Preparation of heat conducting oil with nano-particle for strengthening heat transfer and use thereof in electric oil-filled radiator

A technology of nano-particles and enhanced heat transfer, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problem of low thermal conductivity of heat transfer oil, achieve the effect of improving thermal conductivity, reducing power consumption, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

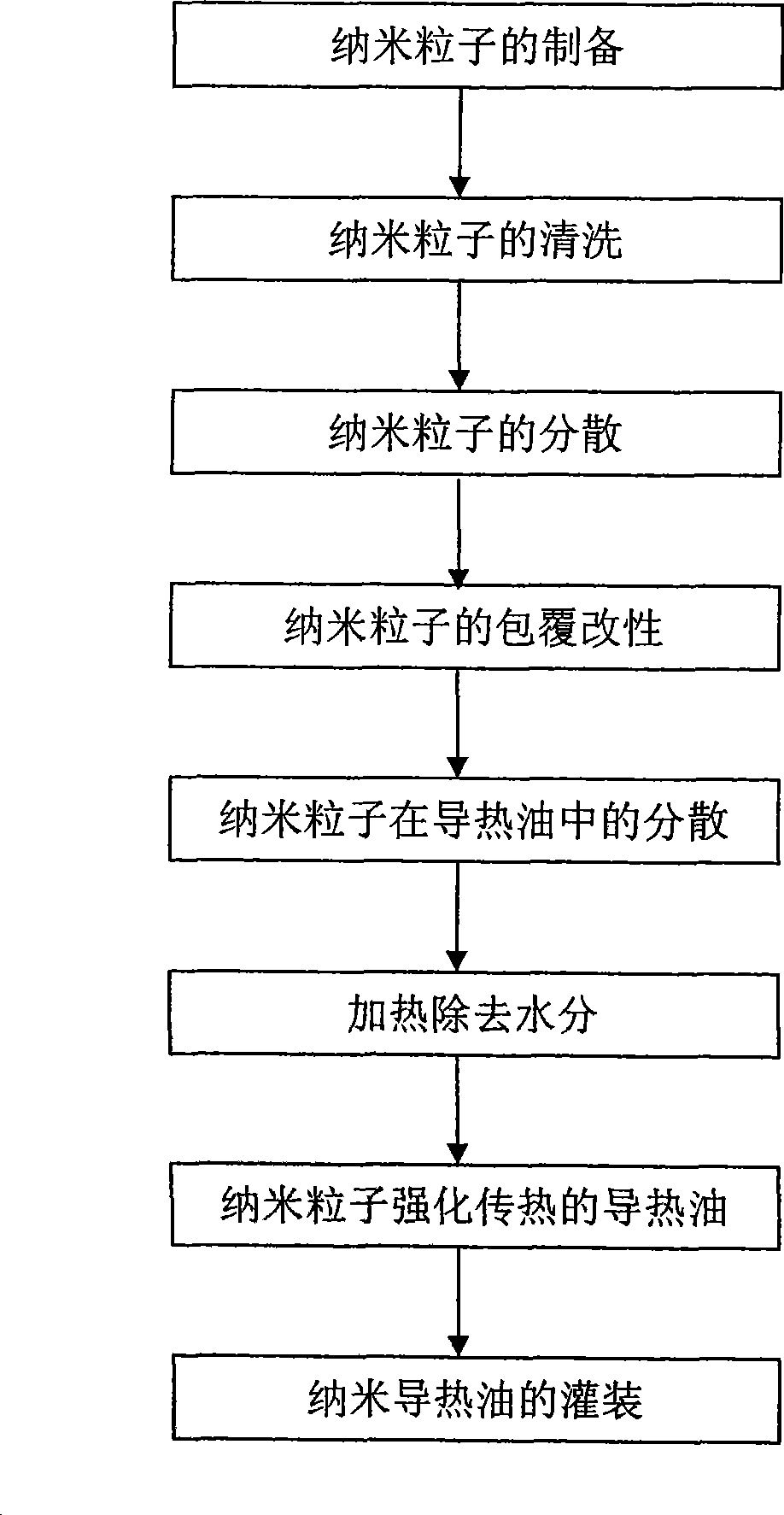

[0032] The preparation of heat-conducting oil using nanoparticles to enhance heat transfer takes the heating pot as the main equipment, and the process flow is as follows figure 1 Shown:

[0033] (1) Preparation of nanoparticles:

[0034] Liquid-phase methods such as chemical precipitation or hydrothermal synthesis or sol-gel methods, or solid-phase methods such as crushing methods, solid-phase chemical methods, or gas-phase methods such as evaporation condensation or sputtering methods, or chemical Nanoparticles can be prepared by any method in the vapor deposition method.

