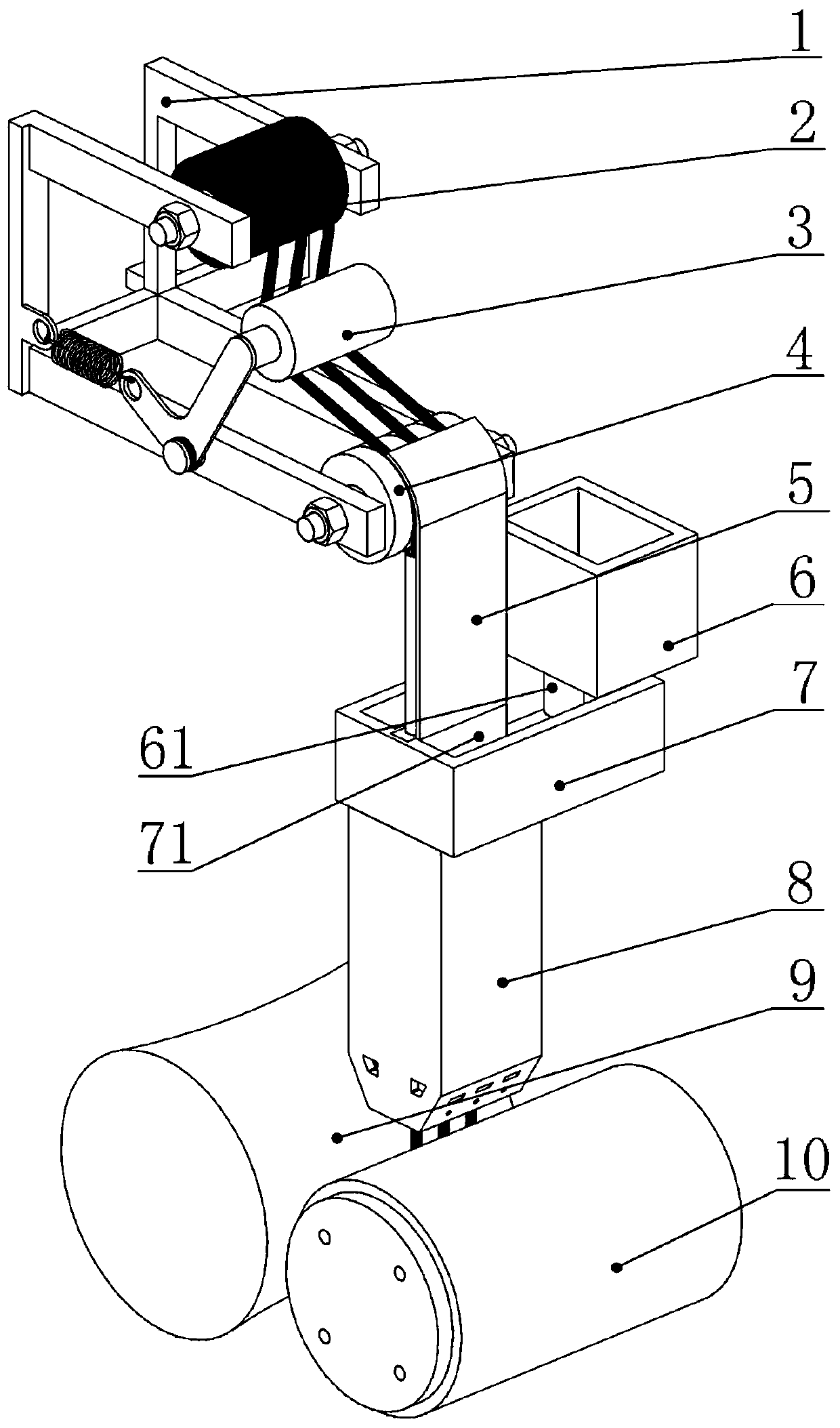

Flexible forming device and method for producing seamless fiber-reinforced metal-based composite tube

A metal-based composite and flexible forming technology, which is applied in the field of composite material processing, can solve the problems of cumbersome product quality and instability, and achieve the effects of avoiding complexity, high production efficiency, and ensuring specification quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

