Patents

Literature

60 results about "Fracture testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coal-rock hydraulic fracturing testing method under true triaxial state

ActiveCN102735547AReveal deformationRevealing intensityMaterial strength using tensile/compressive forcesPermeability/surface area analysisFracture testingHydraulic fracturing

The invention discloses a coal-rock hydraulic fracturing testing method under a true triaxial state. The coal-rock hydraulic fracturing testing method under the true triaxial state comprises the following steps: 1) preparing a test piece; 2) installing the test piece; 3) pre-loading; 4) loading; 5) hydraulically fracturing; 6) unloading; 7) storing all data recorded by a data collection system, taking out the test piece and observing the shape of the test piece. According to the coal-rock hydraulic fracturing testing method, the real work condition can be more really simulated, and a theoretical basis is provided for solving on-site problems.

Owner:CHONGQING UNIV

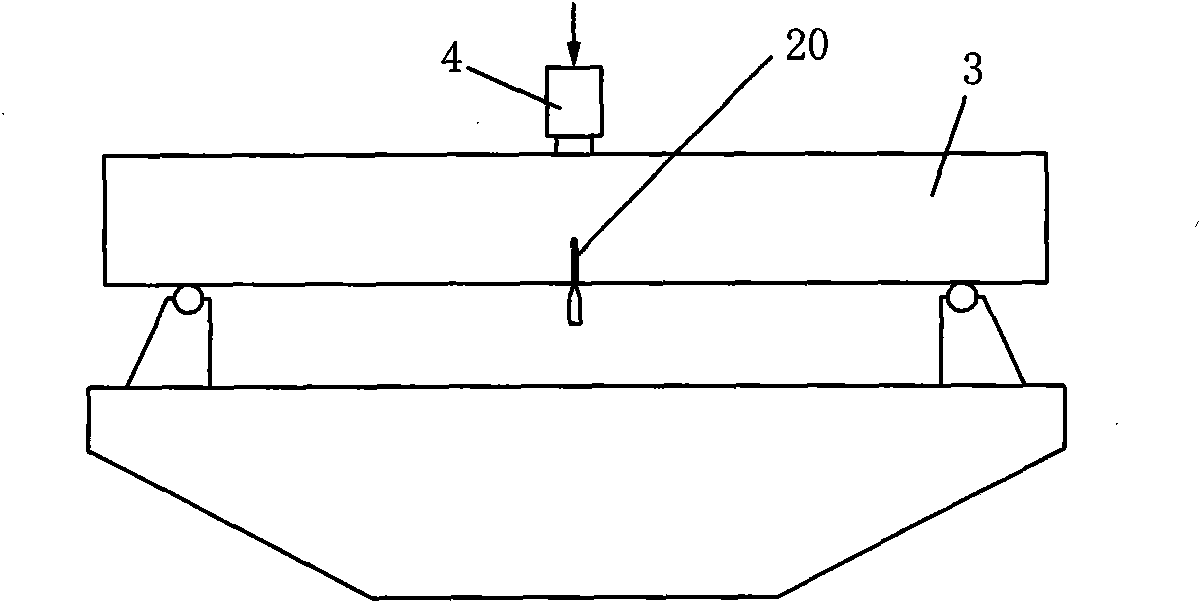

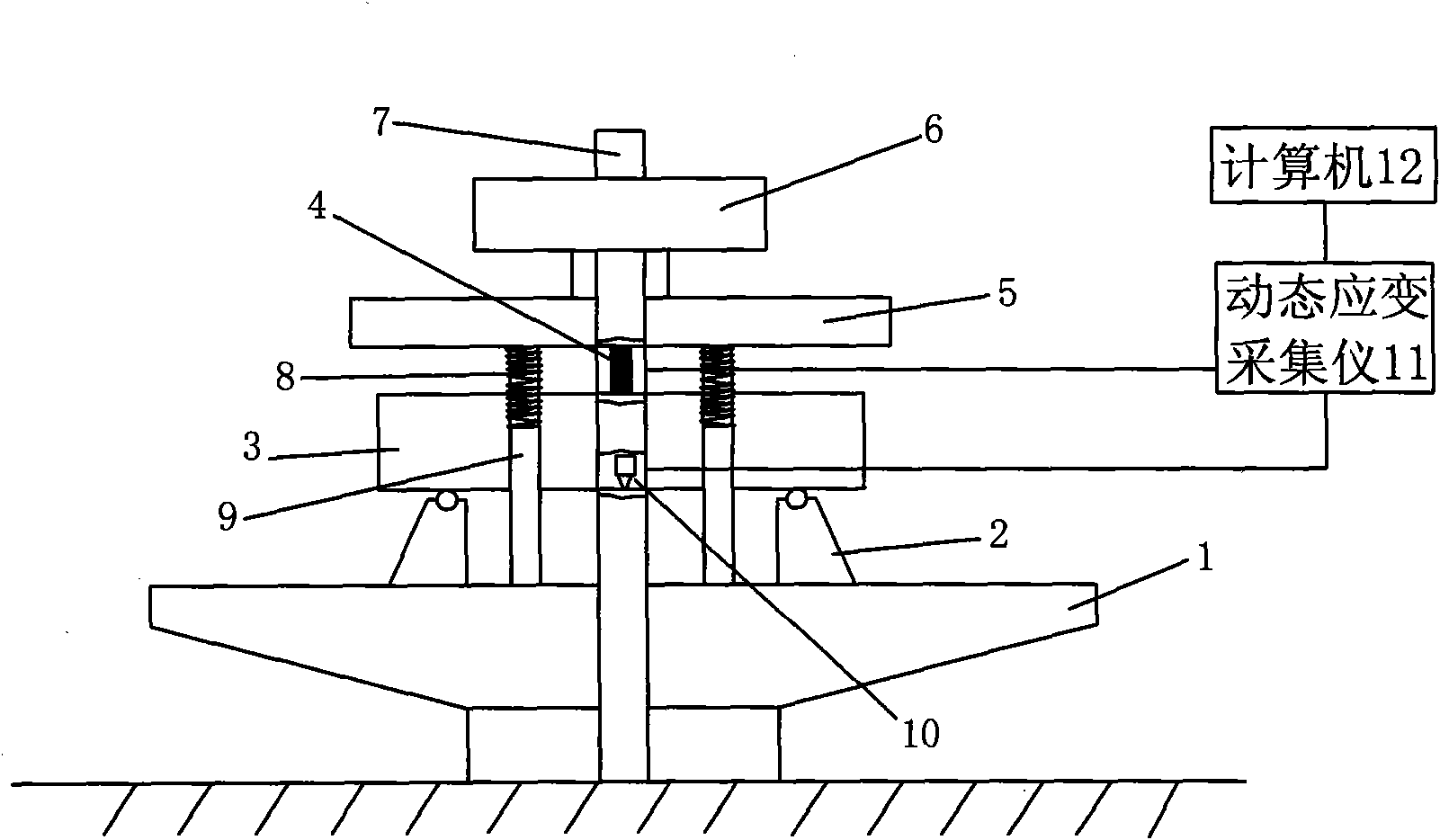

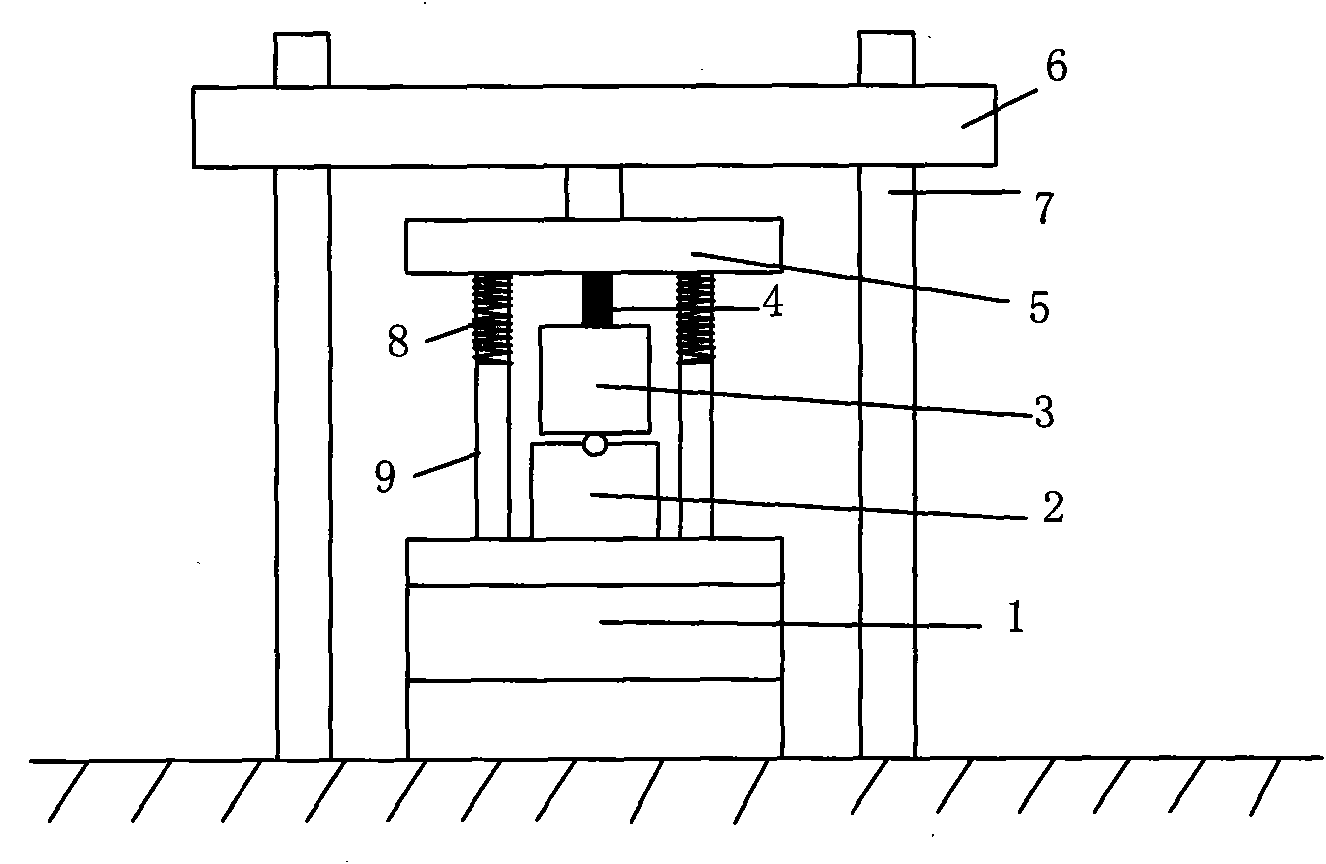

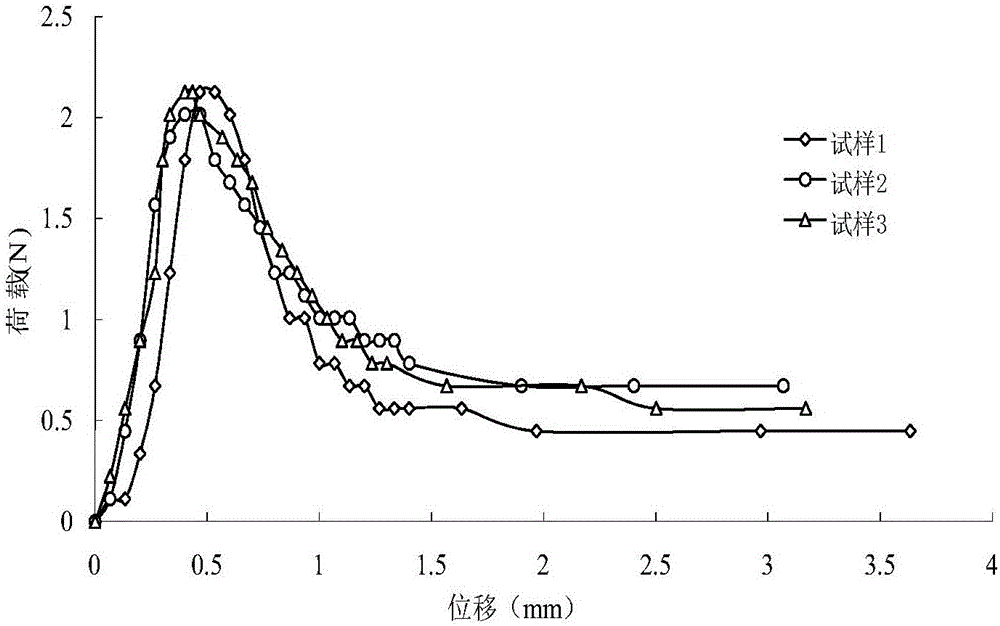

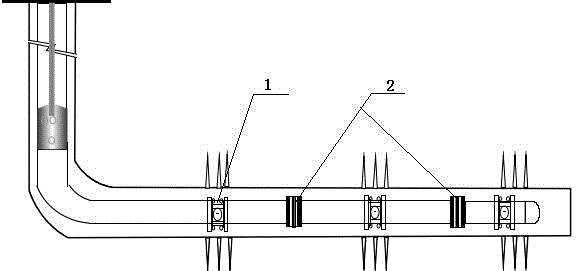

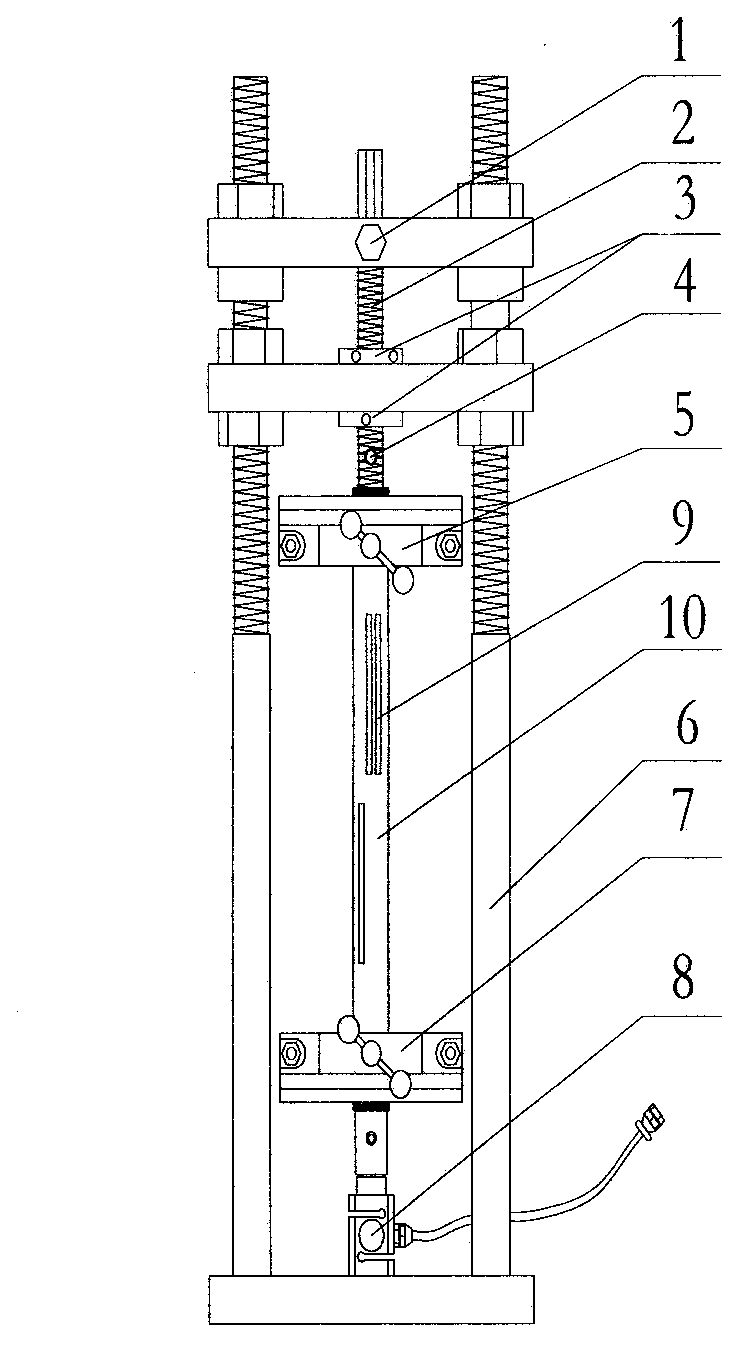

Concrete fracture test system and test method thereof

InactiveCN101975701ASmall loadMeet load rate requirementsMaterial strength using steady bending forcesContact pressureData acquisition

The invention relates to a concrete fracture test system and a test method thereof, and belongs to the technical field of concrete material performance test. The system comprises a measurement system and a data acquisition and processing system; a support for supporting a concrete test piece and even cushion posts symmetrically positioned on the surrounding side of the concrete test piece are arranged on a pressure tester platform of the measurement system; and springs which extend out of the tops of the cushion posts and are higher than pressure sensors are sleeved on the cushion posts. The method comprises the following steps of: when a top plate moves relative to the platform by adopting the system, making the top plate contact the springs and then contact the pressure sensors; when the top plate is contacted with the pressure sensors, controlling the load loaded onto the concrete test piece to be continuously loaded with low loading rate till the concrete test piece cracks, destabilizes and is damaged; and meanwhile, acquiring a load signal and a crack opening displacement signal and transmitting the signals to a computer. The system and the method can acquire a fine load-displacement curve so as to calculate an accurate concrete double-K fracture parameter.

