Natural gas purification system and method

A purification system and natural gas technology, applied in the field of natural gas, can solve problems such as lack of theory, and achieve the effects of real-time adjustment of parameters, increase of production rate, and optimization of parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

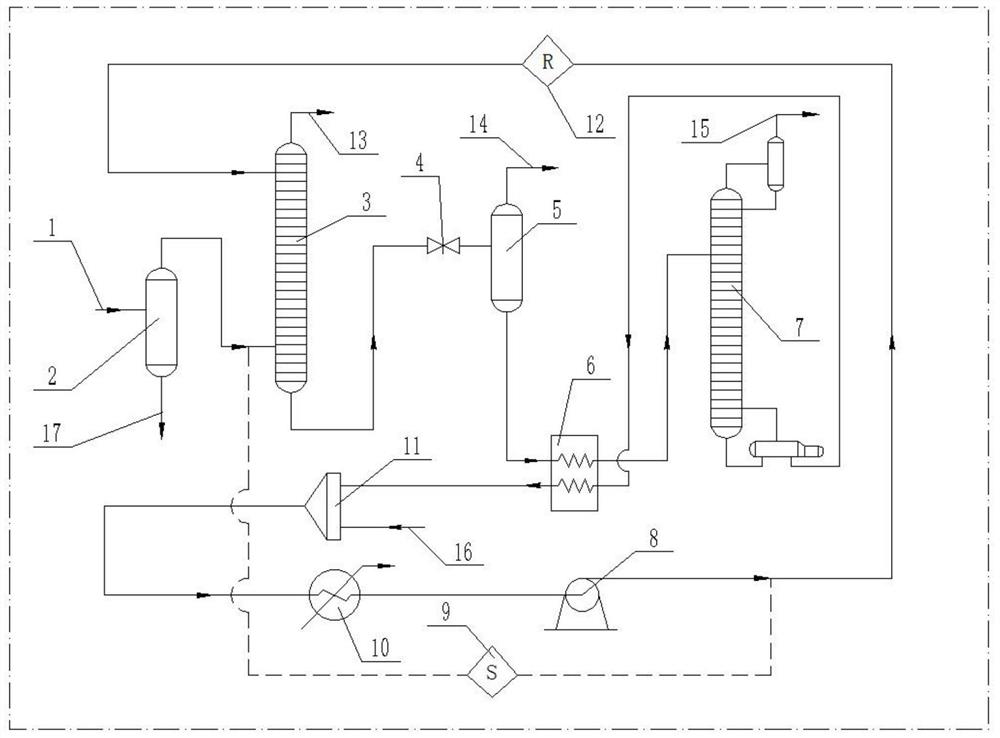

[0035] refer to figure 1 , is a structural schematic diagram of Embodiment 1 of the present invention, a natural gas purification system, comprising

[0036] Intake pipeline 1, one end of the intake pipeline 1 communicates with natural gas raw material gas;

[0037] The gas-liquid separator 2, the air inlet of the gas-liquid separator 2 communicates with the other end of the intake pipeline 1, and the sewage outlet of the gas-liquid separator 2 communicates with the sewage system through the sewage pipeline 17;

[0038] Absorption tower 3, the air inlet of absorption tower 3 is communicated with the outlet of gas-liquid separator 2 by pipeline, and the outlet of absorption tower 3 is communicated with downstream pipeline by absorption tower outlet pipeline 13;

[0039] A regeneration unit, the inlet of the regeneration unit is communicated with the drain of the absorption tower 3 through a pipeline, the gas outlet of the regeneration unit is communicated with the recovery sys...

Embodiment 2

[0045] Compared with Embodiment 1, the difference of this embodiment is that a regulator 9 is connected between the pipeline connected to the inlet of the absorption tower 3 and the pipeline connected to the outlet of the solution pump 8 .

[0046] In actual use: adjust the pressure at the inlet of the absorption tower 3 and the outlet of the solution pump 8 through the regulator 9 to ensure the stability of the inlet pressure of the absorption tower 3 .

Embodiment 3

[0048] Compared with Embodiment 1, the difference of this embodiment is that a circulator 12 is also connected to the pipeline connecting the outlet of the solution pump 8 with the absorption tower 3 .

[0049] In actual use: through the cooperation of the circulator 12 and the solution pump 8, the liquid-phase circulating solution generated by the regeneration unit is pumped into the absorption tower 3 for absorbing H 2 S and CO 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com