Ultra-high performance concrete multi-ribbed plate without transverse ribs

An ultra-high-performance concrete technology, applied in bridge parts, bridges, buildings, etc., can solve the problems of ultra-high-performance concrete shrinkage cracking, adverse effects on structural safety, and the inability to exert the compressive and tensile properties of ultra-high-performance concrete. , to achieve the effect of increasing the effective tensile area, avoiding adverse effects, and increasing the effective reinforcement ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

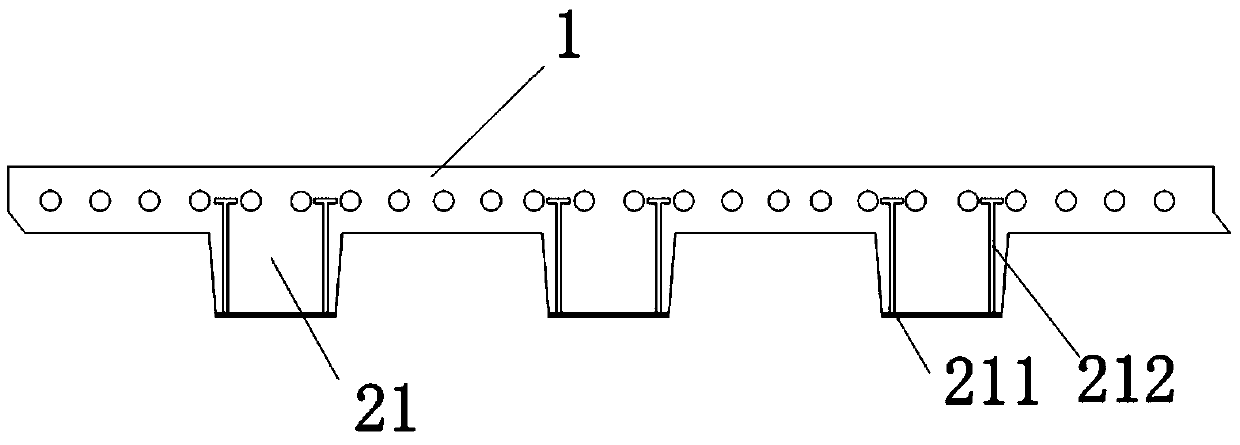

[0027] Embodiment 1, refer to figure 1 , the present invention includes a dense rib 2 and a panel 1, the panel 1 is arranged on the dense rib 2, and the feature is: the dense rib 2 is a longitudinal rib 21, and more than two parallel longitudinal ribs 21 are arranged under the panel 1 , the bottom of the longitudinal rib 21 is provided with a ribbed steel plate 211, and the upper surface of the ribbed steel plate 211 is provided with a long shear force connector 212. The panel 1 is provided with a steel mesh, and one end of the long shear force connector 212 is connected to The other end of the ribbed steel plate 211 extends into the steel mesh in the panel 1, and its top is on the same level as the steel mesh. The longitudinal rib 21 and the panel 1 are integrated by pouring ultra-high performance concrete.

Embodiment 2

[0028] Embodiment 2, refer to Figures 1 to 2 , the long shear connector combination is provided with a rib bottom steel plate 211 at the bottom of the longitudinal rib 21, and a long shear connector 212 is arranged on the upper surface of the rib bottom steel plate 211, and one end of the long shear connector 212 is connected to the rib bottom The other end of the steel plate 211 extends into the steel mesh in the panel 1, and its top is on the same level as the steel mesh. All the other are the same as above-mentioned embodiment.

Embodiment 3

[0029] Embodiment 3, refer to Figures 1 to 2 , no longitudinal steel bars and stirrups are arranged in the longitudinal ribs 21 . All the other are the same as above-mentioned embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com