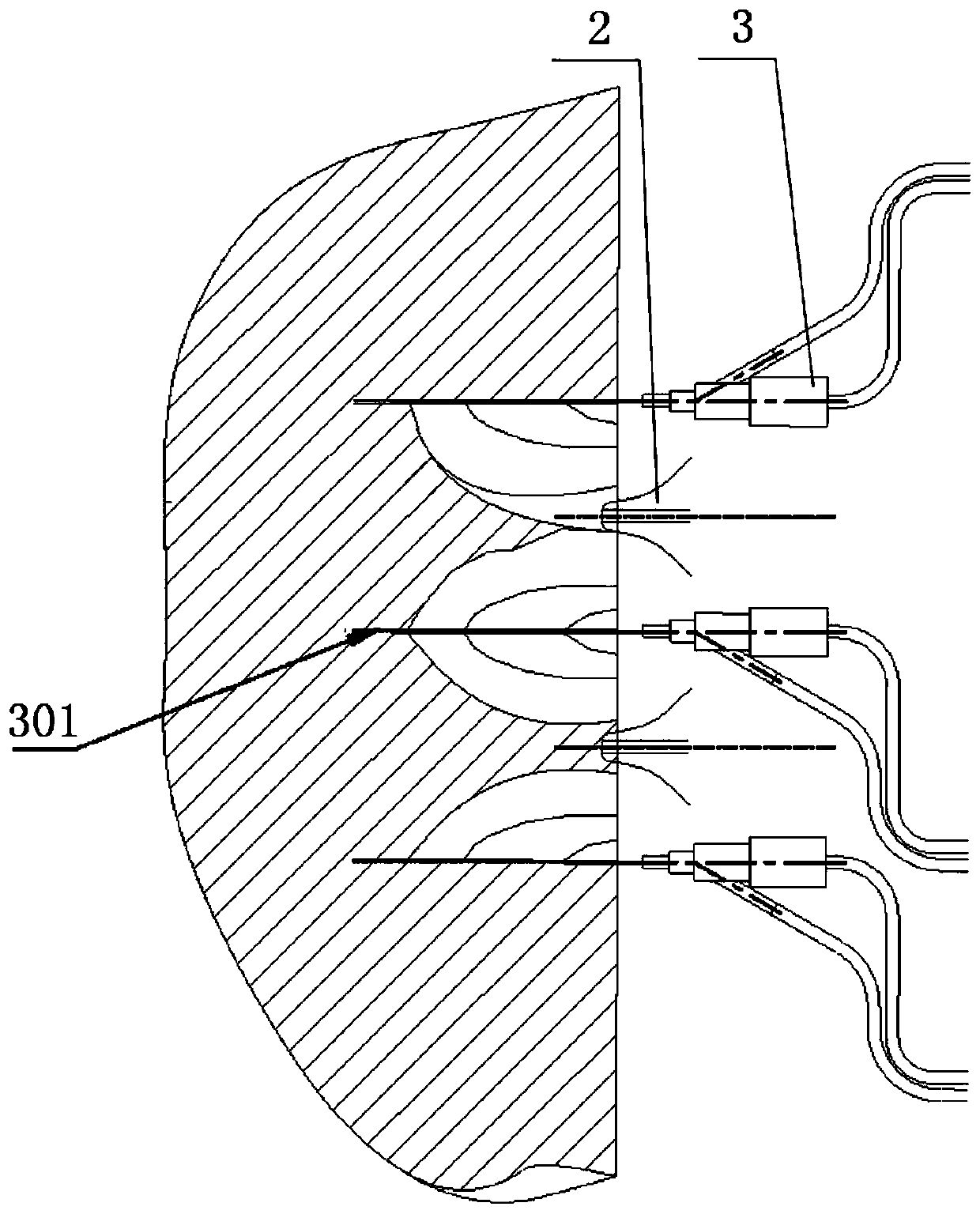

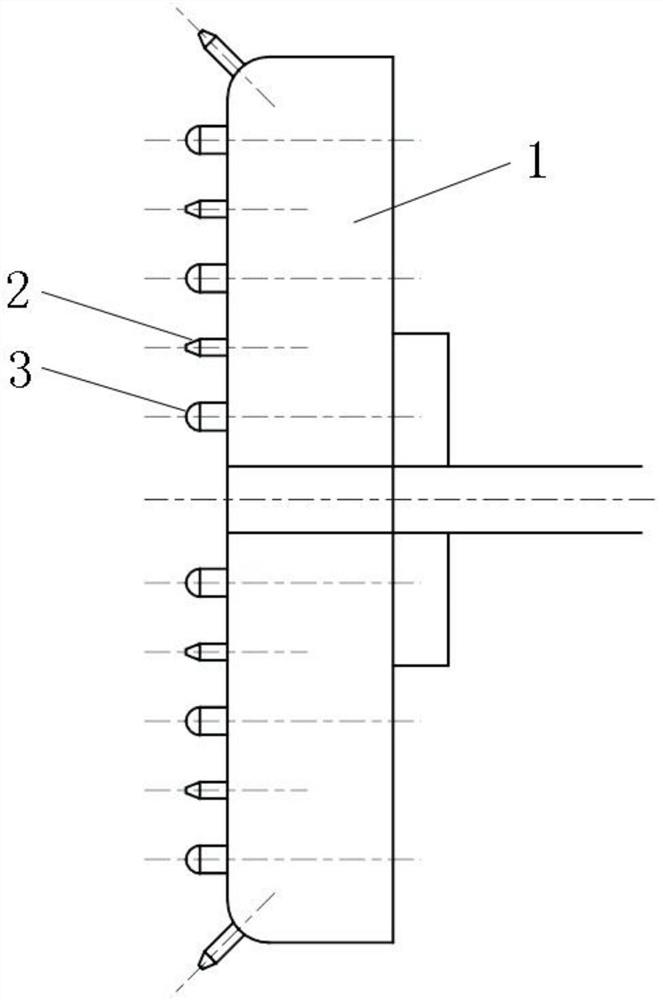

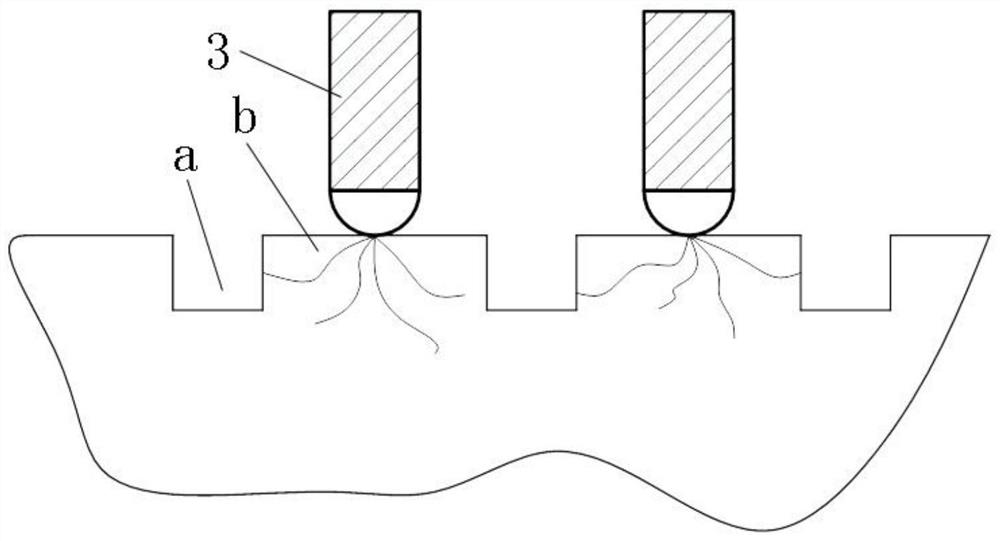

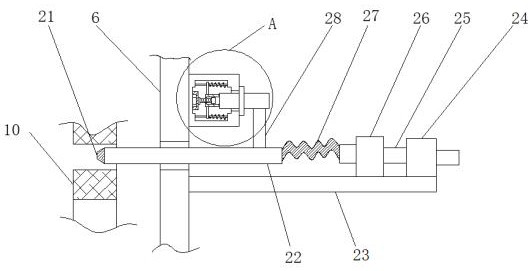

Shield tunneling machine and water jet combined hob rock breaking mechanism thereof

The invention discloses a water jet combined hob rock breaking mechanism, including a cutter disc which is arranged at the front end of a machine body and can feed in the axial direction and rotate inthe circumferential direction, a plurality of layers of hobs arranged on the surface of the cutter disc and distributed in a ring shape, and a jet nozzle arranged on the surface of the cutter disc and between the hobs of the adjacent two layers, and used for cutting a rock face to form several layers of annular cutting slots during the rotation of the cutter disc, and the current depth of the annular cutting seam of each layer is greater than the current cutting depth of the hobs of each layer. According to the water jet combined hob rock breaking mechanism, by use of the annular cutting slots formed by the jet nozzle on the rock surface, the hobs of each layer only needs to overcome the weak shear strength of rocks, rock surface fracture is realized by a shearing failure mode of each layer rock surface ring, the difficulty of tunneling for rocks with high compressive strength is lowered, at the same time, tunneling efficiency is improved and tool wear is reduced. The invention further discloses a shield tunneling machine which has the beneficial effects.

