Composite soil body compression-shearing fracture failure test method and test device

A composite fracture and destructive test technology, applied in the direction of testing material strength by applying stable shear force, testing material strength by applying stable tension/compression, etc., can solve the problem that it is difficult to obtain continuous distribution characteristics of compressive shear combined force and soil sample strain and critical stress relationship, etc., to achieve good continuous distribution characteristics and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

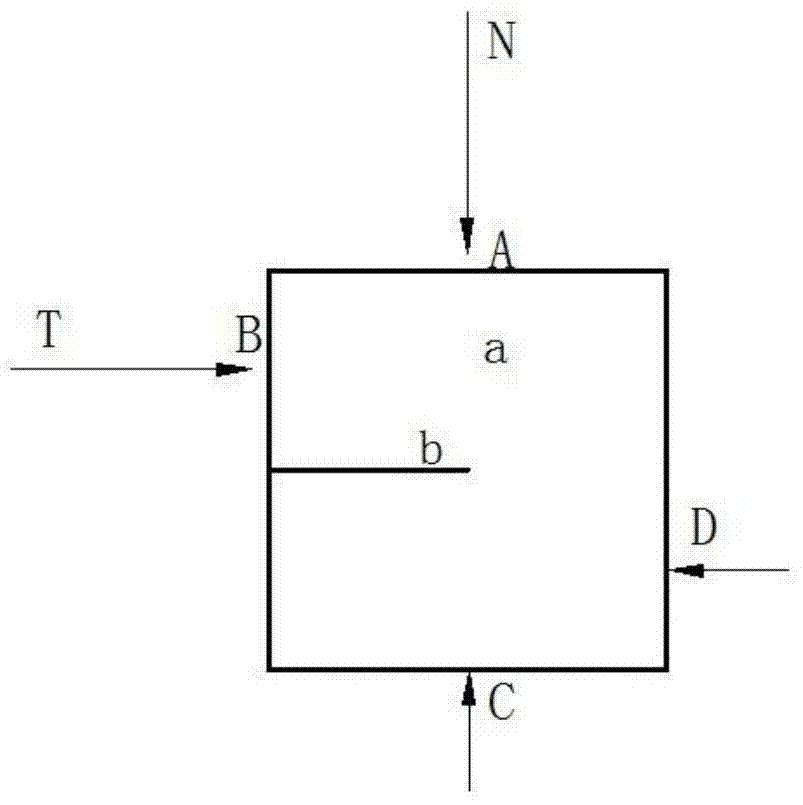

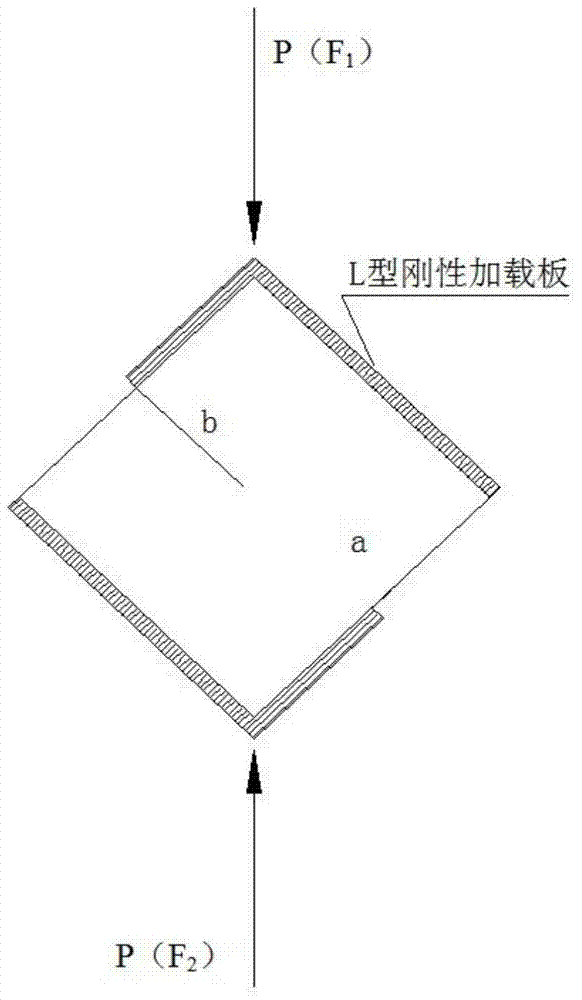

[0033] The soil compression-shear composite fracture failure test method comprises the following steps:

[0034] 1) Prepare the tested sample, which is a cubic soil block, including a top surface, a bottom surface and four sides; when placed, make the top surface of the cubic soil block perpendicular to the horizontal plane, and the bottom surface of the cubic soil block It is also perpendicular to the horizontal plane; in the test, the cubic soil block can be rotated arbitrarily, but it is necessary to keep the state that the top and bottom surfaces of the block are perpendicular to the horizontal plane.