Owner:胡少伟

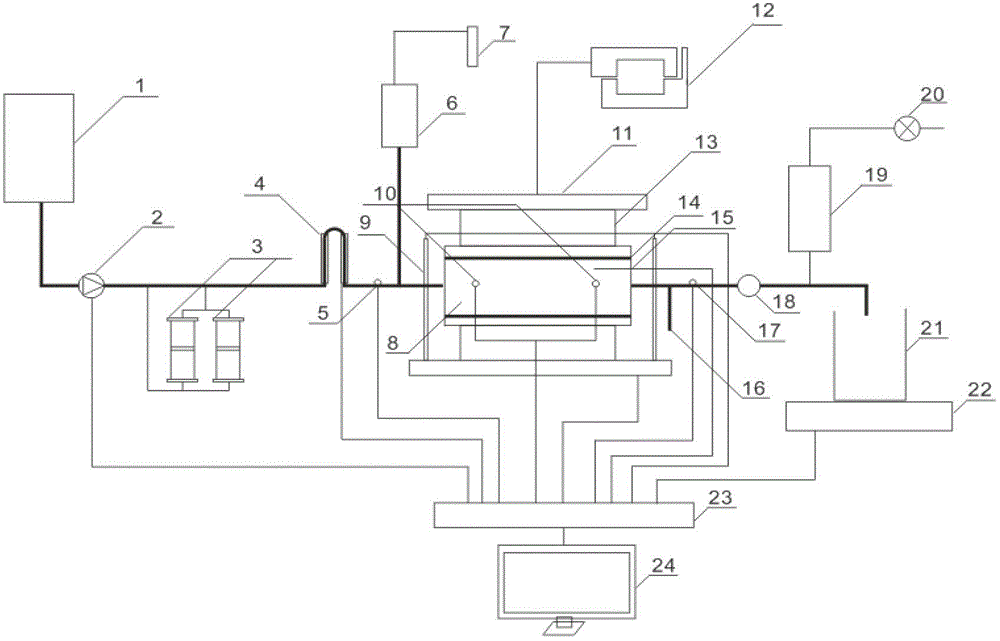

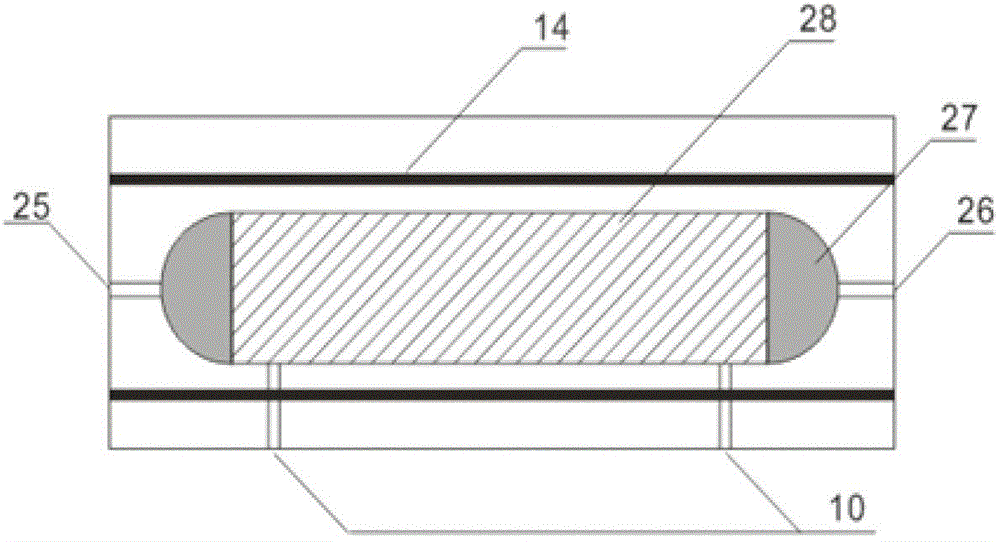

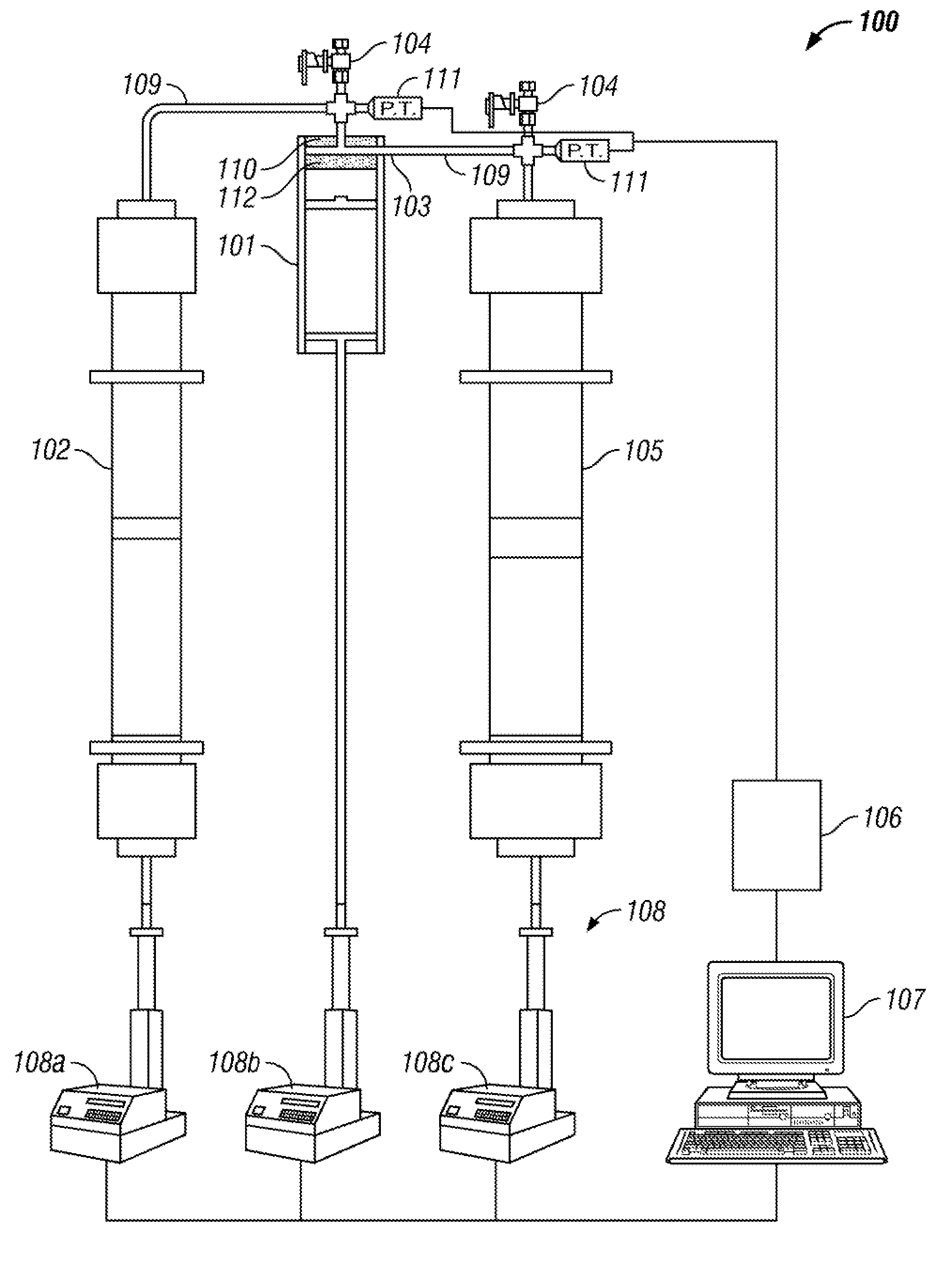

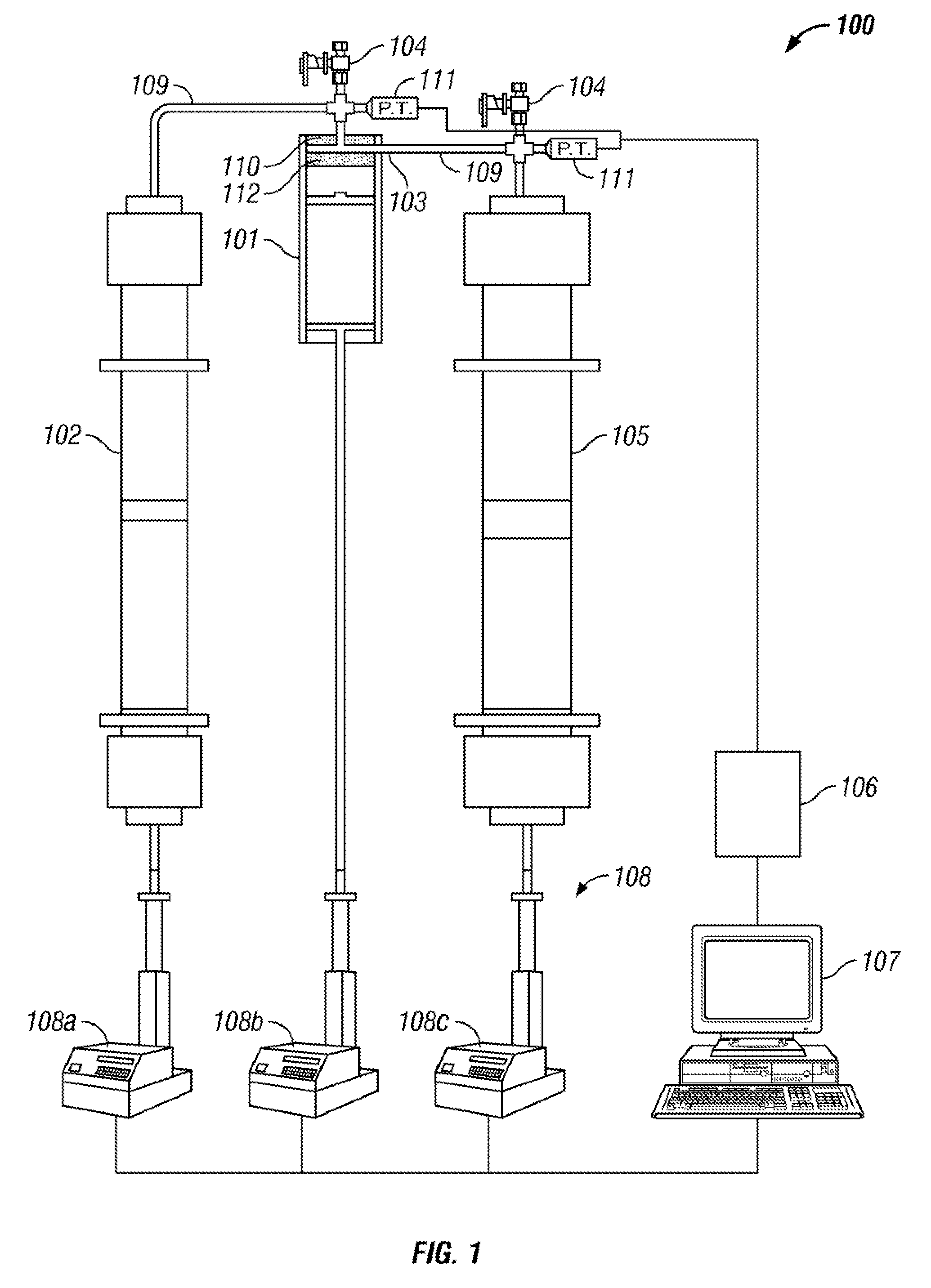

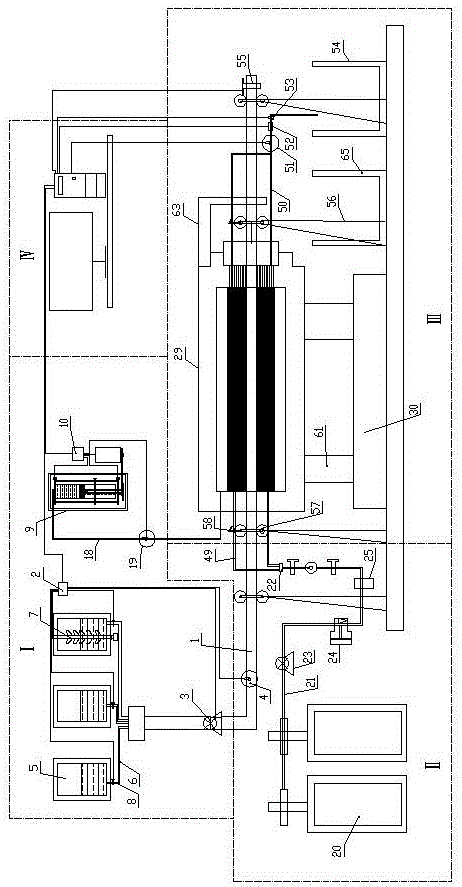

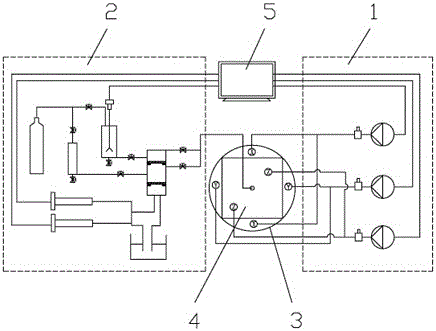

Self-support fracture testing and analyzing device and method for oil-gas field development

ActiveCN102748017AMonitor pressure in real timeMonitor temperature in real timeFluid removalWorking fluidData acquisition

The invention relates to a self-support fracture testing and analyzing device and method for oil-gas field development. The device is mainly composed of a fluid storage tank, an advection pump, a pretreated working fluid tank, a reverse mold fluid tank, a flow conduction chamber, a displacement sensor, a hydraulic press, a fracture maker, a back-pressure controller, a collected fluid bottle, a data acquisition and control board and a computer. The method comprises the following steps: naturally breaking a rock core into two rock plates; putting the rock plates into the inner cavity of the flow conduction chamber to form a self-support in-fracture fluid flow region; applying an initial pressure so that the in-fracture fluid flow region is fully filled with the testing fluid; pretreating the in-fracture fluid flow region; starting the computer, inputting experimental parameters, and injecting the testing fluid; acquiring self-support fracture flow conductivity; treating the in-fracture fluid flow region again; and driving the reverse mold fluid into the flow conduction chamber to form a reverse mold casting. The invention can simulate the actual situation of the self-support fracture to acquire accurate flow conductivity test data, and can also acquire the flow form of the self-support in-fracture fluid.

Owner:SOUTHWEST PETROLEUM UNIV

Method for increasing fracture stimulated reservoir volume of shale gas

ActiveCN106703778AIncrease the volume of the transformationImprove diversion capacityFluid removalHorizontal stressFracture testing

The invention provides a method for increasing the fracture stimulated reservoir volume of shale gas. The method includes the following steps that firstly, the brittleness index of shale is fine analyzed and evaluated; secondly, a proper number of shower holes are selected; thirdly, induced fracturing testing is conducted on each segment; fourthly, acid pretreatment is conducted; fifthly, the amplitude of shale original horizontal stress difference relative to major fracture net pressure is judged, and a fracture is further treated; sixthly, balls are thrown according to the cluster number of perforated holes and the total number of the perforated holes. By fine analyzing and evaluating the brittleness index of shale, selecting reasonable perforated hole parameters, conducting induced fracturing testing on each segment of a horizontal well, well controlling the major fracture net pressure and well controlling a diverting agent in the fracture, generation of network fractures or volume fractures is improved in the shale gas well fracturing process, accordingly the fracture stimulated reservoir volume is increased, and finally the fracture flow conductivity is improved after shale gas fracturing.

Owner:CHINA PETROLEUM & CHEM CORP +1

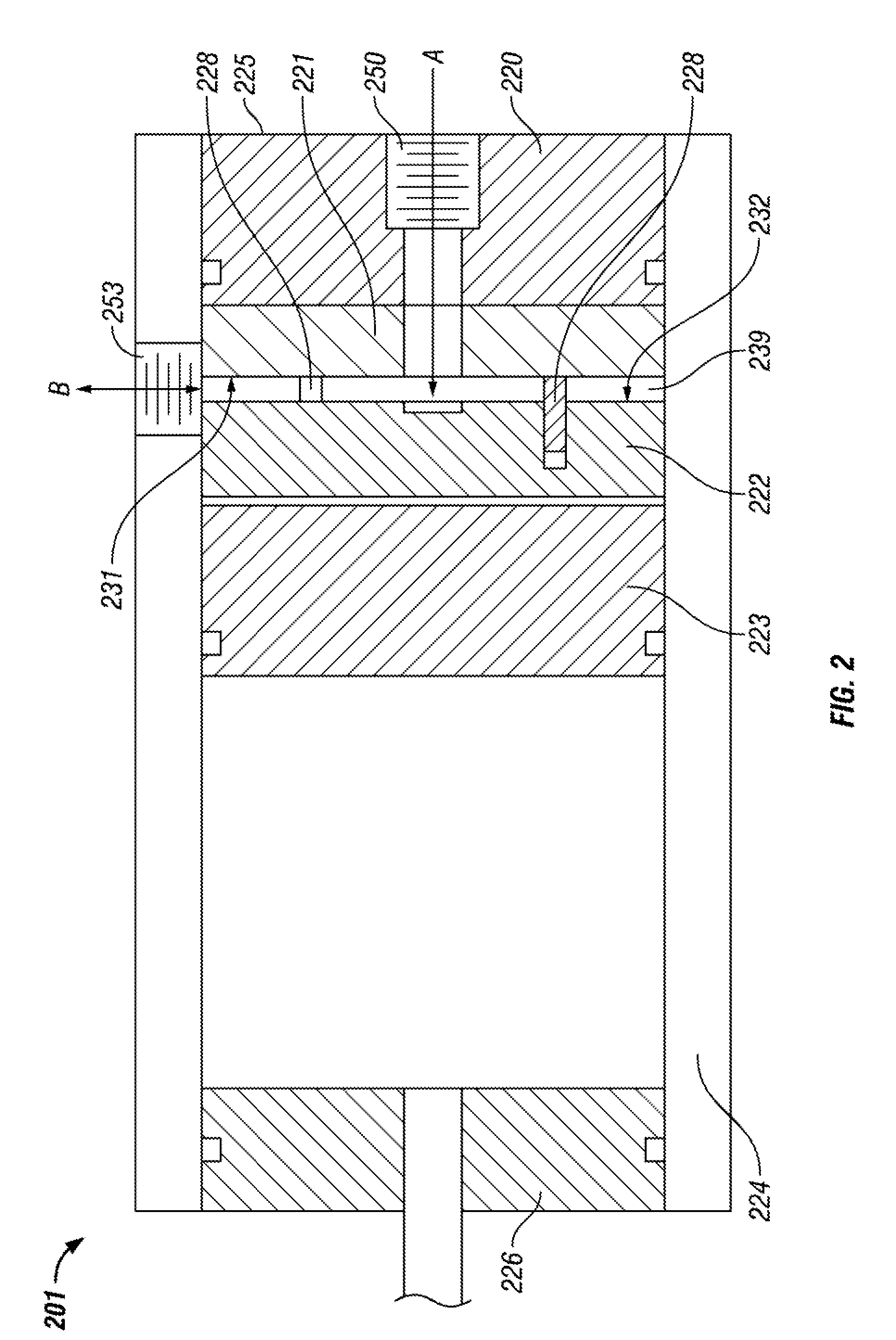

Fracture testing apparatus and method

InactiveUS20110130965A1Electric/magnetic detection for well-loggingConstructionsData acquisitionFracture testing

Owner:MI

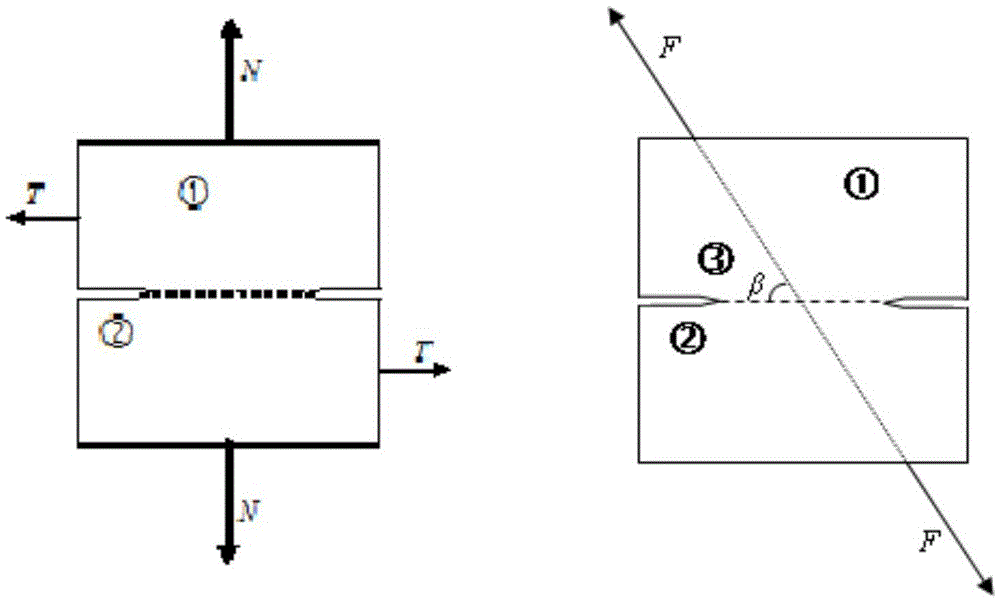

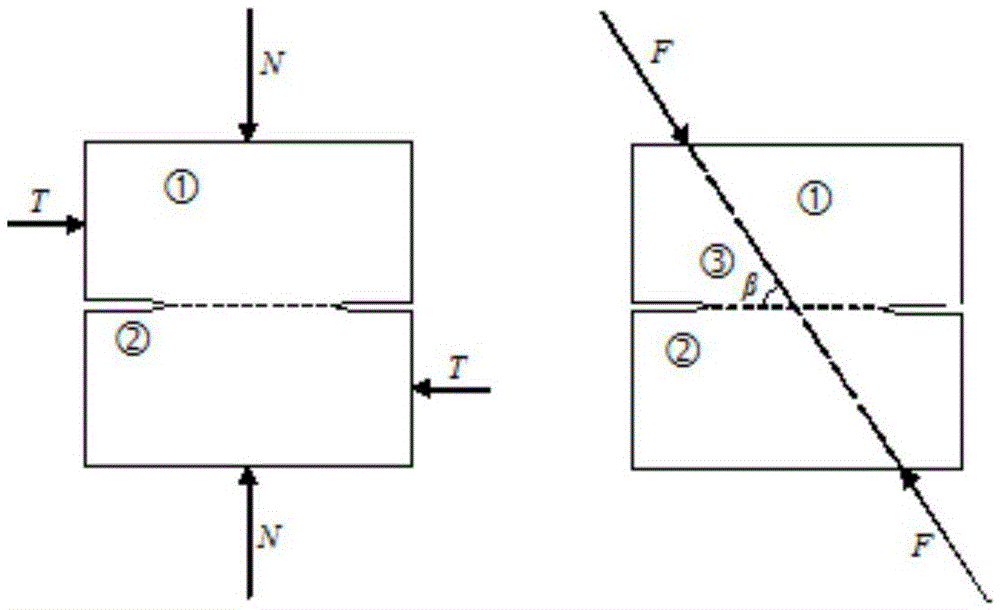

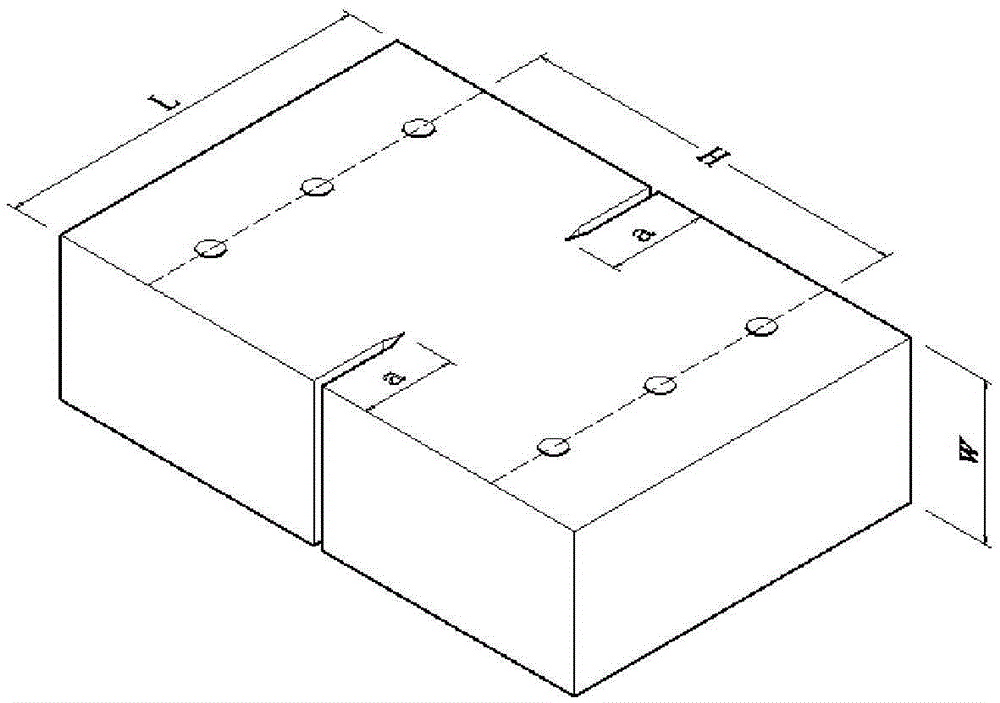

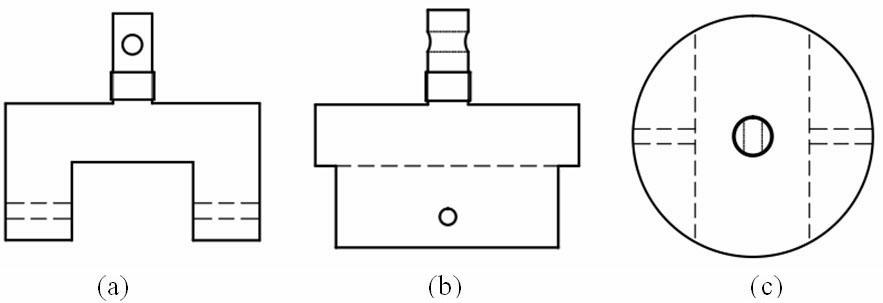

Soil body two-dimensional fracture testing method and device

ActiveCN105486583AGood continuous distributionGood shear forceMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesFracture testingData acquisition

The invention discloses a soil body two-dimensional fracture testing method and device. In the testing method, loading clamps are combined in different forms according to different fracture testing types; the loading clamps are installed on a power loading device according to required loading angles. Loading rods are connected with the external power loading device, and starting and loading modes of the loading rods are controlled by a computer and a data acquisition system. The testing device comprises a sample, a loading plate I and a loading plate II, wherein a loading clamp is formed by the loading plate I and the loading plate II which are completely identical. Each loading plate comprises a clamp body, a loading rod installing hole, a compression-shear assisting plate, a sample fixing hole, a sample clamping plate, a pull-shear assisting plate and the corresponding loading rod, and the compression-shear assisting plates and the pull-shear assisting plates are detachable. The testing device can simultaneously achieve compression-shear type '-I-II type', shear type 'II type', pull-shear type 'I-II type' and stretching type 'I type' fracture testing.

