Radial well fracture testing device

A test device and technology for radial wells, applied in the direction of measurement, wellbore/well components, production fluid, etc., can solve the problem of not having the function of changing diameter and curve, and being unable to observe the shape of the fluid entering the hole and the law of sand settling, which can not be better Simulate formation conditions and other problems to achieve the effect of improving accuracy and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the invention are described in detail below, but the invention can be practiced in many different ways as defined and covered by the claims.

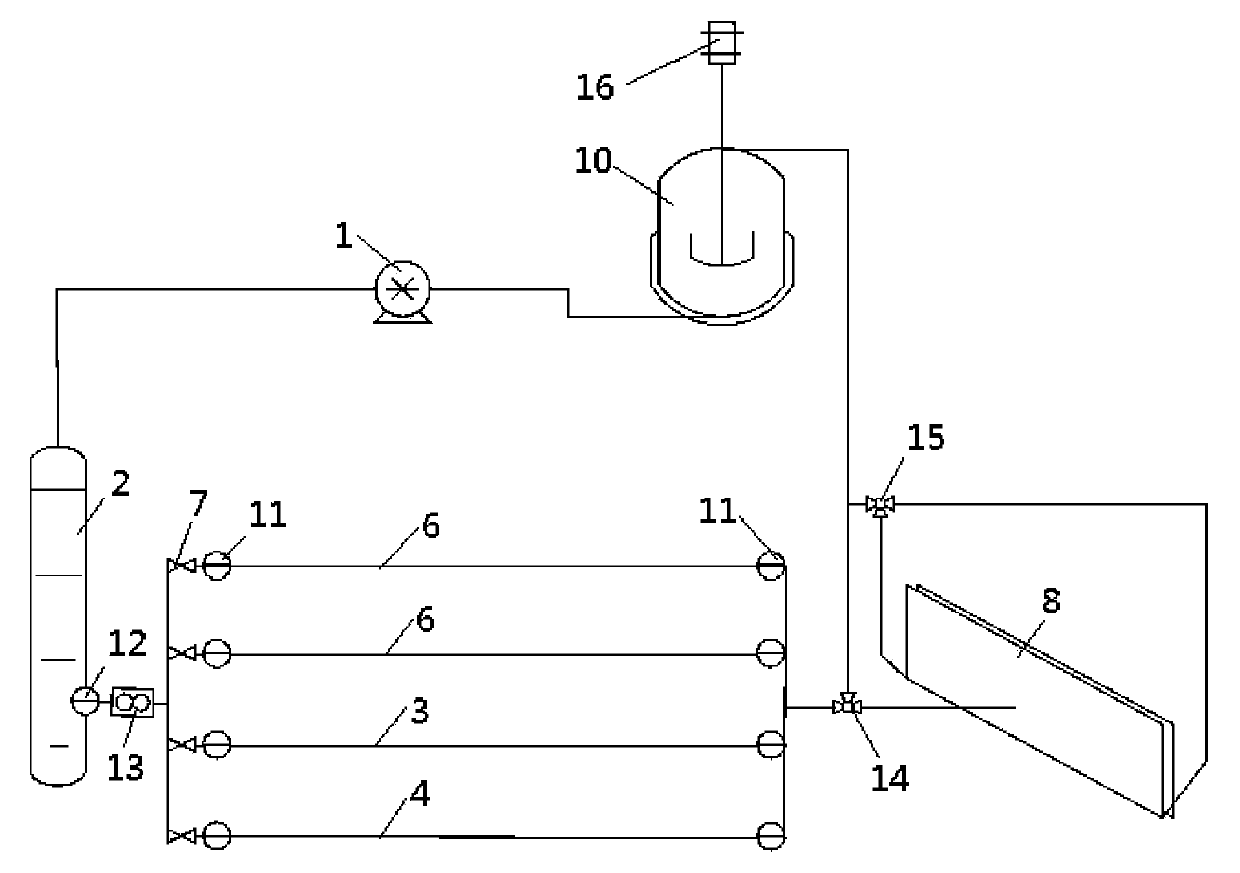

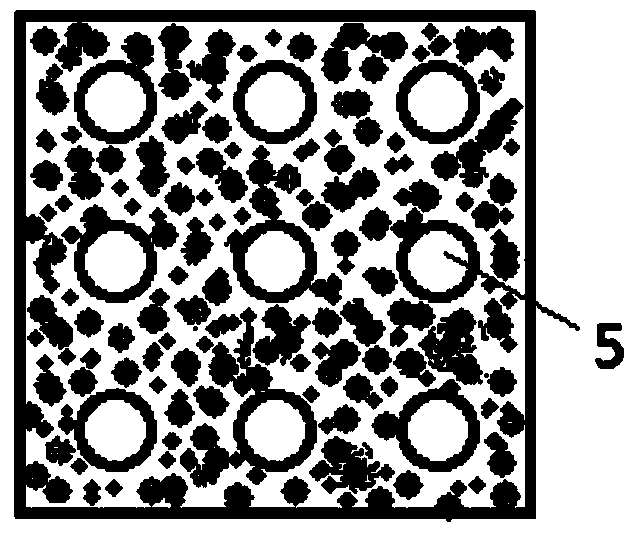

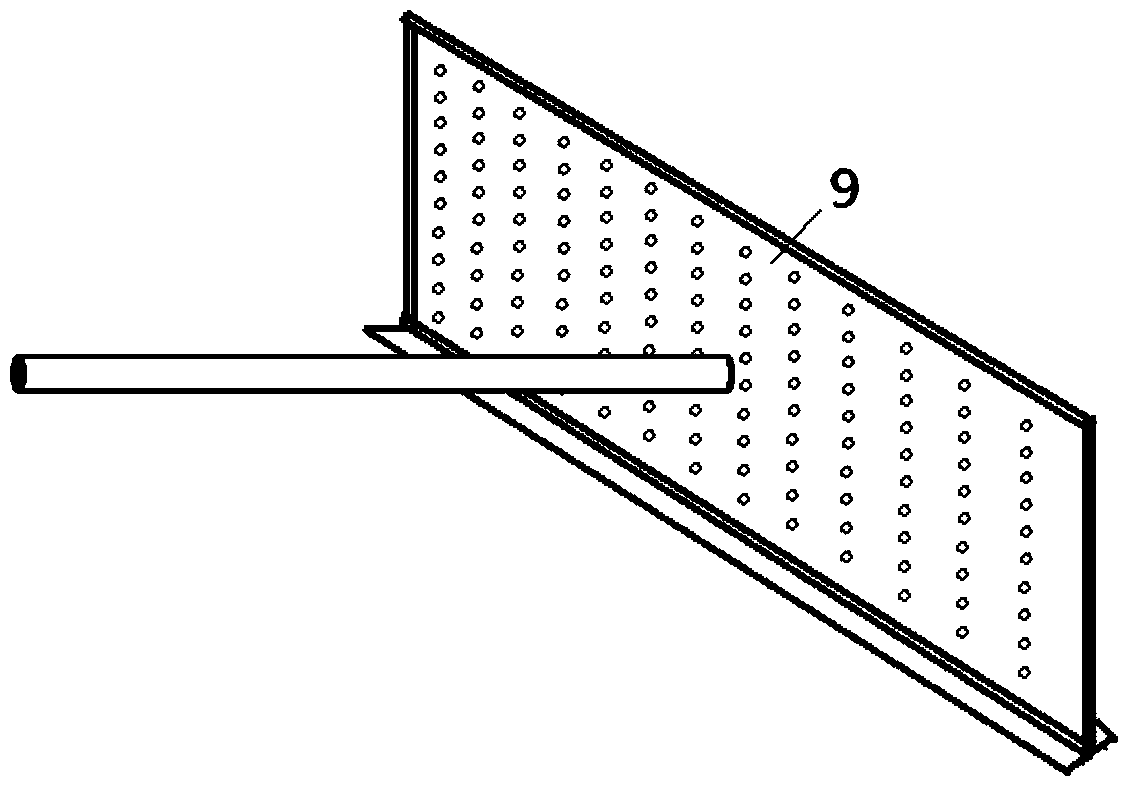

[0022] Please refer to Figure 1 to Figure 3 , the present invention provides a radial well fracturing testing device, comprising: a pumping unit 1 for pumping sand-carrying fluid; a transparent simulated wellbore 2, the inlet of which is connected to the outlet of the pumping unit 1 for observing the law of sand deposition The formation simulation pipeline, the inlet is connected to the outlet of the transparent simulation wellbore 2, and is used for simulating and testing the friction of radial wellbore or pipe string under different reservoir conditions; the transverse fracture simulation device 8, the inlet and the outlet of the formation simulation pipeline The connection is used to simulate and test the proppant settlement law in the transverse fracture formed by radial well fracturing. Preferably, the pumpi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com