A full-section shaft excavation method

A full-section, vertical shaft technology, applied in vertical shaft equipment, sinking, earthwork drilling and mining, etc., can solve the problems of narrow segment assembly space, low reliability of shaft excavation, shield body and segment rotation, etc., to improve reliability Improve performance and excavation efficiency, simplify the construction process and save space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

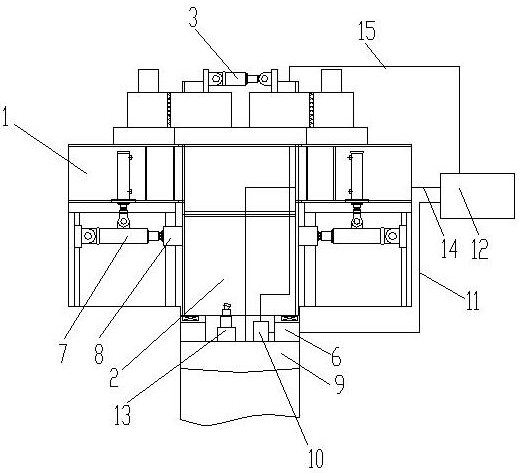

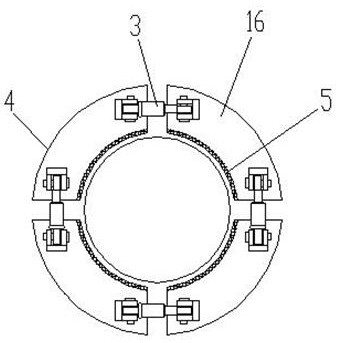

[0034] see figure 1 and figure 2 , a full-section shaft excavation method, comprising the following steps:

[0035] a. Wellhead excavation and foundation construction, install and fix the wellhead frame 1 of the full-section vertical shaft boring machine on the ground plane, hoist the arc-shaped steel pipe sheets by a crane, and assemble and connect a plurality of arc-shaped steel pipe sheets to form a ring-shaped steel pipe 2;

[0036] b. The holding device works, the oil cylinder 3 is retracted, the holding ring 4 is closed, and the holding ring 4 holds the ring 4-shaped steel pipe and the shield body 6 under the action of the friction force of the holding friction block 5; the guiding and propulsion device works , the pushing oil cylinder 7 pushes out the guide friction block 8, the guiding friction block 8 presses the outer wall of the annular steel pipe 2, the guiding friction block 8 transmits the thrust of the pushing oil cylinder 7 to the excavation cutter head 9, ho...

Embodiment 2

[0040] see figure 1 and figure 2 , a full-section shaft excavation method, comprising the following steps:

[0041] a. Wellhead excavation and foundation construction, install and fix the wellhead frame 1 of the full-section vertical shaft boring machine on the ground plane, hoist the arc-shaped steel pipe sheets by a crane, and assemble and connect a plurality of arc-shaped steel pipe sheets to form a ring-shaped steel pipe 2;

[0042] b. The holding device works, the oil cylinder 3 is retracted, the holding ring 4 is closed, and the holding ring 4 holds the ring 4-shaped steel pipe and the shield body 6 under the action of the friction force of the holding friction block 5; the guiding and propulsion device works , the pushing oil cylinder 7 pushes out the guide friction block 8, the guiding friction block 8 presses the outer wall of the annular steel pipe 2, the guiding friction block 8 transmits the thrust of the pushing oil cylinder 7 to the excavation cutter head 9, ho...

Embodiment 3

[0047] see figure 1 and figure 2 , a full-section shaft excavation method, comprising the following steps:

[0048] a. Wellhead excavation and foundation construction, install and fix the wellhead frame 1 of the full-section vertical shaft boring machine on the ground plane, hoist the arc-shaped steel pipe sheets by a crane, and assemble and connect a plurality of arc-shaped steel pipe sheets to form a ring-shaped steel pipe 2;

[0049] b. The holding device works, the oil cylinder 3 is retracted, the holding ring 4 is closed, and the holding ring 4 holds the ring 4-shaped steel pipe and the shield body 6 under the action of the friction force of the holding friction block 5; the guiding and propulsion device works , the pushing oil cylinder 7 pushes out the guide friction block 8, the guiding friction block 8 presses the outer wall of the annular steel pipe 2, the guiding friction block 8 transmits the thrust of the pushing oil cylinder 7 to the excavation cutter head 9, ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com