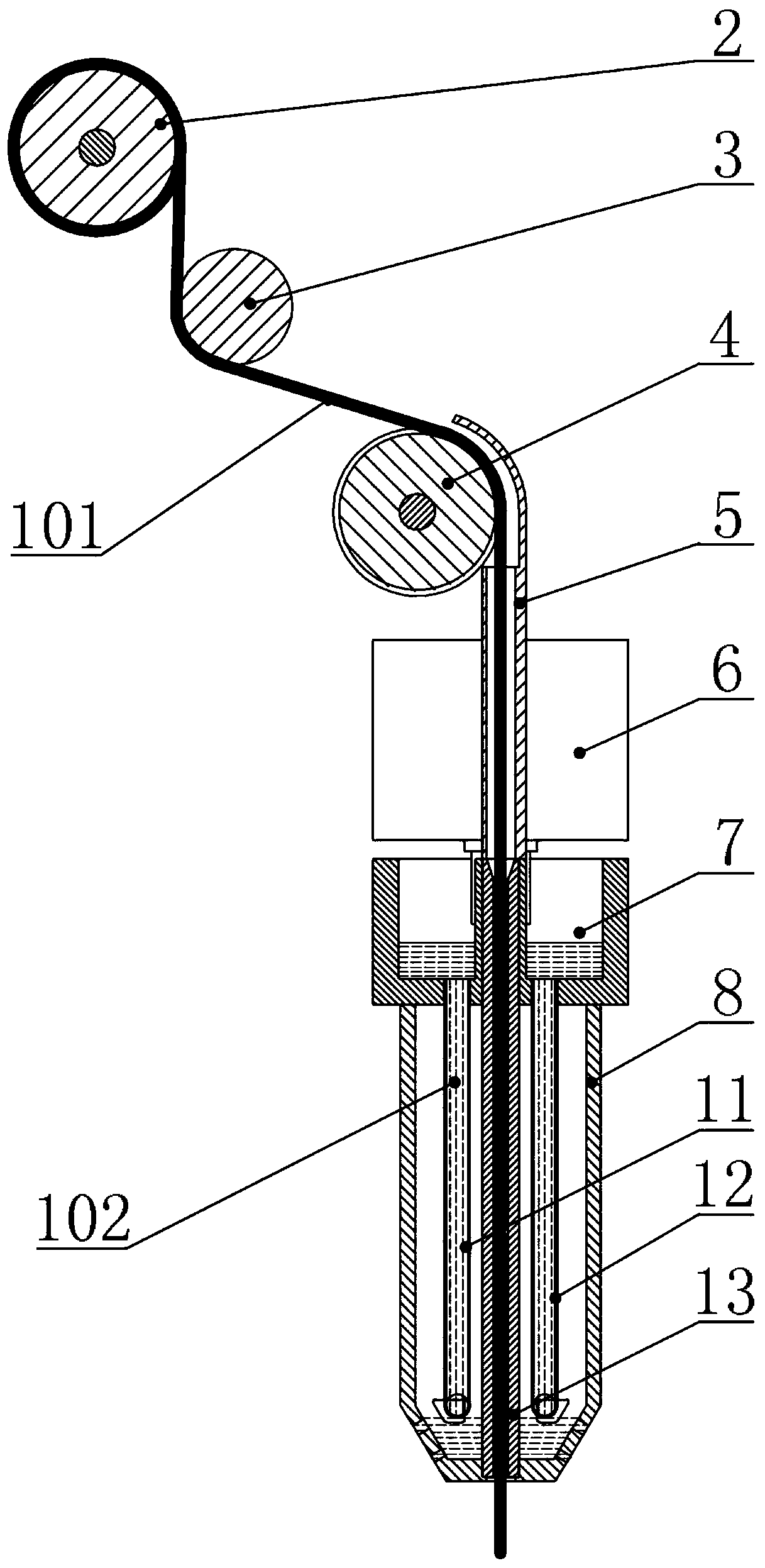

Method used

Image

Examples

specific Embodiment 1

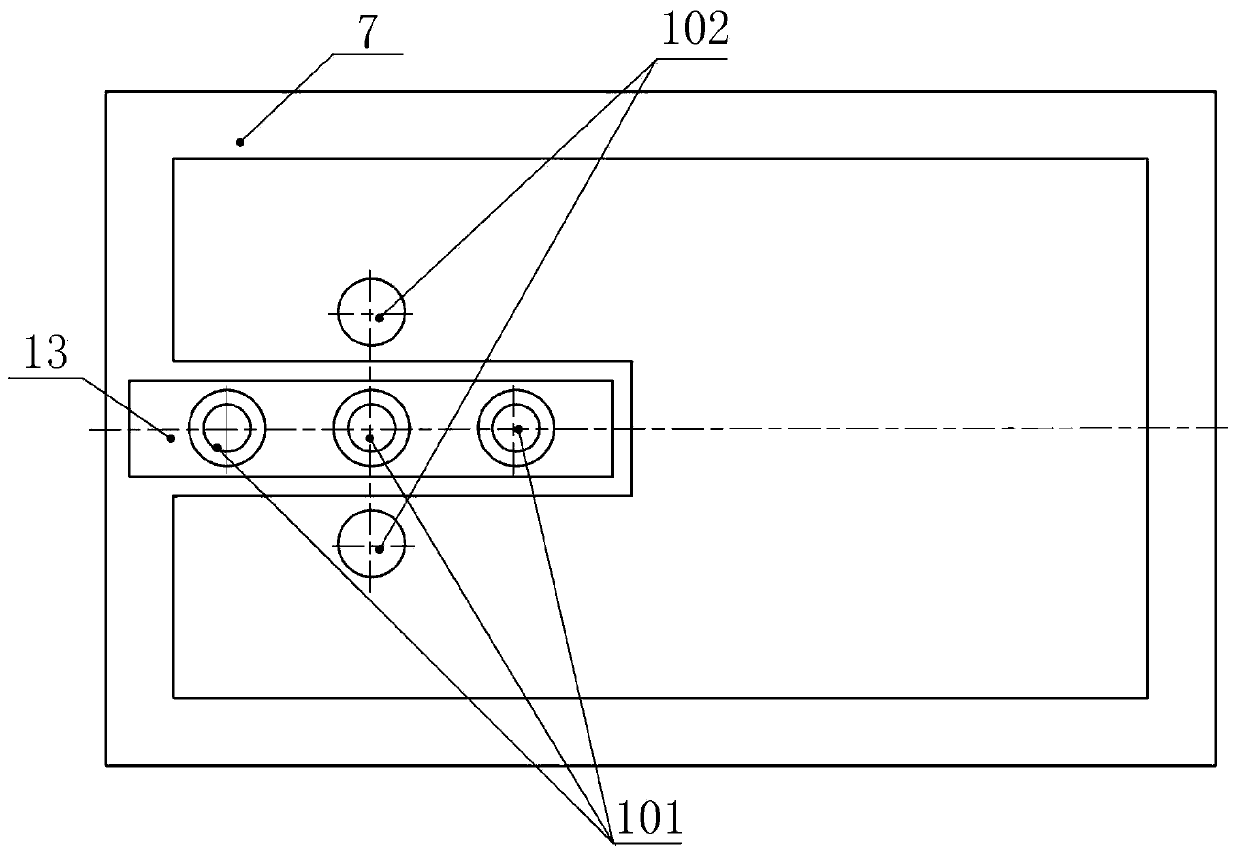

[0059] The metal base is 6061 aluminum alloy, the reinforcing fiber is steel wire, the diameter of the steel wire is φ1.5mm~φ2.5mm, the product wall thickness is 5mm~10mm, and the outer diameter is 80mm~150mm. The melting points of aluminum alloy and steel are quite different, and a metallurgical bond will be formed during the rolling process, which is more closely bonded, has good process performance, and has higher specific stiffness and specific strength. Figure 6 It is a cross-sectional schematic diagram of the product. The reinforcing fiber 101 is steel wire, and the metal base 102 is 6061 aluminum alloy. Since the diameter of the selected steel wire is small, the strength of the pipe can be greatly strengthened by using three fibers, and the pipe can be strengthened as much as possible in a limited space.

[0060] S1. Pickling the steel wire before rolling to remove impurities such as surface oxides, select three constraining blocks 13 with holes slightly larger than the...

specific Embodiment 2

[0067] The metal base is copper, the reinforcing fiber is graphite fiber, the graphite fiber diameter is φ1mm~φ3mm, the product wall thickness is 5mm~10mm, and the outer diameter is 80mm~160mm. Graphite fiber has the characteristics of high melting point, good conductivity and high toughness. It is spirally wound in the seamless copper tube, which reduces the weight of the copper tube and maintains the conductivity of the copper tube. It is used in some applications that require light weight and good conductivity. occasion. Such as Figure 7 As shown, it is a cross-sectional view of the product, the reinforcing fiber 101 is graphite fiber, and the metal matrix 102 is copper.

[0068] S1. Before rolling, the graphite fiber is degummed at a temperature of 560°C for 30 minutes at a high temperature, and the constraining block 13 with a single hole and a hole diameter slightly larger than the graphite fiber is selected and the constraining block 13 is installed, and then a graphi...

specific Embodiment 3

[0075]The metal base 102 is made of 6061 aluminum alloy, the reinforcing fiber 101 is made of silicon carbide fiber, the diameter of the silicon carbide fiber is φ2mm-5mm, the wall thickness of the product is 6mm-15mm, and the outer diameter is 80mm-150mm. Silicon carbide fiber has high axial tensile strength, and due to helical winding, it can greatly enhance the torsional strength of the pipe. Such as Figure 8 As shown, the reinforcing fiber 101 is silicon carbide fiber, and the metal base 102 is 6061 aluminum alloy. The helix angle in the production process is minimized, and the axial direction of the fiber coincides with the circumferential direction of the pipe as much as possible. At this time, the force F1 on the fiber is along the fiber axis, and the component force F1y in the direction of the F1y axis cancels out the torsional force. Because its helix angle is very small, F1x is very small, and F1y is almost the same size as F1, which makes better use of its axis. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com