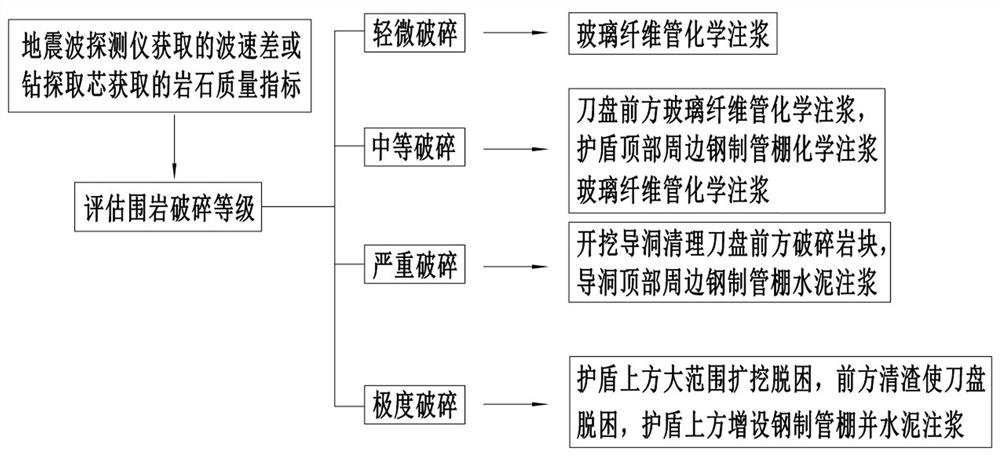

TBM grading anti-blocking and de-trapping construction method for soft and broken stratum tunnel

A construction method and stratum technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as TBM stuck disasters, difficulties in safe and efficient excavation, etc., to reduce material and labor costs, economical and reasonable engineering construction, and shorten construction period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