Owner:重庆山渝道科技有限公司

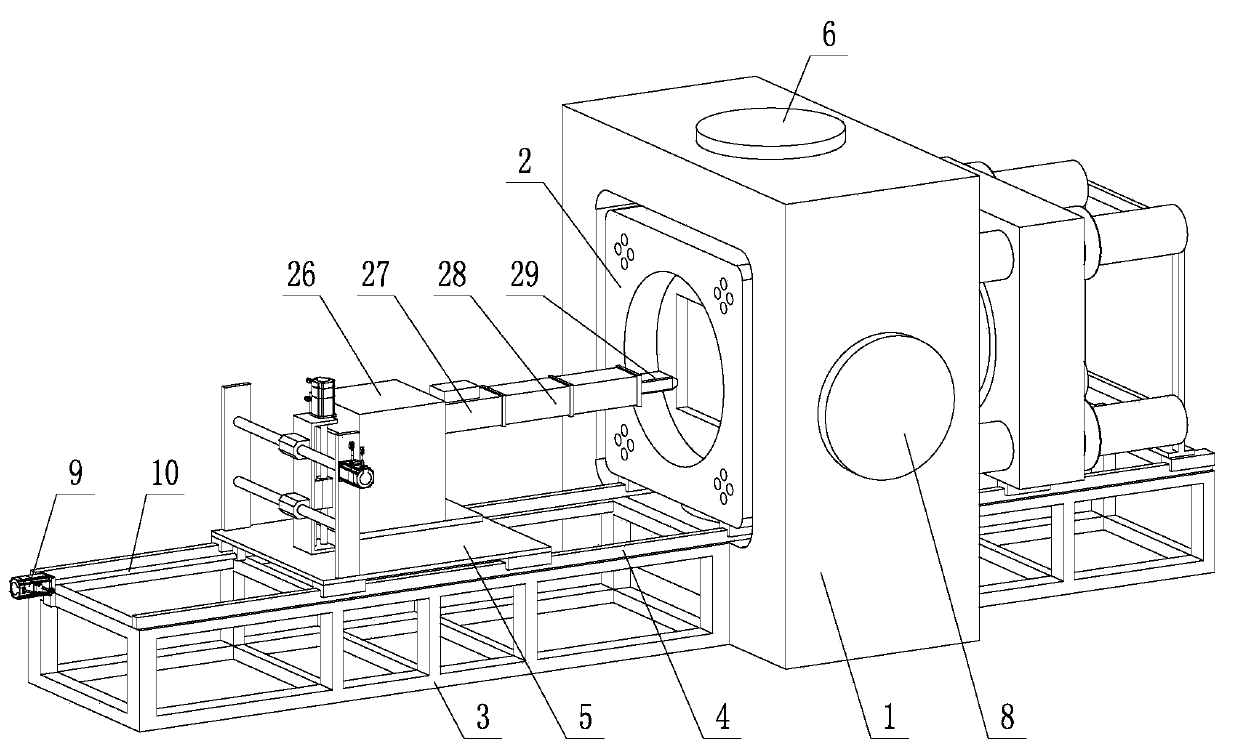

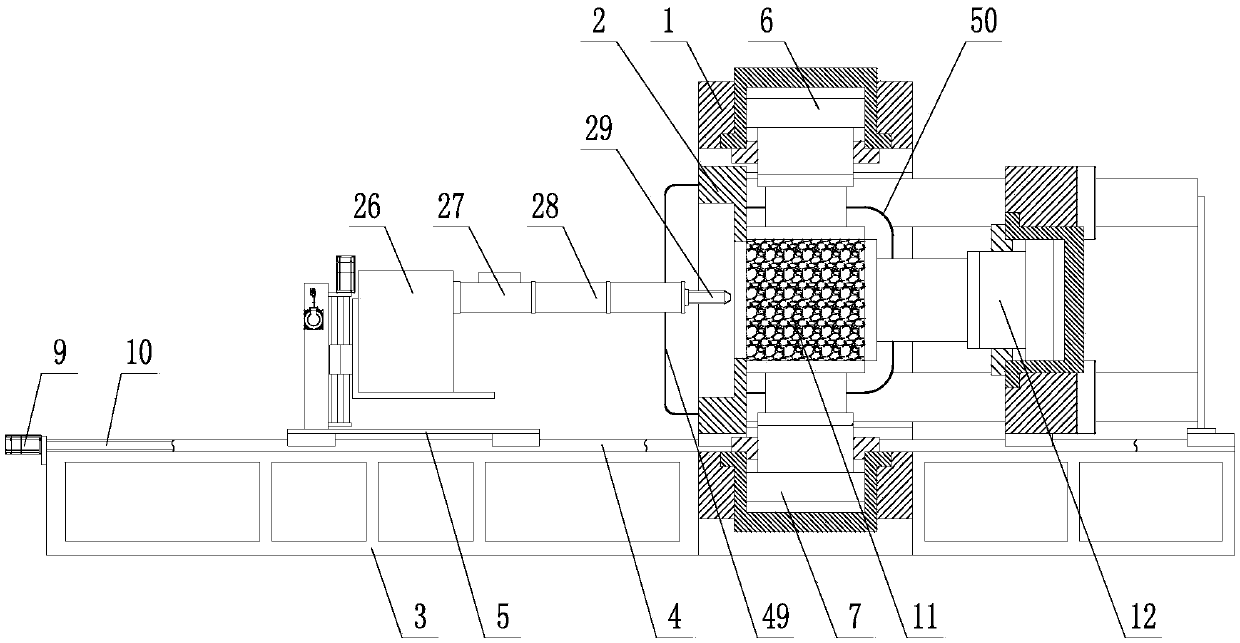

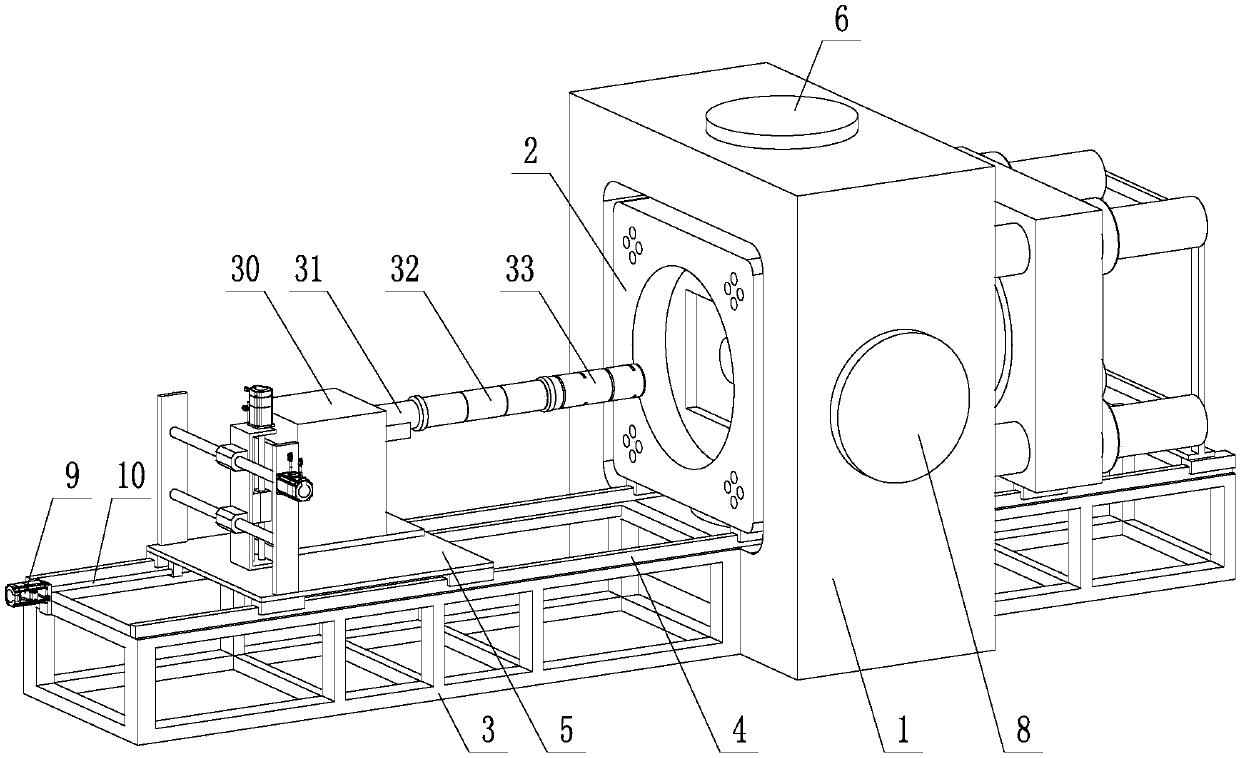

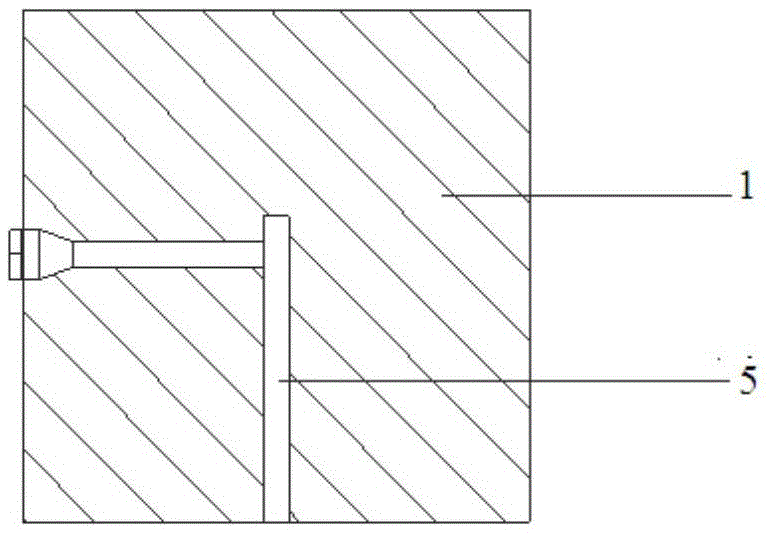

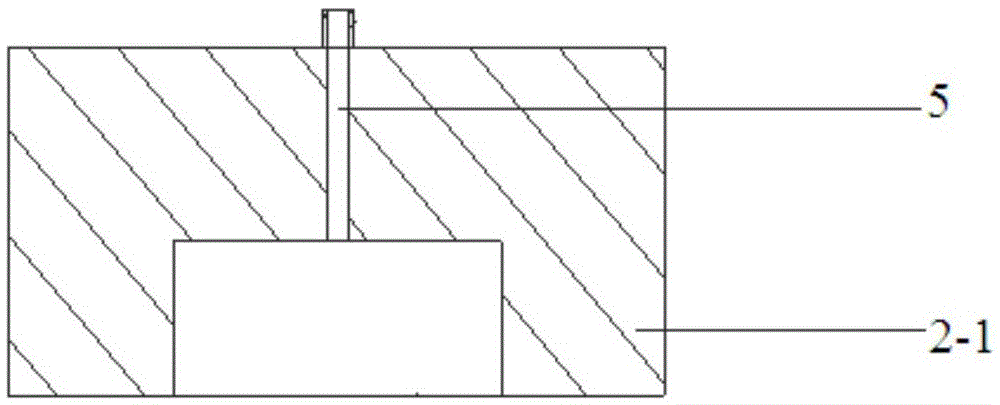

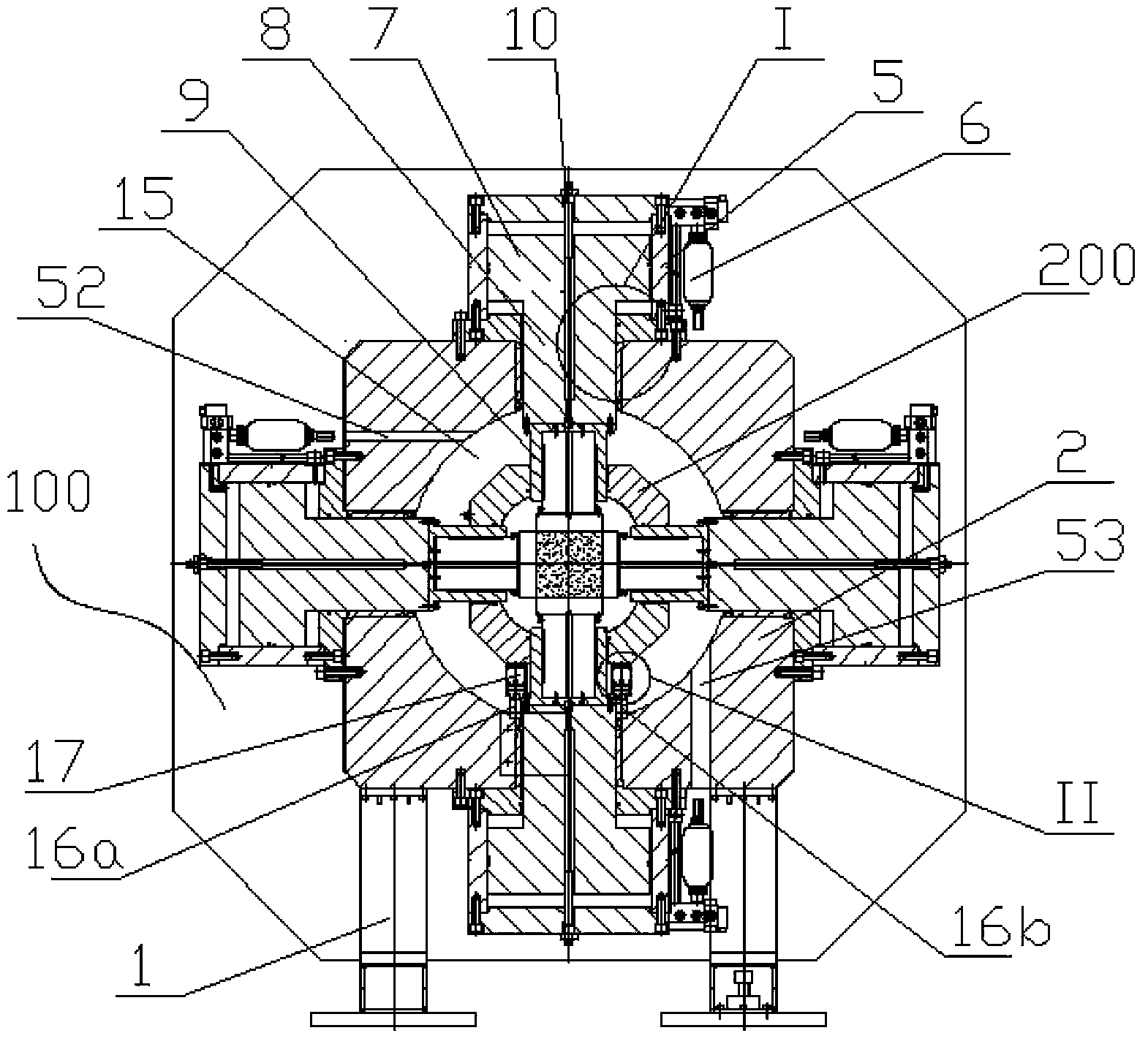

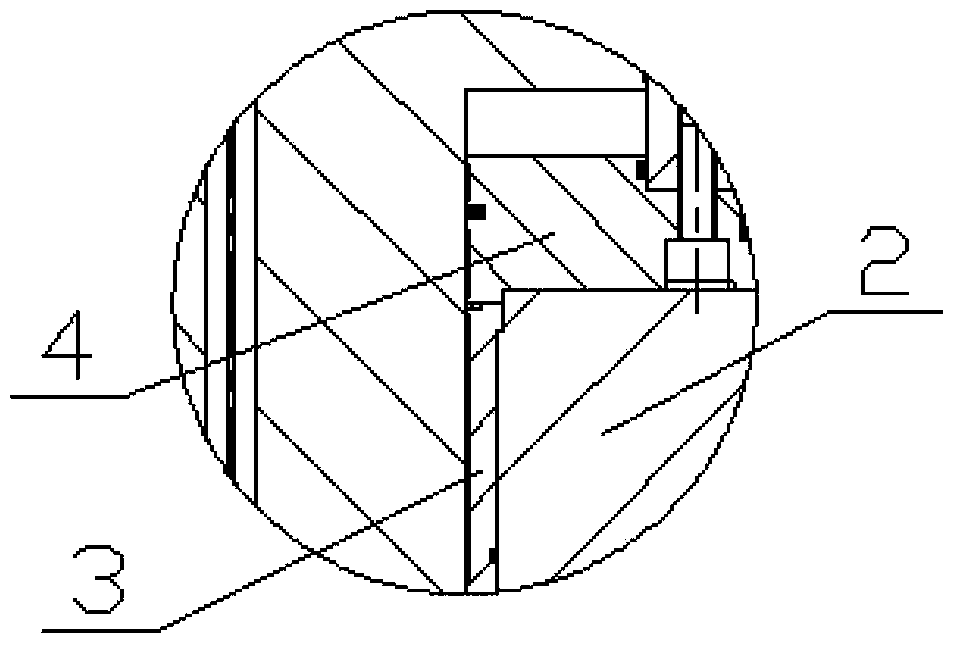

Rock microwave fracturing testing device based on true triaxial loading

ActiveCN108678761AObtain microwave fracturing effectMicrowave heatingEducational modelsThermodynamicsFracture testing

The invention discloses a rock microwave fracturing testing device based on true triaxial loading. The rock microwave fracturing testing device based on true triaxial loading comprises a true triaxialloading assembly and two microwave radiation fracturing assemblies, and the two microwave radiation fracturing assemblies are the microwave radiation surface fracturing assembly and the microwave radiation in-hole fracturing assembly respectively; the true triaxial loading assembly comprises a fixed loading frame, a movable loading frame, a base, a rail, a sliding table and a two-degree-of-freedom movable frame; two groups of Z-direction actuators and two groups of Y-direction actuators are arranged on the fixed loading frame, and an X-direction actuator is arranged on the movable loading frame; a rock sample loading cavity is located in the middle of the fixed loading frame; both the movable loading frame and the sliding table are arranged on the rail through sliding blocks; both the microwave radiation surface fracturing assembly and the microwave radiation in-hole fracturing assembly are installed on the sliding table through the two-degree-of-freedom movable frame, and the slidingtable and the two-degree-of-freedom movable frame are driven by servo motors; a microwave shielding net is arranged on the movable loading frame, and the testing device is wholly arranged in an electromagnetic shielding chamber.

Owner:NORTHEASTERN UNIV

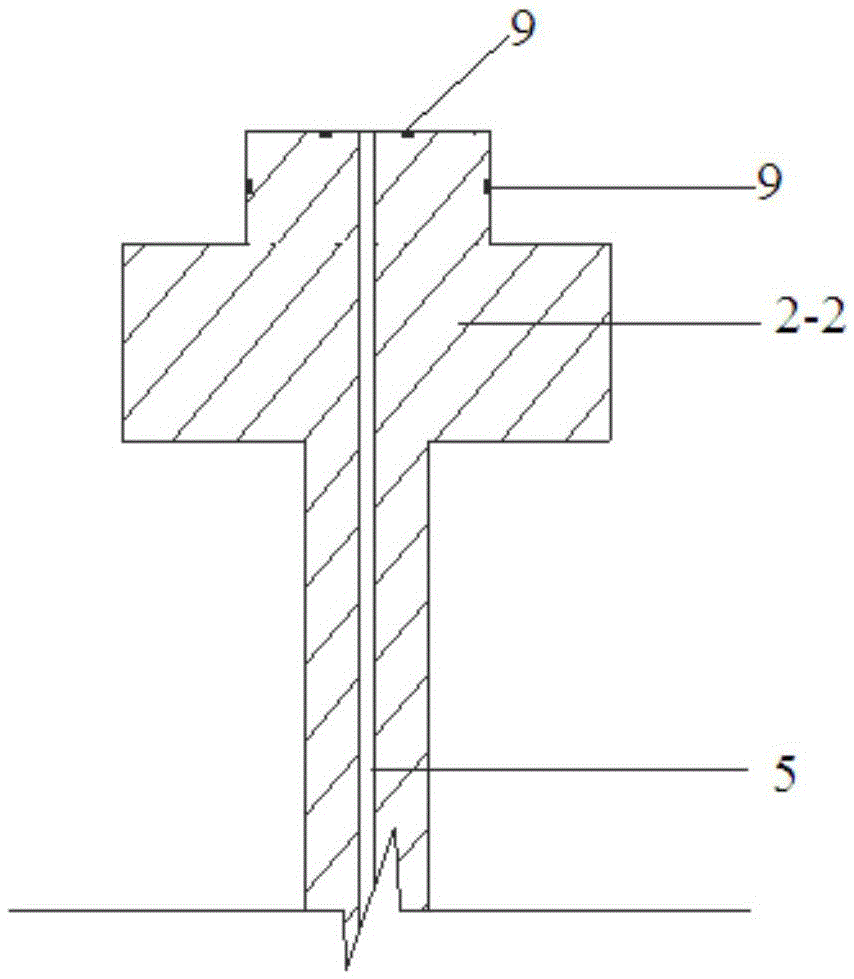

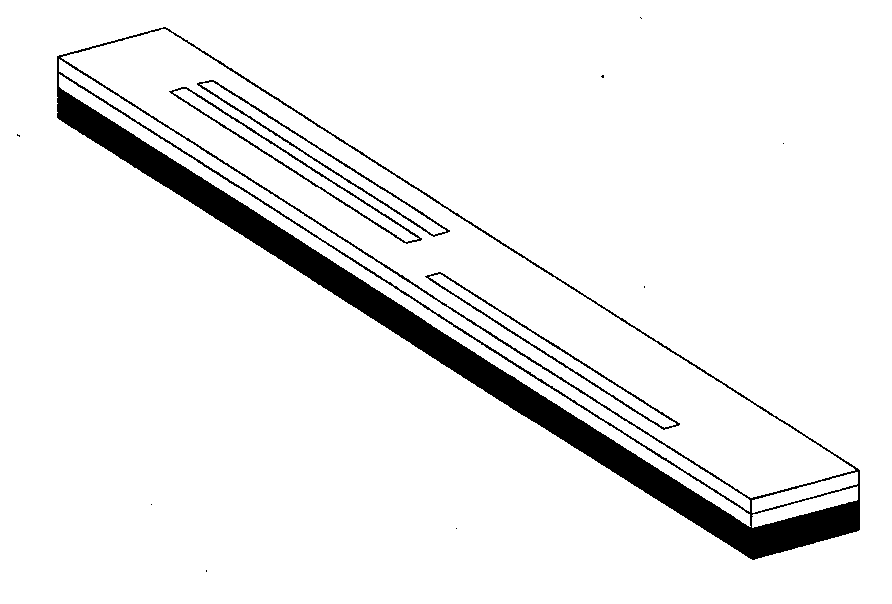

Hydraulic fracturing test apparatus based on conventional testing machine for rock mechanics, rock specimen and hydraulic fracturing testing method

InactiveCN105628507AReduce processing stepsLow costPreparing sample for investigationMaterial strength using tensile/compressive forcesWater channelAxial compression

The invention provides a hydraulic fracturing test apparatus based on a conventional testing machine for rock mechanics. The hydraulic fracturing test apparatus comprises a lower pressing head and an upper pressing head. The lower pressing head is arranged on a triaxial base plate, and an axial compression bar acts on the upper pressing head. Both the upper pressing head and the lower pressing head are designed with pressure water channels. The hydraulic fracturing test apparatus is characterized by further comprising a leak-proof sleeve and a permeable plate; the leak-proof sleeve sleeves the rock specimen to prevent pressure water from mixing with confining oil in a triaxial chamber, and the upper end and the lower end of the leak-proof sleeve are respectively fixed to the upper pressing head and the lower pressing head; the permeable plate is distributed with pressure water permeable holes and is arranged between the rock specimen at the pressure water outlet end and the upper pressing head; one of the upper pressing head and the lower pressing head is a pressing head combination combined by an acting pressing head acting on the rock specimen and an adapting pressing head, and the acting pressing head is connected with the adapting pressing head through a tongue-and-groove insertion structure. The invention further provides the rock specimen for the apparatus and the hydraulic fracturing testing method utilizing the hydraulic fracturing test apparatus based on the conventional testing machine for rock mechanics to achieve hydraulic fracturing tests on the conventional test machine for rock mechanics.

Owner:SICHUAN UNIV

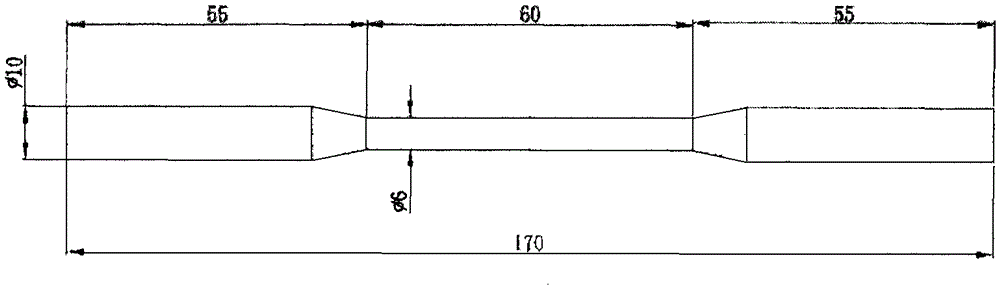

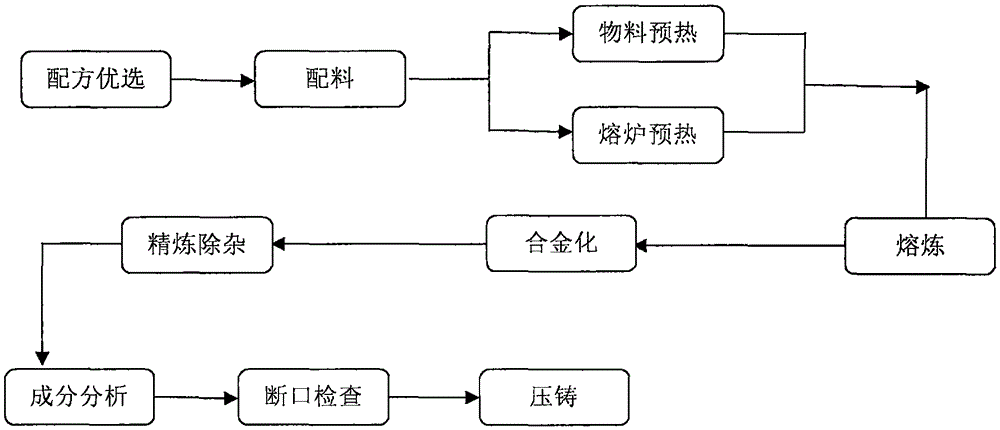

Rare earth-magnesium alloy and preparation method thereof

The invention provides rare earth-magnesium alloy and a preparation method thereof. The rare earth-magnesium alloy comprises 1%-5% of RE, 0-1% of Sr, 0.2%-2% of Zn, 0-1% of Zr and the balance Mg, and RE is one or more of Sm, La, Ce and Y. High heat conductivity, strength and high temperature strength are achieved. Raw materials are preheated after being compounded, then the raw materials are alloyed and microalloyed after being smelted, component analysis and fracture testing are carried out after refining impurity removing, and die-cast formation is achieved after qualification is achieved. The preparation method is easy and convenient to operate, and the prepared rare earth-magnesium alloy is high in purity degree, and suitable for industrial production.