Owner:CHINA RAILWAY CONSTR HEAVY IND

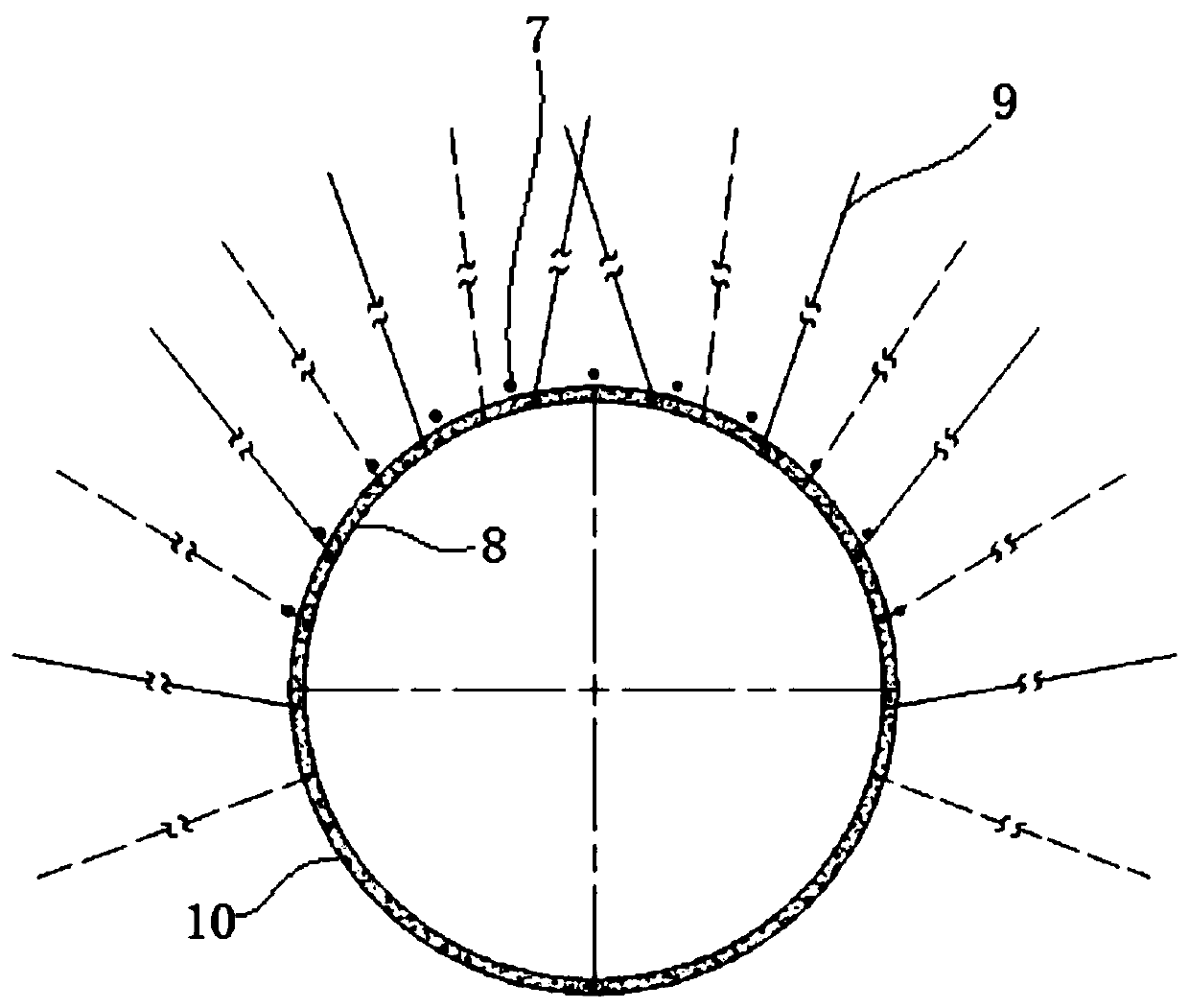

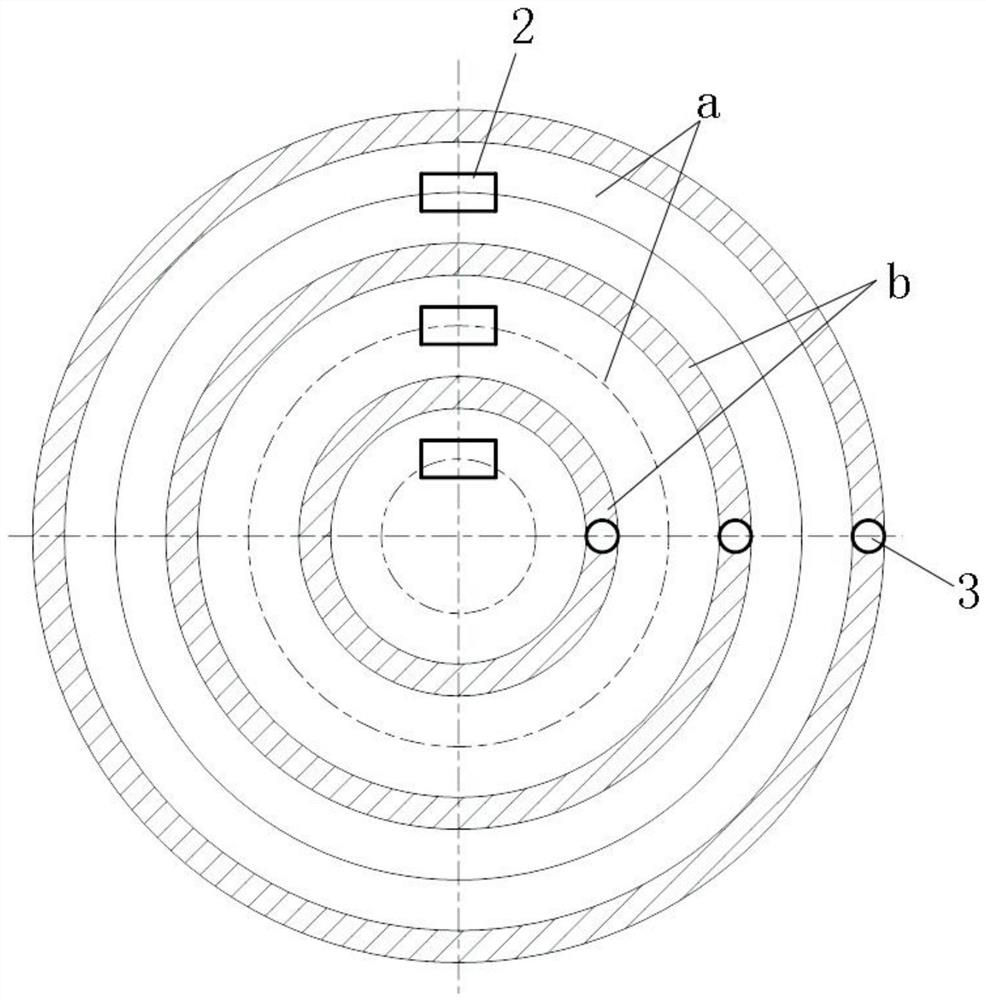

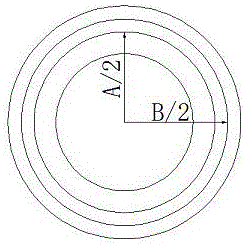

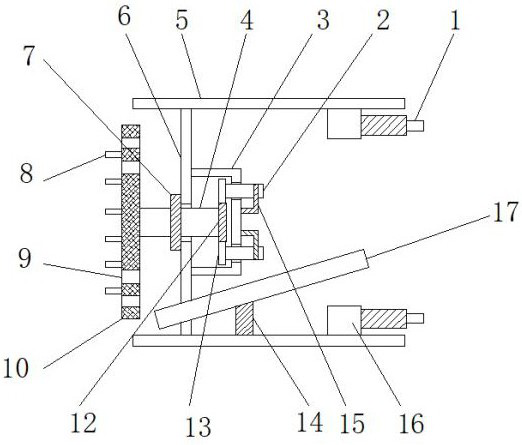

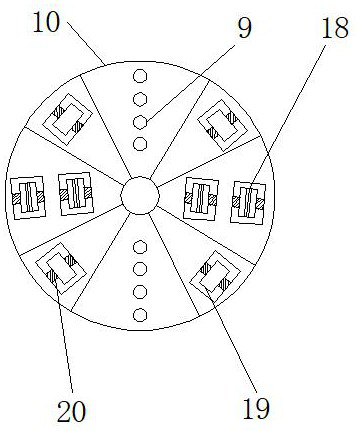

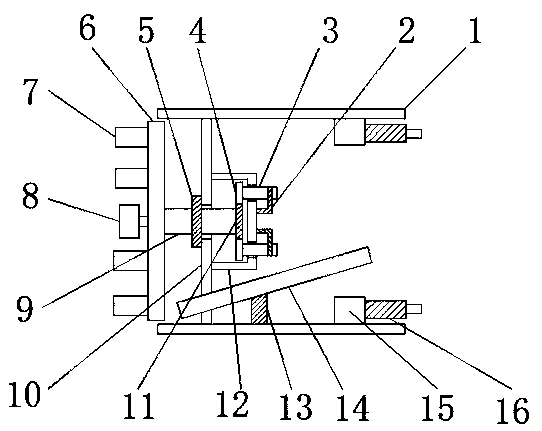

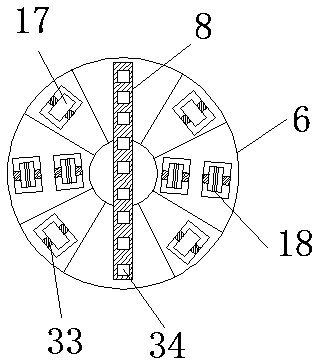

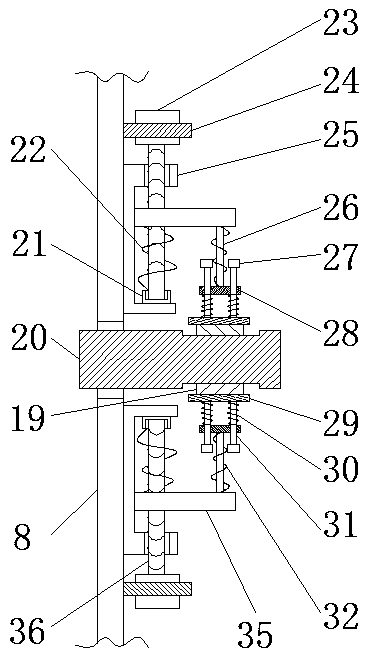

Tunnel boring machine and impact rock breaking cutterhead structure thereof

The invention discloses an impact rock breaking cutterhead structure. The impact rock breaking cutterhead structure comprises a cutterhead body which is arranged at the front end of a machine body andcan feed along the axial direction and rotate along the circumferential direction, impact assemblies arranged on cutterhead body in an axially telescopic mode, distributed in a multi-layer annular mode and used for digging a plurality of layers of annular grooves in a tunnel face along with rotation of the cutterhead body, and rock breaking assemblies arranged on the cutterhead body in an axiallytelescopic mode, distributed in a multi-layer annular mode and used for impacting and breaking annular rock layers located between every two adjacent layers of the annular grooves on the tunnel facealong with rotation of the cutterhead body. Therefore, in the tunneling process, the layers of the annular grooves are formed in a rock surface through the impact assemblies, so that rock breaking assemblies of the layers only need to overcome the weak shear strength of rock, rock surface breaking is achieved through the shear failure mode of the annular rock layers, the tunneling difficulty of rock with large compressive strength is reduced, meanwhile, the tunneling efficiency is improved, and cutter abrasion is reduced. The invention also discloses a tunnel boring machine which has the abovebeneficial effects.

