Steel wire winding device

A technology of winding device and steel wire, applied in the field of manufacturing, can solve problems such as low efficiency and easy occurrence of back strands, and achieve the effects of unique technology, easy control and ingenious conception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

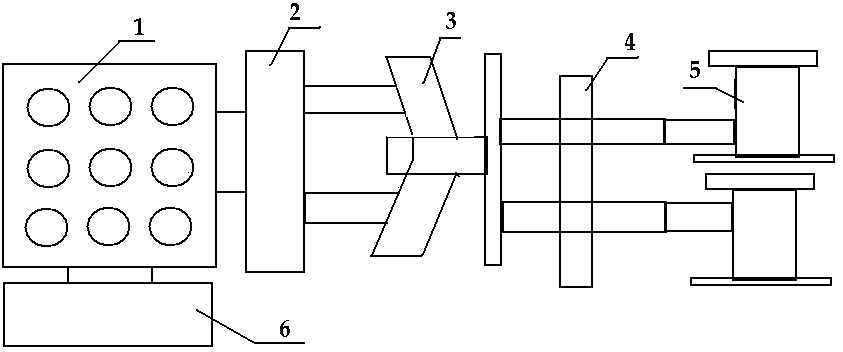

[0010] Referring to the accompanying drawings, a steel wire rewinding device of the present invention includes two sets of rewinding systems 5, a set of wire arrangement system 3, a set of traction system, a set of pay-off system 1 and a control unit 6. The system 5, the cable arrangement system 3 and the traction system are respectively provided with a servo motor and a tension sensor. Three rows are evenly arranged, and each row is equidistantly distributed in three columns. The wire arrangement system 3 is provided with a ply combiner, so that the multi-strand steel wires are combined into one strand. There is a uniform distributor 2, and the uniform distributor 2 is connected to the pay-off system 1 through a conversion device. The conversion device can convert the row steel wire arrangement of the pay-off system into a column by 90 degrees. The winding system 5 is connected to the cable system 3 through the winding mechanism 4, and the control unit 6 is respectively conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com