Owner:KA SHUI TECH HUIZHOU CO LTD

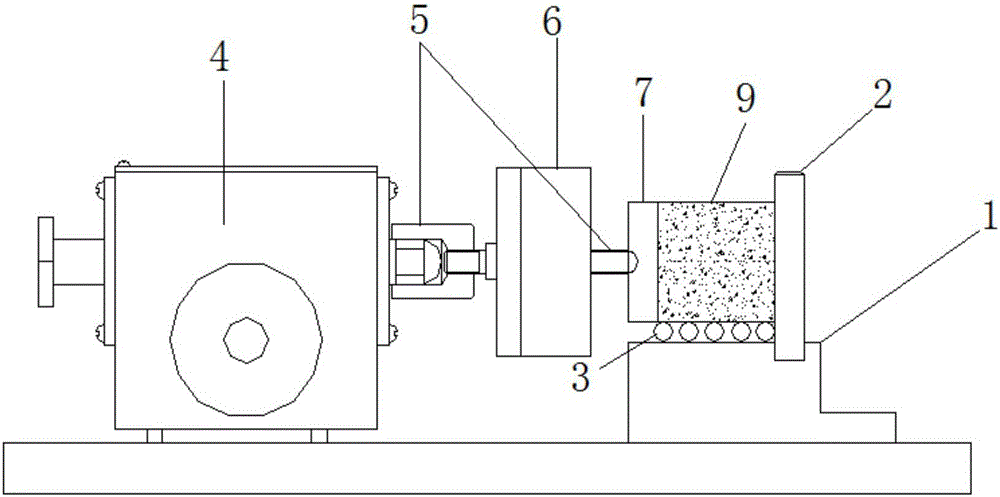

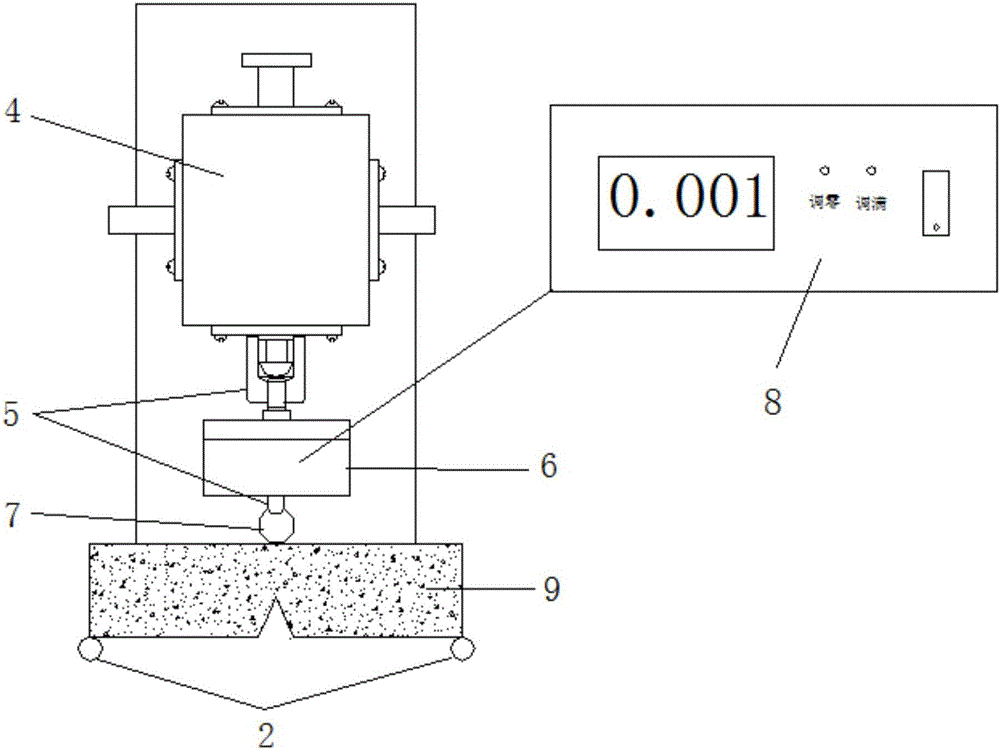

Cohesive-soil strain-control-type I-type fracture toughness tester and testing method

InactiveCN105865924AIngenious ideaUnique structurePreparing sample for investigationMaterial strength using tensile/compressive forcesType fractureTest sample

The invention discloses a cohesive-soil strain-control-type I-type fracture toughness tester and a testing method. The tester comprises an installing table. A motor is arranged on the installing table, and is connected with a stretchable connecting rod, and a sensor is connected to the front end of the connecting rod, and is connected with a pushing rod; a base is arranged on the installing table, sliding rails are arranged on the base, tested samples are arranged on the sliding rails, a pair of stopping rods are fixedly connected to the base, one faces of the tested samples are connected with the stopping rods, the other faces of the tested samples are connected with the pushing rod, and initial fissures are formed in the tested samples. According to the cohesive-soil strain-control-type I-type fracture toughness tester, as the tested samples lie flatly to be subjected to a fracture test, the gravity influence is eliminated; as the tested samples are put onto the sliding rails, the influence of friction force is eliminated.

Owner:NANJING UNIV

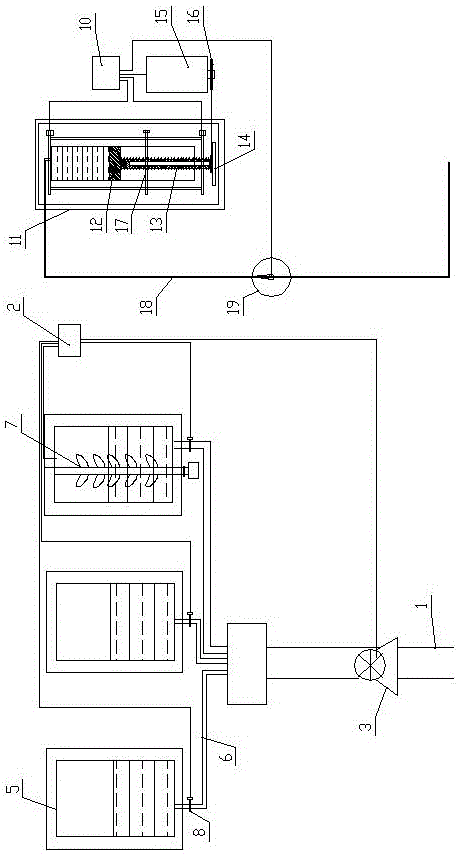

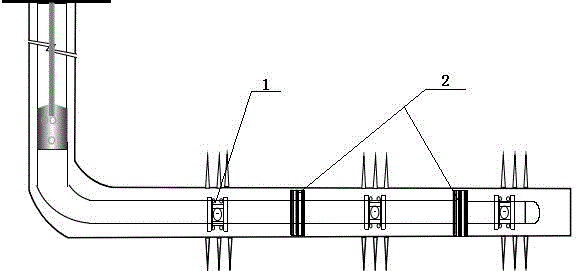

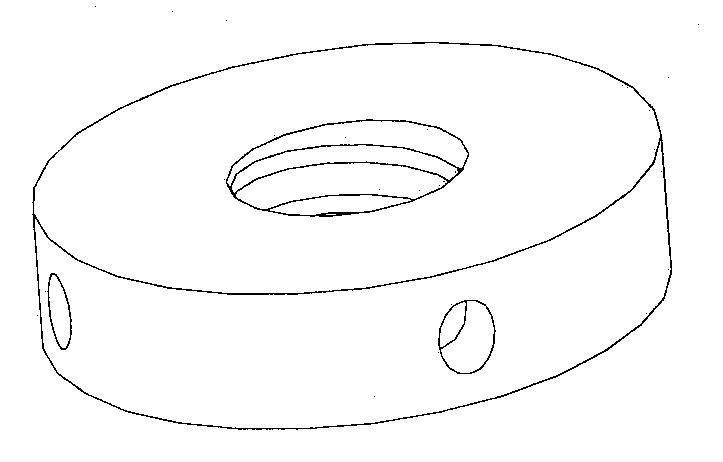

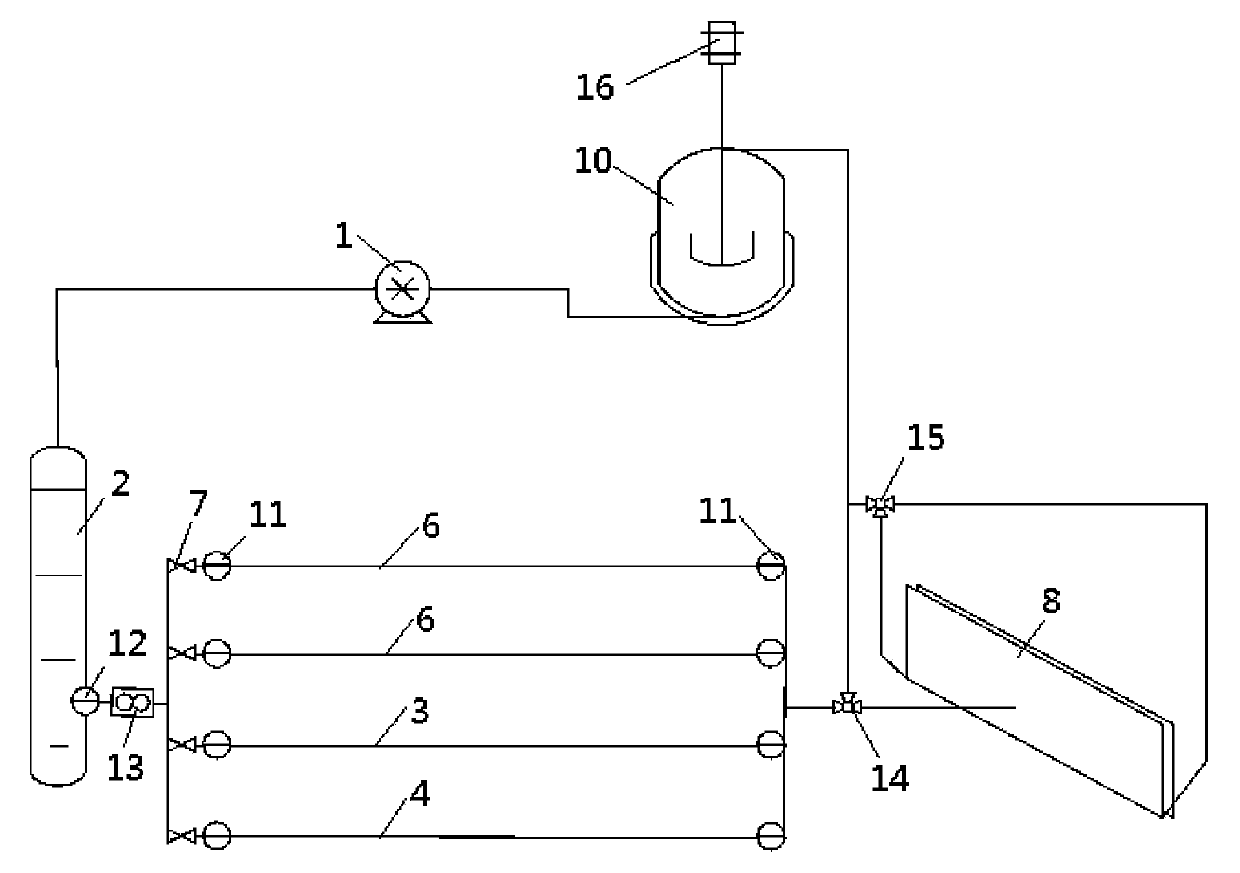

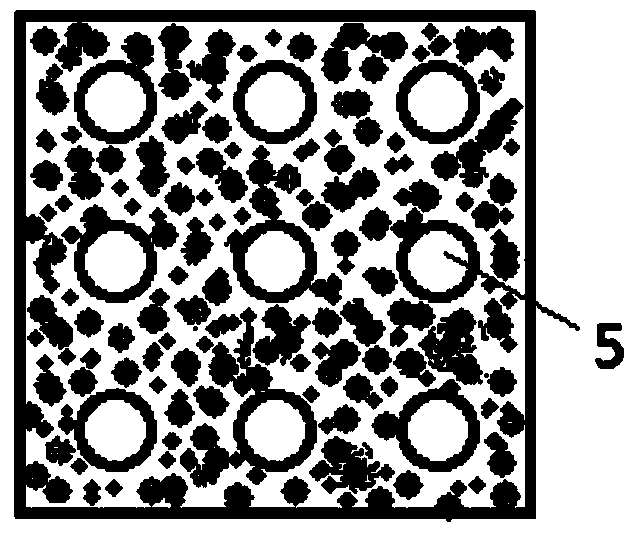

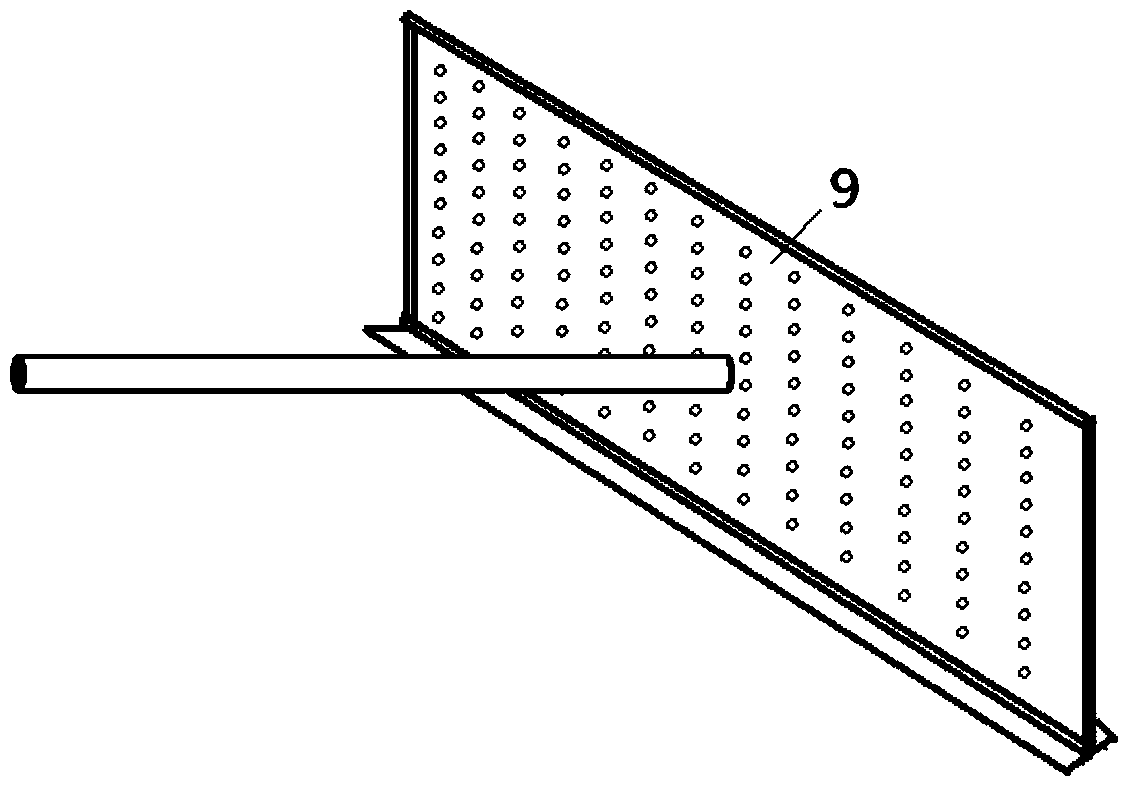

Device for simulating coal-seam hydraulic fracturing effect to monitor discharged excavated pulverized coal change and experimental method thereof

ActiveCN106437694AEven by forceIntegrity guaranteedFluid removalExperimental methodsFracture testing

A device for simulating a coal-seam hydraulic fracturing effect to monitor discharged excavated pulverized coal change comprises a hydraulic fracturing confining-pressure power system, a gas injection system, a hydraulic fracturing testing system and a computer. The gas outlet end of the gas injection system is connected with the gas inlet end of the hydraulic fracturing testing system. The computer is connected with the hydraulic fracturing confining-pressure power system, the gas injection system and the hydraulic fracturing testing system respectively through data lines. The invention further discloses an experimental method of the device for simulating the coal-seam hydraulic fracturing effect to monitor the discharged excavated pulverized coal change. The device is reasonable in design, a prepad fluid, a sand-carrying fluid and a displacement fluid are sequentially injected into a hydraulic fracturing pipe through the hydraulic fracturing confining-pressure power system, high-pressure gas is injected into an annular clamp and the injection amount of the high-pressure gas is regulated through the gas injection system and a confining-pressure device, and coal-seam hydraulic fracturing under the conditions of different coal-seam attribute parameters, different formation stress parameters and different particle sizes and the pulverized coal discharge amount produced under a hydraulic fracturing simulation effect are monitored by controlling the computer to be connected with the hydraulic fracturing confining-pressure power system, the gas injection system, the confining-pressure device, the monitoring device, the annular clamp and the hydraulic fracturing pipe.

Owner:HENAN POLYTECHNIC UNIV

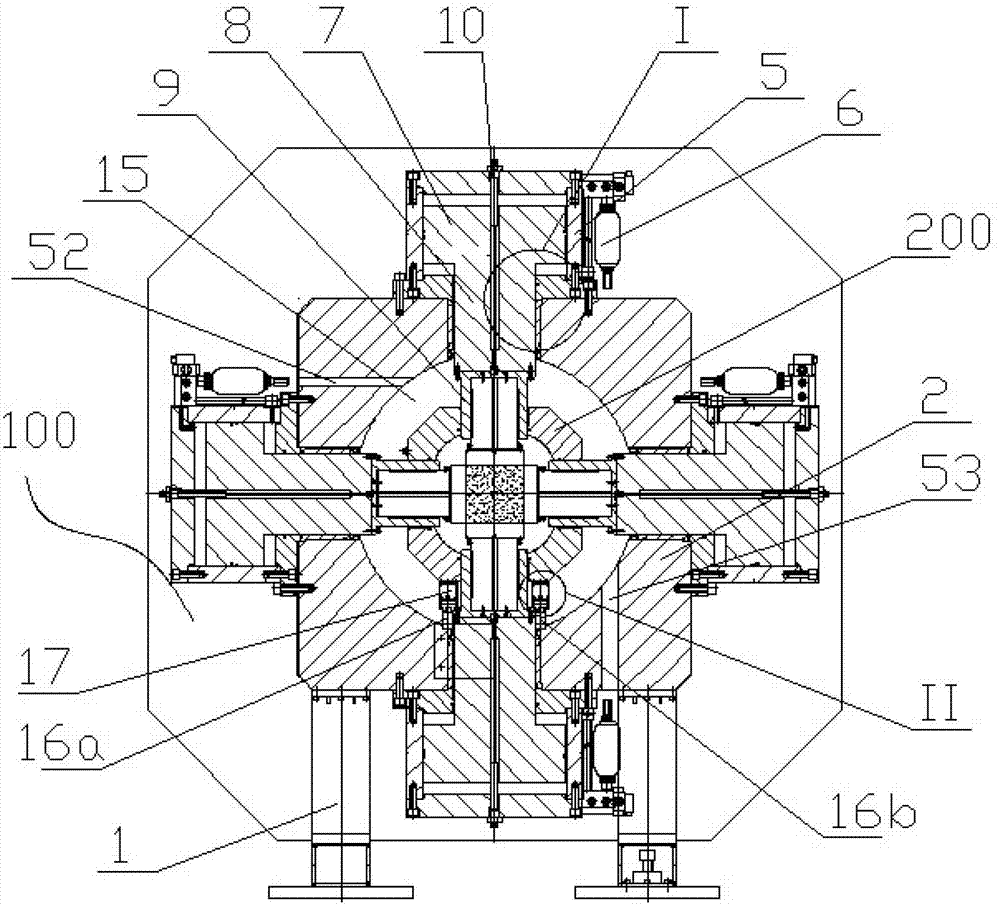

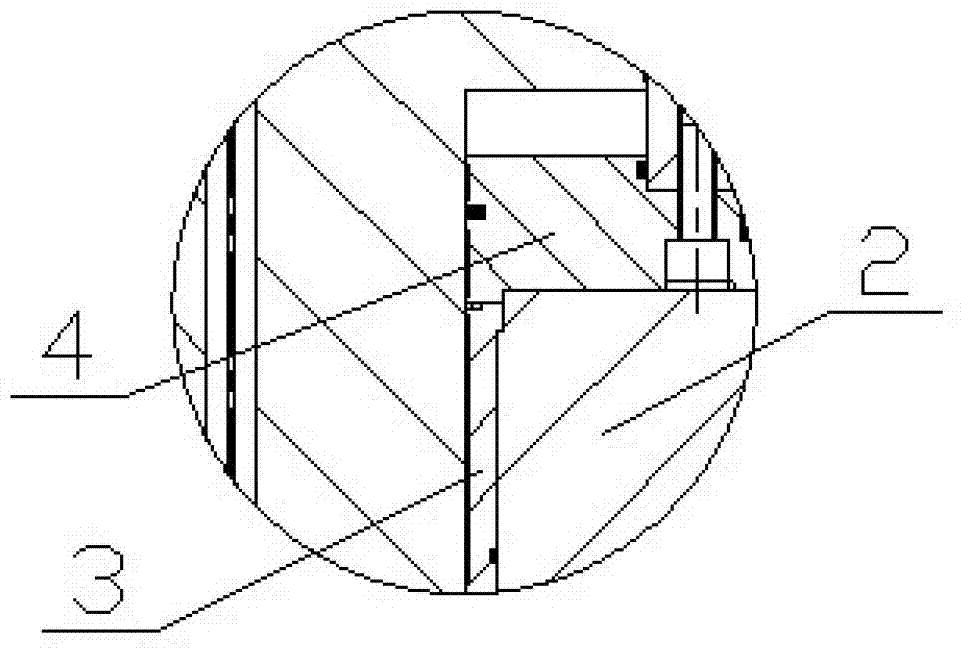

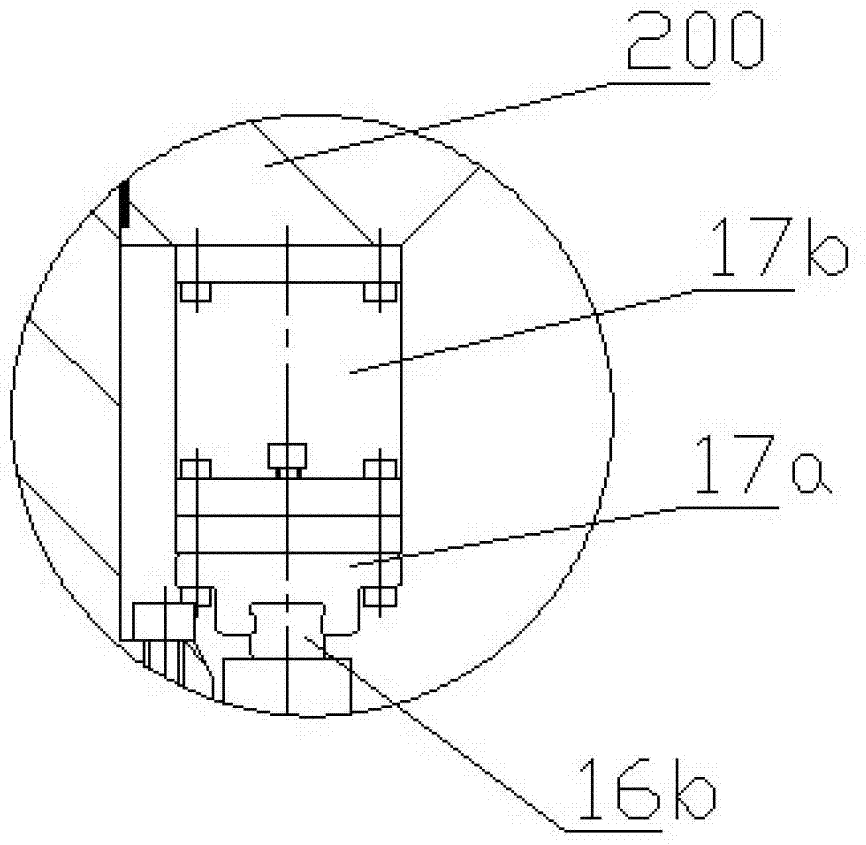

True triaxial sand fracturing testing machine and testing method

The invention relates to a true triaxial sand fracturing testing machine, which comprises a confining pressure system and an injecting system, wherein the injecting system comprises a first fracturing fluid container, a second fracturing fluid container and a piston container; two piston sheet baffle plates are arranged in the piston container. A true triaxial sand fracturing testing method comprises the following steps that stirring is performed in the second fracturing fluid container to form sand-carrying fracturing fluid; prepositive fracturing fluid is injected into the first fracturing fluid container; the prepositive fracturing fluid and the sand-carrying fracturing fluid are respectively injected into a middle cavity and an upper cavity of the piston container by pressure; through a first constant-pressure constant-speed plunger pump and / or a second constant-pressure constant-speed plunger pump, water is discharged into a lower cavity of the piston container; the prepositive fracturing fluid, the sand-carrying fracturing fluid and displacement fracturing fluid sequentially enter a downhole core for fracturing; after the fracturing is finished, the downhole core is taken out; the crack expanding condition is observed. The technical scheme is simple and is easy to understand; the operation is convenient and fast; the unified control on the confining pressure system and the injecting system can be realized; the fracturing fluid replacement is convenient.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