Owner:CHINA RAILWAY CONSTR HEAVY IND

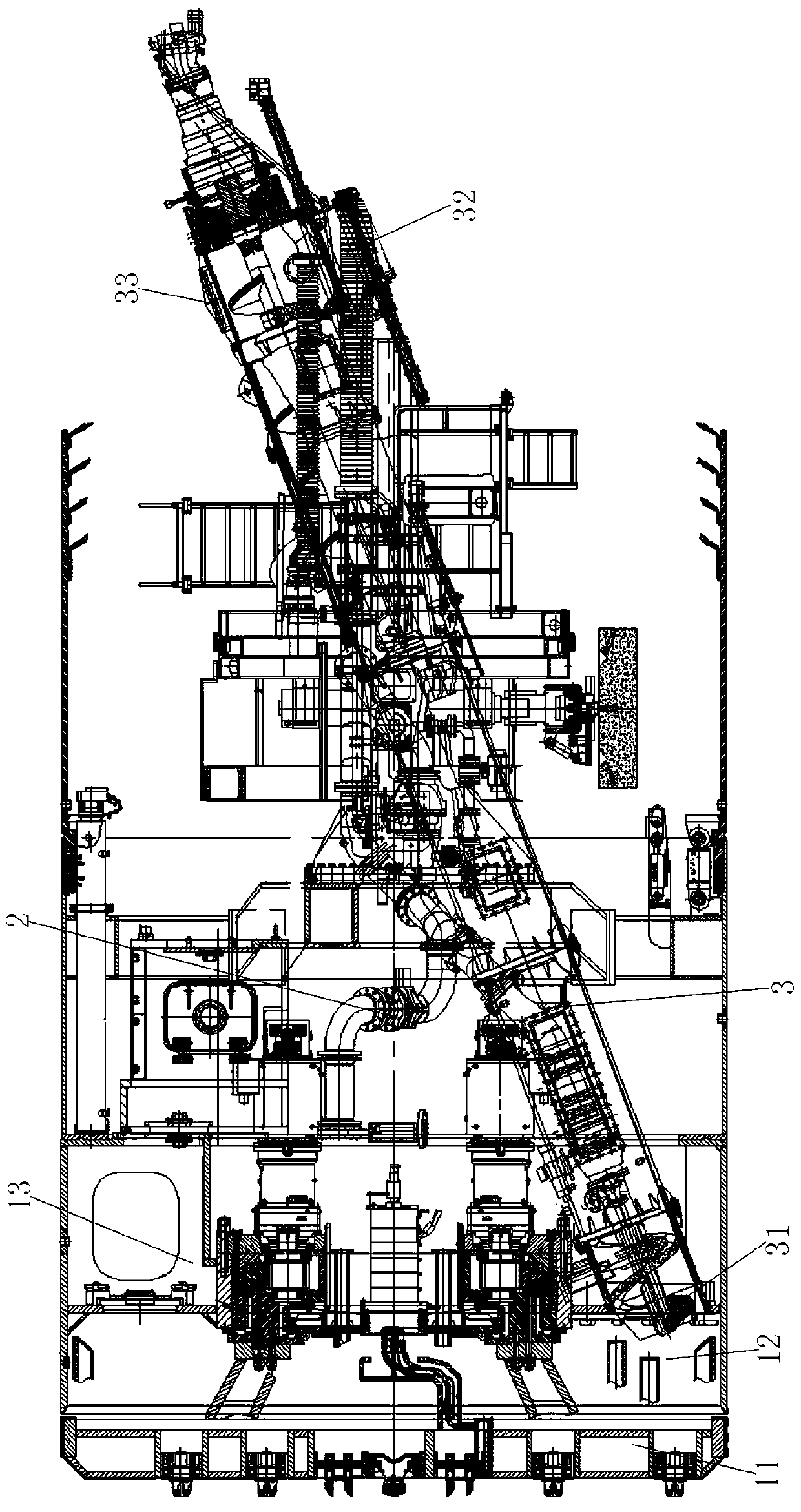

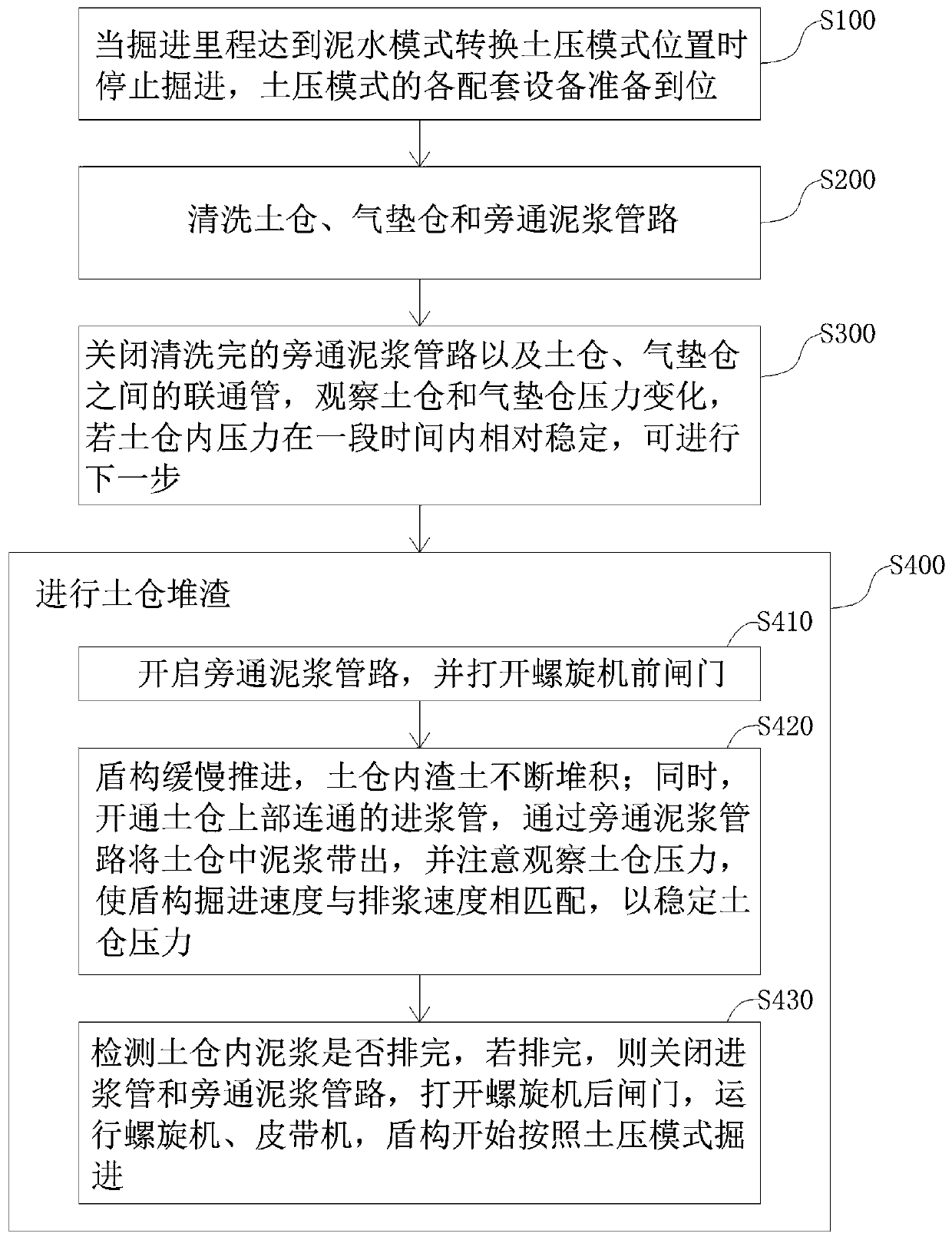

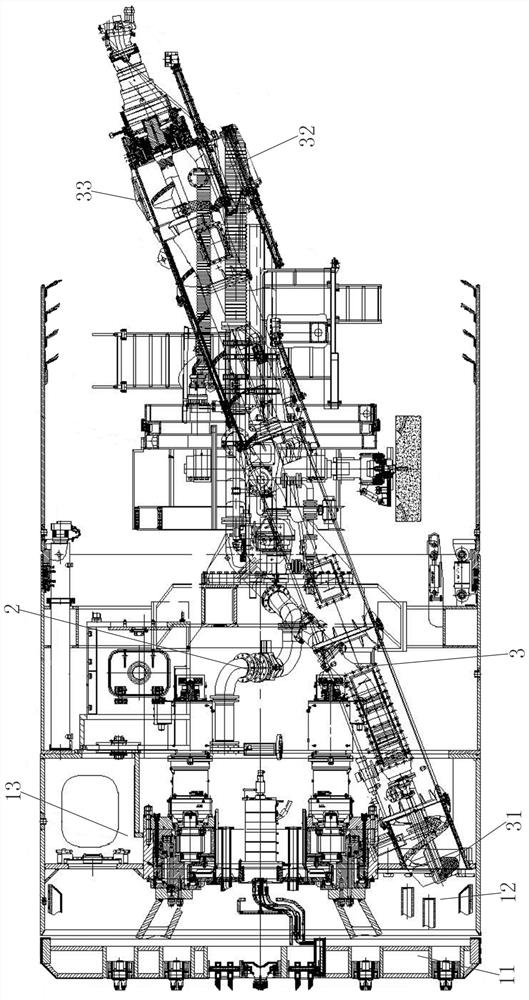

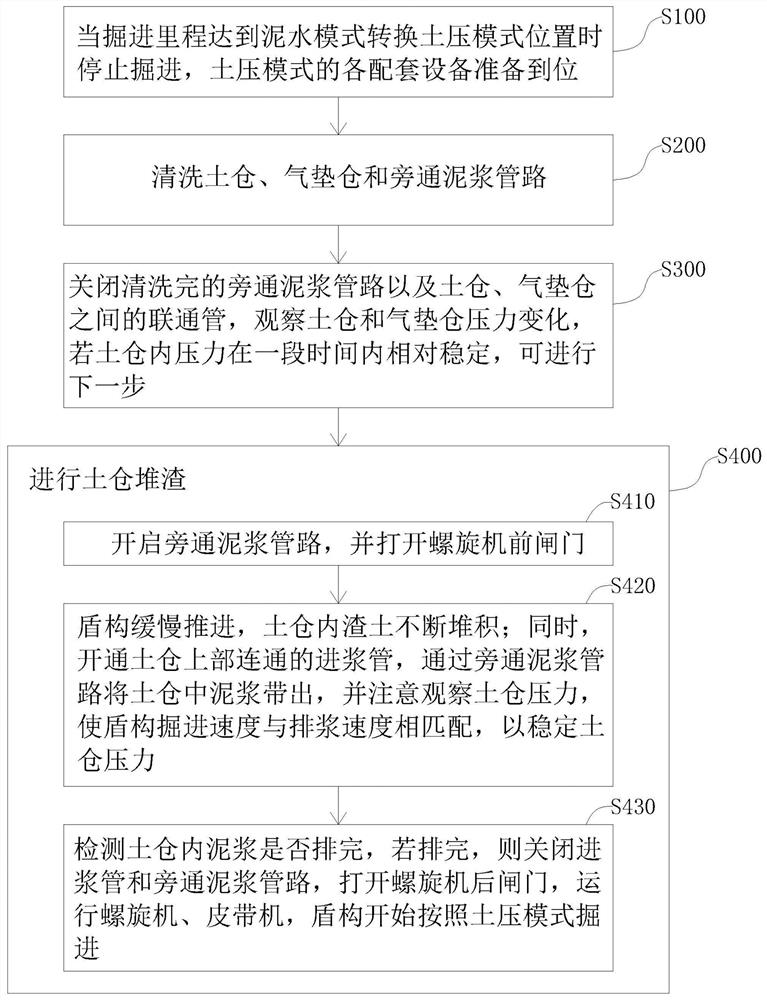

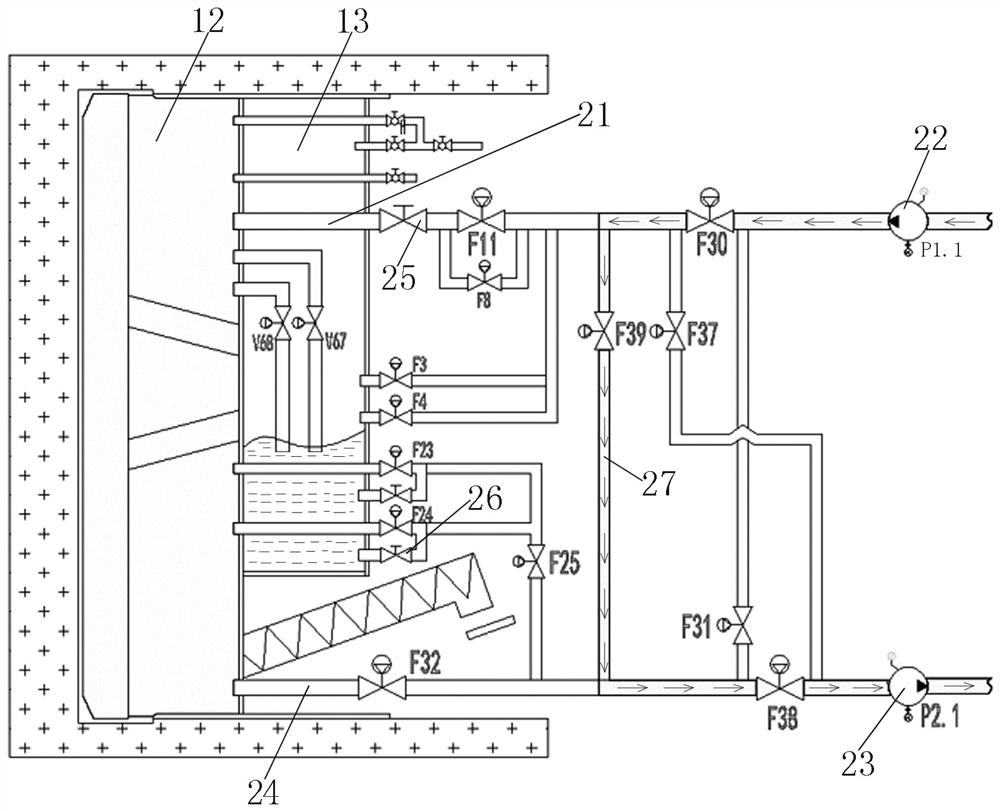

Muddy water/soil pressure dual-mode shield and driving mode conversion method thereof

The invention discloses a muddy water / soil pressure dual-mode shield and a driving mode conversion method thereof. The muddy water / soil pressure dual-mode shield is provided with devices and supporting equipment required for driving in a muddy water mode and a soil pressure mode, and can adopt muddy water and soil pressure dual modes for driving. During converting of the muddy water mode into thesoil pressure mode, after a bypass mud pipeline and a communicating pipe are closed, the pressure changes of a soil bin and an air cushion bin are observed, and then whether conversion can be carriedout or not is judged, so that the stable pressure of the soil bin in the conversion process is ensured advantageously; and in the reverse flow mud discharging process, the mud discharging speed can becontrolled through a mud discharging pump and is matched with the driving speed of the shield, and thus the stable pressure in the soil bin can be actively maintained. During converting of the soil pressure mode into the muddy water mode, a part of muck is discharged through a screw conveyor firstly, and the screw conveyor discharges the muck quickly, so that the conversion efficiency is improvedadvantageously; and reserved muck is subjected to muck-mud replacement through a back-washing mode so that the situation that gushing appears when the screw conveyor discharges the remaining small amount of muck, and consequently, the pressure of the soil bin loses stability can be prevented.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

