Horizontal well section testing method by adopting soluble rubber sleeve packer

A testing method and sol-gel technology, which can be used in sealing/sealing, measurement, earth-moving drilling, etc., can solve the problems of high friction between the well wall and the rubber cylinder, and difficulty in unsealing, and achieve reliable and low-cost sealing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In order to overcome the problem of difficulty in unsealing due to the excessive friction between the well wall and the rubber tube caused by the rubber tube being turned over if the rubber tube of the conventional packer cannot be retracted when it is unsealed, this embodiment provides a The sol cartridge packer implements a horizontal well segmented testing method, including the following steps:

[0027] 1) The well is drilled with a well gauge; the well is drilled to the artificial well bottom of the operating well to ensure that the wellbore is unobstructed;

[0028] 2) Coat a layer of temperature control film on the surface of the sol tube packer 2 of the sol tube packer, and match the sol tube packer 2 coated with the temperature control film with the downhole switch 1, the centralizer, and the tubing for the oil well pump. Connected into a string tool string, the centralizer is located at both ends of the sol-sol cartridge packer 2;

[0029] 3) Run the pipe stri...

Embodiment 2

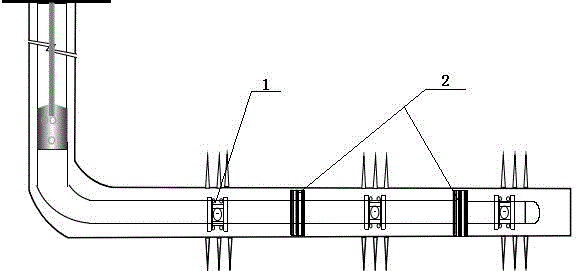

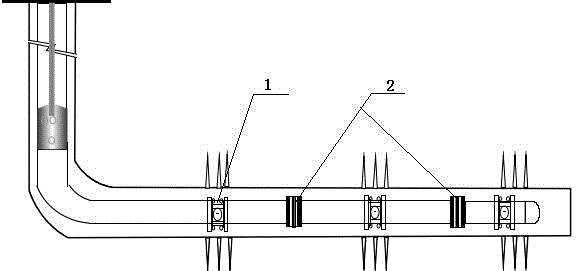

[0035] Such as figure 1 and figure 2 As shown, this embodiment provides a specific implementation process of using the soluble rubber cartridge packer to realize the horizontal well segmented test method for horizontal well three-stage segmental testing, wherein there are three sets of downhole switches, and the soluble rubber cartridge packer There are two spacers, and the specific operation process is as follows:

[0036] 1) Drain the well with the drilling gauge; from the well to the artificial well bottom of the operating well, if there is blockage in the middle of the well, perform circular flushing or repair the cause of the obstruction before proceeding with the well operation to ensure the wellbore is unobstructed.

[0037] 2) Coat a layer of temperature control film on the surface of the sol tube of the sol tube packer 2 (the temperature control film can be purchased from Nanjing Shousu Special Engineering Plastic Products Co., Ltd.), put the sol tube coated with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com