Normal pressure hobbing cutter and teeth cutter exchange technological method for compound stratum shield

A technology of composite formation and process method, applied in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems of unhealthy operators, incomplete equipment, and increase the time for tool replacement, so as to shorten the tool change time and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

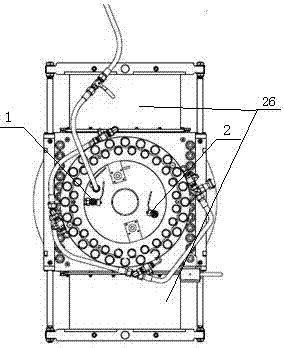

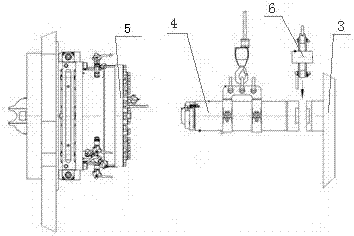

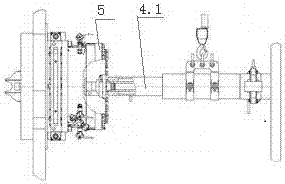

[0089] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0090] A hob-tooth-cutter interchangeable method under normal pressure for complex stratum shield tunneling, comprising the following steps:

[0091] Step 1. Rinse the knife barrel. The purpose of flushing the knife barrel is to clean up the sand between the inner knife barrel and the outer knife barrel, so as to avoid the inner knife barrel being stuck by the sand during the movement;

[0092] Step 2, fixing the oil cylinder, the oil cylinder is used as a power component to provide a certain pulling force for the movement of the knife barrel;

[0093] Step 3, loosen the knife barrel bolt;

[0094] Step 4, retract the oil cylinder and lift the knife barrel. The retraction of the oil cylinder in this step is to retract the knife barrel to the gate position;

[0095] Step 5: Flush th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com