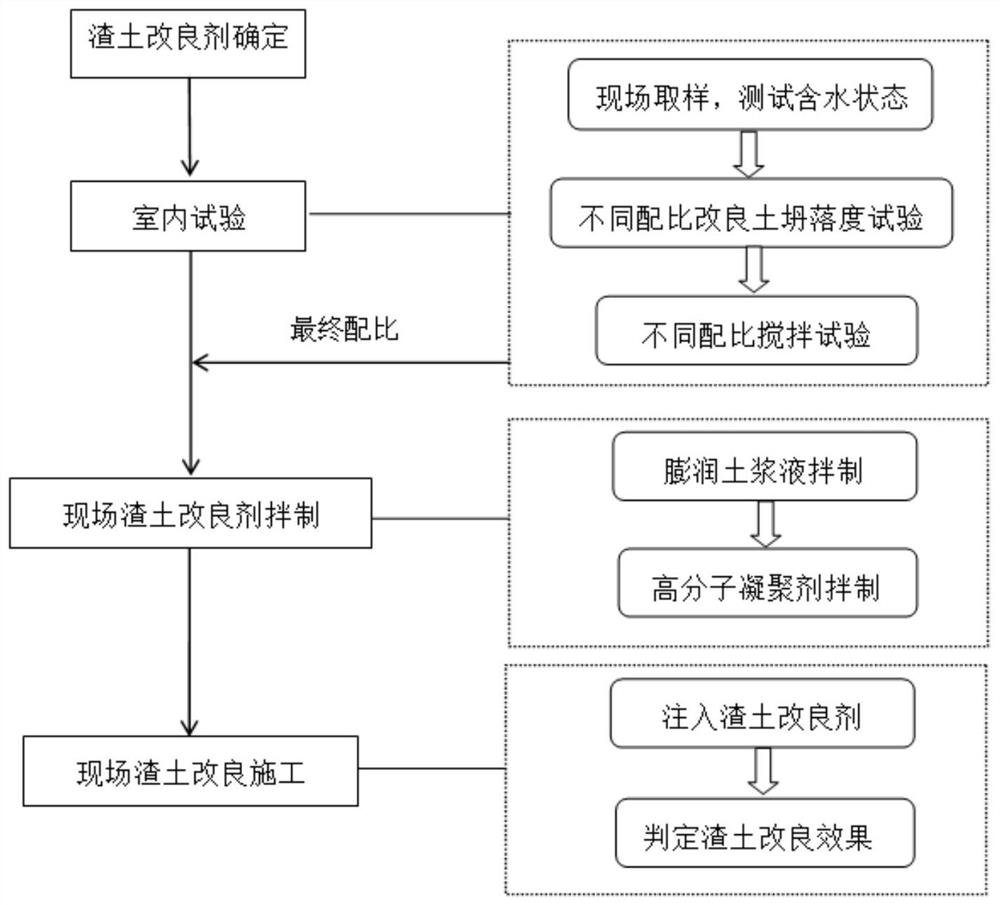

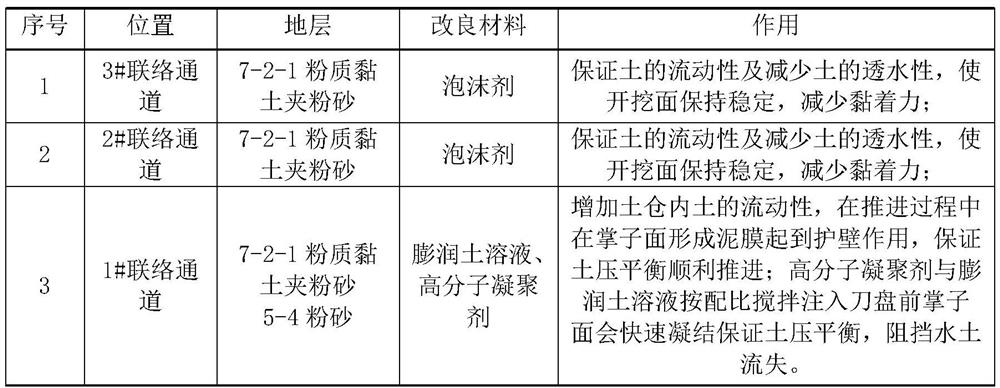

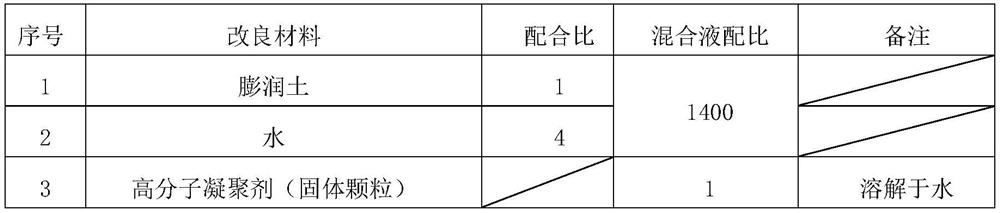

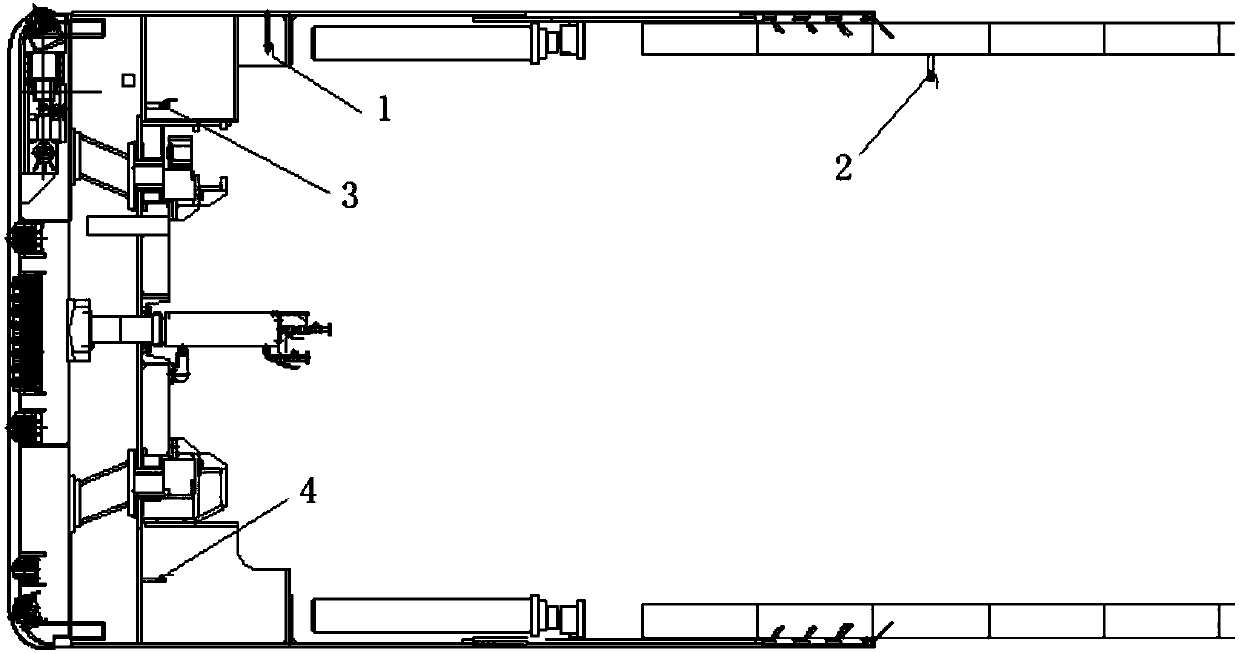

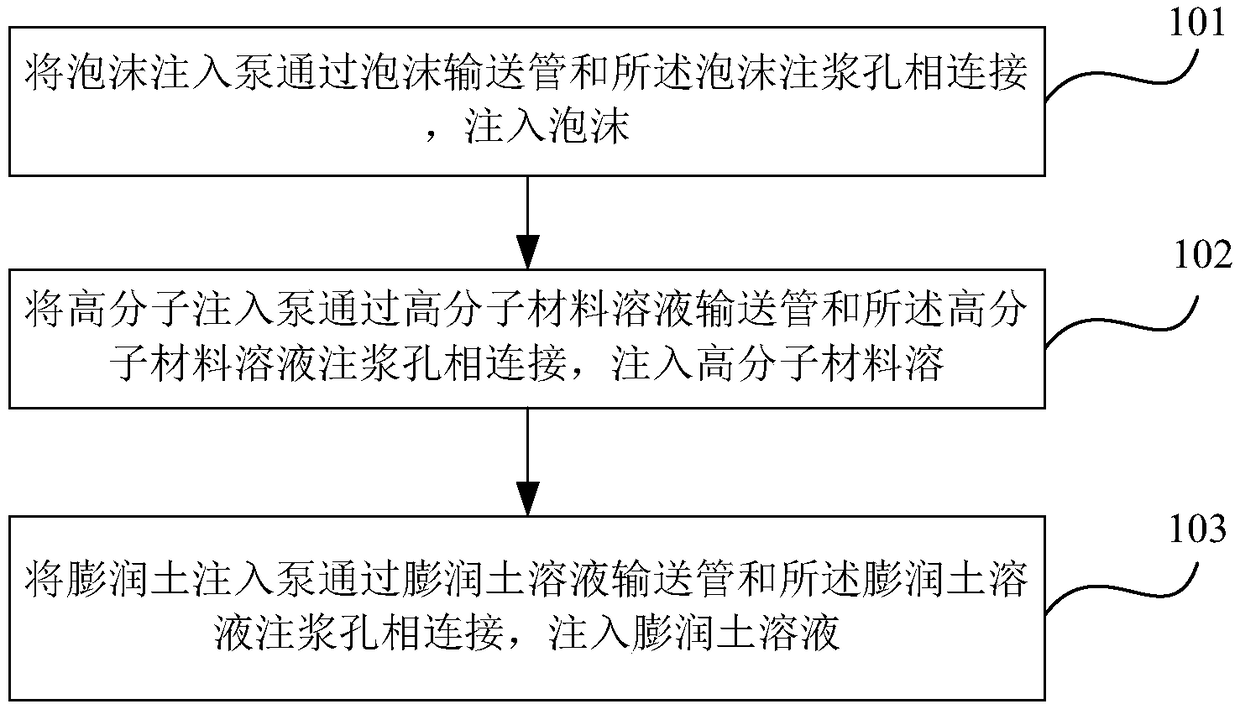

Method for improving full-section muck in silt soil layer during construction of contact channel pipe jacking machine

PendingCN113775345AChange the permeability coefficientNot easy to gushSilicon compoundsTunnelsSoil sciencePolymer solution

The invention relates to a method for improving full-section muck in a silt soil layer during construction of a contact channel pipe jacking machine. The method comprises the following steps of: S1, determining a muck improver; S2, performing an indoor test; S3, mixing the muck improver on site; and S4, performing site construction. The method has the beneficial effects that the muck is improved by adopting a bentonite improver (a bentonite solution and a high-molecular flocculant), a high-molecular polymer solution has relatively high adhesion and can well absorb soil moisture, and the permeability coefficient of the muck is changed through cutter head cutting and screw machine stirring, so that the muck is fully improved. The improved muck is not easy to gush and cake, the permeability of the muck in a soil bin is effectively reduced, and the gushing is further inhibited, so that shield tunneling is smooth and efficient, the shutdown time is shortened, the muck in a screw machine is prevented from being solidified, and the construction safety and smoothness are guaranteed.

Owner:浙江杭海城际铁路有限公司 +2

Construction method of below-sensitive-building water-enriched rock stratum full-section grouting shield

ActiveCN107642364AEasy to excavateMeet the rapid excavationUnderground chambersTunnel liningBedrockSodium Bentonite

Provided is a construction method of a below-sensitive-building water-enriched rock stratum full-section grouting shield. The construction method of the below-sensitive-building water-enriched rock stratum full-section grouting shield includes the construction steps of reinforcing shield sealing, filling the periphery of the shield with bentonite, supplementing grout to gaps behind duct-piece walls, replacing muck with gas, replacing the gas with grout, grouting full sections, detecting grouting effects and conducting shield tunneling. By the adoption of the construction method of the below-sensitive-building water-enriched rock stratum full-section grouting shield, base-rock gap channels can be effectively sealed in all directions, loss of underground water is reduced, tunneling environment is improved, soil transporting of a screw conveyor is facilitated, so that the shield tunnels rapidly, and descending of buildings on the earth surface can be effectively controlled.

Owner:YSD RAIL TRANSIT CONSTR CO LTD

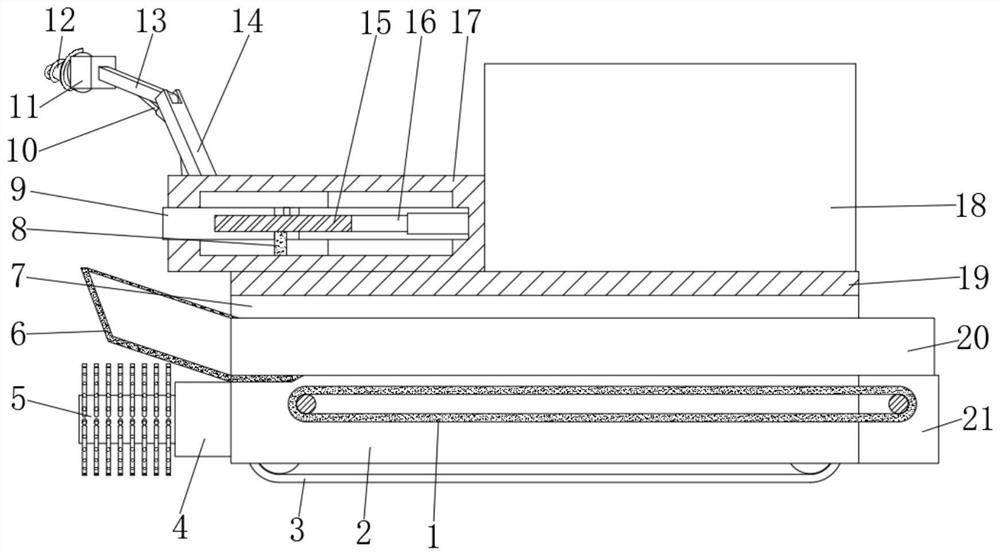

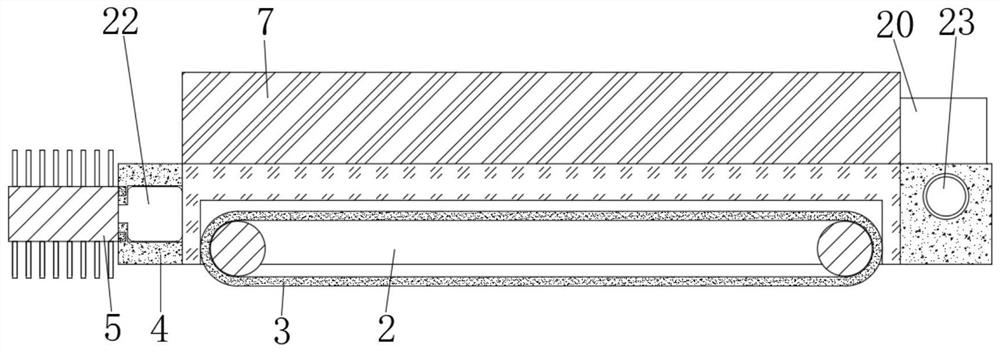

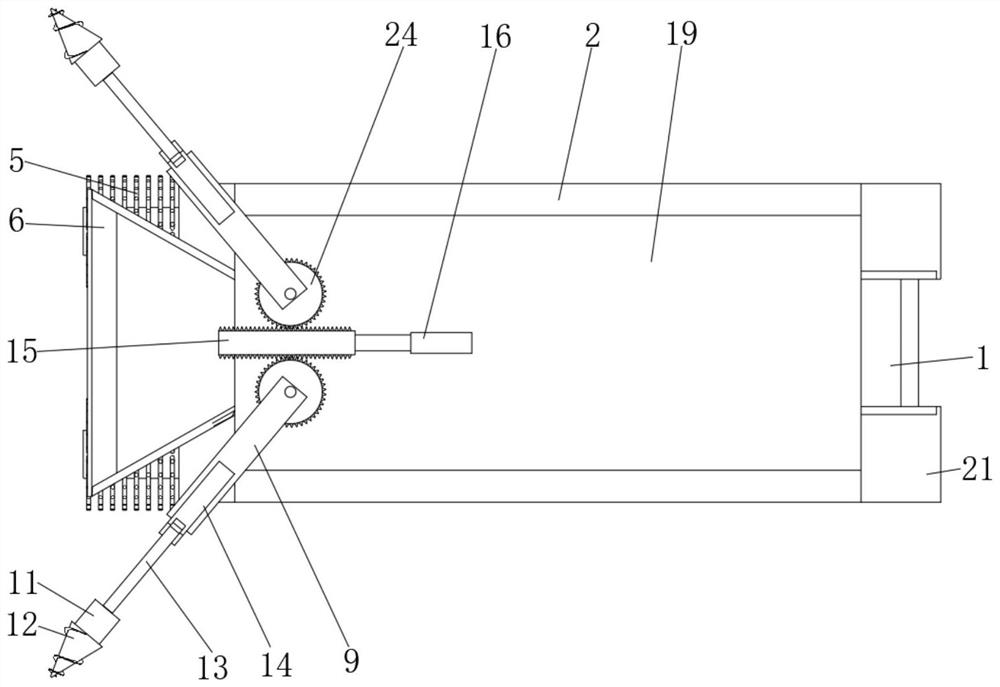

Coal mine roadway rapid tunneling auxiliary device

InactiveCN111946362AFacilitate excavation workImprove work efficiencyTunnelsMining engineeringDrill bit

The invention belongs to the technical field of coal mine excavation, and particularly relates to a coal mine roadway rapid tunneling auxiliary device. Aiming at solving the technical problems that atunneling machine is small in excavation crushing area and slow in progress during coal mine excavation, the following scheme is put forward currently, the coal mine roadway rapid tunneling auxiliarydevice comprises a base plate, a base is fixed to the outer wall of the top of the base plate, a third telescopic rod is fixed to the inner wall of the rear side of the base, and a toothed plate is fixed to the top end of the third telescopic rod. According to the coal mine roadway rapid tunneling auxiliary device, through arrangement of the third telescopic rod, the toothed plate, a rotating rodand a toothed disc, the third telescopic rod extends and retracts, the toothed plate moves forwards and backwards, thus the toothed disc and the rotating rod are made to rotate leftwards and rightwards, and therefore the transverse direction of drill bit excavation is controlled; and through arrangement of a second connecting rod, a first connecting rod, a second telescopic rod and a first telescopic rod, the second telescopic rod and the first telescopic rod are telescopically matched to enable the drill bit to move up and down, so that the longitudinal excavation direction of the drill bit is controlled, through cooperation, coal mine excavation work of the coal mine roadway rapid tunneling auxiliary device is facilitated, and the coal mine excavation work efficiency is improved.

Owner:鄢德恒 +4

Remanufacturing method of shield protection cutting tools

A remanufacturing method of shield protection cutting tools belongs to a civil engineering art field. According to practical wear conditions of the shield protection cutting tools, the remanufacturing method of the shield protection cutting tools is characterized by remanufacturing the shield protection cutting tools through fully utilizing abandoned beck knives and on-site resources, saving steel and alloy of remanufacturing the shield protection cutting tools, prolonging service life of the shield protection cutting tools around shield cutterheads, providing guarantees for the shield protection cutting tools to drive successfully. The process of the remanufacturing method of the shield protection cutting tools comprises the following technological steps: (1) measuring the shield protection cutting tools, recording the shield protection cutting tools data, ensuing raw materials of utilizing the shield protection cutting tools, (2) confirming the height of the remanufacturing shield protection cutting tools, (3) making the remanufacturing shield protection cutting tools, (4) welding the remanufacturing shield protection cutting tools, (5) checking and accepting. Remanufacturing the abandoned beck knives into the shield protection cutting tools around the shield cutterheads has the advantages of saving economic costs and schedule costs, efficiently avoiding a series of construction risks caused by serious wear of the shield protection cutting tools in the specific strata.