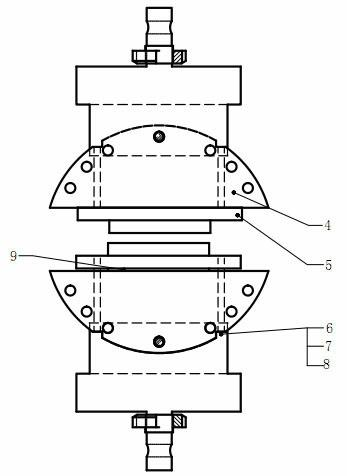

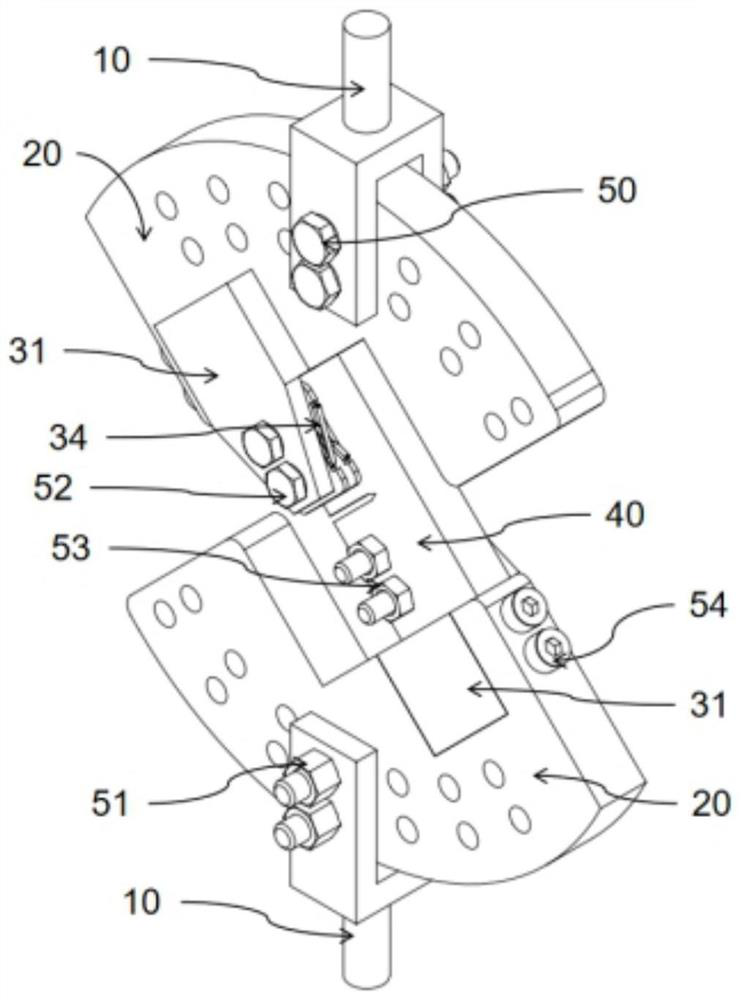

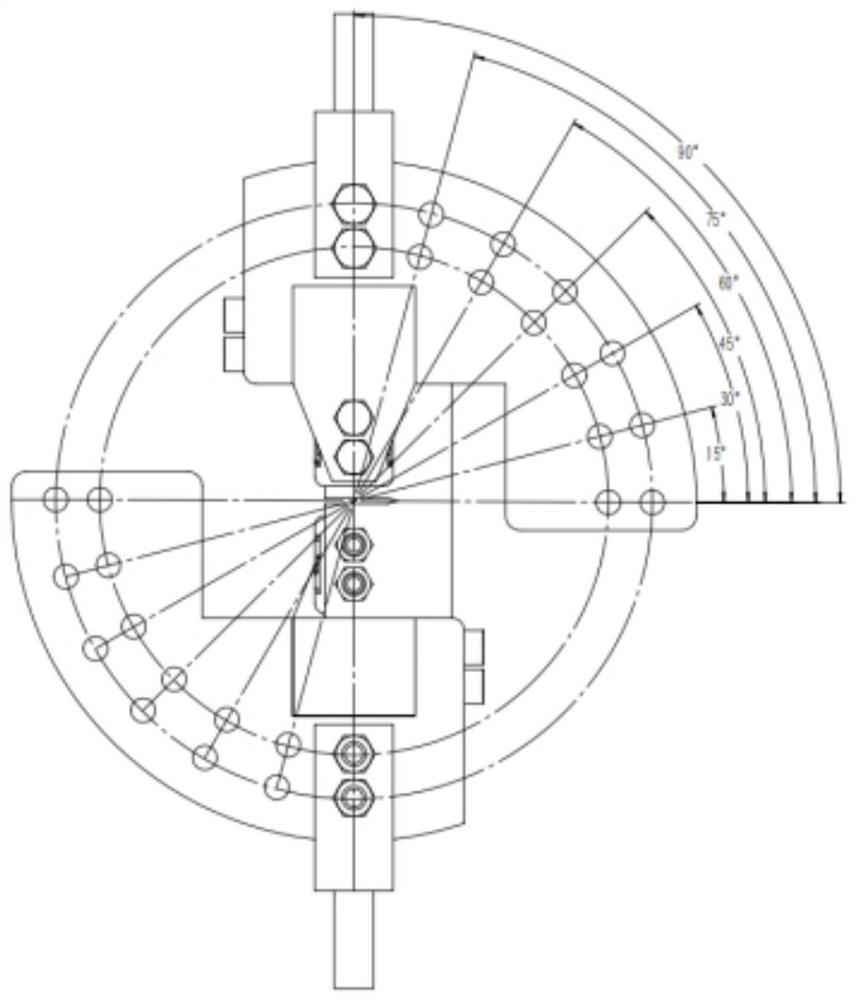

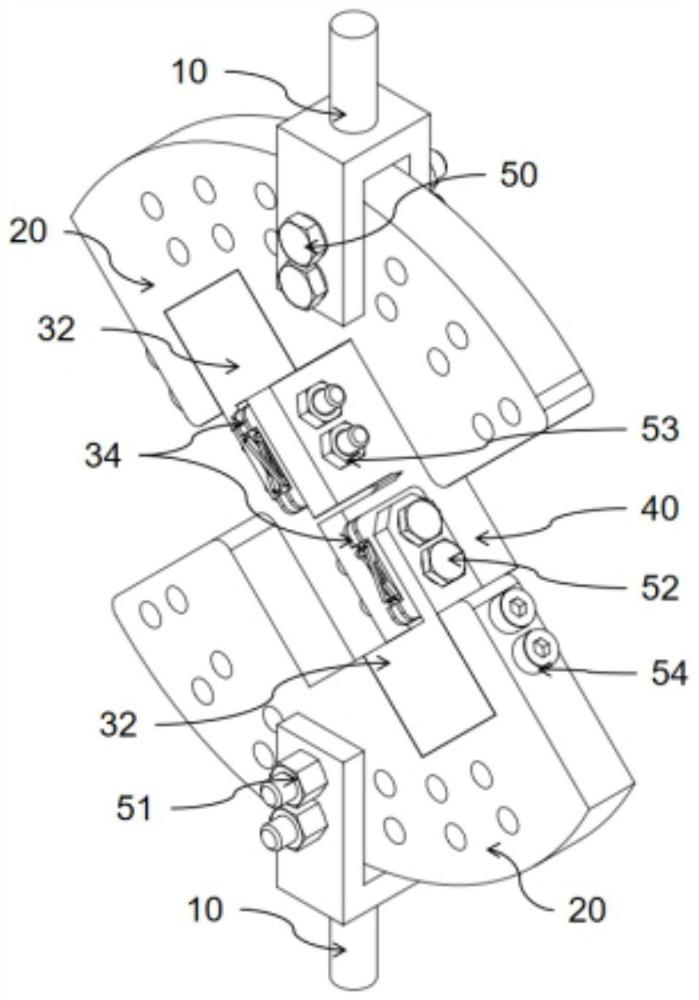

Clamp for mixed fracture test of dual-phase material interface

The invention belongs to the technical field of a material detection, and particularly relates to a clamp for mixed fracture test of a dual-phase material interface. The clamp is divided into an upper part and a lower part that are symmetric to each other; each of the upper part and the lower part consists of a pulling rod, a semiround plate and a sample table; the sample table is connected with the semiround plate by bolts; the semiround plate is connected with the pulling rod by a bolt; a plurality of round holes are symmetrically arranged at the edge of the semiround plate; and the upper pulling rod and the lower pulling rod are fixedly connected with an upper force-applying system and a lower force-applying system of a pulling machine respectively. The clamp can be used together with a universal mechanic tensile testing machine; a sample with a pre-crack is fixed on the clamp; subsequently the clamp can be rotated so as to apply the pull forces of different angles to the sample; the critical fracture strength of the interface crack can be calculated according to a force-displacement curve. The clamp can be used for conveniently determining the situations of the I-type mixed fracture mode and the II-type mixed fracture mode under different tensile loading angles, and is also applicable to determinine the I-type fracture situation of the dual-phase material interface.

Owner:FUDAN UNIV

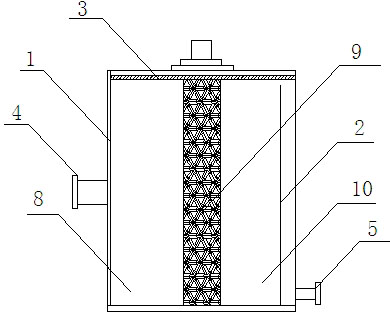

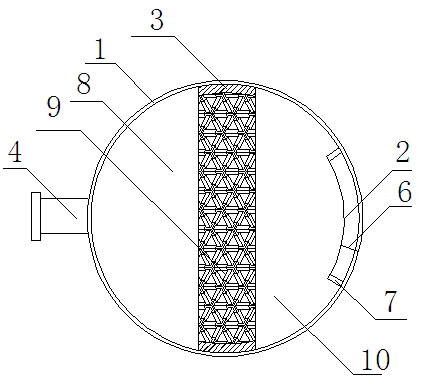

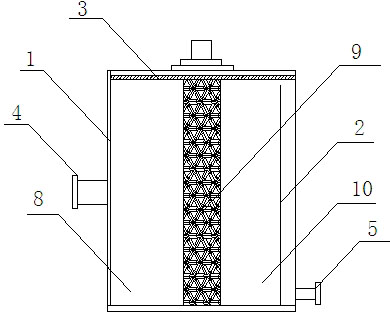

Device and method for bituminous concrete hydraulic fracture testing

InactiveCN102662044ASimple boundary conditionsMaterial testing goodsFracture testingHydraulic engineering

The invention relates to a research device and a technique which can be widely used in the bituminous concrete hydraulic fracture mechanism in engineering including the hydraulic engineering and the geotechnical engineering, in particular to a device and a method for bituminous concrete hydraulic fracture testing. A barrel cover is arranged at the top end of a rigid barrel, a pressure water inlet is arranged outside the lateral wall of the rigid barrel, a downstream leakage water outlet is arranged outside the rigid barrel on the other side of the pressure water inlet, and the pressure water inlet is higher than the downstream leakage water outlet. Samples of the device and the method include a bituminous concrete upstream material source, bituminous concrete and a bituminous concrete downstream material source, and modulus difference of materials is considered. Boundary conditions of the samples are simple, deflection of bituminous concrete can be controlled through telescopic bolts, and real simulation of the site actual working condition is achieved. In addition, the device exerts water pressure at the pressure water inlet to form a steady seepage field, and the bituminous concrete hydraulic fracture mechanism can be analyzed quantitatively.

Owner:HOHAI UNIV

Low temperature fracture testing instrument of asphalt mixed material

InactiveCN1719223AEnsure consistencyPrevent shrinkage deformationMaterial strength using tensile/compressive forcesControl systemFracture testing

The present invention relates to an asphalt mixture material low-temperature breaking test instrument. Said test instrument includes base seat, supporting frame, sample holder, force sensor, heating compensation system, control system, heating jacket and temperature sensor. Besides, said invention also includes condenser tube, heat-insulating tube and constant temperature channel, etc.

Owner:马骉 +2

Horizontal well section testing method by adopting soluble rubber sleeve packer

ActiveCN104632196AOvercome the disadvantage of excessive friction that makes unsealing difficultOvercoming the disadvantages of unblocking difficultiesSurveySealing/packingTemperature controlFracture testing

The invention belongs to the technical field of the oil production engineering in the oil field, and particularly provides a horizontal well section testing method by adopting a soluble rubber sleeve packer. The method comprises the following steps: firstly, wiper trip is carried out by a wiper trip tool; secondly, the surface of a soluble rubber sleeve is coated with a layer of a temperature control film, and a pipeline column tool string is formed by connecting of the soluble rubber sleeve packer, an downhole switch gear, a centralizer and an oil-well pump through an oil pipe in a matching mode; thirdly, the pipeline column tool string formed in the second step is descended to a pre-set position into the well once to carry out testing; fourthly, the testing section layer is opened through the soluble rubber sleeve packer, and sectionalizing testing is carried out on the to-be-pumped layer of the oil well; fifthly, after the testing is finished, the soluble rubber sleeve on the soluble rubber sleeve packer is automatically dissolved; sixthly, after the soluble rubber sleeve finishes dissolving, the tested pipeline tool string is taken out. The soluble rubber sleeve on the soluble rubber sleeve packer is automatically dissolved after the horizontal well fracturing testing is finished, and the defect that a the dissolution is difficult caused by the greater friction force of the well wall and the rubber sleeve due to the fact that a common packer rubber sleeve cannot retract and the rubber sleeve turns outward during the dissolution is solved.

Owner:PETROCHINA CO LTD

Analog semi-rigid underlying structure temperature shrinkage fracture testing method and device

InactiveCN103076236AAccurate application of tensionNo rotationMaterial strength using tensile/compressive forcesTemperature controlFracture testing

The invention discloses an analog semi-rigid underlying structure temperature shrinkage fracture testing method and a device. The device mainly consists of a bracket, a gripping head, a screw rod, positioning bolts and a force sensor, and the selected materials of an analog test piece are organic glass plate and rubber tire. The testing method comprises the following steps: fixing a test piece pasted with a strain disc on the device through the gripping head, then placing in a temperature control test box, and connecting the strain disc and a strain box through a conducting wire which penetrates through the test box; turning the positioning bolts to apply a tensile force to the test piece through the control of the force sensor, and realizing the purpose of applying the tensile force to the test piece; and while applying the tensile force to the test piece, ensuring that the test piece and the gripping head are in the same plane, and fixing the test piece through a fastening bolt and the screw rod, so as to ensure that the test piece does not generate torsion. The method provided by the invention can simulate the fracture condition generated by fracture of a semi-rigid underlying structure after the action of temperature and load, and provides an effective way for research of underlying structure indoor analog and the fracture condition under the condition of temperature variation; and the structure is simple, the operation is convenient and the effect is good.

Owner:程培峰

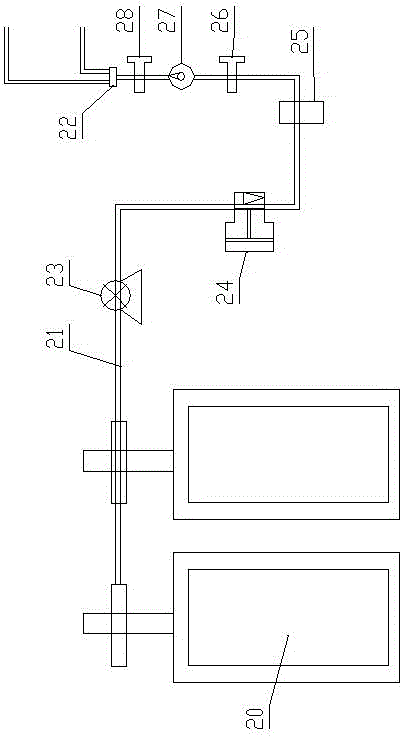

Radial well fracture testing device

InactiveCN103993877AHigh precisionImprove practicalitySurveyFluid removalFracturing fluidFracture testing

The invention relates to a radial well fracture testing device. The radial well fracture testing device comprises a pumping unit, a transparent wellbore hole simulator, a stratum simulation pipeline and a transversely-cut seam simulation device. The pumping unit is used for pumping sand-carrying fluid. The inlet of the transparent wellbore hole simulator is connected with the outlet of the pumping unit, and the transparent wellbore hole simulator is used for allowing a user to observe the sand setting rule. The inlet of the stratum simulation pipeline is connected with the outlet of the transparent wellbore hole simulator, and the stratum simulation pipeline is used for simulating and testing radial wellhole or tubular column friction drag under different reservoir stratum conditions. The inlet of the transversely-cut seam simulation device is connected with the outlet of the stratum simulation pipeline, and the transversely-cut seam simulation device is used for simulating and testing the propping agent setting rule of a transversely-cut seam formed by fracture of a radial well. The sand-carrying fluid can be used when the friction drag of the radial well is tested, the roughness of the wall of the well and the leak-off process of fracturing fluid are simulated, and accuracy and practicability of a friction drag test are improved; meanwhile, the sand setting rule can be observed through the transparent wellbore hole simulator and the propping agent setting rule of the transversely-cut seam under the leak-off condition can be tested through the transversely-cut seam simulation device.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

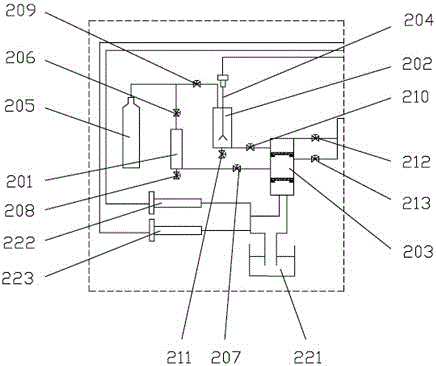

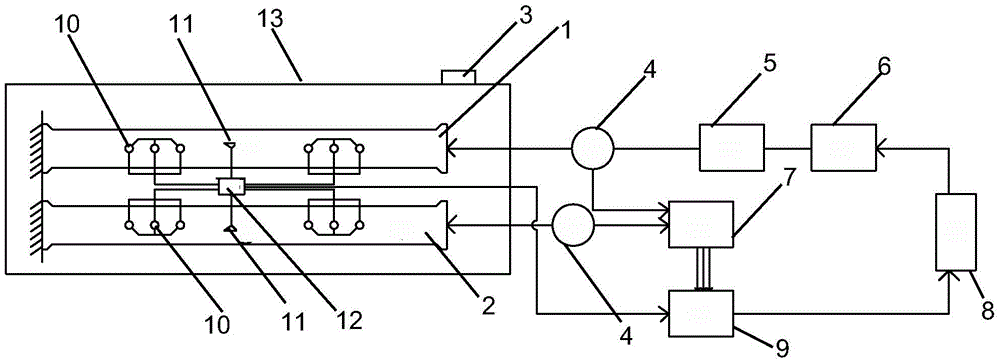

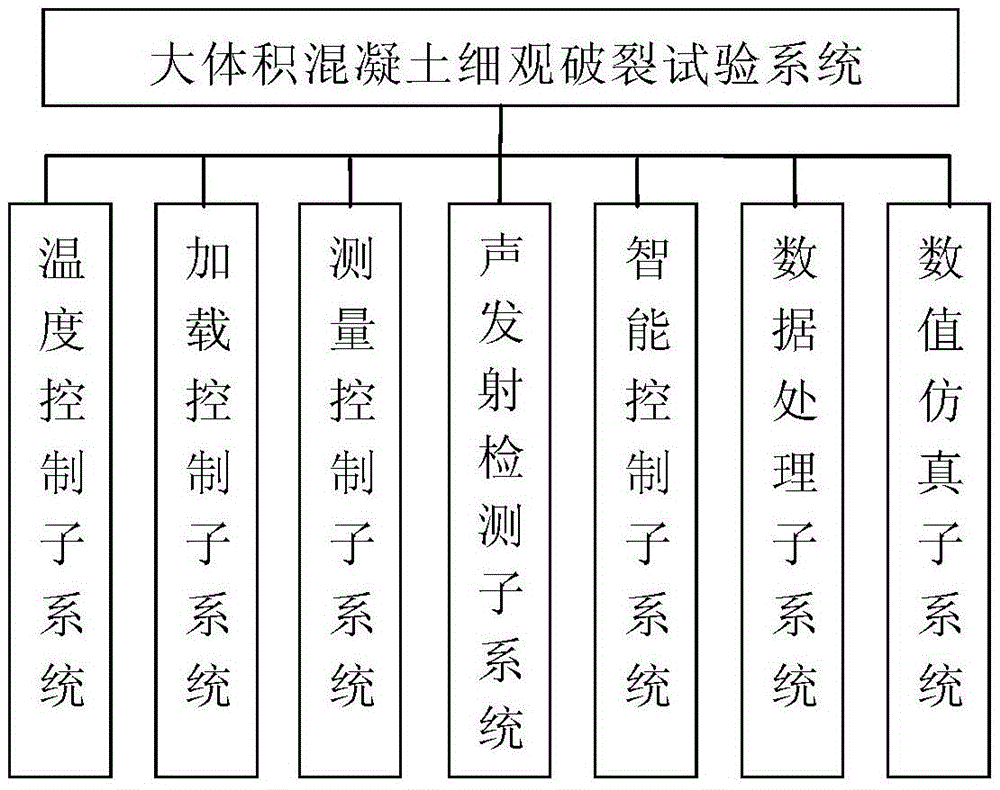

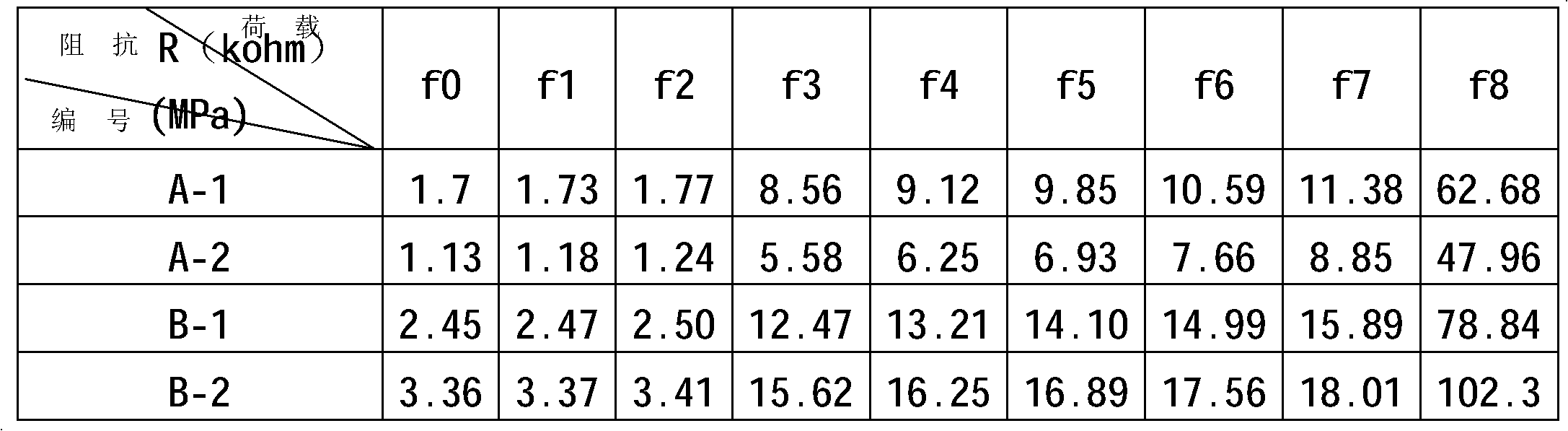

Mass concrete microscopic fracture testing system

ActiveCN105527311AAccurate measurementThe test data is accurateMaterial analysis using acoustic emission techniquesMaterial thermal analysisTemperature stressFracture testing

