Soil body two-dimensional fracture testing method and device

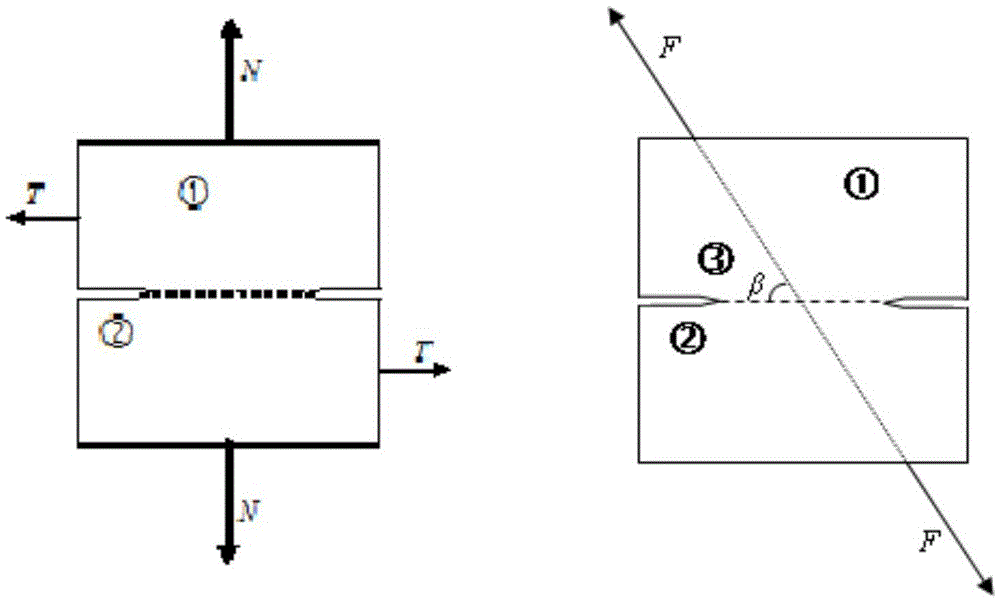

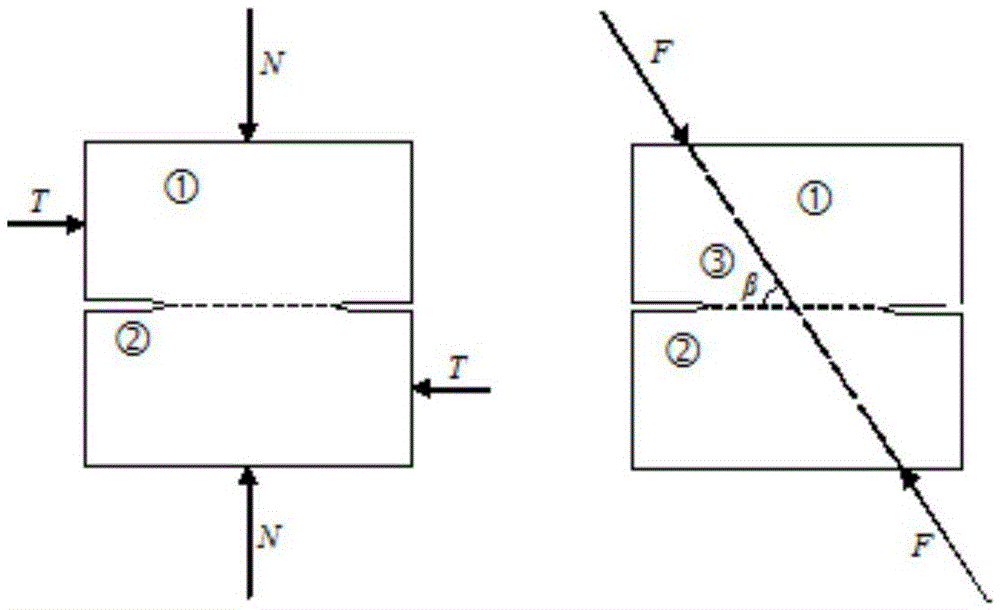

A technology of fracture test and test device, which is applied in the direction of testing material strength by applying stable shear force and testing material strength by applying stable tension/compression, which can solve the problem of obtaining continuous distribution characteristics of compressive shear combined force and soil sample strain and critical stress relationship, comparative study of inconvenient fracture problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