Owner:NANCHANG UNIV +2

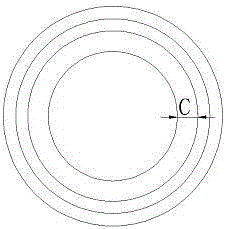

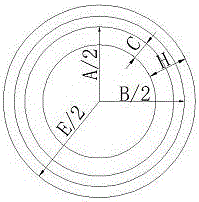

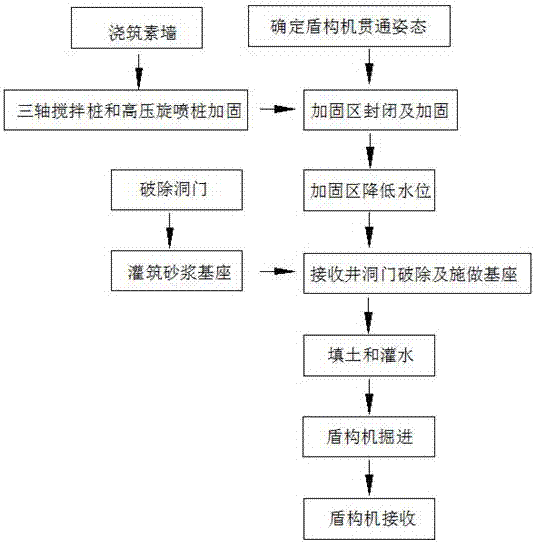

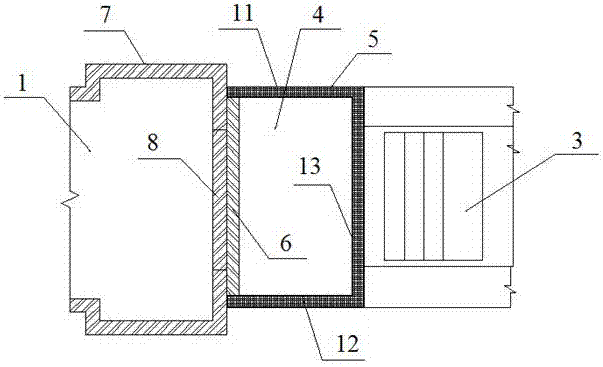

Covering earth balanced safe receiving method of large-diameter shield tunneling machine

The invention provides a covering earth balanced safe receiving method of a large-diameter shield tunneling machine. The method comprises the following steps of determining the through posture of the shield tunneling machine, sealing and reinforcing a reinforced area, lowering the water level of the reinforced area, removing a portal of a receiving well, manufacturing a substrate, performing earth filling and watering, enabling the shield tunneling machine to perform tunneling, and receiving the shield tunneling machine. By means of the covering earth balanced safe receiving method of the large-diameter shield tunneling machine, the shield tunneling machine can arrive at the receiving well safely while water and soil pressure balance and effective counter-force are maintained. Besides, a protection measure of an underwater arrival method is adopted for receiving of the shield tunneling machine in order to reduce the construction risk. The method has the advantages of safety and low cost, and can better achieve safe receiving of the shield tunneling machine.

Owner:CHINA RAILWAY SHISIJU GROUP CORP

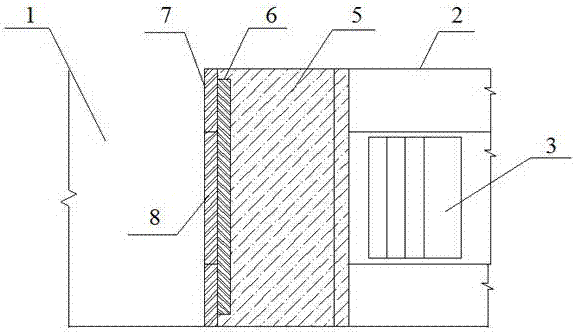

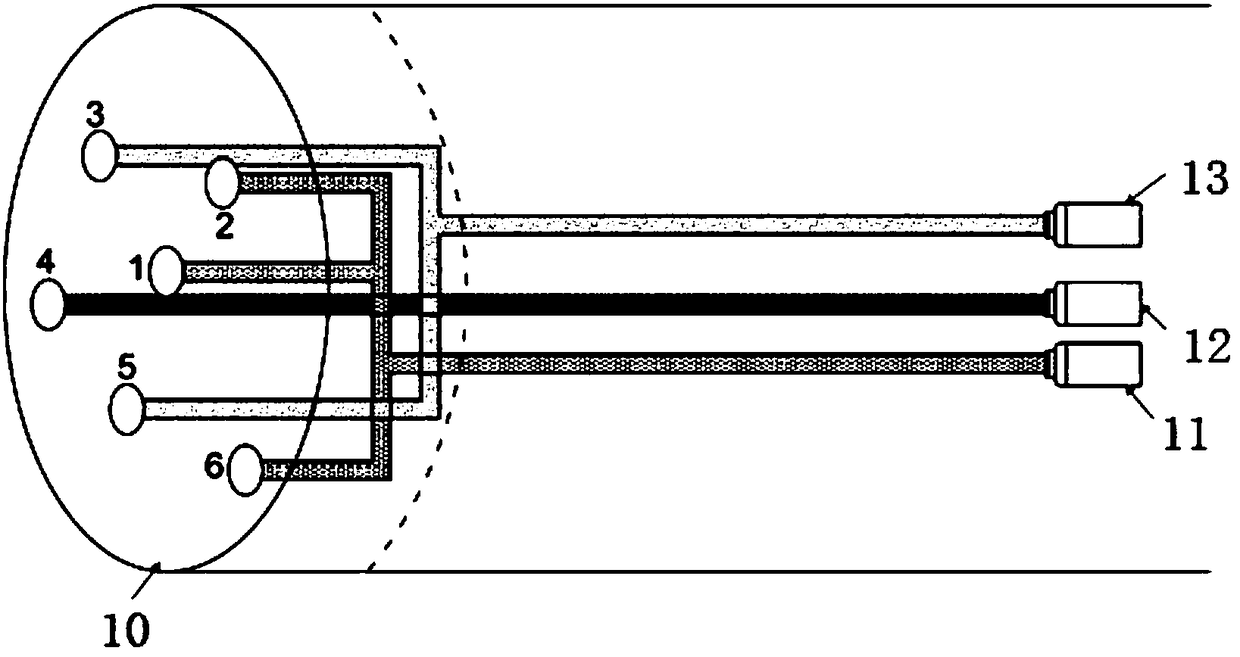

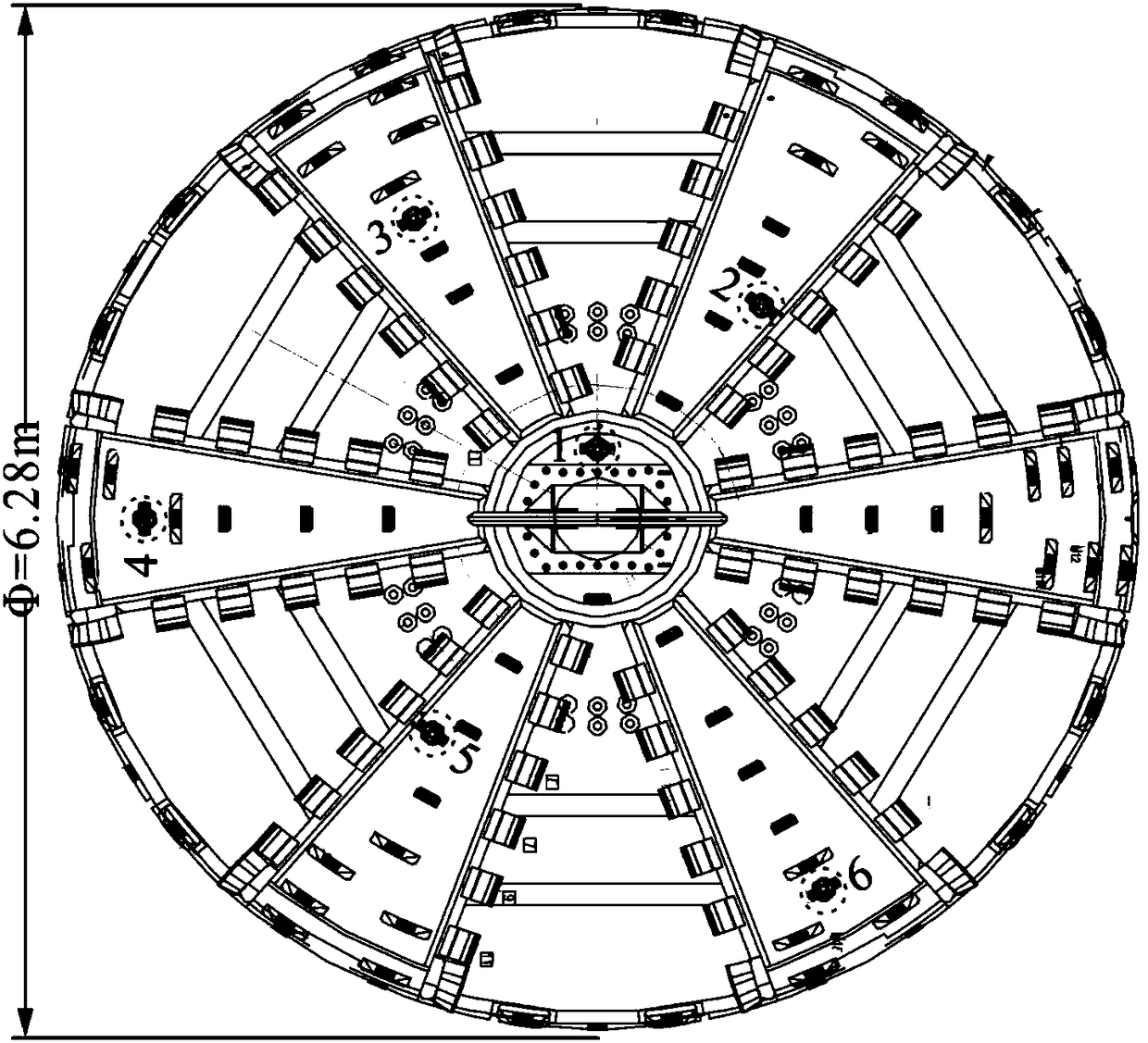

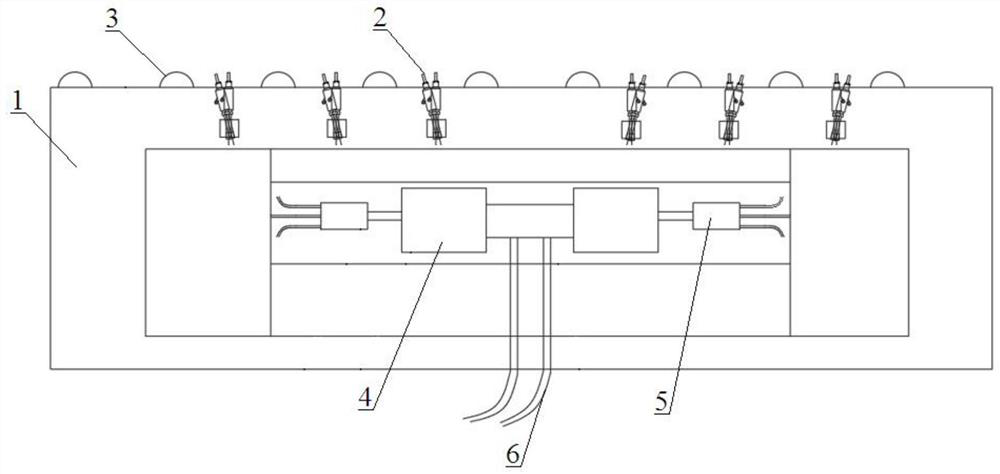

Slag soil improvement construction device and method for shield construction

The embodiment of the invention provides a slag soil improvement construction device and method for shield construction. The device comprises a shield cutter head, a foam injection pump, a polymer injection pump and a bentonite injection pump; at least three grouting holes are formed in the shield cutter head from the center position to the outside, and the three grouting holes include a foam grouting hole, a bentonite solution grouting hole and a polymer material solution grouting hole; the foam injection pump is connected with the foam grouting hole through a foam conveying pipe; the polymerinjection pump is connected with the polymer material solution grouting hole through a polymer material solution conveying pipe; the bentonite injection pump is connected with the bentonite solutiongrouting hole through a bentonite solution conveying pipe. The device ensures the smooth tunneling of a shield, the foam injection hole ensures that the foam plays a role in reducing the resistance tothe cutter head, and the bentonite solution grouting hole and the polymer material solution grouting hole achieve the purpose of improving the flow plasticity and permeability of slag soil during theconstruction of a coarse sand layer zone in the rich water.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Soil mass stabilization agent and production method and application thereof

InactiveCN109971485AImprove reinforcementSmooth tunnelingOrganic fertilisersTunnelsCross-linkShield tunneling

The invention discloses a soil mass stabilization agent and a production method and application thereof. The soil mass stabilization agent is composed of A liquid and B liquid; the A liquid comprisesthe following components of, in parts by weight, 15-25 parts of acrylamide, 0.5-1.5 parts of methylene diacrylamide, 0.4-1.0 part of tetramethylethylenediamine and 70-85 parts of water; and the B liquid is an ammonium persulfate aqueous solution with a mass percent of 0.8-1.6%. Ammonium persulfate is used as an initiator, the acrylamide is used as a polymerization monomer raw material, the methylene diacrylamide and the tetramethylethylenediamine are used as cross-linking agents, and firstly, a curing effect of generated polymer sol is used for making a soil mass solidify to form a whole, so that the soil mass is stabilized, the soil mass stabilization agent has an excellent stabilization effect, and tunneling can be smoothly conducted; and secondly, the generated polymer sol is low in cohesiveness and good in watertightness, and not only are bin pasting of a shield tunneling machine and mud lining of a cutter panel of the shield tunneling machine avoided, but also inflow of the rear portion of a shield tail can be sealed, so that fast tunneling of the shield tunneling machine is achieved, and accordingly the soil mass stabilization agent plays a positive role in tunnel construction.