The invention discloses a mass concrete microscopic fracture testing system. The mass concrete microscopic fracture testing system comprises a temperature stress testing machine and a sound emission detection device, wherein the temperature stress testing machine comprises a machine case for accommodating a concrete sample, a heating and cooling system, a displacement sensor, a force sensor, a stepper motor, a controller, a signal amplifier, a temperature sensor which is buried in the concrete sample, and a server, wherein the server is used for controlling the actions of the stepper motor according to data collected by each sensor and processing the data collected by each sensor to obtain temperature stress test parameters; the sound emission detection device comprises a sound emission sensor buried in the concrete sample and a signal processing unit, and the sound emission sensor is connected with the data input end of the server through the signal processing unit; concrete deformation data collected by the sound emission sensor are transmitted to the server after the amplification of the signal processing unit and analog-digital conversion processing. The system takes the occurrence of concrete microscopic fractures as a test result, so that accurate measurement of temperature parameters under concrete microscopic fractures can be realized.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

Performance evaluation method for fracture acidizing temporary plugging agents

InactiveCN106285613AImprove single well productivityFluid removalSealing/packingWell drillingFracture testing

The invention relates to a performance evaluation method for fracture acidizing temporary plugging agents. The performance evaluation method comprises a step of sampling, specifically, a square core serves as a sample piece; a step of borehole drilling, specifically, a borehole is drilled in the center of the sample piece; a step of well barrel inserting-in, specifically, a well barrel is inserted in and fixed along the borehole, and an open hole section is reserved between the well barrel and the borehole; a step of evaluation parameter setting, specifically, evaluation parameters comprise temporary plugging agent kinds, triaxial pressure and displacement; a step of testing setting, at least three groups of triaxial pressure and displacement are set for each temporary plugging agent; and a step of fracture testing, specifically, fracture testing is conducted on each temporary plugging agent. The performance evaluation method has the beneficial effects that the performance evaluation method for the fracture acidizing temporary plugging agents is provided, the temporary plugging agents can be evaluated, the performance of the temporary plugging agents is known through the valuation parameters, the construction design of shale fracture is guided, a shale fracture gap net form can be controlled by selecting the suitable temporary plugging agents, and thus shale gas single well productivity is improved.

Owner:YANCHANG OIL FIELD

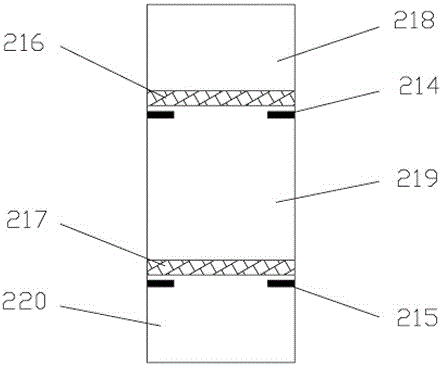

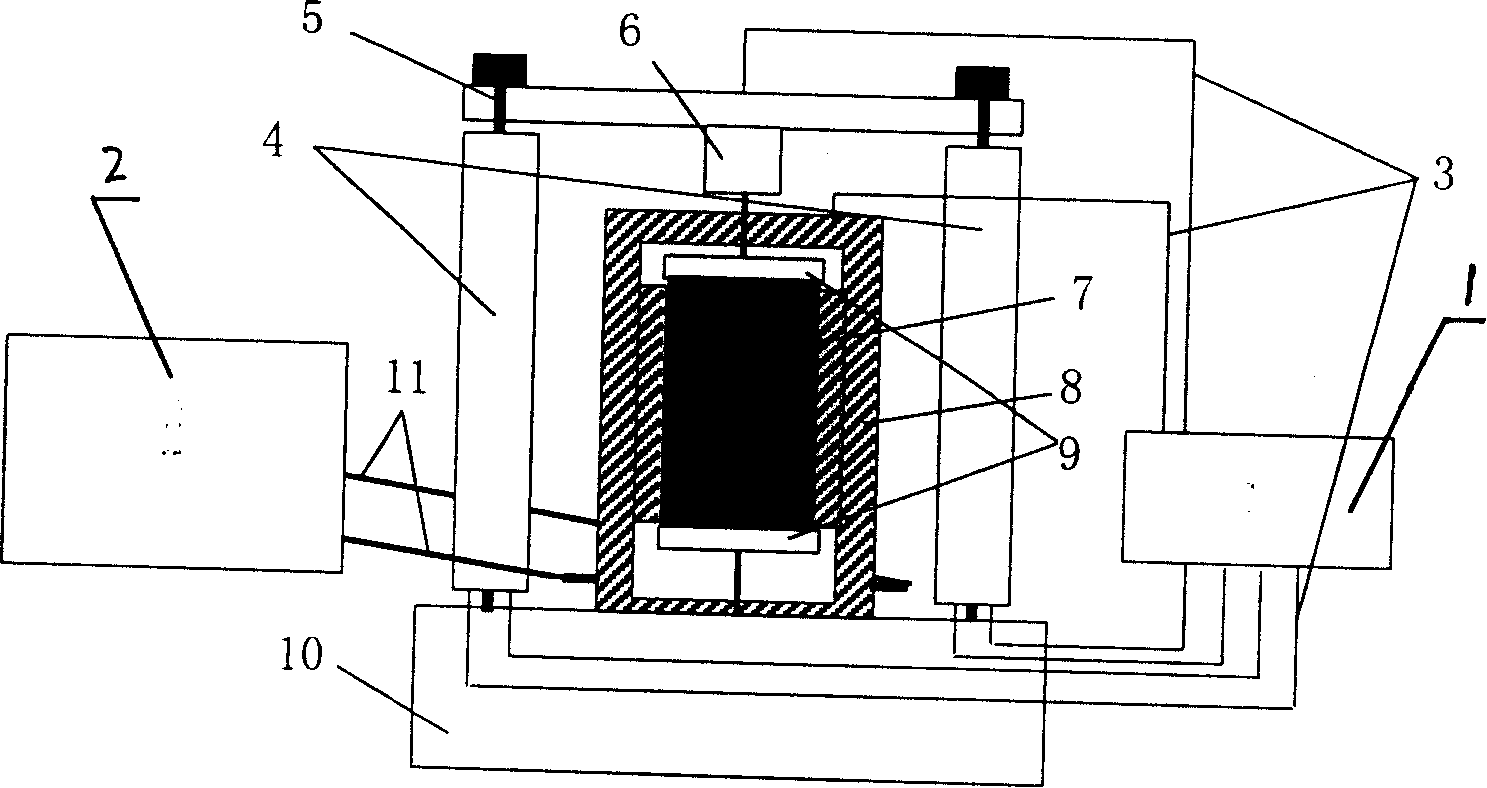

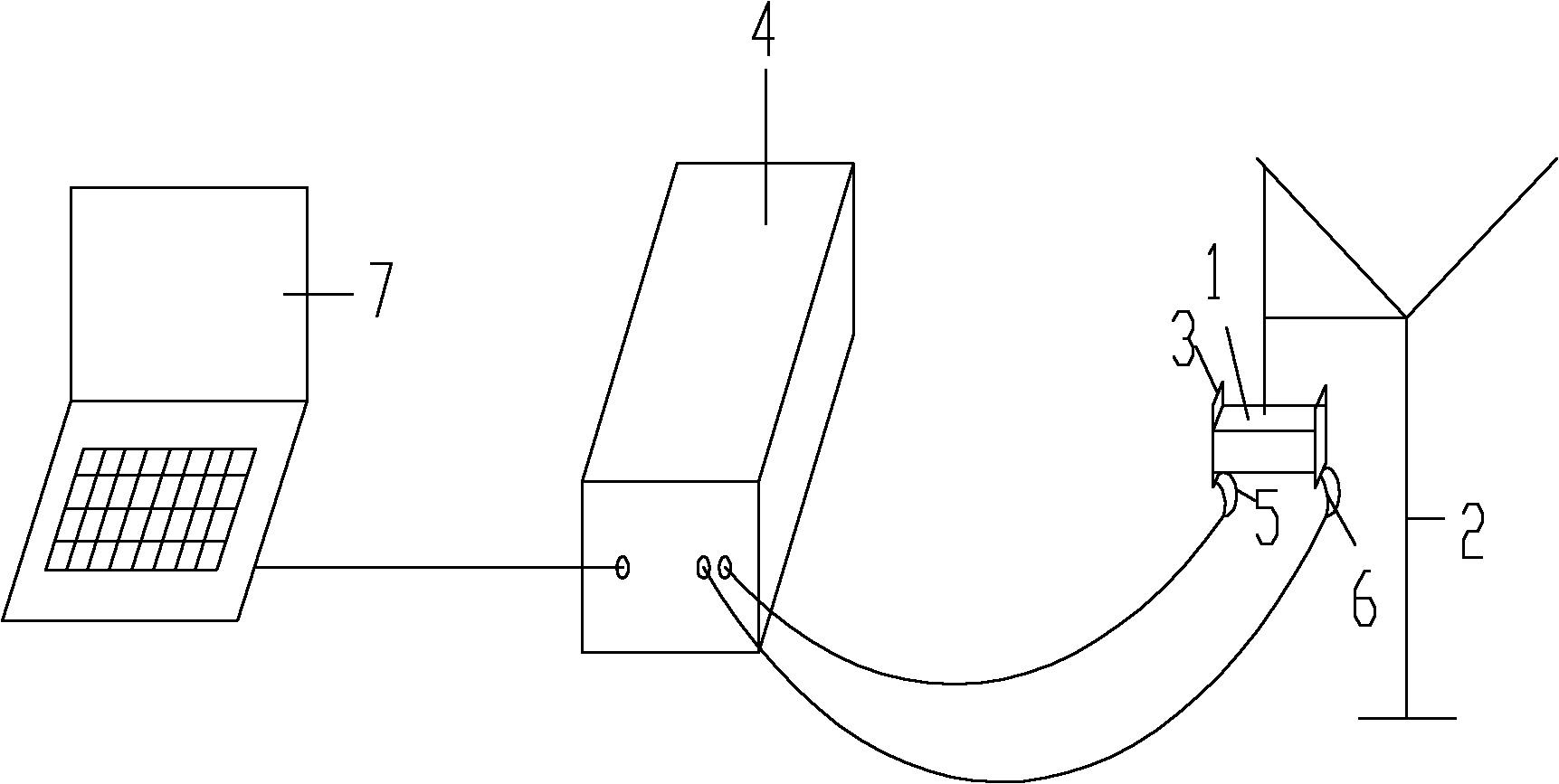

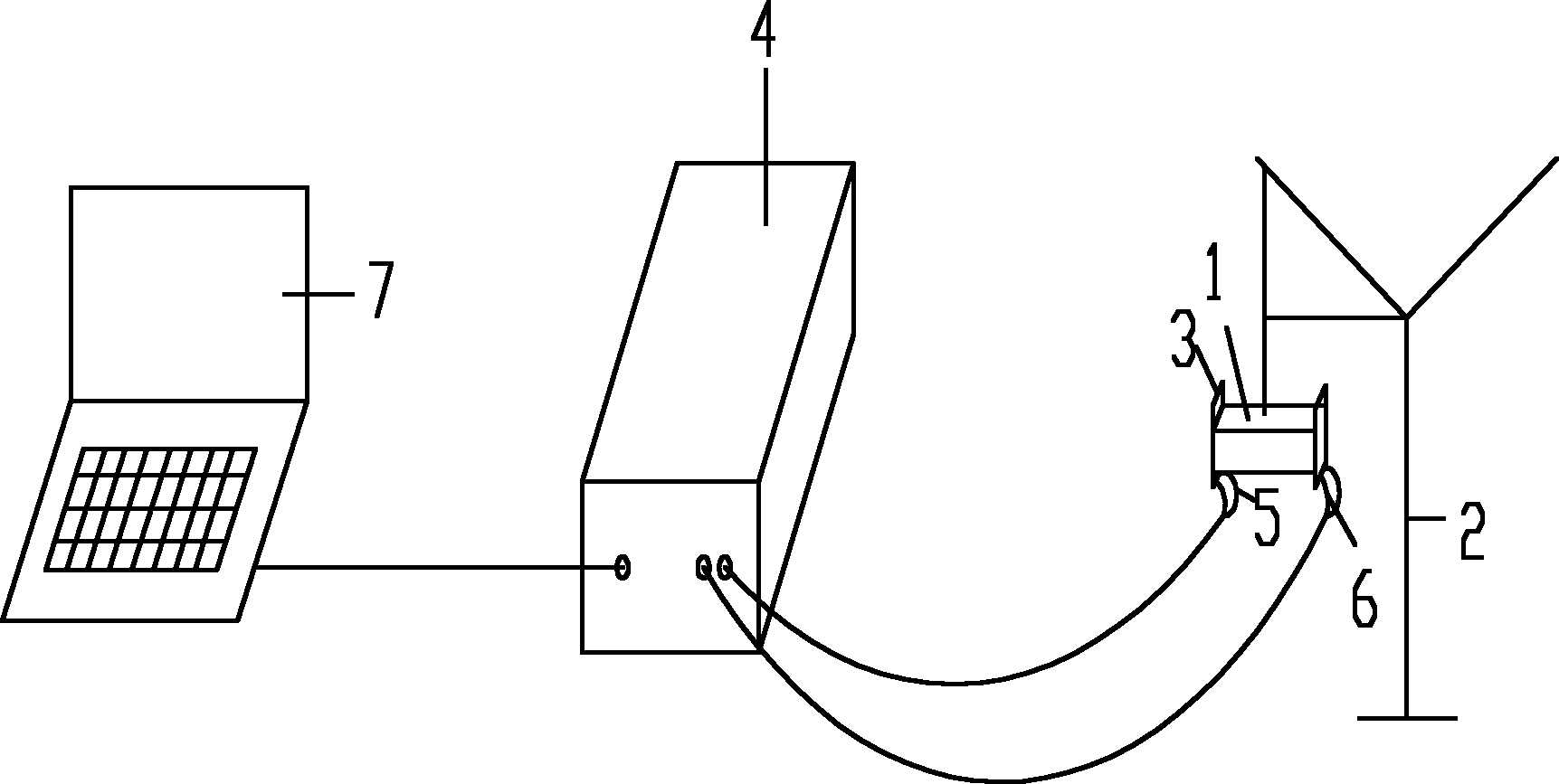

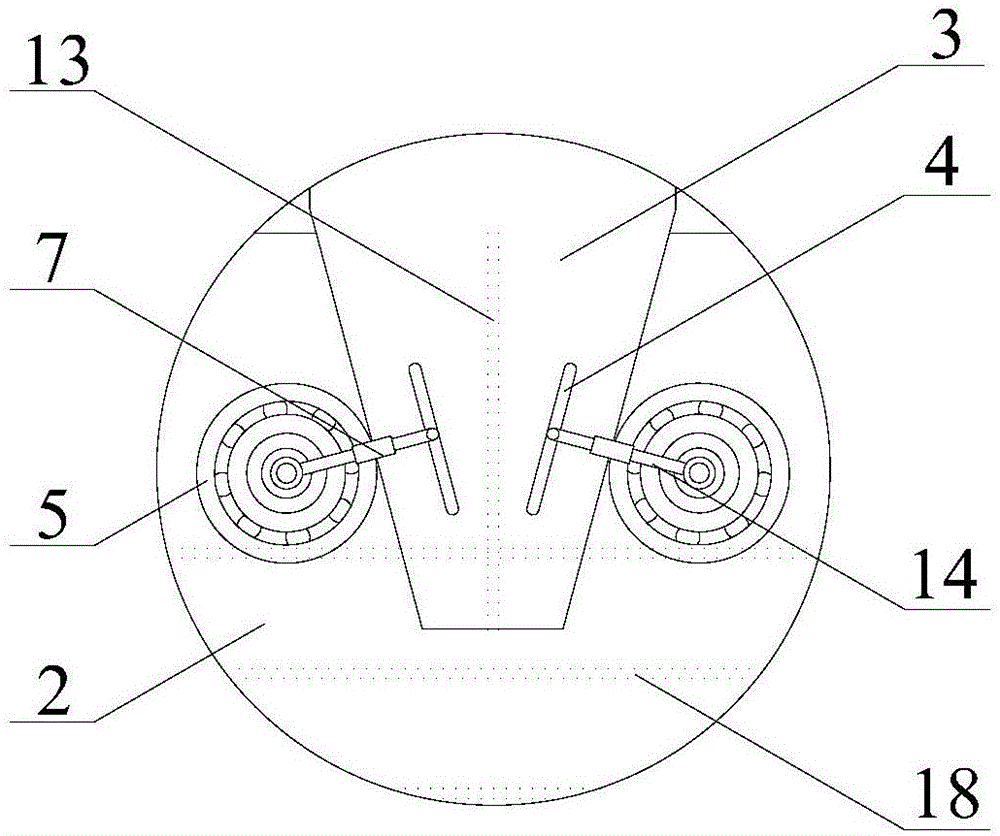

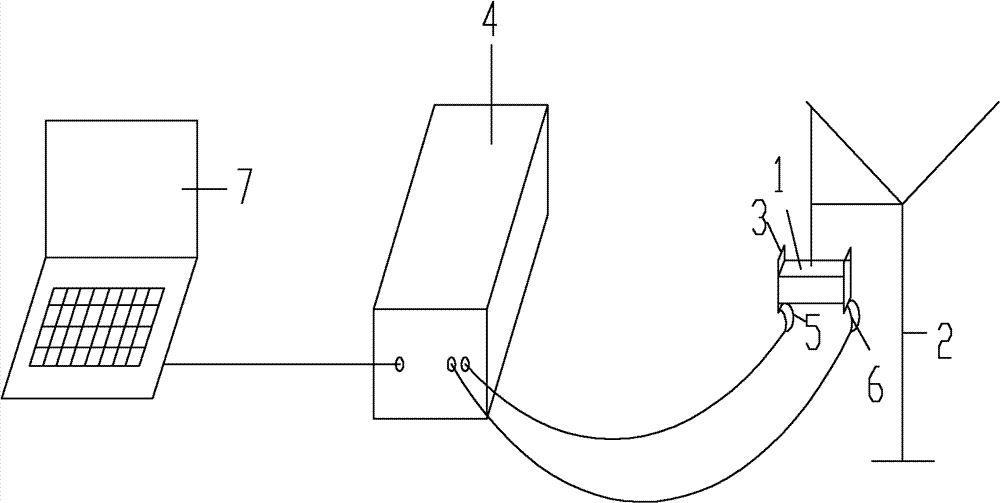

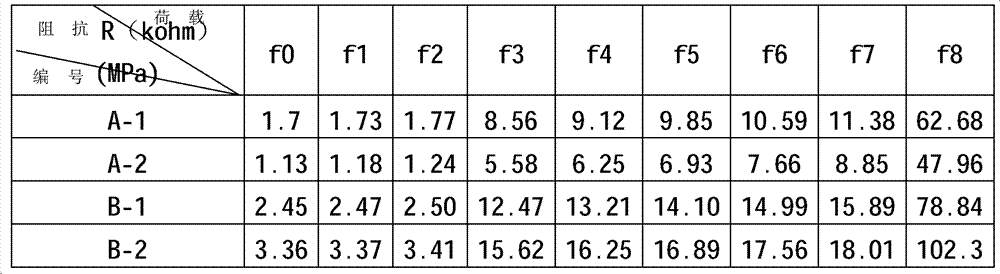

Device for testing different cracking conditions of interior of cement-based material and method

ActiveCN102147387ASimple and quick determinationThe test result is accurateMaterial resistanceSpectroscopyEngineering

The invention relates to a device for testing different cracking conditions of the interior of a cement-based material and a method, belonging to the testing field of a building material. The testing method comprises the following steps: the periphery of a cement-based material test specimen (1) with the standard size of 40*40*160mm is wrapped and sealed by a plastic film and fixed in an anti-fracture testing machine (2); two stainless steel electrodes (3) are respectively fixed on two opposite 40*40mm parallel surfaces of the test specimen (1); and the two stainless steel electrodes (3) and a constant potential rectifier are respectively connected by a working electrode (5) and a reference electrode (6). During testing, the anti-fracture testing machine (2) applies different grades of bending loads to the test specimen (1) so as to lead the test specimen (1) to reach different cracking conditions and complete a test procedure of the alternating current impedance spectroscopy of the constant potential rectifier (4); and impedance parameters collected by a computer (7) are used for reflecting different cracking conditions of the interior of the cement-based material. The testing method can rapidly and accurately reflect different cracking conditions of the interior of the cement-based material and is simple and practical.

