Water jet assisted bolter miner and tunneling method

A technology of water jet and bolter, which is applied in the direction of cutting machinery, slitting machinery, earthwork drilling and mining, etc. It can solve the problems such as the limitation of the total height of the roadway and affect the construction progress, so as to improve the efficiency of construction and excavation and prolong the service life , the effect of reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

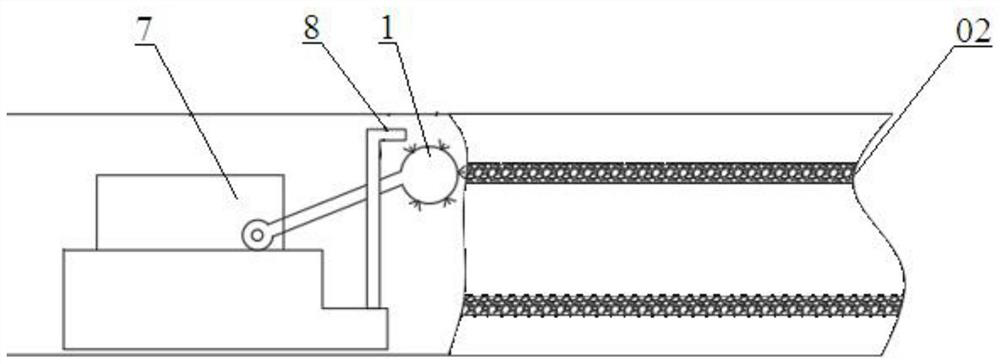

[0041] see Figure 1-Figure 7 , a water jet assisted bolter, including a fuselage 7, a cutting drum 1 and a plurality of water jet injection assemblies.

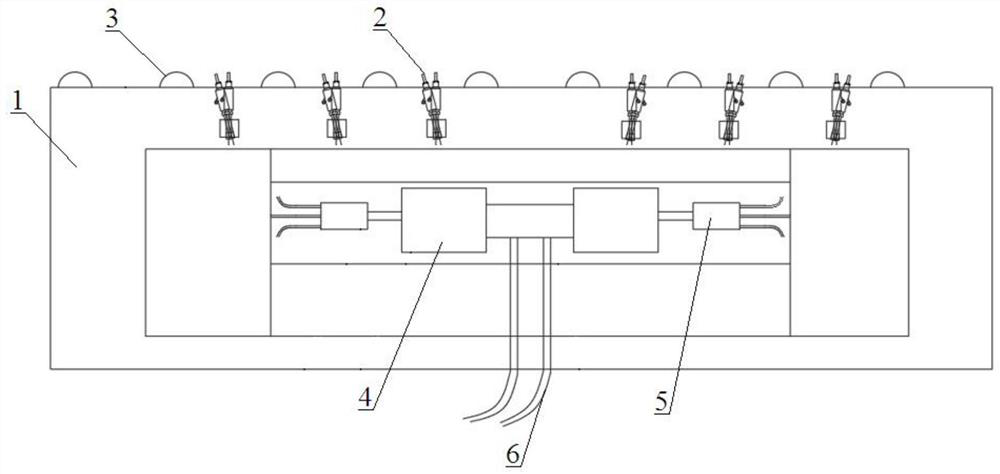

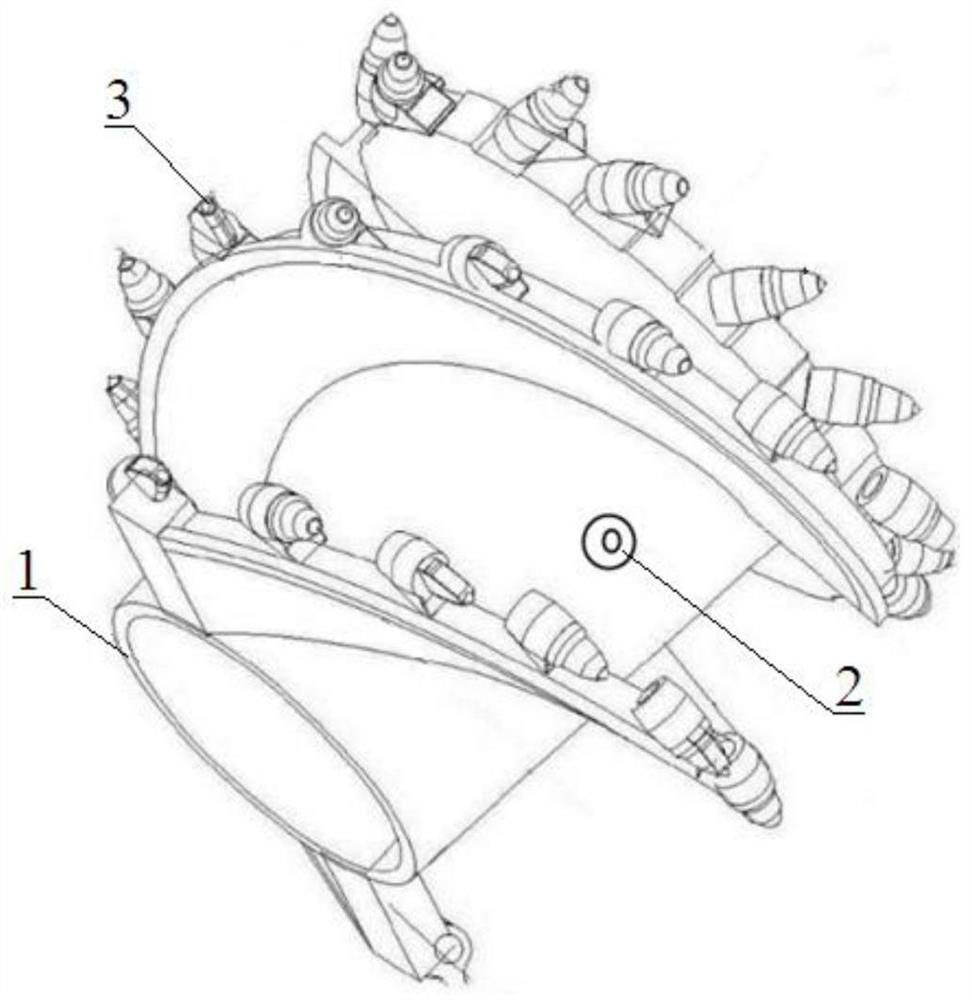

[0042] The cutting drum 1 is horizontally arranged at the working front end of the fuselage 7 and facing the face of the excavation. The cutting drum 1 is connected with the power arm on the fuselage 7 through the rotary joint 4, and can be mounted on the fuselage 7. Driven to move up and down along the palm surface and to and fro in the circumferential direction. During the operation, the above two movements are compounded at the same time. A plurality of picks 3 are helically arranged on the outer surface of the cutting drum 1 .

[0043] A plurality of said water jet injection assemblies are arranged at intervals along the axial direction of the cutting drum 1, and the number of nozzles 2 in each water jet injection assembly is equal and at least one, and the nozzles 2 are arranged on the outer surface of the cutting drum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com