Owner:NANNING RAIL TRANSIT

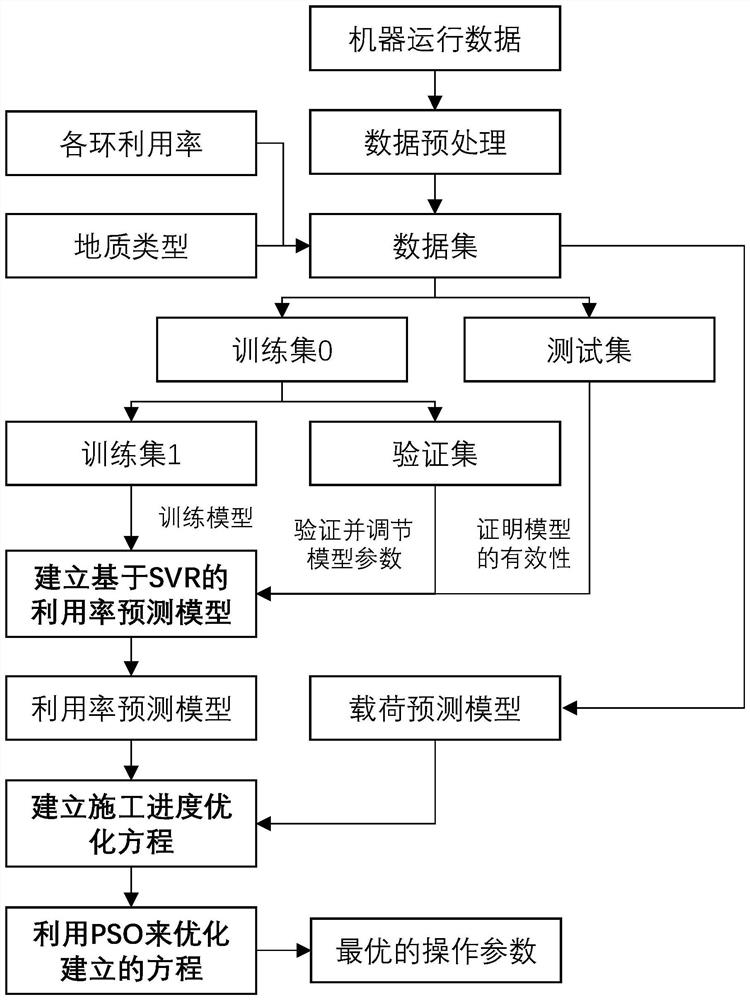

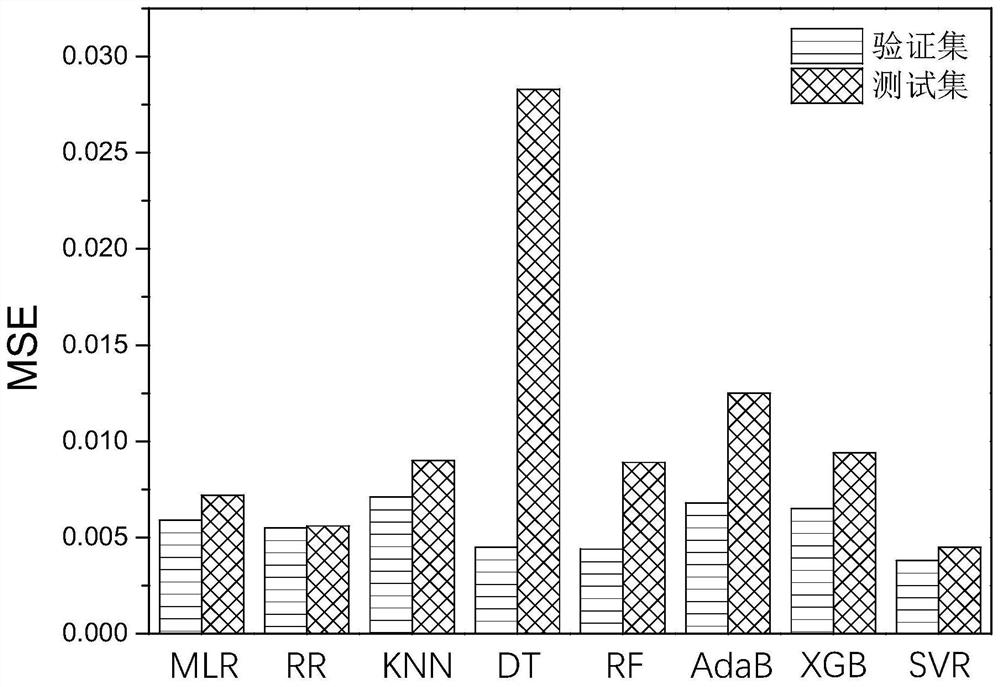

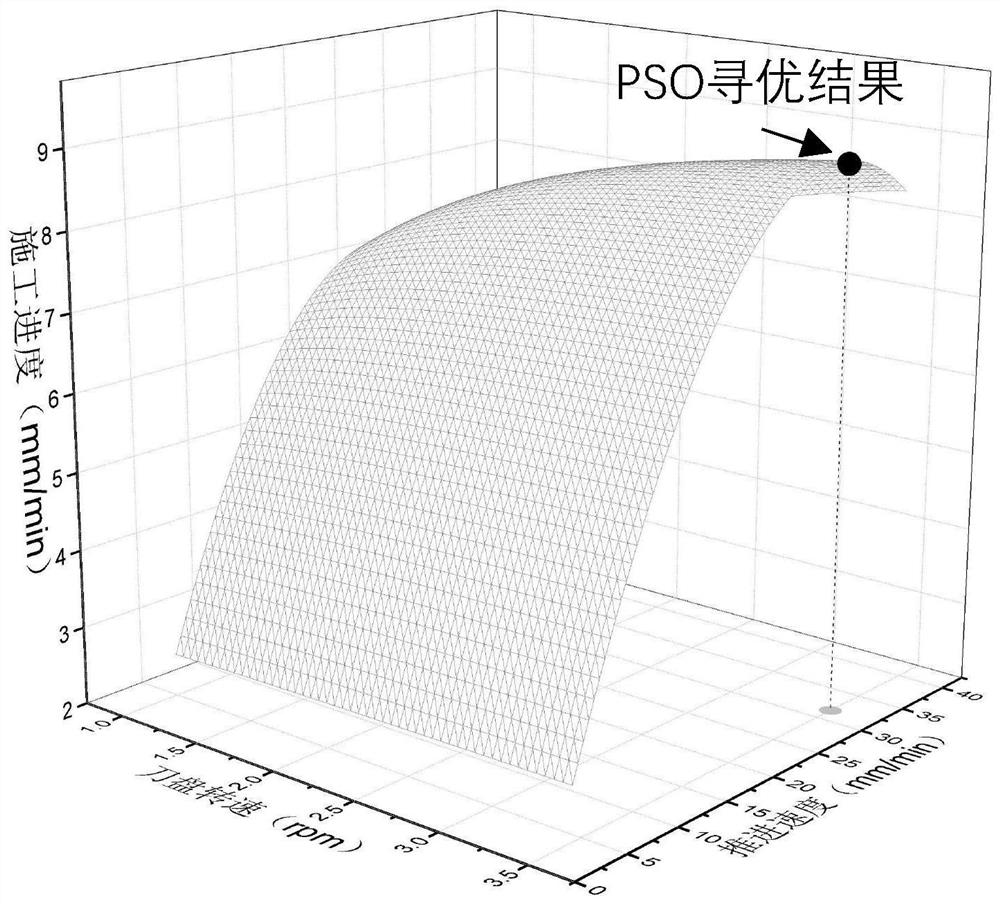

Shield utilization rate prediction and operation parameter optimization method and system based on SVR and PSO

PendingCN113435056ASmooth tunnelingEnables real-time forecastingDesign optimisation/simulationComplex mathematical operationsData setUtilization rate

The invention provides a shield utilization rate prediction and operation parameter optimization method and system based on SVR and PSO. The method comprises the following steps of 1, screening load and operation parameters from machine operation data, and preprocessing the screened data; 2, constructing a data set by using the preprocessed data, the geological type and the utilization rate of each ring, and dividing the data set; 3, establishing a shield utilization rate prediction model by using the SVR and the data set; 4, constructing an optimization equation with the maximum construction progress as a target and operation parameter changes, load changes and geological types as constraint conditions; and 5, obtaining optimal operation parameters under a specific geological type by using an equation established by PSO optimization, so that the construction progress is maximum. According to the method, the utilization rate can be accurately predicted, shield operation can be optimized, safe and rapid tunneling can be achieved, and good engineering application value is achieved.

Owner:SHANGHAI JIAO TONG UNIV

Deformation control construction method for building close to foundation pit

PendingCN113737774AReduce stress transferReduce distortionProtective foundationTunnelsDeformation controlLarge deformation

The invention discloses a deformation control construction method for a building close to a foundation pit. The method comprises the steps: I, conducting deformation protection on the building close to the foundation pit; II, reinforcing isobathic groove walls of a diaphragm wall; III, enclosing the underground diaphragm wall and controlling deformation of adjacent buildings; and VI, reinforcing the pit bottom and the end. According to the construction method, deformation of adjacent buildings can be effectively reduced, safety and normal use of surrounding pipelines and adjacent buildings can be guaranteed, stability of groove walls and smooth construction are guaranteed in the enclosure structure construction process, perfection and smooth tunneling of a shield tunneling machine are guaranteed in the shield station-crossing process, stability of a foundation pit is guaranteed in the foundation pit excavation process, the diaphragm wall has no large deformation, and joints have no water seepage.

Owner:中铁二十局集团第五工程有限公司 +1

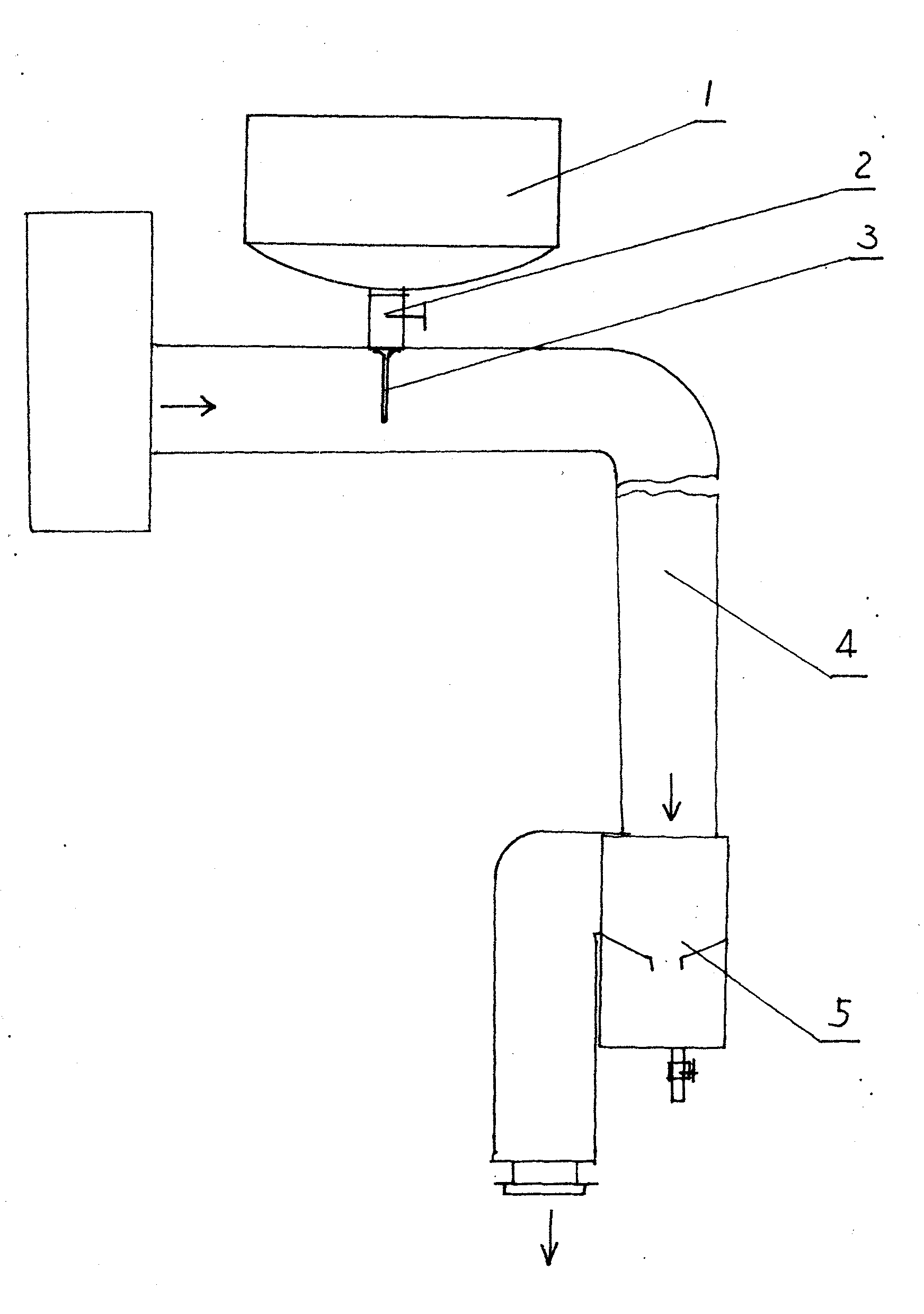

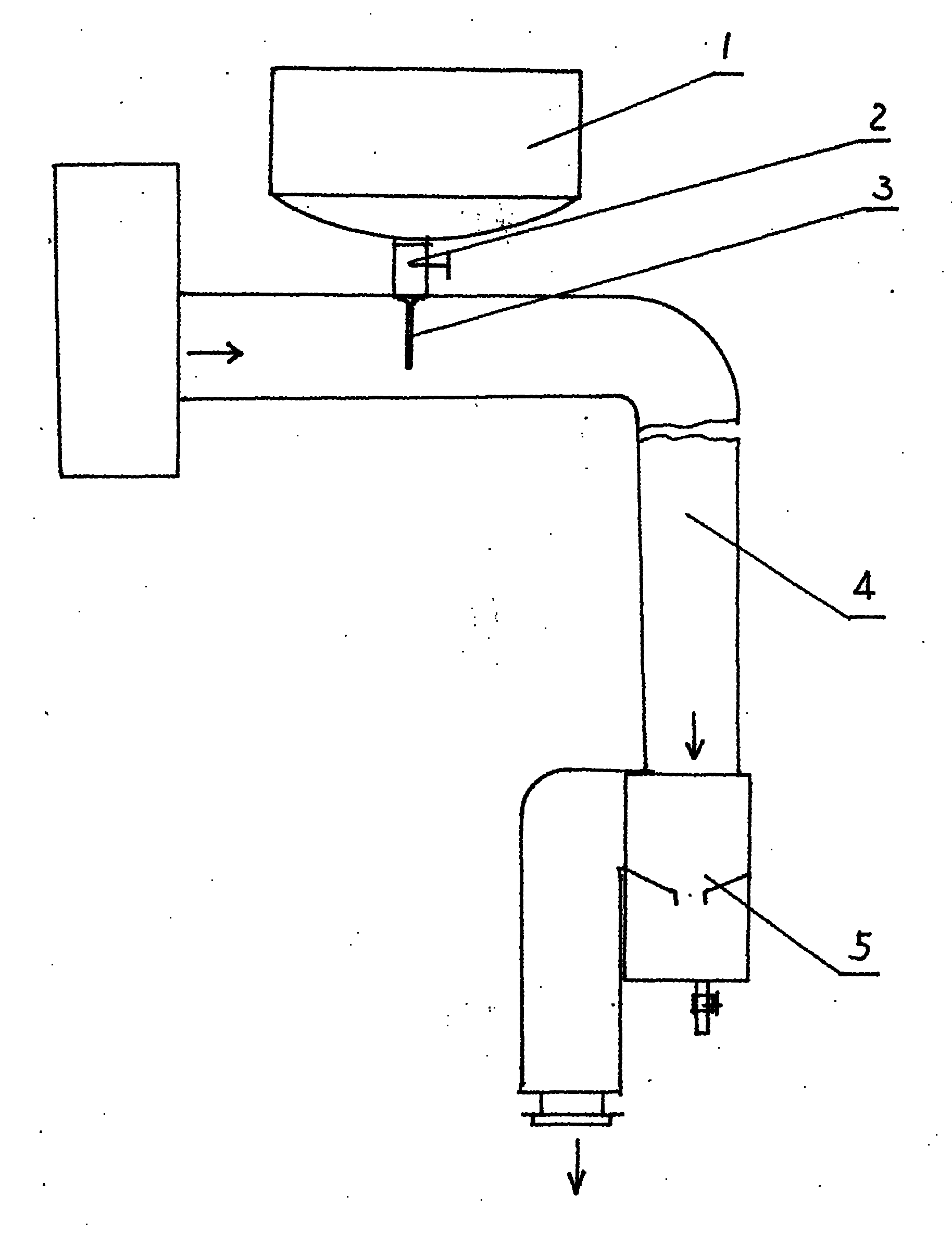

Severe cold area compressed air antifreezing method and antifreezing device thereof

InactiveCN101825223ALowering the freezing pointNot easy to freezePipeline systemsThermodynamicsAlcohol

The invention discloses a severe cold area compressed air antifreezing method and an antifreezing device thereof. In the method, when compressed air is transported, pure alcohol is sprayed at the upstream of a transport pipeline, and the downstream of the transport pipeline is connected in series with a condensed water collector. In the antifreezing device, a quantitative regulation valve is installed at the bottom of an alcohol tank, and a wind needle type dropper is connected to the quantitative regulation valve and is inserted into a compressed air pipeline. The method utilizes a principle that the freezing point of alcoholic solution is lower than the freezing point of water to spray the pure alcohol into humid compressed air, the humidity in the compressed air gradually achieves a dewpoint to separate out the moisture, the moisture forms low concentration alcoholic solution with the alcohol together, and the low concentration alcoholic solution enters the condensed water collector and is not easy to freeze because the freezing point of the alcoholic solution is low, thereby reaching the antifreezing purpose.