Owner:BEIJING UNIV OF TECH

Rock mass mesoscopic fracture testing method based on three-dimensional digital speckles

ActiveCN110987765ASimple structureEasy to buildUsing optical meansPermeability/surface area analysisImaging processingComputer graphics (images)

The invention relates to the technical field of rock mass deformation measurement, in particular to a rock mass mesoscopic fracture testing method based on three-dimensional digital speckles. The method comprises the following steps: building a discrete physical model according to the working face geological conditions of a to-be-researched object; manufacturing speckles on the surface of the model, and keeping the shooting direction of a digital camera device perpendicular to the model; and collecting model images under different advancing distances by using the digital camera device, processing the images through an image processing device, and acquiring displacement and strain values of different measuring line positions under different advancing distances to realize microcosmic fracture positioning and fracture opening degree and fracture development length determination. According to the rock mass mesoscopic fracture testing method, the generation and development of the mesoscopicfractures of the overlying strata can be quantitatively described, the mesoscopic fractures can be effectively detected, high measurement precision can be realized, rock deformation is visualized into a mesoscopic scale, and effective technical and data support is provided for research of rock mass failure rules, rock stratum development rules and the like.

Owner:XIAN UNIV OF SCI & TECH

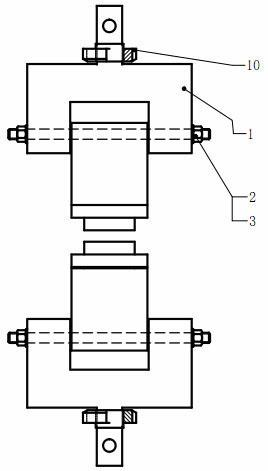

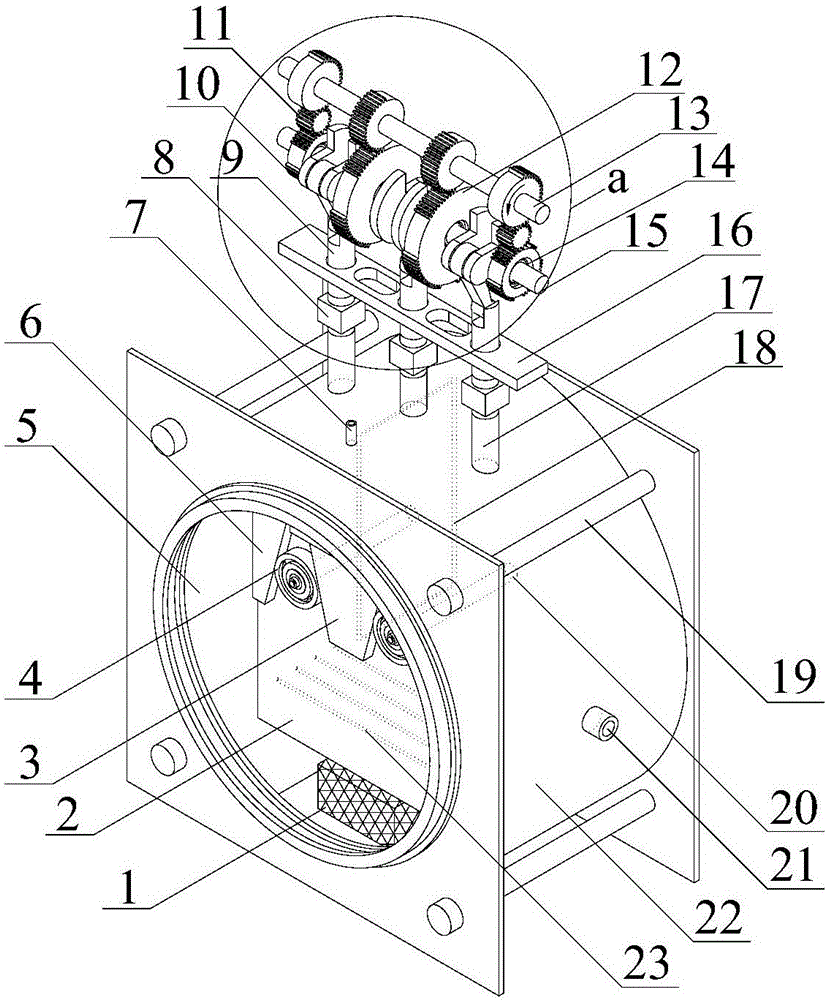

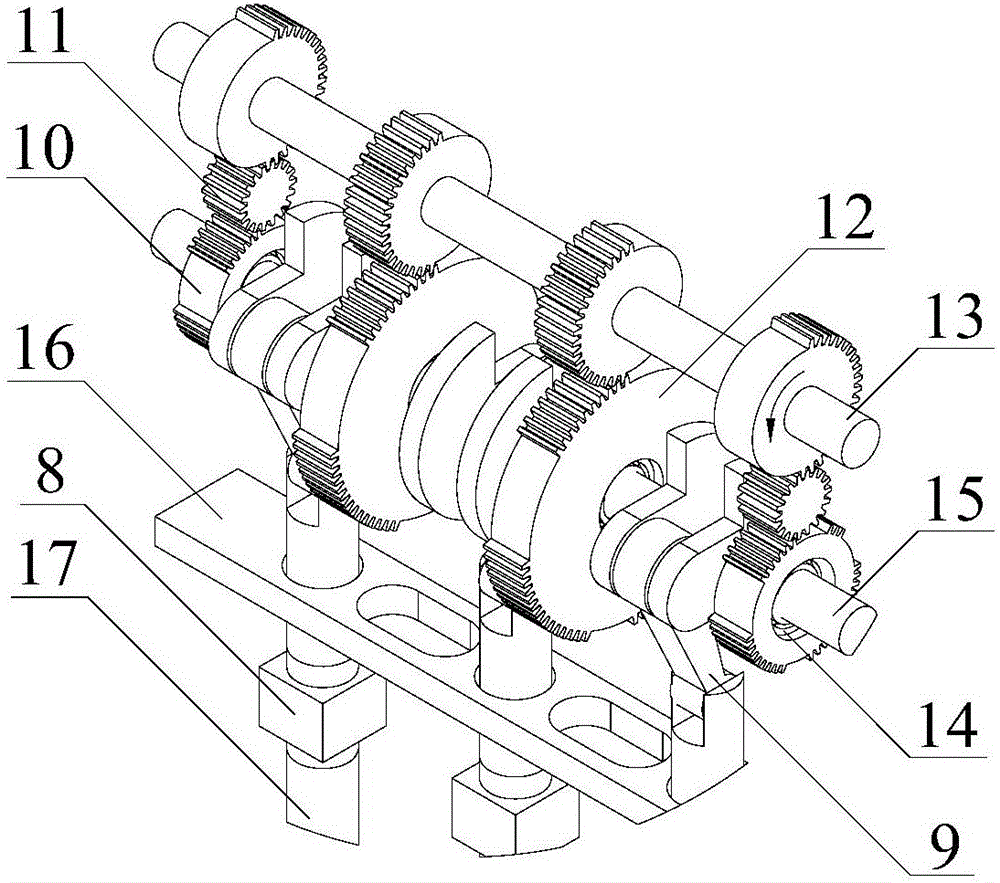

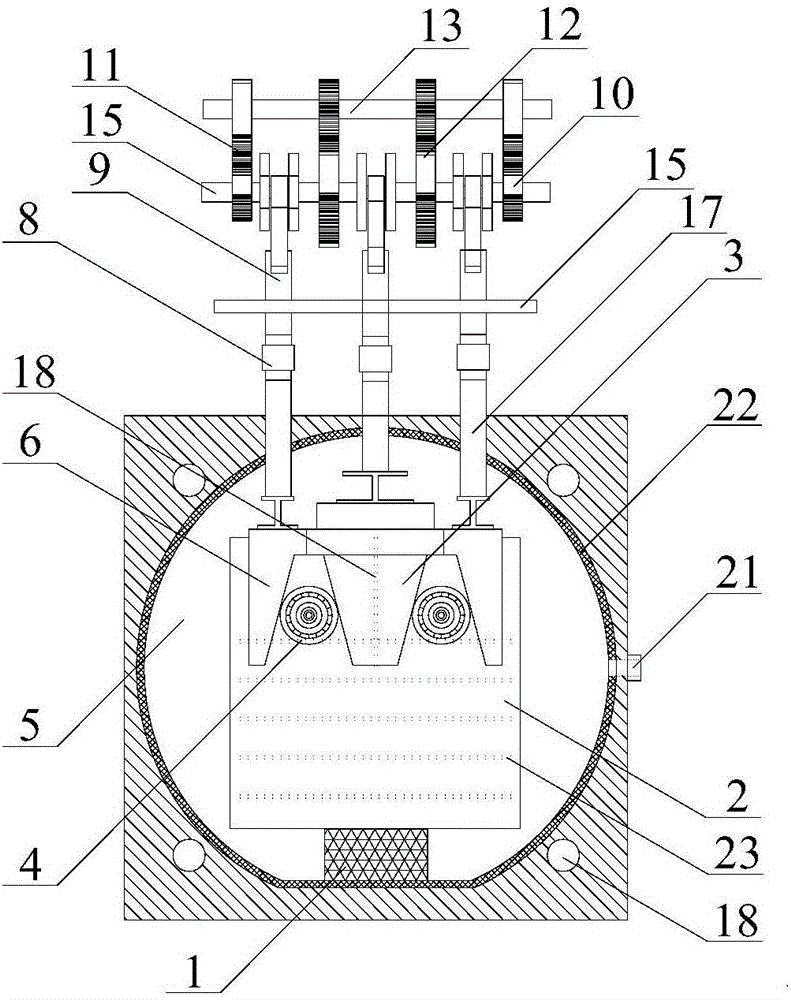

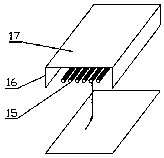

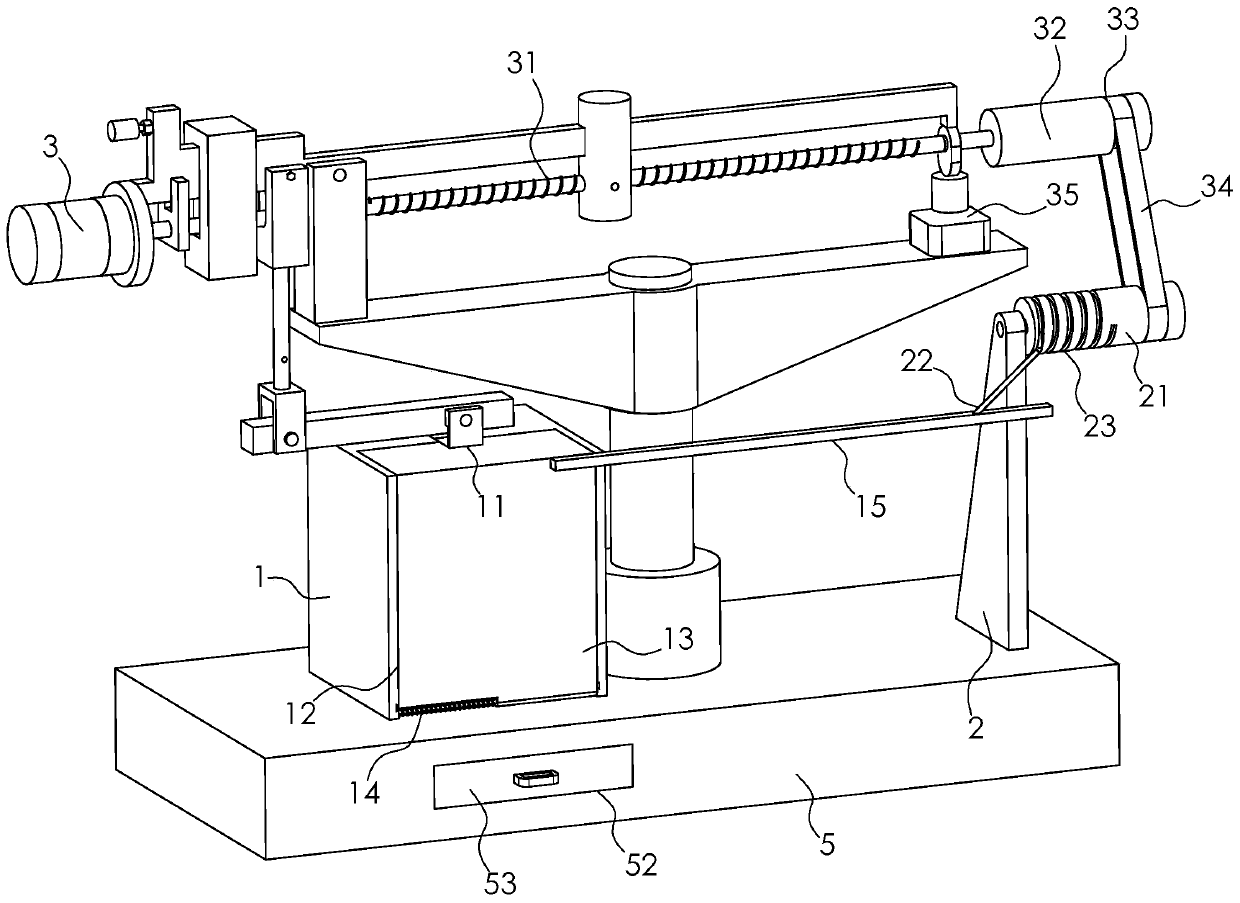

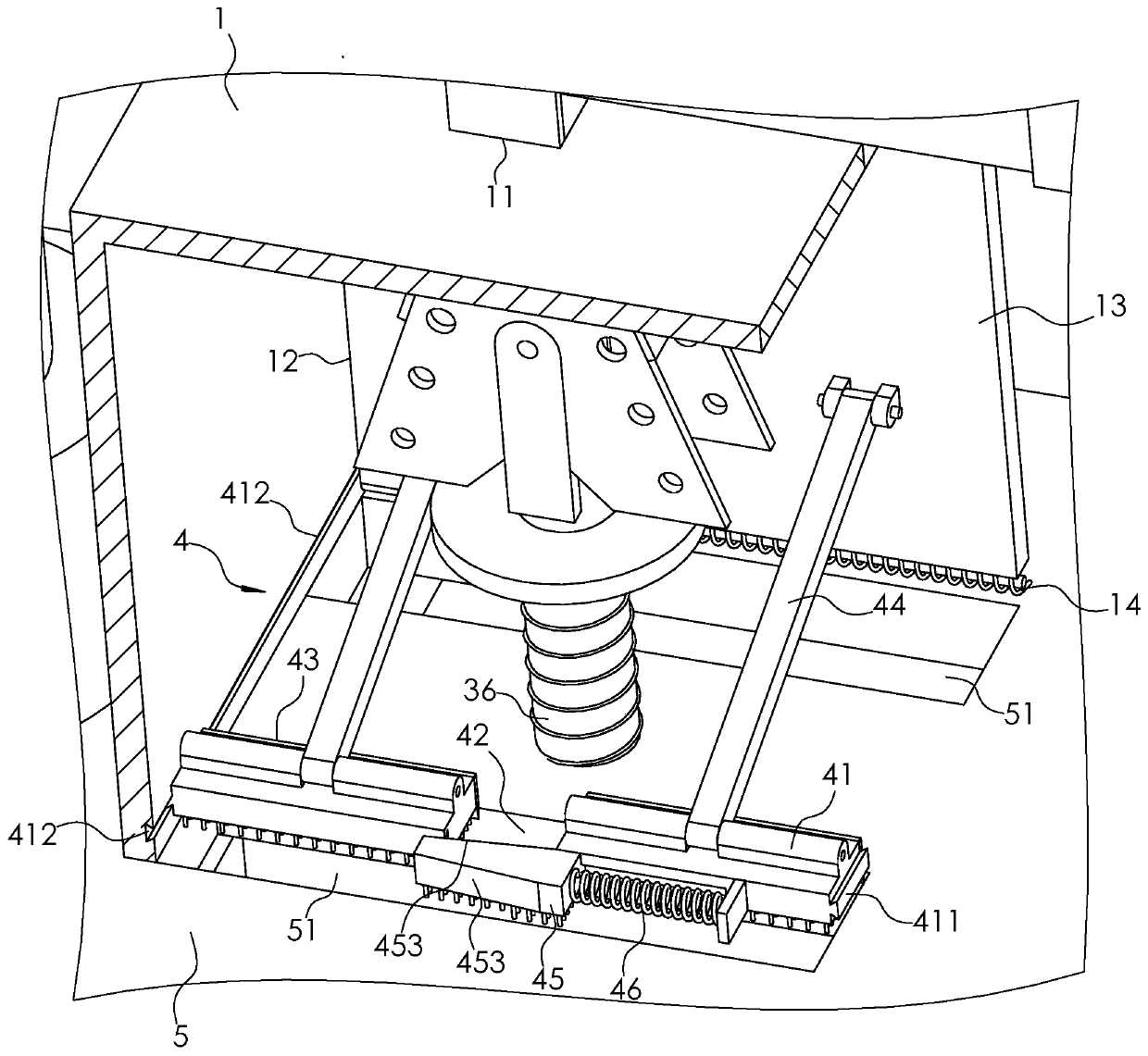

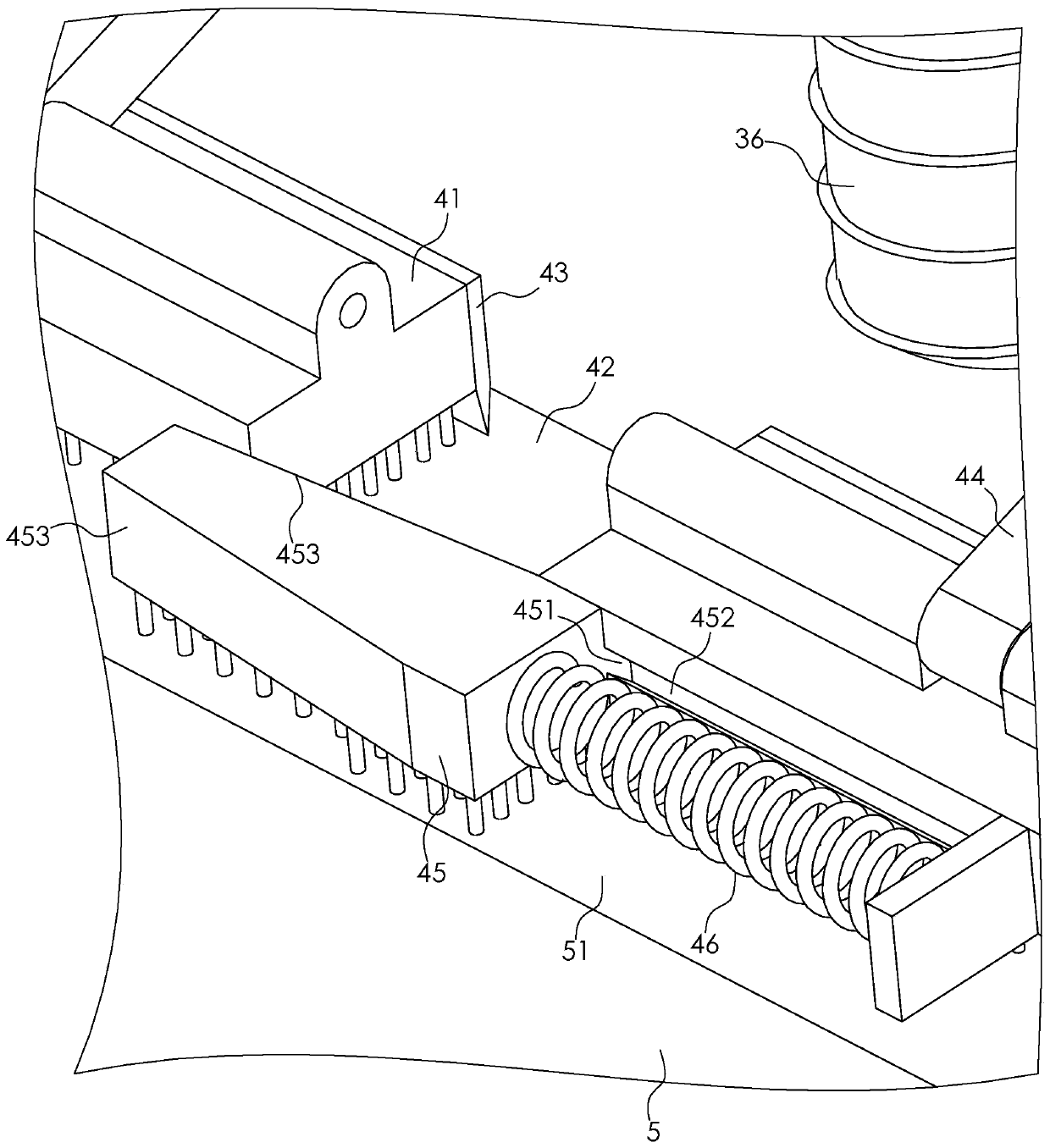

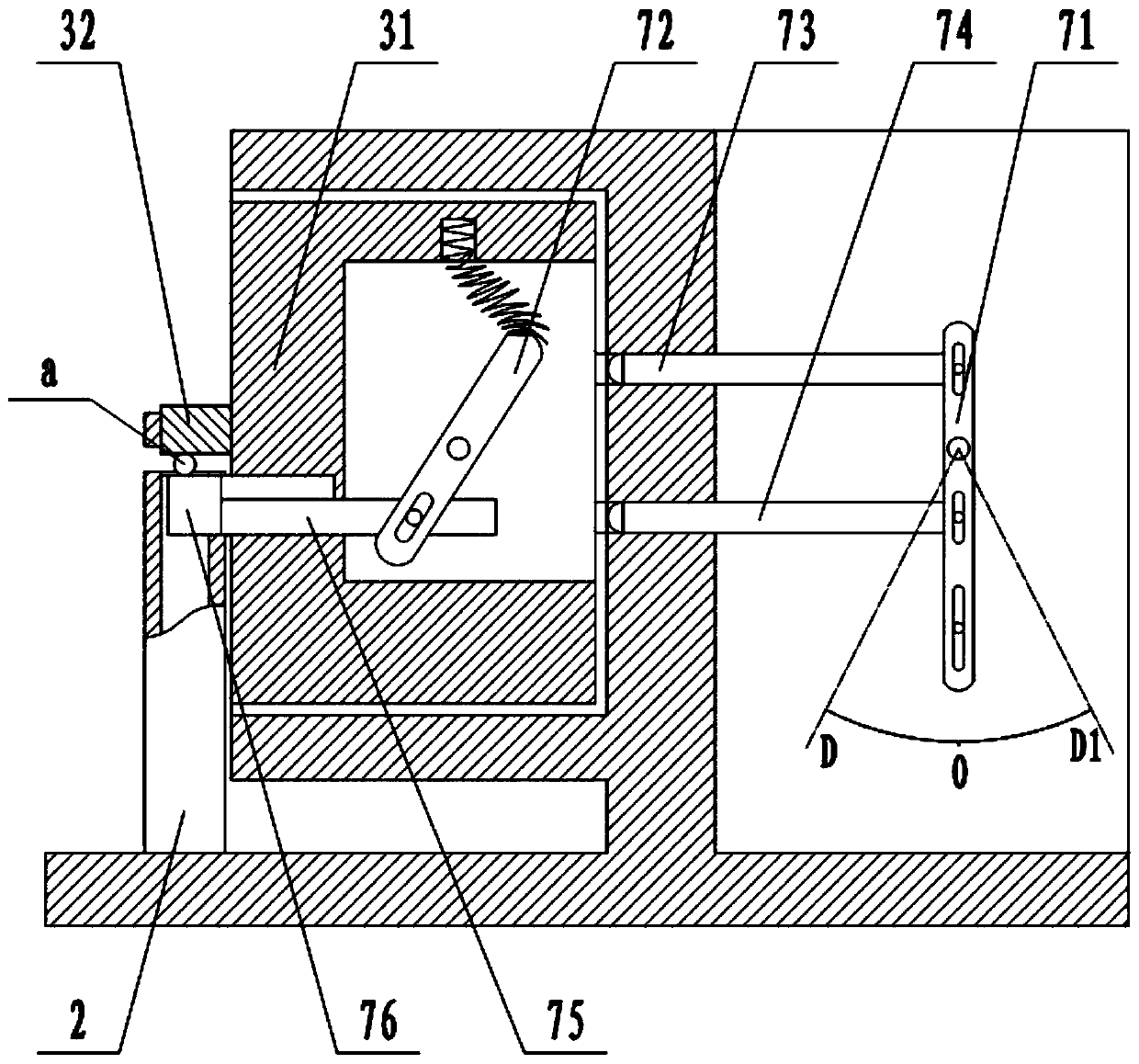

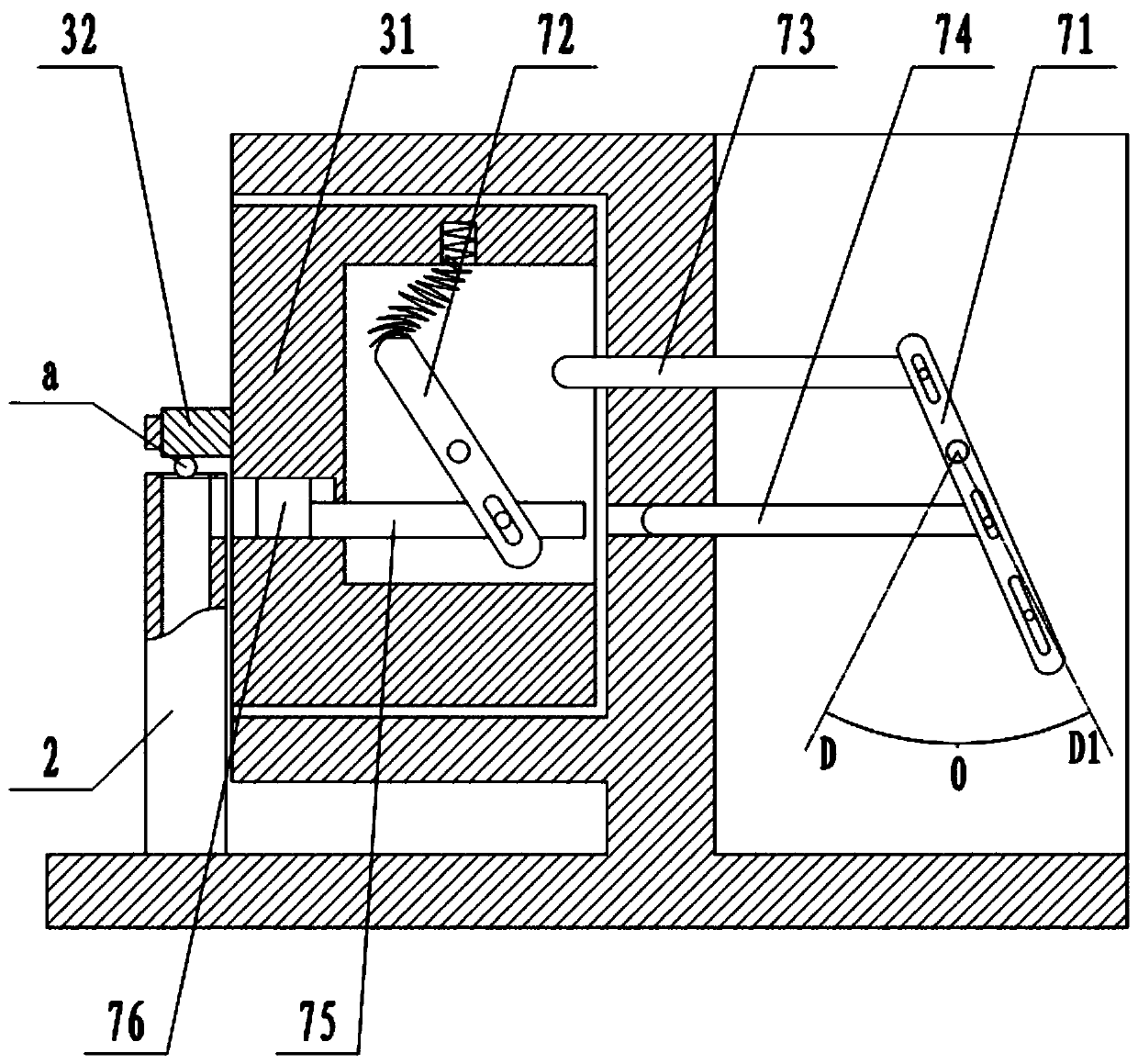

Testing machine for testing reciprocating load adjustable concrete member hydraulic fracture

InactiveCN106226179ASimple structural designEasy to operateMaterial strength using repeated/pulsating forcesEngineeringTooth number

The invention provides a reciprocating load adjustable concrete member hydraulic fracture testing machine. The reciprocating load adjustable concrete member hydraulic fracture testing machine comprises a power transmission frame, an anticlockwise transmission gear, an indirect gear, a clockwise transmission gear, a one-way bearing, a crankshaft, a transmission link, a guide rail, an axial force sensor, an actuation connecting rod, a convex type loading frame, a concave type loading frame, a bearing, a force transferring steel shaft, a high pressure sealed cylinder, a sealed cylinder connecting rod, a non-contact type flash ranging window, an exhaust vent and a water filling pipe, wherein the power transmission frame drives the anticlockwise transmission gear and the clockwise transmission gear to rotate in sequence, further the convex type loading frame and the concave type loading frame move up and down alternatively, and reciprocated load loading can be achieved; the one-way bearing can rotate to change direction freely, and can be used for adjusting different tooth number meshed regions of gears, so as to adjust different repeated loadings. The testing machine provided by the invention is multifunctional, the process is safe and controllable, the operation is simple and convenient, the structure is simple, and the testing machine can be used for researching the problem of hydraulic fracture of concrete members under high water pressure and reciprocating loading effects.

Owner:HOHAI UNIV

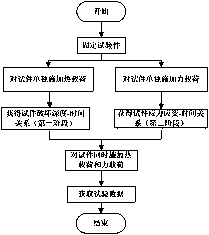

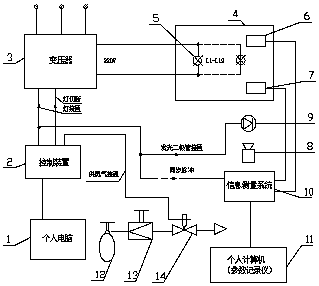

Ablation performance testing system for thermal insulation material test piece

InactiveCN109738298AMaterial strength using tensile/compressive forcesStructural deformationThermal insulation

The invention relates to an ablation performance testing system for a thermal insulation material test piece. The ablation performance testing system comprises a control device, a fracture testing machine, a quartz halogenated incandescent lamp device, a fracture force sensor, a clamp displacement sensor, an information measuring system and an electromagnetic valve. The scheme of the invention isapplicable to the determination of the ablation performance of a thermal insulation layer in a solid rocket motor, and can simulate the working conditions of the thermal insulation layer in the solidrocket motor under boundary conditions such as structural deformation, thermal load and the like; and the test data can be used for comparing ablation characteristics of different materials, and alsohas important reference value for the thermal insulation structure design and thermal insulation ablation tests of the solid rocket motor.

Owner:内蒙动力机械研究所

Coal-rock hydraulic fracturing testing method under true triaxial state

ActiveCN102735547BReveal deformationRevealing intensityMaterial strength using tensile/compressive forcesPermeability/surface area analysisFracture testingHydraulic fracturing

The invention discloses a coal-rock hydraulic fracturing testing method under a true triaxial state. The coal-rock hydraulic fracturing testing method under the true triaxial state comprises the following steps: 1) preparing a test piece; 2) installing the test piece; 3) pre-loading; 4) loading; 5) hydraulically fracturing; 6) unloading; 7) storing all data recorded by a data collection system, taking out the test piece and observing the shape of the test piece. According to the coal-rock hydraulic fracturing testing method, the real work condition can be more really simulated, and a theoretical basis is provided for solving on-site problems.

Owner:CHONGQING UNIV

Testing device and method suitable for non-standard multi-element compound fatigue fracture

PendingCN114705536AMeet the requirements of fatigue fracture testingSatisfy the loading conditionMaterial strength using repeated/pulsating forcesFatigue fracturesFracture testing

