Solid-free strong inhibition foam drilling fluid

A drilling fluid and strong suppression technology, applied in petroleum, coalbed methane exploitation, and natural gas fields, can solve the problems of weak anti-pollution ability, unstable foam system, poor temperature resistance, etc., and achieve low cost, which is conducive to popularization and application, and good The effect of dynamic shear force and dynamic plastic ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

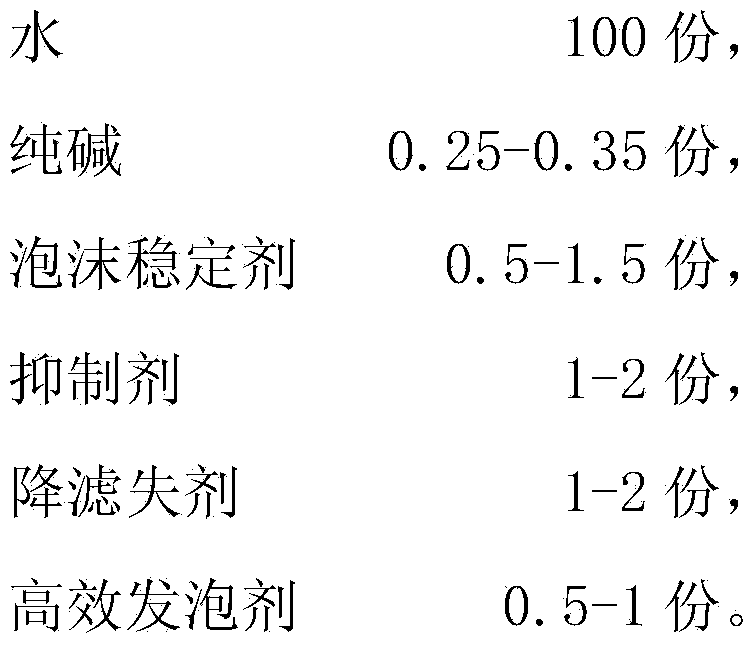

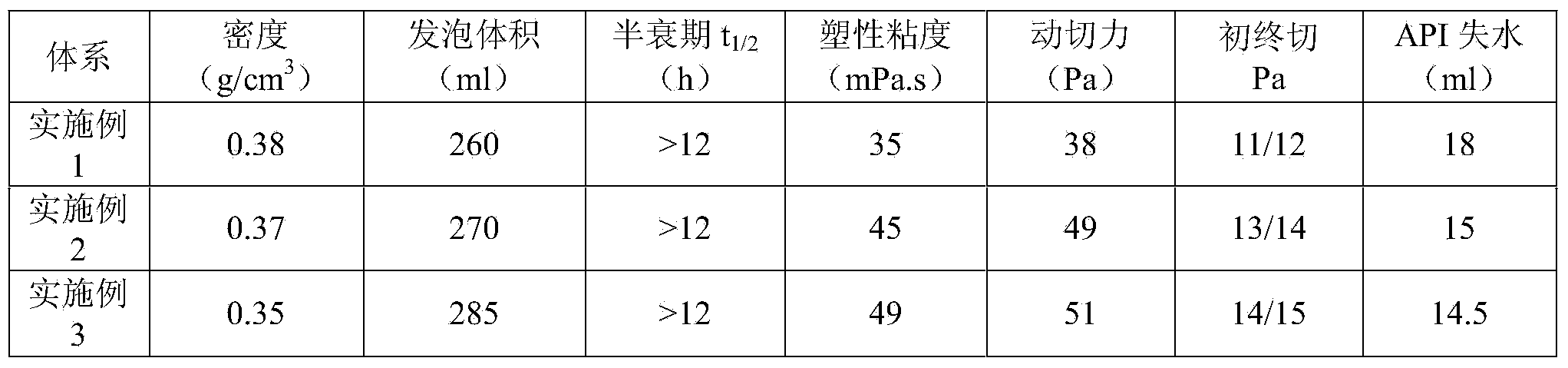

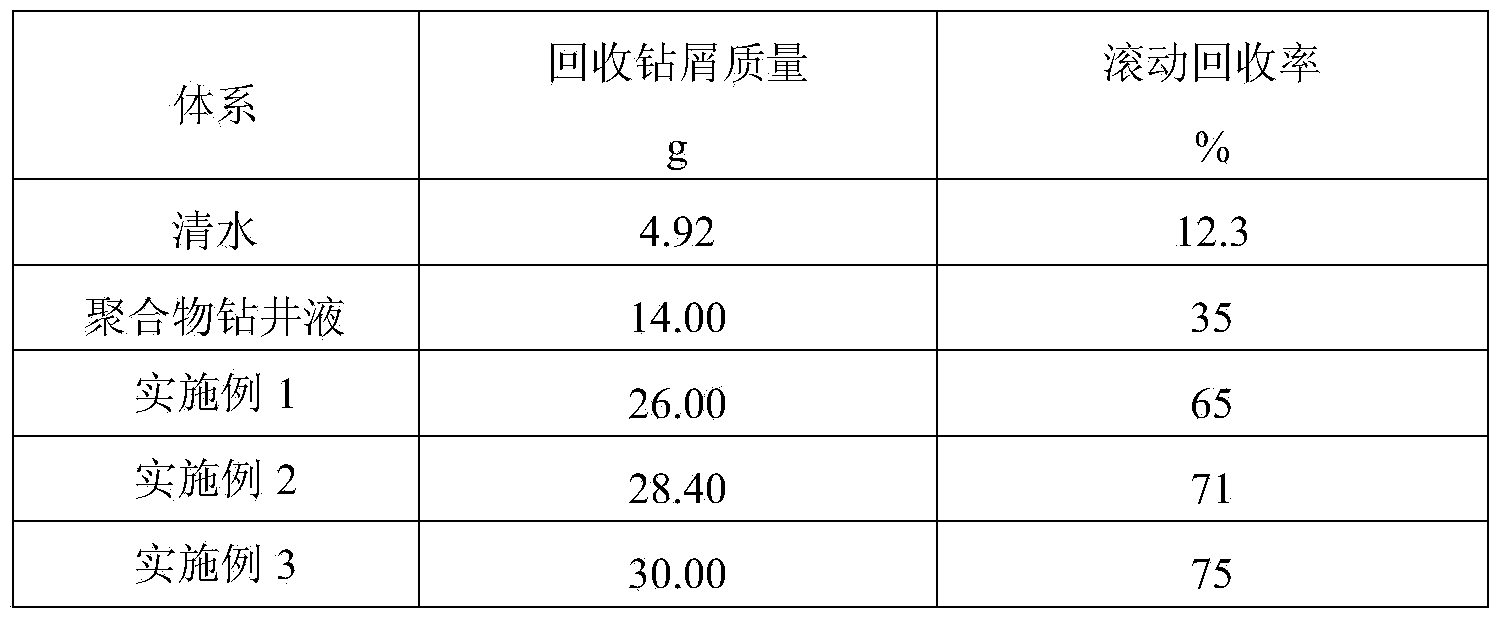

Embodiment 1

[0016] The preparation method of the non-solid-phase strongly suppressed foam drilling fluid described in this embodiment is composed of: 100g of water, 0.25g of soda ash, 0.5g of foam stabilizer (xanthan gum), inhibitor (BZ-JAI, Bohai Drilling Engineering Technology Research Institute) 1g, fluid loss reducer 1g (among them, modified starch 0.5g, white asphalt 0.5g), high-efficiency foaming agent 0.5g (among them, sodium dodecylsulfonate 0.25g, α-olefin sulfonic acid Sodium 0.25g), add soda ash, foam stabilizer, inhibitor, fluid loss reducer in proportion to the state of stirring at 10000 rpm in turn to prepare the base liquid, then slowly add high-efficiency foaming agent under stirring at 8000 rpm agent, and continued to stir for 3 minutes to obtain the foam drilling fluid.

Embodiment 2