Owner:亓荣强

Waste soil modifier capable of guaranteeing that shield tunneling machine smoothly tunnels in conglomerate layer with boulders

InactiveCN103131422AEnsure safetySmooth tunnelingBuilding constructionsOrganic fertilisersEngineeringShield tunneling

Disclosed is a waste soil modifier capable of guaranteeing that a shield tunneling machine smoothly tunnels in a conglomerate layer with boulders. The waste soil modifier is composed of sodium bentonite mud, foam solution and a shield slurrying agent, and the mass parts are respectively 40-55 parts of the sodium bentonite mud, 50-70 parts of the foam solution and 3-5 parts of the shield slurrying agent. The waste soil modifier can not only ensure that the shield tunneling machine smoothly tunnels but also reduce abrasion of a cutter disc, abrasion of a cutter, and replacing of the cutter, and accordingly cost is reduced, time limit for a project is shortened and safety construction of the project is guaranteed.

Owner:北京城建设计发展集团股份有限责任公司

Water jet assisted bolter miner and tunneling method

ActiveCN113266351AHigh hardnessSmooth tunnelingSlitting machinesCutting machinesDust controlWater flow

The invention provides a water jet assisted bolter miner and a tunneling method. The bolter miner comprises a cutting roller and a water jet injection assembly, the water jet injection assembly comprises at least one spray head movably arranged on the surface of the cutting roller, the spray head comprises a cutting nozzle, a dust removal nozzle and a nozzle switching assembly arranged between the cutting nozzle and the dust removal nozzle, the nozzle switching assembly comprises a plugging piece and an elastic piece, and the plugging piece reciprocates between the two nozzles under the combined action of water flow and the elastic piece, so that water is sprayed out of the cutting nozzle to form clustered jet flow or sprayed out of the dust removal nozzle to form diffused jet flow. During tunneling operation, the tunneling anchor machine switches the operation mode of the spray head by controlling the pressure of the output flow of a pump station; in the high-pressure small-flow mode, the cluster jet flow cuts a gangue layer to form a groove; and in the low-pressure large-flow mode, the cutting roller rotates to crush rocks, and the diffused jet flow cools cutting teeth and remove dust during construction, so that shutdown tool changing and complex nozzle switching operation can be avoided, and the working efficiency is improved.

Owner:CHINA RAILWAY CONSTR HEAVY IND

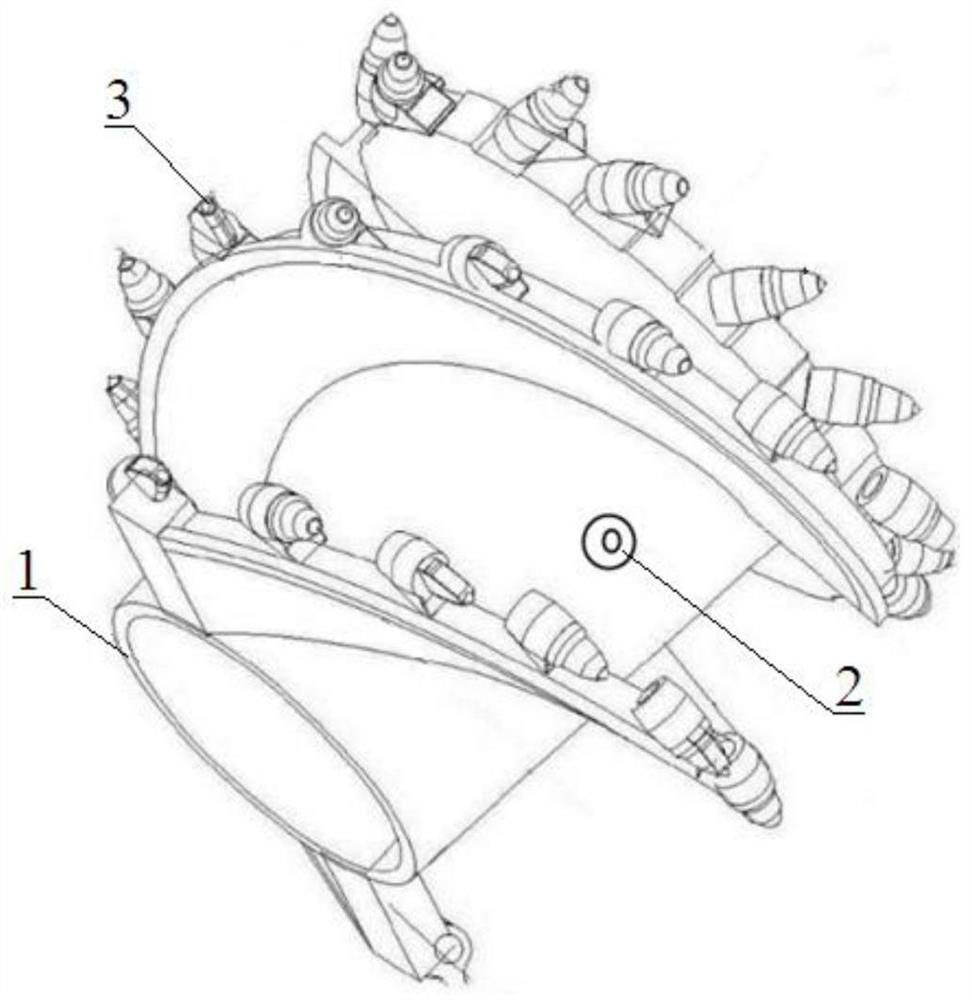

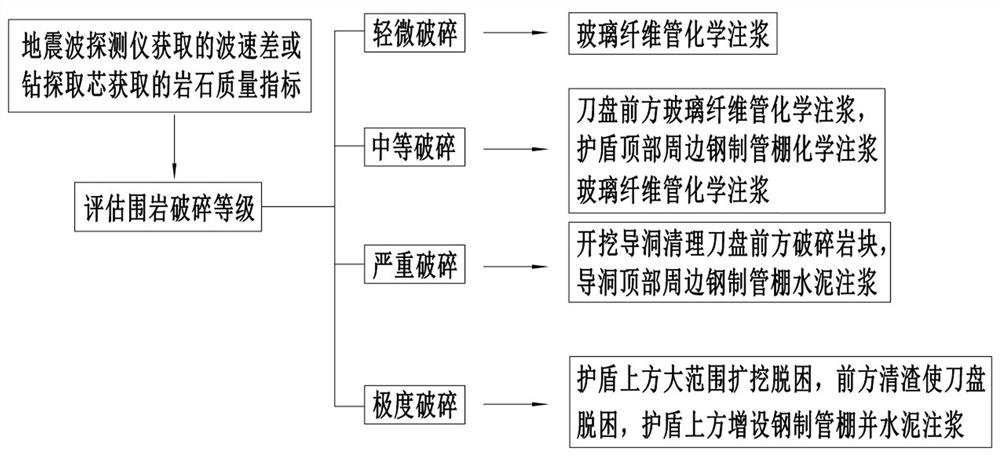

TBM grading anti-blocking and de-trapping construction method for soft and broken stratum tunnel

ActiveCN113202492ASmooth tunnelingShorten the construction periodMining devicesUnderground chambersClassical mechanicsStructural engineering

The invention relates to a TBM grading anti-blocking and de-trapping construction method for a soft and broken stratum tunnel. The TBM grading anti-blocking and de-trapping construction method comprises the following steps that a corresponding relation is established through a wave velocity difference detected by a seismic wave detector and a rock quality index obtained by drilling and coring by an advanced drilling machine, and surrounding rock crushing grades are divided into four grade standards of slight crushing, medium crushing, serious crushing and extreme crushing; and different TBM anti-blocking and de-trapping methods are determined according to the different surrounding rock crushing grades. According to the TBM grading anti-blocking and de-trapping construction method, the surrounding rock crushing grades in front of the tunnel can be reasonably evaluated, a reasonable TBM anti-blocking and de-trapping method can be conveniently adopted in a construction site according to the surrounding rock crushing grades, the situation that the construction period is delayed due to frequent blocking or difficult de-trapping of a TBM caused by improper measures is avoided, and the construction efficiency of the TBM is improved.

Owner:STATE KEY LAB OF SHIELD & TUNNELING TECH +2

A kind of soft rock tunnel construction method

ActiveCN103410524BHigh measurement accuracyReduce investmentUnderground chambersTunnel liningRock tunnelBuilding construction

Owner:GEZHOUBA XINJIANG ENG +1

A tunnel boring machine using high-pressure water to break rock

The invention discloses a tunnel borer using high-pressure water to break rock. Thetunnel borercomprises a shield shell, wherein the shield shell is fixedly connected with a side plate, and a cutter disc is arranged on one side of the side plate, and the cutter disc is provided with a plurality of through holes;a plurality of storage slots are formed in the side, away from the side plate, of the cutter disc, a cutter is disposed in each storage slot, and a shield cover is fixed on the other side of the side plate; and a first gear is disposed between the shieldcover and the side plate, and a rotating shaft is fixed to the center of the first gear, and one end of the rotating shaft penetrates through the side plate and is fixedly connected with the center of the cutter disc, and two first servo motors are symmetrically arranged on the side, away from the side plate, of the shield cover. The tunnel boreris simple in structure, the water pressure and water spray quantity can beconveniently adjusted, andnozzles operate separately, work efficiency isimproved, and resources aresaved.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

A laser device for cutting the boulder in front of the tunnel

The invention discloses a laser device for cutting solitary stones in front of a tunnel, including a shield case. A side plate is fixedly connected inside the shield case. A cutter head is arranged onone side of the side plate. Multiple placement slots are arranged in one side of the cutter head away from the side plate. Cutter knives are arranged in the placement slots respectively. A laser mounting bracket is fixed in the middle of the cutter head. A protective cover is fixed on the other side of the side plate. A second gear is arranged between the protective cover and the side plate. A rotating shaft is fixed in the center of one side of the second gear. One end of the rotating shaft runs through the side plate and fixedly sleeves the center of the cutter head. The rotating shaft is sleeved with a sealing ring in a sliding manner. The sealing ring is fixedly connected with one side of the side plate near the cutter head. Two first servo motors are symmetrically arranged on one side of the protective cover away from the side plate. The laser device for cutting solitary stones in front of a tunnel is simple in structure and convenient to operate, can freely control the work of any laser, and is easy to disassemble, install and maintain.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

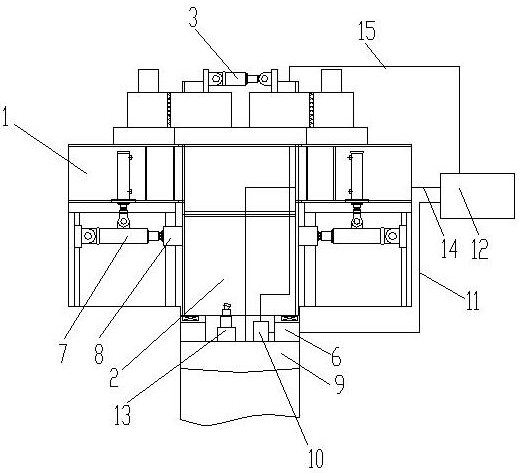

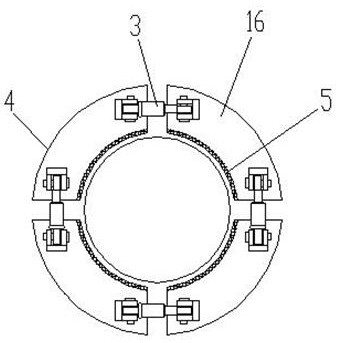

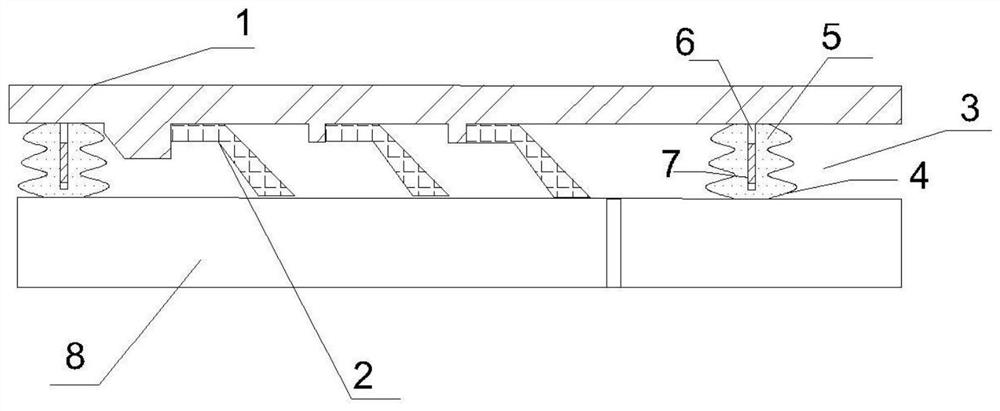

Cable installation connection structure of shield tunneling machine power system and connection method thereof

PendingCN110735643ASmooth tunnelingImprove the connection of construction processCable junctionsArrangements using take-up reel/drumDistribution power systemStructural engineering

The invention discloses a cable installation connection structure of a shield tunneling machine power system and a connection method thereof. The shield tunneling machine power system comprises a ground power supply system, a shield power distribution system and a cable, wherein a relay box is arranged on an annular pushing iron or a pushing system, the cable is divided into a fixed part cable anda movable part cable, one end of the fixed part cable is connected with the ground power supply system, the other end of the fixed part cable is connected with the wire inlet end of the relay box, one end of the movable part cable is connected with the wire outlet end of the relay box, and the other end of the movable part cable is connected with the shield power distribution system. According tothe structure and the method, through the addition of the relay box, on the basis of meeting the safety power utilization specification, the whole original cable is broken into two parts, so that after a section of pipe joint is finished in the tunneling construction, only the cable in the finished pipe joint of a tunnel needs to be disconnected with the wire outlet end of the relay box, the installation and positioning of a next pipe joint can be met, the connection of the construction process is improved, and the smooth tunneling of a rectangular shield tunneling machine is guaranteed.