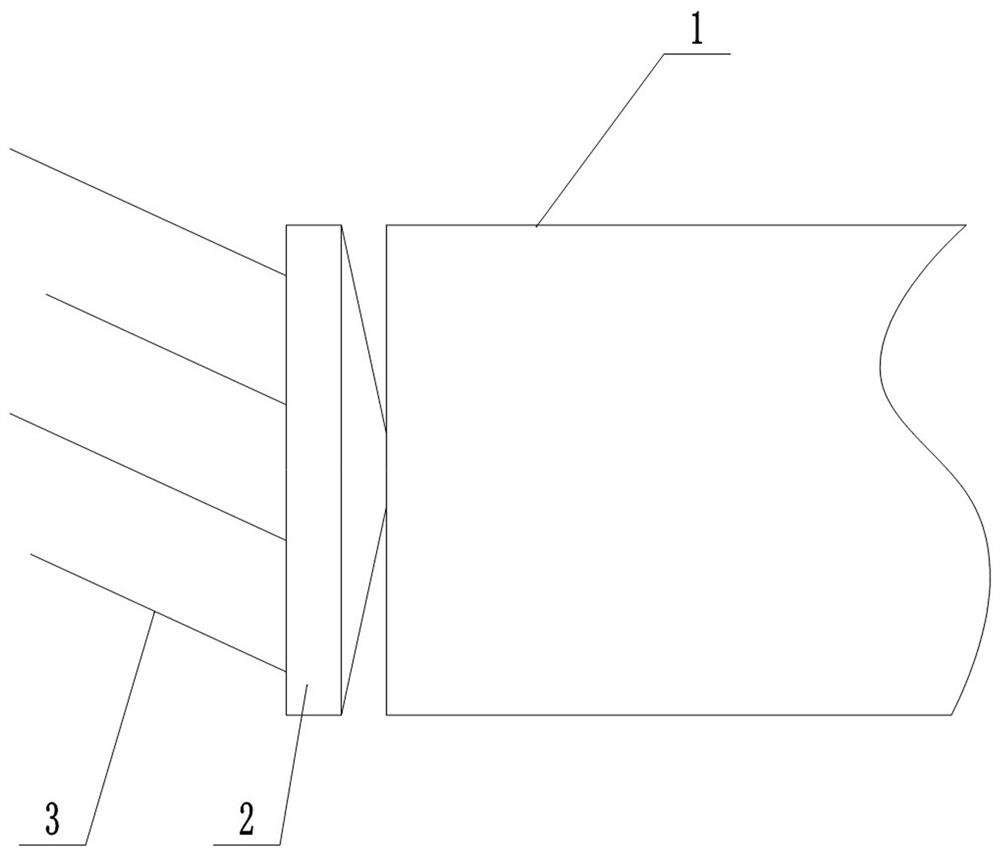

[0035] Example 1, when the crushing level of the surrounding rock is slightly broken, chemical grouting with glass fiber pipe 3 is used, the length of each glass fiber pipe 3 is 1m, and the length of the single glass fiber pipe 3 is extended with a sleeve, and the reinforcement depth in front of the cutter head 2 is not less than 3m.

Embodiment 2

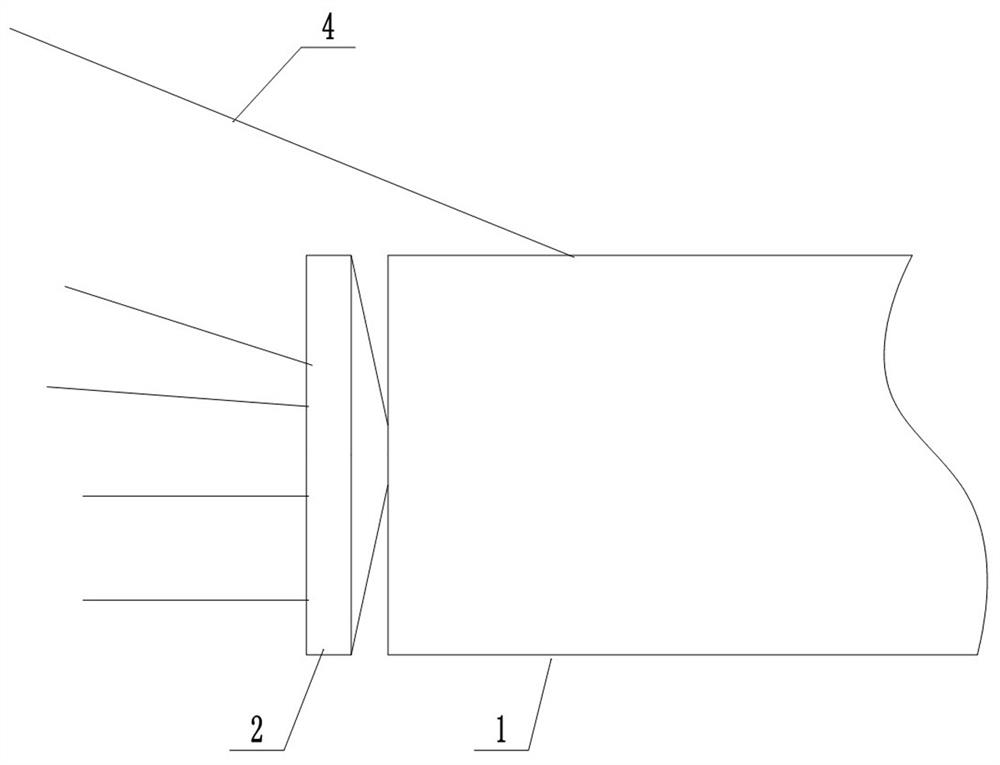

[0036]Example 2, when the crushing level of the surrounding rock is moderately broken, chemical grouting is carried out through the glass fiber pipe 3 in front of the cutter head 2, and a first steel pipe shed 4 is added above the shield 1, and chemical grouting is carried out , the diameter of steel pipes used in the first steel pipe shed 4 is 42mm, the length is not less than 8m, and the distance is 1m. The installation range is the 90° fan-shaped area on the top of the shield 1.

Embodiment 3

[0037] Example 3, when the crushing level of the surrounding rock is severely broken, the position of the excavated pilot tunnel 5 is located at 12 o'clock above the shield 1, the surrounding of the pilot tunnel 5 is supported by HW150 steel 7, and a second tunnel is built on the top of the pilot tunnel 5. Steel pipe shed 6, and stabilize the surrounding broken ground by cement grouting. The diameter of the steel pipe in the second steel pipe shed 6 is 76mm and the length is not less than 10m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com