Angle brace bracket

A technology of brackets and corner braces, applied in excavation, construction, infrastructure engineering, etc., can solve the problems of non-reusable, difficult to control deformation, and no standardized connection size, etc., to achieve the effect of easy disassembly and good shear force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

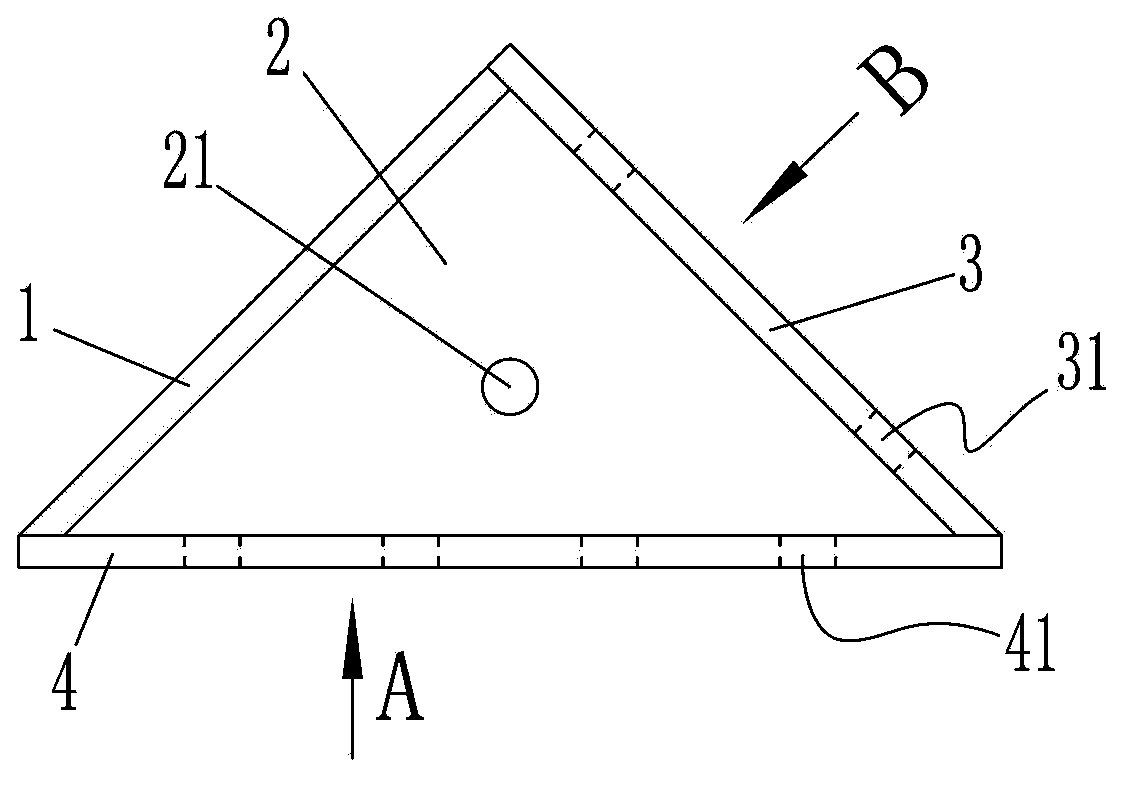

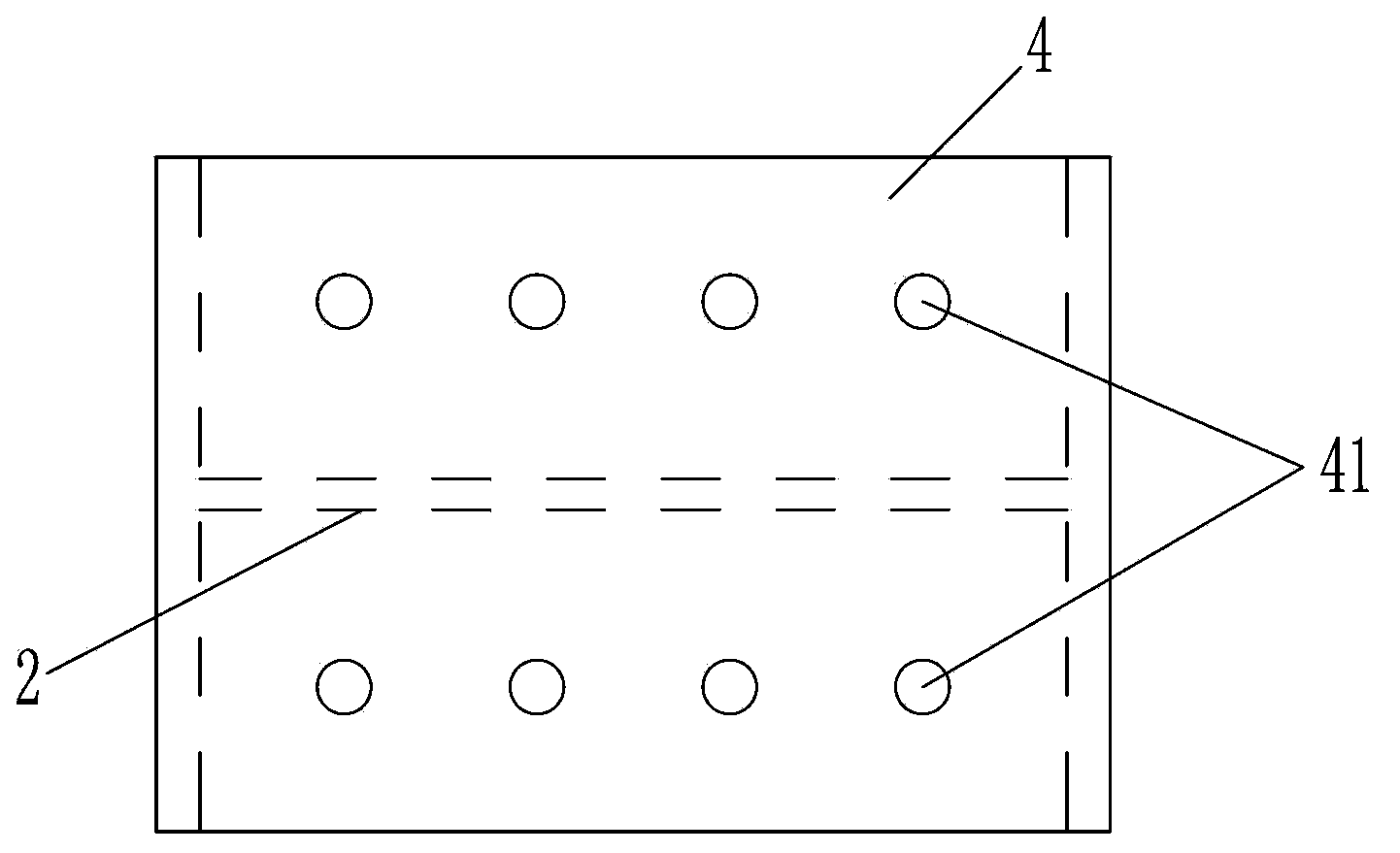

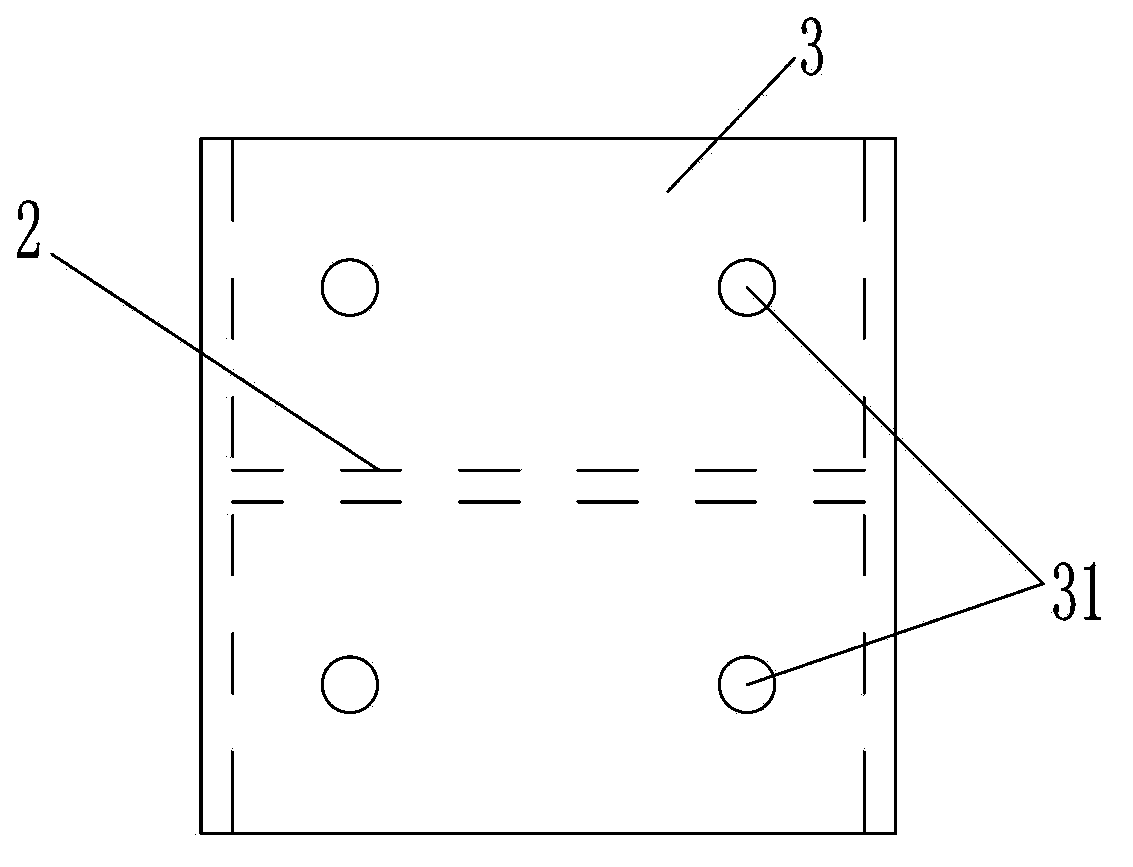

[0012] Such as figure 1 , figure 2 , image 3 The gusset bracket of the high-rigidity overall prestressed assembled foundation pit support inner support system shown includes an isosceles right-angled triangle reinforcement plate 2, a first waist plate 1, a second waist plate 3 and a bottom plate 4 , the first waist side plate 1, the second waist side plate 3 and the bottom side plate 4 are welded to form a barrel-shaped structure with an isosceles right-angled triangle in cross section, and an isosceles right-angled triangle reinforcement plate 2 is arranged inside the barrel-shaped structure, The three sides of the isosceles right triangle reinforcing plate 2 are respectively welded and fixed to the first waist plate 1, the second waist plate 3 and the bottom plate 4, wherein the bottom plate 4 is provided with eight connection holes A41, The eight connecting holes A41 are divided into two rows up and down, and each row has four equidistantly arranged and corresponds to e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com