Owner:CHENGDU JIANGONG ROAD & BRIDGE CONSTR

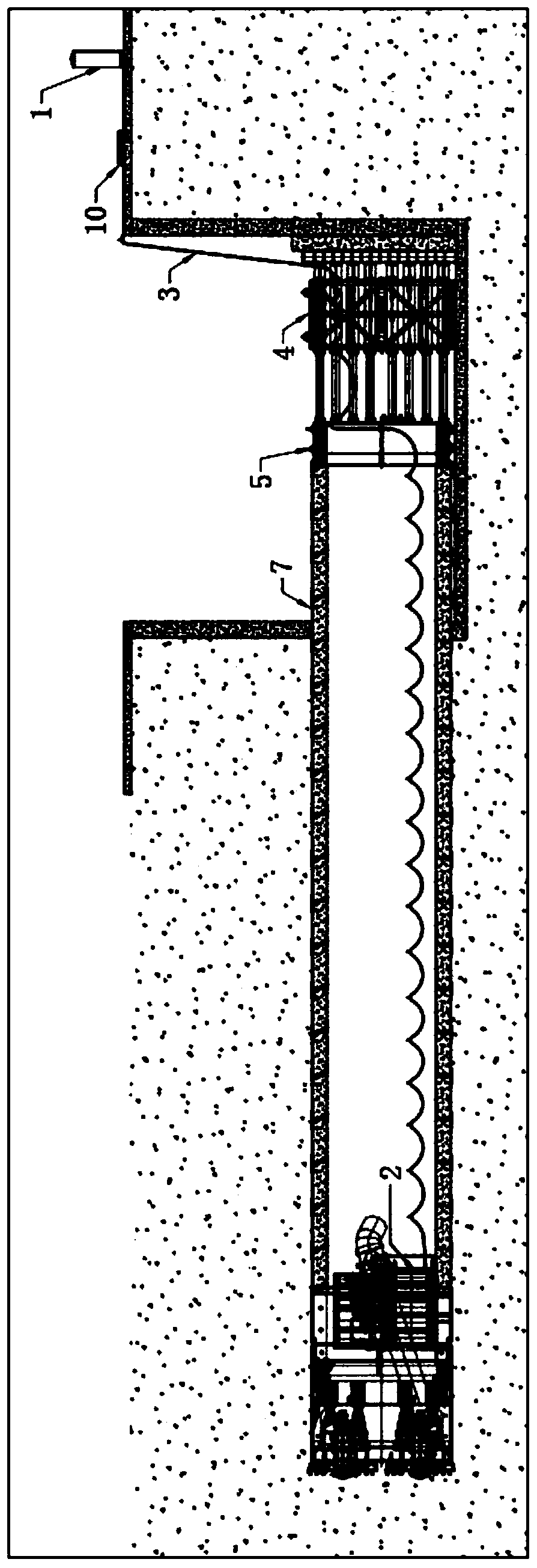

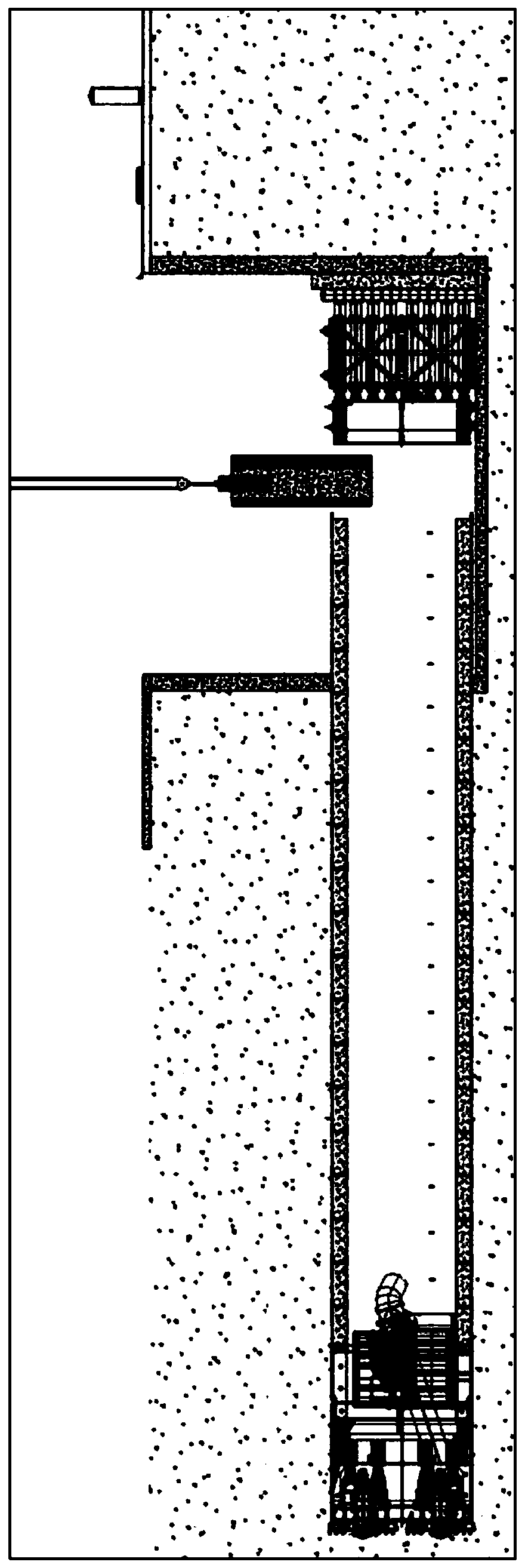

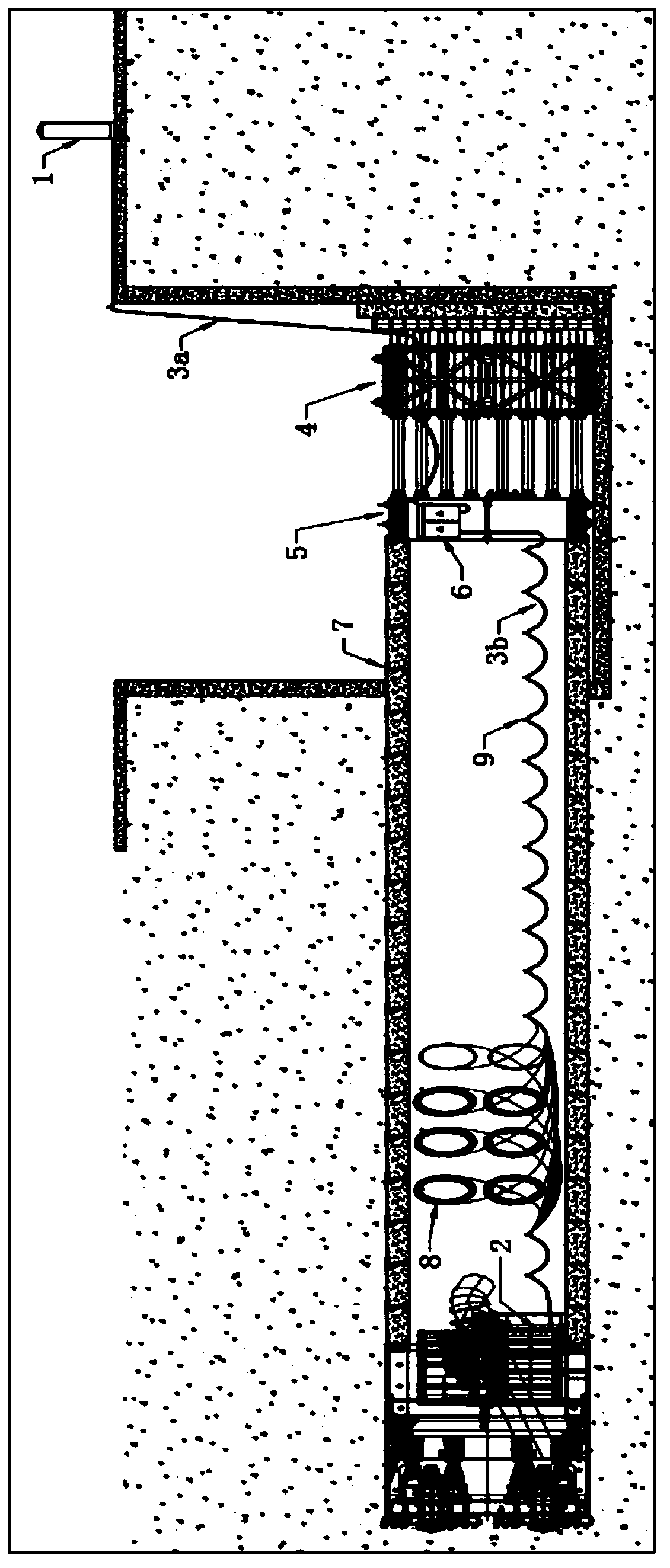

A full-section shaft excavation method

ActiveCN111764906BEasy dischargeImprove reliabilityHydro energy generationFlushingArchitectural engineeringWater circulation

The invention discloses a full-section shaft excavation method, belonging to the technical field of shaft construction. Hold the annular steel pipe and the shield body; the guiding friction block transmits the thrust of the propulsion cylinder to the excavation cutter head, and the excavation cutter head rotates downward and vertically under the action of the driving member, and the mud-water circulation device works to discharge the mud; c. The crane lifts the arc-shaped steel pipe sheet, assembles the next ring-shaped steel pipe, and connects the two ring-shaped steel pipes, holds the oil cylinder to extend, opens the holding ring, and repeats the excavation operation. The invention can save space for the assembly of the arc-shaped steel pipe sheet, improve the holding reliability, simplify the construction process, facilitate disassembly and assembly, and can quickly discharge the mud during the downward vertical excavation process, and improve the reliability and excavation efficiency of the vertical shaft excavation. , the whole excavation process is easy to operate.

Owner:SINOHYDRO JIAJIANG HYDRAULIC MACHINERY +1

Mud-water/earth pressure dual-mode shield tunneling and its tunneling mode conversion method

The invention discloses a mudwater / earth pressure dual-mode shield and a method for switching the excavation mode thereof. The mudwater / earth pressure dual-mode shield is equipped with devices and supporting equipment required for muddy water mode and earth pressure mode excavation, and can use muddy water and earth pressure dual mode excavation. When the mud-water mode is converted to the earth pressure mode, after closing the bypass mud pipeline and the connecting pipe, observe the pressure change of the soil tank and the air cushion tank, and then judge whether the conversion can be performed, which is conducive to ensuring the stability of the soil tank pressure during the conversion process; During the slurrying process, the slurry discharge speed can be controlled by the slurry discharge pump to match the tunneling speed of the shield machine, so that the pressure in the soil bin can be actively maintained stable. When the soil pressure mode is converted to the mud-water mode, a part of the dregs is first discharged through the screw machine. The screw machine discharges the dregs quickly, which is conducive to improving the conversion efficiency; and the reserved dregs are replaced by the backwash mode to prevent the screw When the machine discharges the remaining small amount of soil slag, gushing occurs and the pressure of the soil bin becomes unstable.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

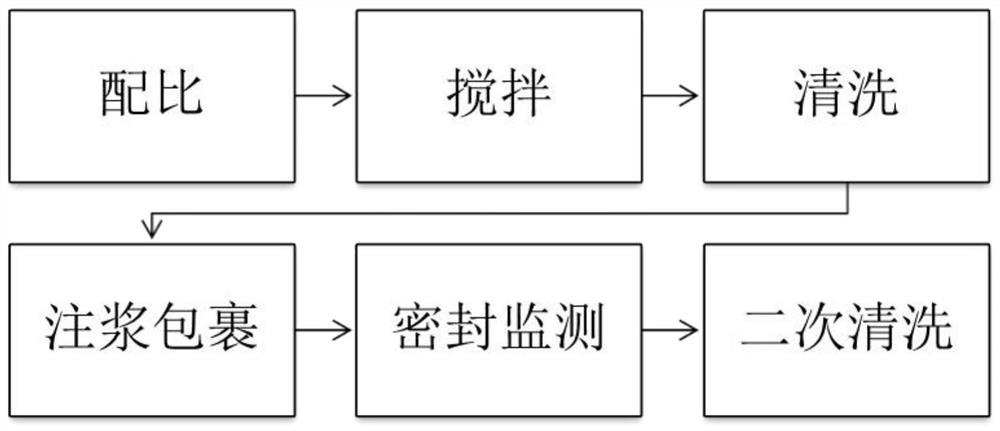

A shield grouting wrapping method

ActiveCN110005422BBlock the escapePrevent inflowUnderground chambersBuilding constructionsO-Phosphoric AcidSlurry

The invention provides a shield grouting encapsulation method. The water glass solution and the phosphoric acid solution are prepared according to the ratio of mixing, and the double liquid slurry injection system of the shield machine is used to inject the shield body from the radial grouting hole reserved around the shield body. , form a "protective layer" around the shield body to prevent the slurry from escaping to the shield body when the double slurry is backfilled and reinforced, causing the body to "lock up", and support and strengthen the soil around the shield body; set up a sealing failure device, An effective seal is formed between the shield tail and the segment to prevent muddy water from flowing into the shield machine and ensure the smooth excavation process of the shield machine.

Owner:CHINA CREC RAILWAY ELECTRIFICATION BUREAU GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com