[0035] 2) A slit is made on one side of the tested sample, that is, the tested sample is slit on one side. The method of opening the slit can adopt the common method for preparing soil samples in this field, such as cutting with a knife edge.

[0036] 3) Place the first loading plate and the second loading plate on both sides of the tested sample.

[0037] There are two s...

Embodiment 2

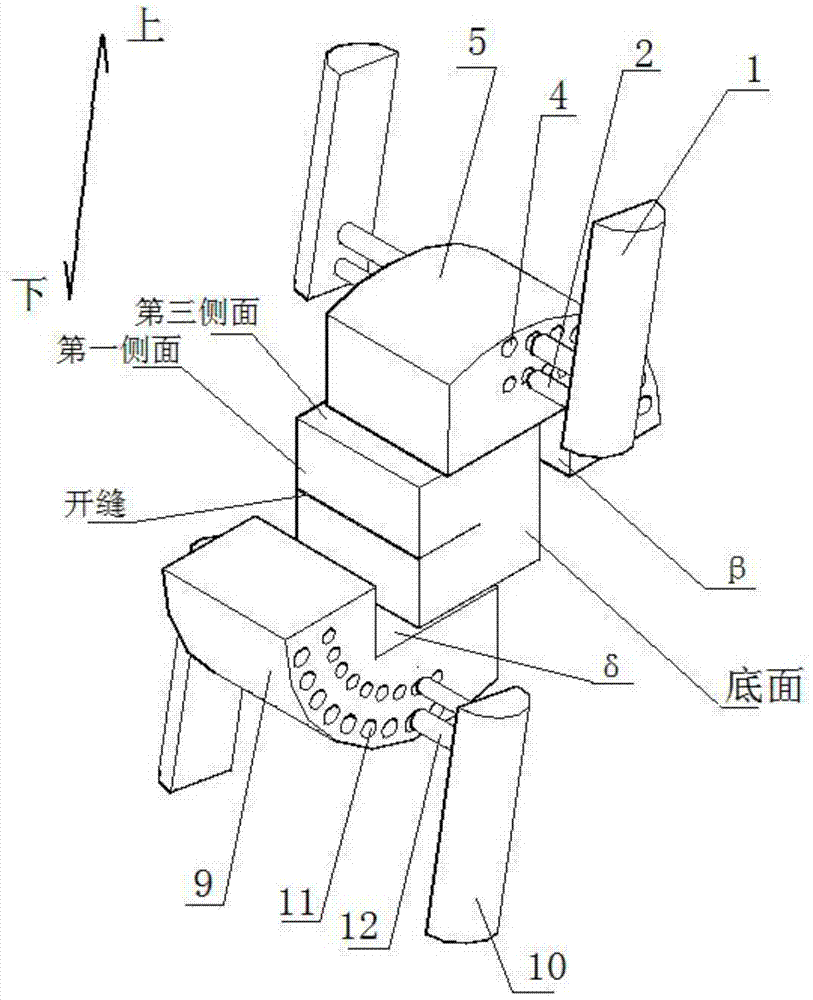

[0045] This embodiment provides a device capable of implementing the method described in Embodiment 1.

[0046] The soil compression-shear composite fracture failure test device includes a first loading plate 5 and a second loading plate 9 with the same shape, and the first loading plate 5 and the second loading plate 9 are respectively located above and below the tested sample. The tested sample is a cubic soil block having a top surface, a bottom surface, a first side, a second side, a third side and a fourth side, and the top surface and the bottom surface are perpendicular to the horizontal plane. In this embodiment, the upper end of the first loading plate 5 can be connected to the mechanical loading device, and the lower end of the second loading plate 9 can also be connected to the mechanical loading device.

[0047] see image 3 , the tested sample is marked as number 6 in the figure, the two sides of the third side of the tested sample 6 are respectively adjacent to ...

Embodiment 3

[0057] This embodiment provides a device whose shape and structure are exactly the same as image 3 , 4 As shown in and 5, the method described in embodiment 1 can be preferably realized.

[0058] The soil compression-shear composite fracture failure test device includes a first loading plate 5 and a second loading plate 9 of the same shape, the first loading plate 5 is located above the sample to be tested, and the second loading plate 9 is located below the sample to be tested. The tested sample is a cubic soil block (same as the sample prepared in Example 2) having a top surface, a bottom surface, a second side, a first side, a third side and a fourth side.

[0059] Both the first loading plate 5 and the second loading plate 9 are rigid plates with a certain thickness. Preferably, the thickness of the first loading plate 5 and the second loading plate 9 in the horizontal direction is greater than or equal to the edge length of the tested sample. In this embodiment, the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com