A tunnel boring machine using high-pressure water to break rock

A technology of tunnel boring machine and high-pressure water, which is applied in tunnels, mining equipment, earthwork drilling and mining, etc. It can solve the problems of inability to adjust nozzles, inconvenient operation of high-pressure water guns, and inconvenient adjustment of water pressure, so as to save resources and meet crushing requirements. , the effect of reducing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

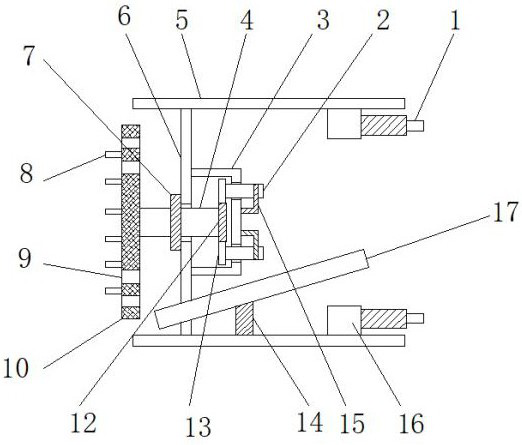

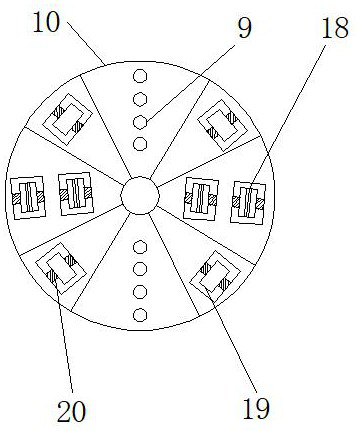

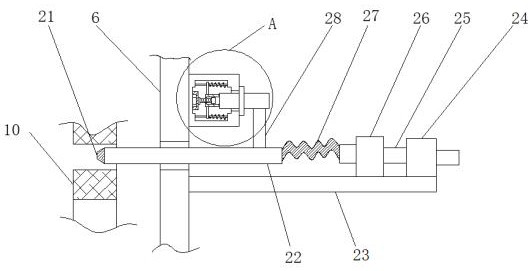

[0030] refer to Figure 1-4 , a tunnel boring machine using high-pressure water to break rocks, including a shield shell 5, a side plate 6 is fixedly connected to the shield shell 5, a cutter head 10 is provided on one side of the side plate 6, and a plurality of through-holes are arranged on the cutter head 10. Hole 9, the through hole is convenient for the penetration of water pipe 22, and the side of cutterhead 10 away from side plate 6 is provided with a plurality of storage slots, is provided with cutter 8 in the storage slot, and cutter 8 is used for breaking rock, and side plate 6 The other side of the protective cover 3 is fixed, the first gear 12 is arranged between the protective cover 3 and the side plate 6, the center of the first gear 12 is fixed with a rotating shaft 4, and one end of the rotating shaft 4 runs through the side plate 6 and connects with the cutter head The center of 10 is fixedly connected, and the side of the protective cover 3 away from the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com