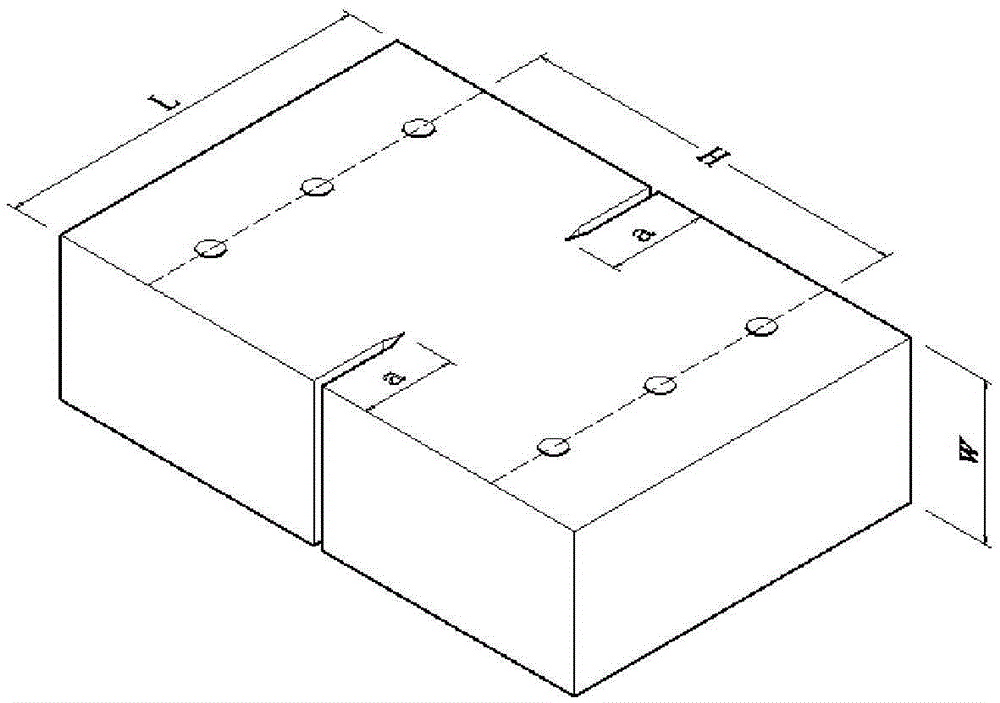

[0051] The test device includes a sample, a loading plate I1 and a loading plate II2. The loading plate I1 and the loading plate II2 are identical loading plates, and together constitute a loading fixture. The installation of the test device, the test is fixed by the pin through the sample fixing hole I1-4 and the sample fixing hole II2-4 respectively with the sample holding plate I1-5 and the sample holding plate II2-5 On the loading plate, the loading rod I1-7 and the loading rod II2-7 are respectively fixed on the loading rod installation hole I1-2 and the loading rod installation hole II2-2. The other ends of the loading rod I1-7 and the loading rod II2-7 are respectively connected to the external loading power device, and the loading rod I1-7 and the loading rod II2-7 are always kept on the same straight line. The start-up, loading mode, loading rate and termination operation of loading rod I1-7 and loading rod II2-7 are all controlled by computer control and data acquis...

Embodiment 2

[0063] The test device includes a sample, a loading plate I1 and a loading plate II2. The loading plate I1 and the loading plate II2 are identical loading plates, and together constitute a loading fixture. The installation of the test device, the test is fixed by the pin through the sample fixing hole I1-4 and the sample fixing hole II2-4 respectively with the sample holding plate I1-5 and the sample holding plate II2-5 On the loading plate, the loading rod I1-7 and the loading rod II2-7 are respectively fixed on the loading rod installation hole I1-2 and the loading rod installation hole II2-2. The other ends of the loading rod I1-7 and the loading rod II2-7 are respectively connected to the external loading power device, and the loading rod I1-7 and the loading rod II2-7 are always kept on the same straight line. The start-up, loading mode, loading rate and termination operation of loading rod I1-7 and loading rod II2-7 are all controlled by computer control and data acquis...

Embodiment 3

[0075] The test device includes a sample, a loading plate I1 and a loading plate II2. The loading plate I1 and the loading plate II2 are identical loading plates, and together constitute a loading fixture. The installation of the test device, the test is fixed by the pin through the sample fixing hole I1-4 and the sample fixing hole II2-4 respectively with the sample holding plate I1-5 and the sample holding plate II2-5 On the loading plate, the loading rod I1-7 and the loading rod II2-7 are respectively fixed on the loading rod installation hole I1-2 and the loading rod installation hole II2-2. The other ends of the loading rod I1-7 and the loading rod II2-7 are respectively connected to the external loading power device, and the loading rod I1-7 and the loading rod II2-7 are always kept on the same straight line. The start-up, loading mode, loading rate and termination operation of loading rod I1-7 and loading rod II2-7 are all controlled by computer control and data acquis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com