Device and method for orientation of air floating type liquid crystal substrate

A liquid crystal substrate, air-floating technology, applied in the field of alignment equipment for air-floating liquid crystal substrates, to achieve uniform heating, reduce bending, and avoid uneven alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

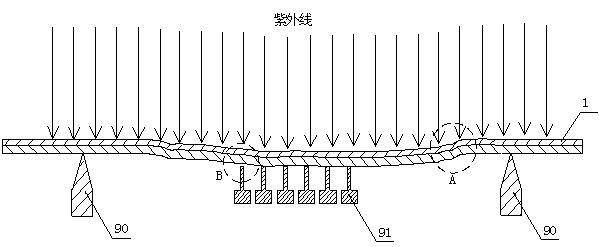

[0048] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

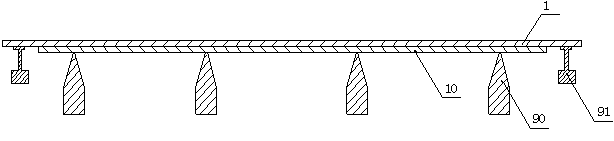

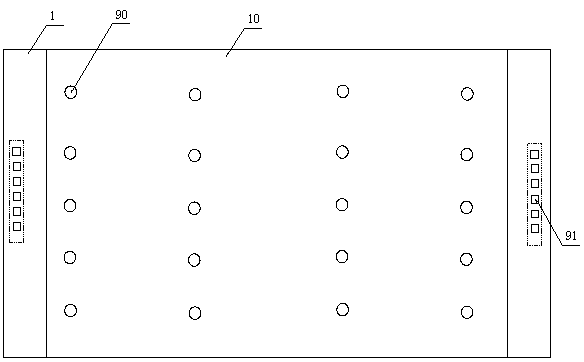

[0049] Please combine Figure 5 to Figure 8 Shown is a schematic structural view of an air-floating liquid crystal substrate alignment device according to the present invention. In this embodiment, the alignment equipment of the air-floating liquid crystal substrate at least includes:

[0050] The heating platform 2 is provided with a plurality of air holes 230, and the air holes 230 are used to deliver hot air with a uniform temperature and vertically upward;

[0051] The support frame 3 is arranged around the heating platform 2, and is used to support and clamp the liquid crystal substrate 1 to be aligned. The support frame 3 is further provided with a mechanism for aligning the liquid crystal substrate 1, and for liquid crystal substrate 1. clamping fixed clamping mechanism 6;

[0052] A plurality of supporting thimbles 4 are evenly arranged in the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com