[0018] The preparation method of foam drilling fluid described in the present embodiment is composed of: water 100g, soda ash 0.30g, foam stabilizer 0.8g (wherein, xanthan gum 0.5g, polyanion cellulose 0.3g), inhibitor (BZ- JAI, produced by Bohai Drilling Engineering Technology Research Institute) 1.5g, fluid loss reducer 2g (among them, modified starch 1.0g, white asphalt 1.0g), high-efficiency foaming agent 0.75g (among them, sodium dodecylsulfonate 0.5 g, α-olefin sulfonate sodium 0.25g), add soda ash, foam stabilizer, inhibitor, fluid loss reducer under the state of stirring at 10000 revs / min rotating speed successively in proportion, make base liquid, then 8000 revs / min rotating speed Slowly add the high-efficiency foaming agent under stirring, and continue stirring for 3 minutes to obtain the foam drilling fluid.

Embodiment 3

[0020] The preparation method of foam drilling fluid described in the present embodiment is composed of: water 100g, soda ash 0.32g, foam stabilizer 1g (wherein, xanthan gum 0.5g, carboxymethyl cellulose 0.5g), inhibitor (BZ- JAI, produced by Bohai Drilling Engineering Technology Research Institute) 1g, fluid loss reducer 2g (among them, modified starch 1.0g, white asphalt 1.0g), high-efficiency foaming agent 1g (among them, sodium dodecylsulfonate 0.5g, Sodium α-olefin sulfonate 0.5g), add soda ash, foam stabilizer, inhibitor, fluid loss reducer under the stirring state of 10000 rev / min rotating speed successively in proportion, make base liquid, then 8000 rev / min rotating speed stirring Slowly add high-efficiency foaming agent and continue stirring for 3 minutes to obtain the foamed drilling fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com