Soft rock tunnel construction method

A technology of tunnel construction and construction method, applied in the field of machinery, can solve problems such as inability to adapt to the construction of soft rock tunnels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

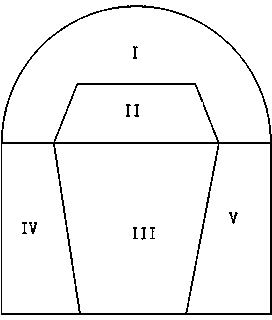

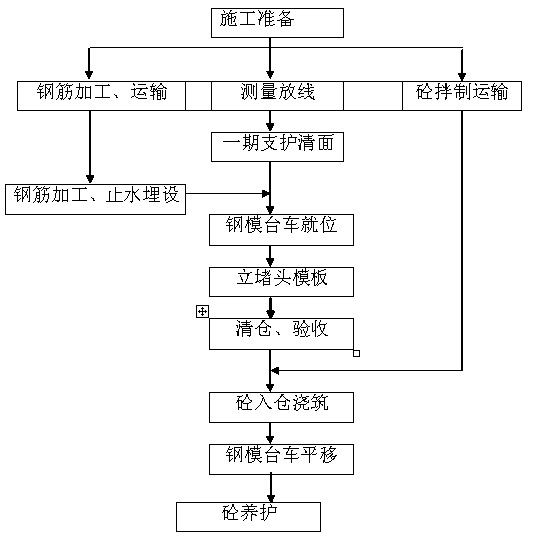

[0017] Such as figure 1 As shown, the first step: a support construction

[0018] 1. Cavern excavation

[0019] The construction is carried out by two-step step-by-step parallel excavation method. Excavate the upper pilot tunnel first, and manually excavate to the design line with pneumatic picks and shovels in the first area of the upper pilot tunnel. Small excavators (0.2m 3 ) with ballasting. Immediately after the excavation of the upper pilot tunnel is completed, the reinforcement arch, mesh and connecting bars shall be installed, and C25 concrete shall be sprayed to the design line of the first lining. Then use a small excavator (0.2m 3 ) to excavate the core soil platform (area II, about 3m long) and area III. Simultaneously carry out the excavation of area IV (area V) of the side wall, that is, use a small excavator to directly excavate and load the ballast, and transport it with 3 to 5 5T dump trucks. , Immediately after the completion of the excavation, instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com