Low temperature fracture testing instrument of asphalt mixed material

A technology of asphalt mixture and fracture test, which is applied in the direction of instruments, scientific instruments, analytical materials, etc., can solve problems such as shrinkage and deformation, and achieve the effect of avoiding shrinkage and deformation and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

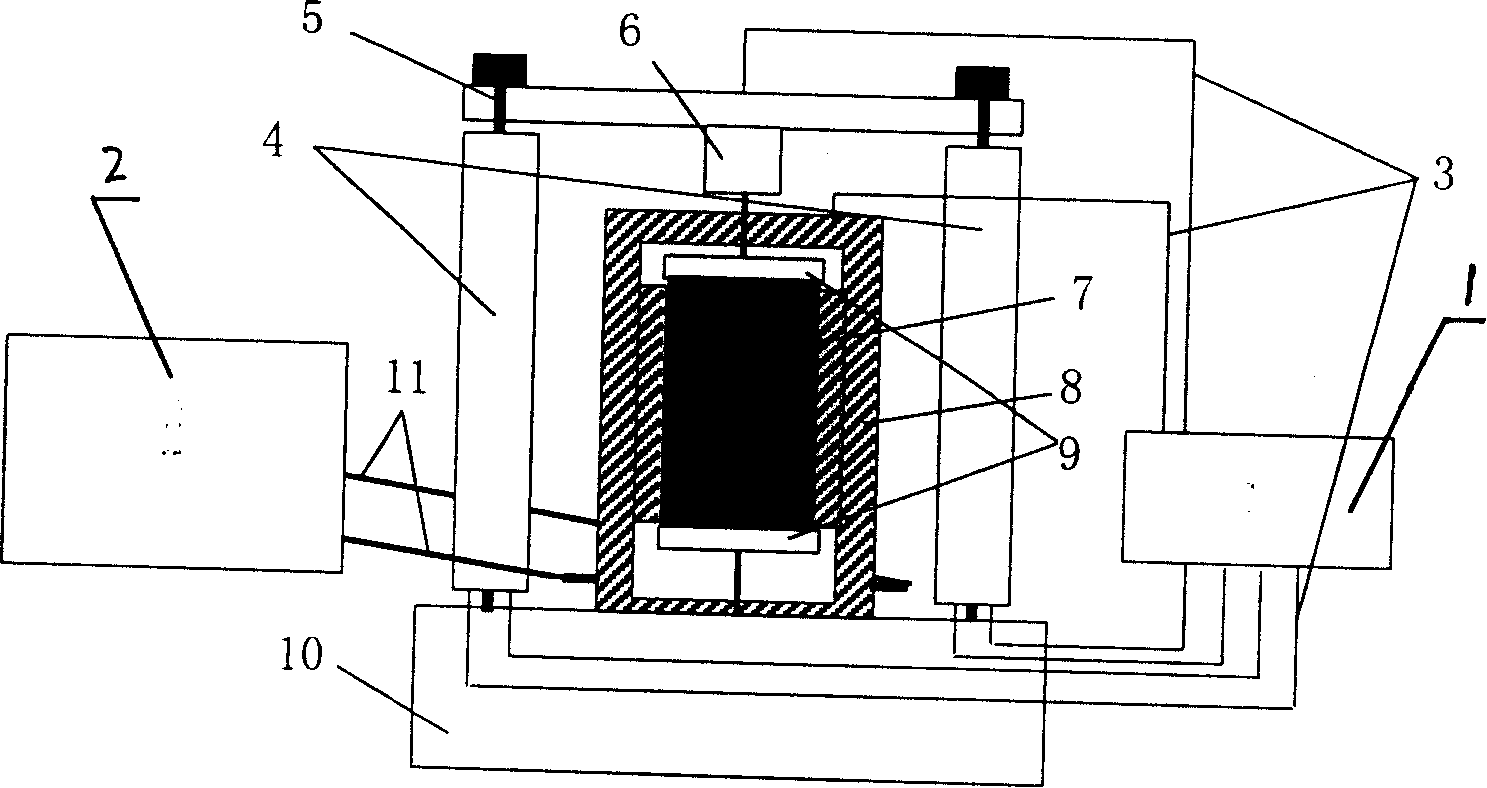

[0014] Referring to the attached figure, the Asphalt Mixture Low Temperature Fracture Tester is a special equipment used to evaluate the low temperature crack resistance of asphalt mixture. It uses the refrigeration system to cool the specimen, and measures the fracture temperature, Fracture strength, to analyze the low-temperature crack resistance of the mixture. The structural composition of the asphalt mixture low-temperature fracture tester is shown in the attached figure, which is mainly composed of a reaction force frame, a specimen fixture 9, a cooling system, a control system 1, a data acquisition system, and a heating compensation system 4. The counter force frame is composed of a base and a bracket 5, and is required to have sufficient strength to avoid excessive deformation. The test piece fixture 9 includes two sets of upper and lower sets, which are used to fix the test piece 7. Each set includes two sets of dovetail grooves connecting the upper and lower pieces. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com