The invention discloses a testing device and method suitable for non-standard multi-element compound fatigue fracture, and belongs to the technical field of compound fatigue fracture testing. The device comprises an upper clamp, a lower clamp, an auxiliary clamp, a self-adaptive support, a composite crack propagation sample, and matched and customized screws for fixing the auxiliary clamp and corresponding upper and lower clamps and a plurality of positioning bolts and nuts. According to the invention, I type, II type, III type and I-II compound type, I-III compound type and II-III compound type fatigue fracture experiments with different compound ratios can be realized by replacing the auxiliary clamp; meanwhile, the fatigue fracture test of samples with different thicknesses can be realized by adding the self-adaptive supporter, the assembly precision of the samples and the device is reduced by using the self-adaptive supporter, and the problem of composite crack size effect test research is also solved. And by using the auxiliary clamp and the self-adaptive support, the whole device is convenient and rapid to operate, economical and practical.

Owner:CHANGZHOU UNIV

Cleaning and protecting device for cement anti-fracture testing machine

ActiveCN110813808AImplement blocking collectionEasy to operateDirt cleaningCleaning using toolsFracture testingElectric machinery

The invention relates to the technical field of cement test equipment, in particular to a cleaning and protecting device for a cement anti-fracture testing machine. The cleaning and protecting devicecomprises a protective cover, an opening and a closing plate are arranged on one side of the protective cover, a first elastic element is arranged at the position of the opening, a support is fixed tothe base, a driven roller and a traction rope are arranged on the support, a spiral groove is formed in the side wall of the driven roller, a driving roller is fixed to the end of a main screw rod, and the same belt is tightly wound around the driving roller and the driven roller. A main motor is started to enable the main screw rod to rotate, the main screw rod drives a moving weight to move andcause the driving roller to rotate, the driven roller rotates and causes the traction rope to be gradually embedded into the spiral groove, the pulling rope pulls the closing plate to rotate and closethe opening, and waste chips generated by a workpiece are blocked; and then the main screw rod and the driving roller rotate to fall, the belt loosens, and the first elastic element drives the closing plate to rotate, so that the opening is exposed. The cleaning and protecting device reduces the occurrence of potential safety hazards and facilitates the cleaning and collection of the waste chips.

Owner:杭州正方实业集团有限公司

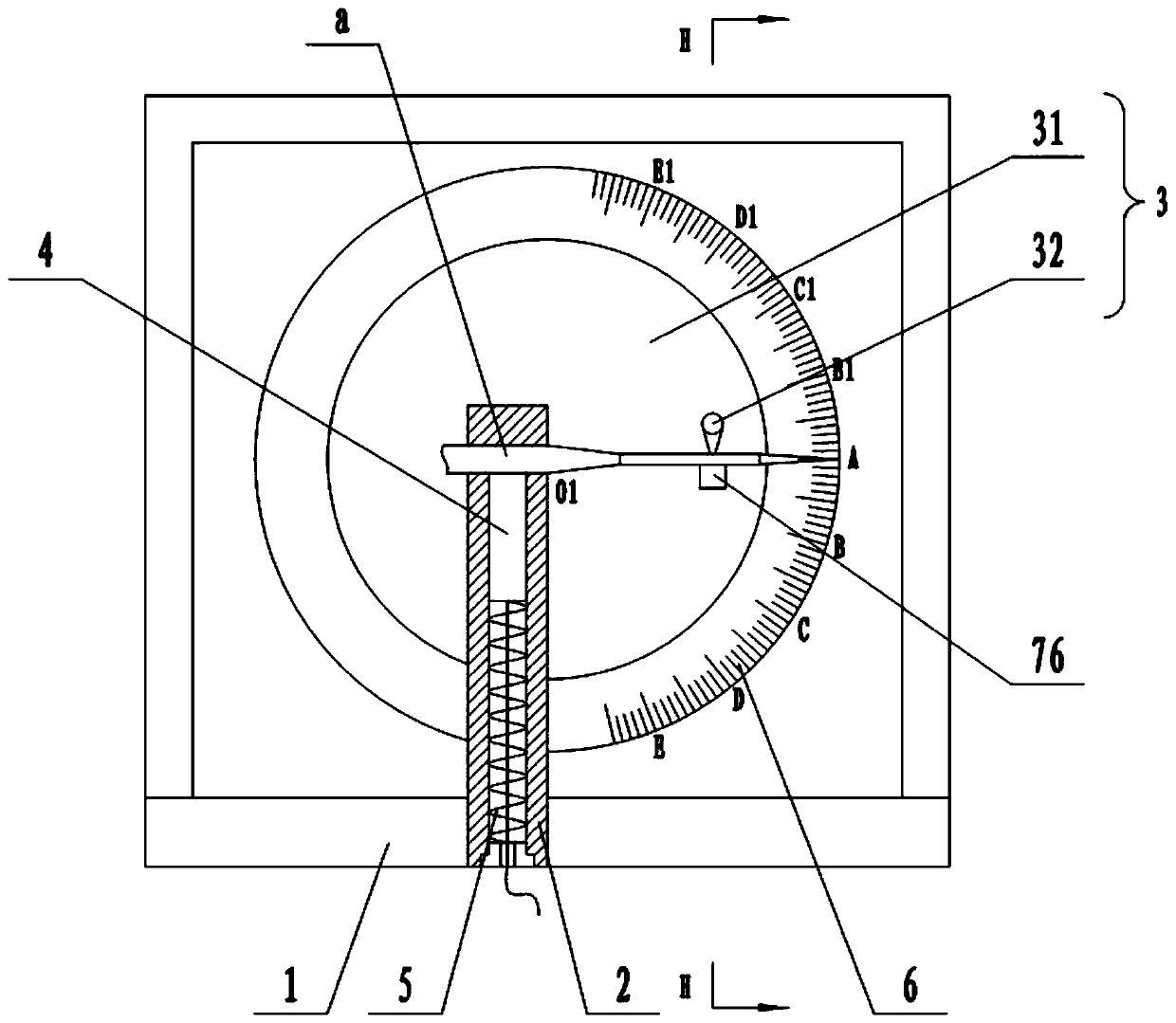

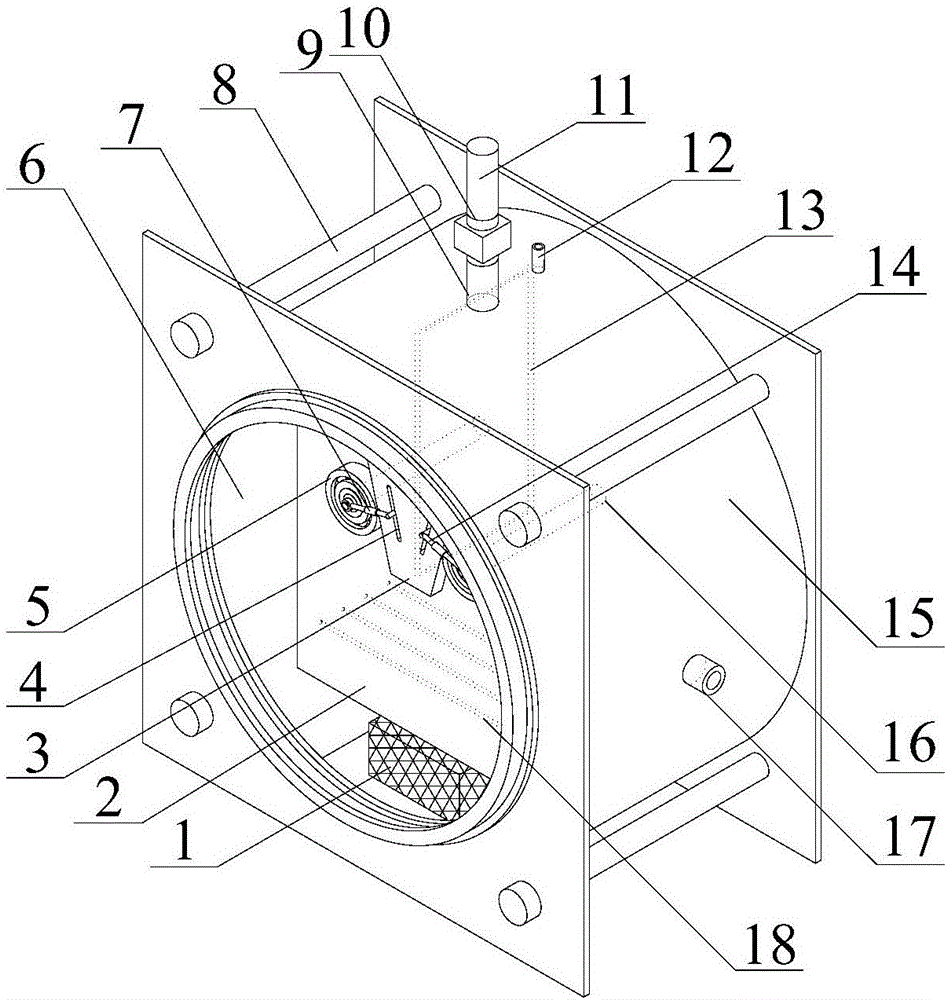

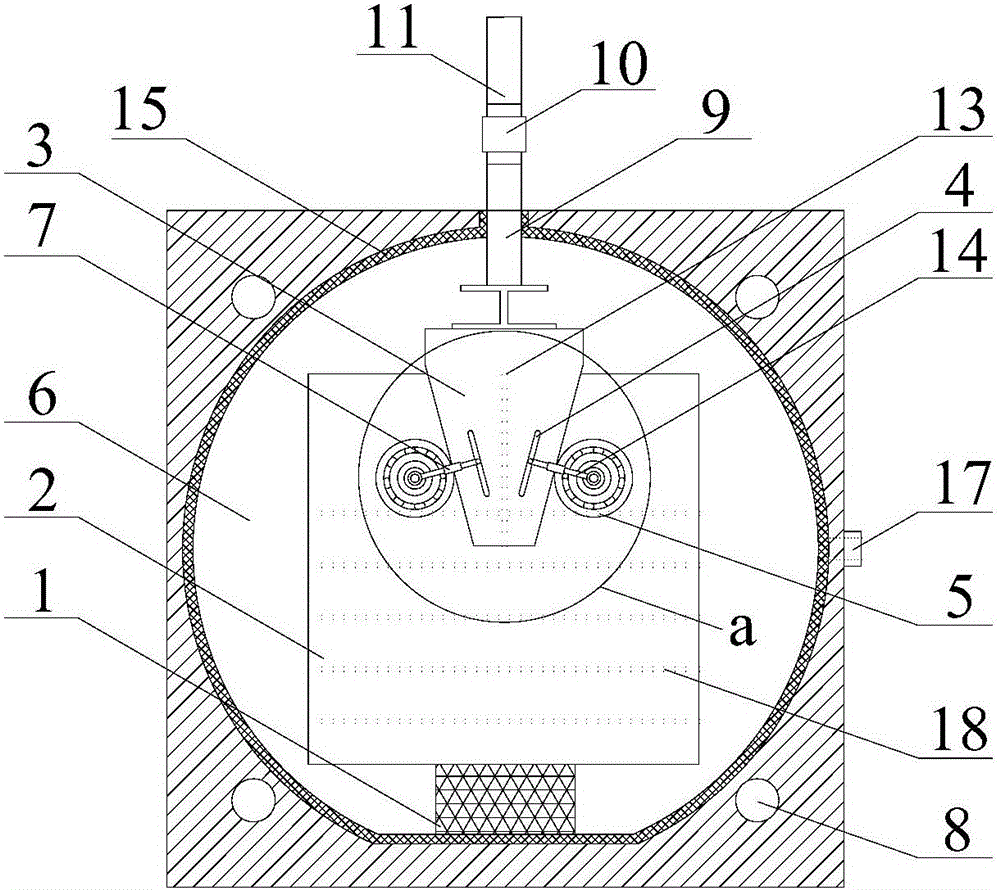

Needle tester and needle testing method

PendingCN111487140AAccurate measurementSimulation is accurateMaterial strength using steady bending forcesFracture testingTester device

The invention discloses a needle tester and a needle testing method, and relate to the technical field of needle testing. The needle tester comprise a support, and further comprise a fixing table anda rotating assembly, wherein the fixing table is arranged on a support and used for fixing a tested needle a; and the rotating assembly is arranged on the support, and the rotating assembly provides swinging arc force for the tested needle a when rotating. The beneficial effects of the invention are that a professional tester is designed, accurate measurement can be carried out on the tested needle, the acting force for testing the needle is enabled to be always stable in position, and the force simulation is more accurate; and the tester has multiple functions and can be used for conducting rebound resilience testing, bending fatigue testing, bending-resistant angle testing and fracture testing.

Owner:青岛锦钻针业有限公司

Hydraulic fracturing testing machine for concrete members under reciprocating load and high water pressure

InactiveCN106404565AEasy to operateSimple structural designMaterial strength using repeated/pulsating forcesFracture testingOptical measurements

The invention provides a hydraulic fracturing testing machine for concrete members under reciprocating load and high water pressure. The testing machine comprises an MTS testing machine actuating head, an axial force sensor, an actuating connecting rod, a wedge-shaped loading frame, bearings, force transmitting steel shafts, small axial force sensors, small actuating connecting rods, linear guide rails, a high-pressure seal cylinder, seal cylinder connecting rods, a non-contact optical measurement window, an exhaust hole and a water injection tube, wherein the transmission part consisting of the small actuating connecting rods, the small axial force sensors, the bearings and the force transmitting steel shafts is perpendicular to the linear guide rails throughout; the outer edge surface of the wedge-shaped loading frame and the linear guide rails are used for providing the reciprocating load during opening and closing of fractures; the real-time condition of the fractures in nearby areas can be recorded through the non-contact optical measurement window, and water pressure distribution among the fractures is measured through water pressure measuring holes. The testing machine has multiple test functions, is convenient and controllable to operate and simple in structural design and can be used for research on hydraulic fracturing of the concrete members under reciprocating load and high water pressure.

Owner:HOHAI UNIV

Device for testing different cracking conditions of interior of cement-based material and method

ActiveCN102147387BSimple and quick determinationThe test result is accurateMaterial resistanceStainless steel electrodeSpectroscopy

The invention relates to a device for testing different cracking conditions of the interior of a cement-based material and a method, belonging to the testing field of a building material. The testing method comprises the following steps: the periphery of a cement-based material test specimen (1) with the standard size of 40*40*160mm is wrapped and sealed by a plastic film and fixed in an anti-fracture testing machine (2); two stainless steel electrodes (3) are respectively fixed on two opposite 40*40mm parallel surfaces of the test specimen (1); and the two stainless steel electrodes (3) and a constant potential rectifier are respectively connected by a working electrode (5) and a reference electrode (6). During testing, the anti-fracture testing machine (2) applies different grades of bending loads to the test specimen (1) so as to lead the test specimen (1) to reach different cracking conditions and complete a test procedure of the alternating current impedance spectroscopy of the constant potential rectifier (4); and impedance parameters collected by a computer (7) are used for reflecting different cracking conditions of the interior of the cement-based material. The testing method can rapidly and accurately reflect different cracking conditions of the interior of the cement-based material and is simple and practical.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com