[0035] (2) Cleaning of nanoparticles:

[0036] The prepared nanoparticles were washed with deionized water to remove possible impurities on the surface.

[0037] (3) Dispersion of nanoparticles:

[0038] Disperse the cleaned nanoparticles in deionized water, and use mechanical stirring or ultrasonic dispersion to promote their uniform dispersion.

[0039] (4) Coating modification of nanoparticles:

...

Embodiment

[0047] (1) Preparation of nanoparticles: Nano-Fe3O4 particles were prepared by chemical precipitation.

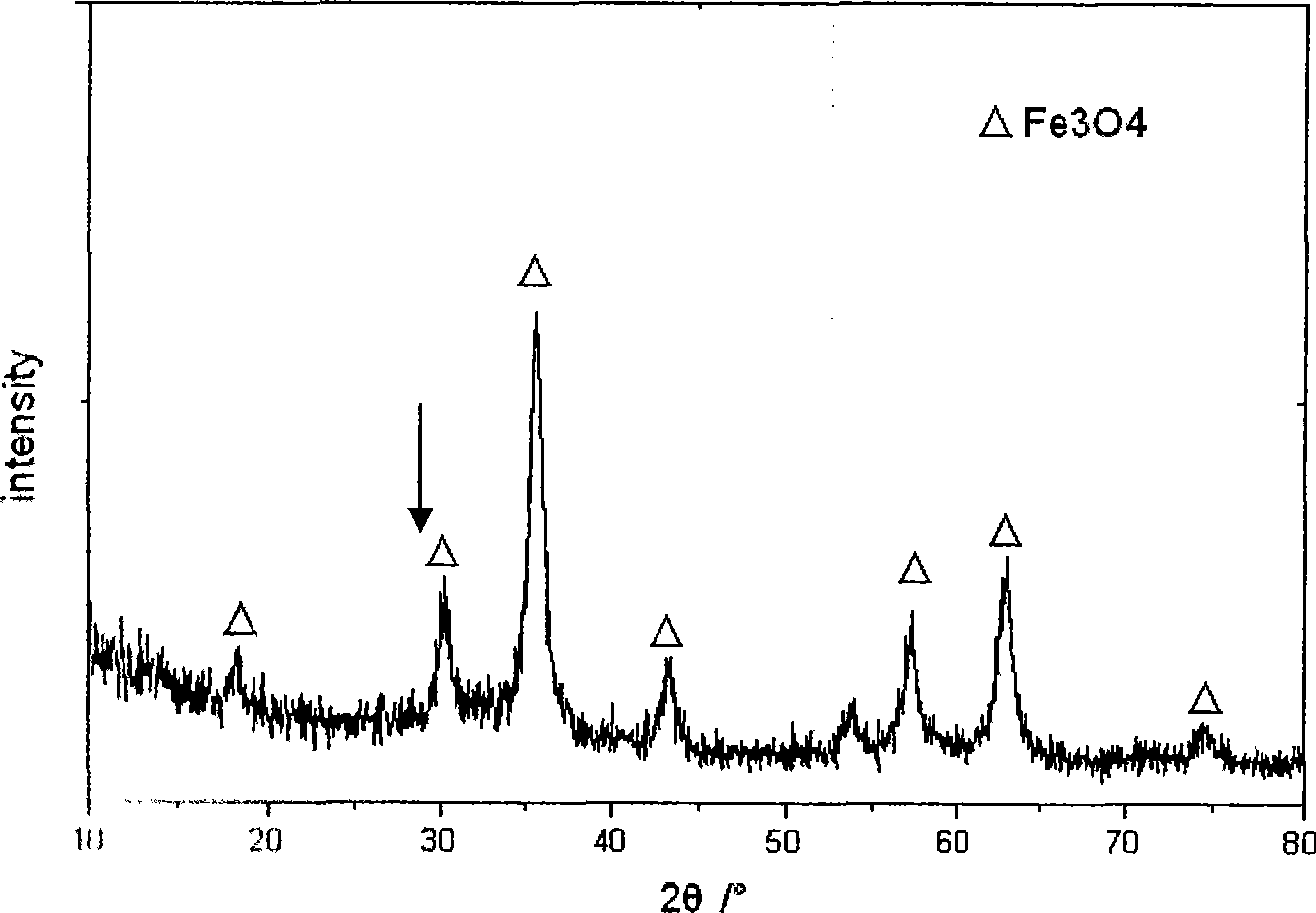

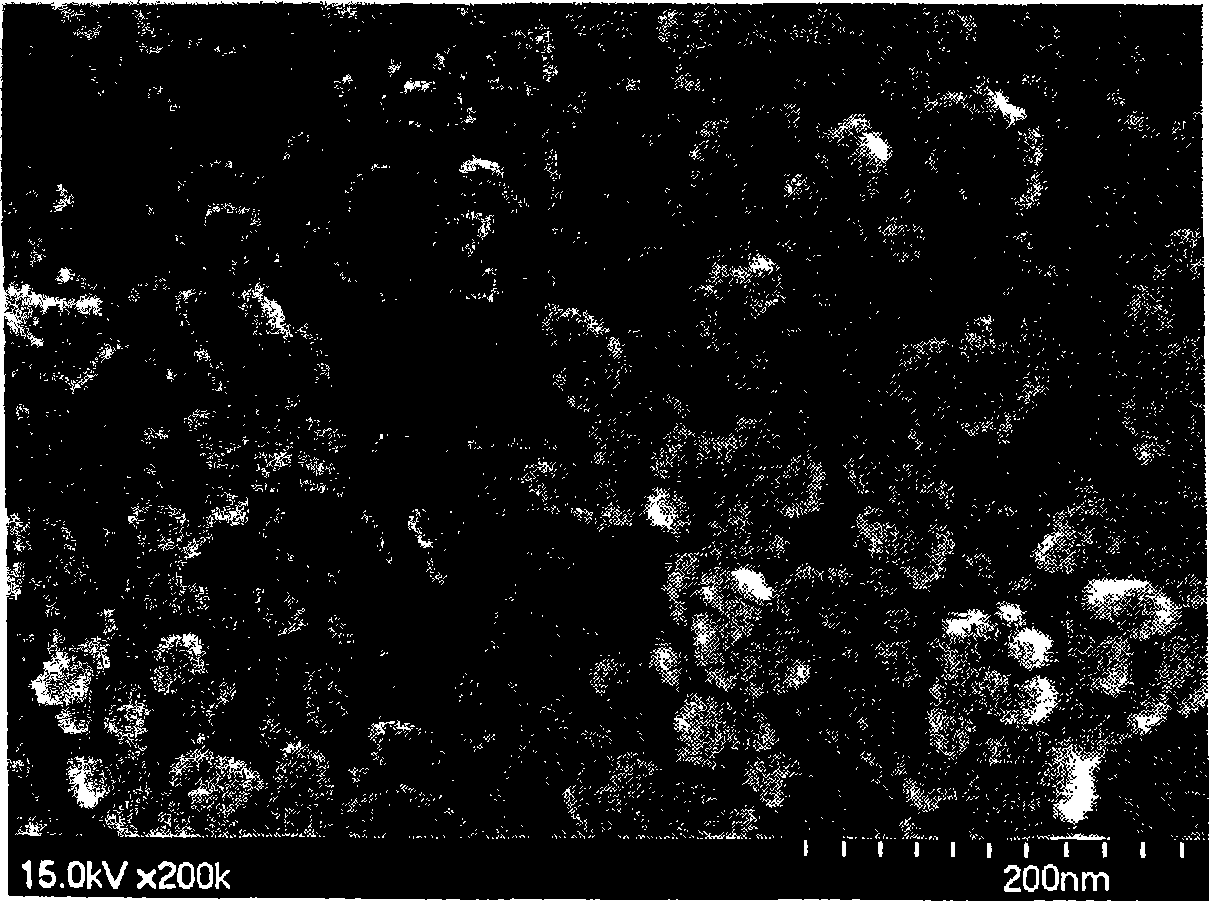

[0048] (2) Cleaning of nanoparticles: the prepared nano-Fe3O4 particles were cleaned with deionized water to remove impurities that may exist on the surface. figure 2 is the XRD spectrum line of nano-Fe3O4 particles, image 3 It is the SEM photo of nano-Fe3O4 particles.

[0049] (3) Dispersion of nanoparticles: disperse the cleaned nano Fe3O4 particles in deionized water, and adopt mechanical stirring method to promote their uniform dispersion.

[0050] (4) Coating modification of nanoparticles: at 60-70°C, slowly add modifier Span 85 according to 20% by weight of nanoparticles during constant stirring, and then naturally cool after coating and modification for 2 hours. Figure 4It is the SEM photo of coated nano-Fe3O4 particles after modification.

[0051] (5) Dispersion of nano-particles in heat-conducting oil: 0.5-1% by weight of coated and modified nanoparticles is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com