Covering earth balanced safe receiving method of large-diameter shield tunneling machine

A receiving method and shield machine technology, which can be applied in the direction of earth drilling, mining equipment, tunnels, etc., can solve the problems of difficulty in retaining water in advance wells, ground subsidence, and high cost, so as to avoid the occurrence of receiving risks and control surface subsidence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

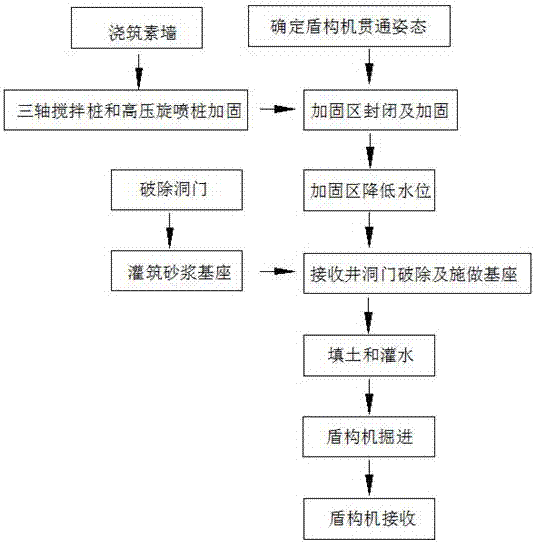

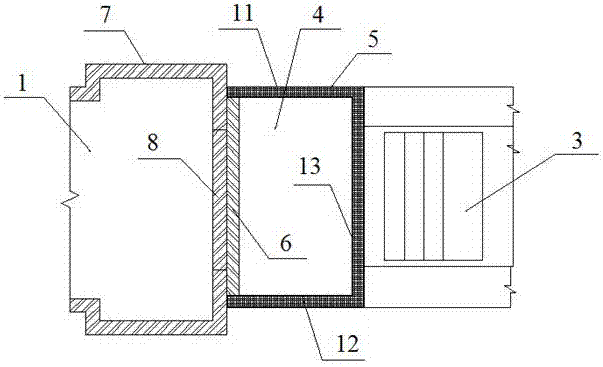

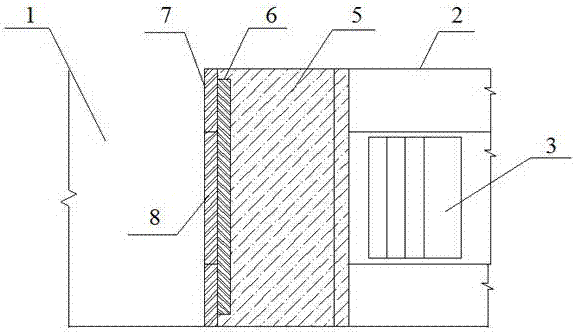

[0036] A large-diameter shield machine covering soil balance safe receiving method, the steps are as follows:

[0037] (1) Determine the penetration attitude of the shield machine 3: adjust the attitude of the shield machine 3 100 meters before the cutter head of the shield machine 3 enters the door 8, and use the method of manual measurement to calculate the measured data to obtain the shield machine 3’s horizontal orientation, roll angle and slope angle, combined with the geometric relationship between the front mark and the back mark of the machine’s built-in measurement system in the shield machine 3, the center coordinates of the shield head and shield tail are obtained, and at the same time, combined with the central axis of the tunnel design, the shield is adjusted. The position of the tunneling machine 3, so that the central axis of the shield machine 3 is consistent with the position of the central axis of the tunnel design;

[0038] (2) Sealing and reinforcement of r...

Embodiment 2

[0049] A large-diameter shield machine covering soil balance safe receiving method, the steps are as follows:

[0050] (1) Determine the penetration attitude of the shield machine 3: adjust the attitude of the shield machine 3 100 meters before the cutter head of the shield machine 3 enters the door 8, and use the method of manual measurement to calculate the measured data to obtain the shield machine 3’s horizontal orientation, roll angle and slope angle, combined with the geometric relationship between the front mark and the back mark of the machine’s built-in measurement system in the shield machine 3, the center coordinates of the shield head and shield tail are obtained, and at the same time, combined with the central axis of the tunnel design, the shield is adjusted. The position of the tunneling machine 3, so that the central axis of the shield machine 3 is consistent with the position of the central axis of the tunnel design;

[0051] (2) Sealing and reinforcement of r...

Embodiment 3

[0062] A large-diameter shield machine covering soil balance safe receiving method, the steps are as follows:

[0063] (1) Determine the penetration attitude of the shield machine 3: adjust the attitude of the shield machine 3 100 meters before the cutter head of the shield machine 3 enters the door 8, and use the method of manual measurement to calculate the measured data to obtain the shield machine 3’s horizontal orientation, roll angle and slope angle, combined with the geometric relationship between the front mark and the back mark of the machine’s built-in measurement system in the shield machine 3, the center coordinates of the shield head and shield tail are obtained, and at the same time, combined with the central axis of the tunnel design, the shield is adjusted. The position of the tunneling machine 3, so that the central axis of the shield machine 3 is consistent with the position of the central axis of the tunnel design;

[0064] (2) Sealing and reinforcement of r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com